How to Use Diagnostic Software to Check Automatic Transmission Parameters?

Unlock the full potential of your vehicle’s automatic transmission by mastering diagnostic software. CARDIAGTECH.NET provides the insights and tools you need to accurately assess transmission health, optimize performance, and prevent costly repairs. Dive in to discover how to read parameters, interpret data, and troubleshoot issues effectively, ensuring your vehicle runs smoothly. Explore advanced diagnostic techniques and transmission control module insights today.

1. What is Diagnostic Software for Automatic Transmissions?

Diagnostic software for automatic transmissions is a specialized tool that interfaces with a vehicle’s Transmission Control Module (TCM) to read and interpret data related to the transmission’s operation. With diagnostic software, auto repair experts can monitor, troubleshoot, and optimize the performance of these sophisticated systems.

Automatic transmission diagnostic software serves as a crucial bridge between automotive technicians and the intricate workings of a vehicle’s transmission system. This powerful tool enables technicians to access a wealth of data, including sensor readings, diagnostic trouble codes (DTCs), and real-time operating parameters. By interpreting this information, technicians can accurately diagnose issues, troubleshoot problems, and optimize the performance of automatic transmissions.

1.1 Key Functions of Diagnostic Software

- Reading Diagnostic Trouble Codes (DTCs): Retrieves codes that indicate potential issues within the transmission system.

- Monitoring Live Data Streams: Provides real-time data on various transmission parameters, such as temperature, speed, and pressure.

- Performing Actuator Tests: Allows technicians to activate specific components to verify their functionality.

- Reprogramming TCMs: Enables updating or modifying the software within the transmission control module.

- Clearing Codes: Resets the TCM after repairs are completed, turning off the check engine light.

1.2 The Growing Importance of Diagnostics

As modern vehicles become increasingly complex, diagnostic software has evolved into an indispensable tool for automotive technicians. According to a 2023 report by the Auto Care Association, the average car has over 100 million lines of code, highlighting the sophistication of modern automotive systems. This complexity demands advanced diagnostic capabilities to ensure accurate and efficient repairs. CARDIAGTECH.NET understands these demands and offers cutting-edge solutions to meet them.

1.2.1 Regulatory Compliance

Additionally, environmental regulations, such as those mandated by the Environmental Protection Agency (EPA), require vehicles to maintain optimal performance and emissions standards. Diagnostic software helps technicians identify and address issues that could lead to non-compliance. This makes it an invaluable tool for maintaining regulatory compliance and ensuring vehicles operate within specified parameters.

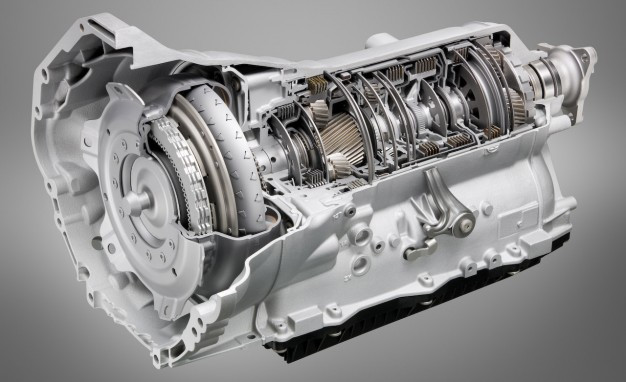

2. Understanding Automatic Transmission Parameters

Automatic transmission parameters are specific data points that provide insights into the operational status and performance of the transmission system. Monitoring these parameters is essential for diagnosing issues, ensuring optimal performance, and preventing potential failures. Key parameters include transmission fluid temperature, input and output shaft speeds, and clutch engagement.

Gaining a comprehensive understanding of automatic transmission parameters is vital for effective diagnostics and maintenance. Each parameter offers unique insights into the health and performance of the transmission, enabling technicians to pinpoint problems and implement targeted solutions. For instance, monitoring transmission fluid temperature can prevent overheating and potential damage, while tracking shaft speeds can indicate slippage or other mechanical issues.

2.1 Key Transmission Parameters Explained

- Transmission Fluid Temperature (TFT): Indicates the temperature of the transmission fluid, which is crucial for proper lubrication and cooling.

- Input Shaft Speed (ISS): Measures the rotational speed of the transmission’s input shaft, reflecting engine speed.

- Output Shaft Speed (OSS): Measures the rotational speed of the transmission’s output shaft, reflecting vehicle speed.

- Torque Converter Slip: Indicates the difference between engine speed and transmission input speed, showing how efficiently torque is being transferred.

- Clutch Engagement: Monitors the engagement status of various clutches within the transmission, ensuring smooth gear changes.

2.2 Why Monitoring These Parameters is Important

According to a study by the Society of Automotive Engineers (SAE), monitoring these parameters can significantly reduce transmission-related failures. Regular monitoring enables technicians to identify anomalies early, preventing minor issues from escalating into major problems. This proactive approach not only extends the life of the transmission but also saves vehicle owners significant repair costs.

2.2.1 Practical Benefits of Parameter Monitoring

- Early Detection of Problems: Identifying unusual readings can help detect issues before they cause significant damage.

- Improved Performance: Optimizing transmission parameters can enhance vehicle performance and fuel efficiency.

- Preventative Maintenance: Regular monitoring allows for timely maintenance, reducing the risk of breakdowns.

- Accurate Diagnostics: Providing a clearer picture of the transmission’s condition, leading to more precise diagnoses.

3. Essential Tools for Checking Automatic Transmission Parameters

Checking automatic transmission parameters requires specialized tools that can interface with the vehicle’s TCM. The primary tools include diagnostic scanners, multimeters, and specialized software like that offered by CARDIAGTECH.NET. These tools enable technicians to accurately read and interpret data, perform tests, and troubleshoot issues effectively.

Equipping yourself with the right tools is essential for accurately assessing and maintaining automatic transmissions. Diagnostic scanners provide a comprehensive overview of the transmission’s health, while multimeters allow for detailed electrical testing. Specialized software from CARDIAGTECH.NET offers advanced diagnostic capabilities, ensuring technicians can tackle even the most complex transmission issues.

3.1 Diagnostic Scanners

Diagnostic scanners are handheld devices that connect to a vehicle’s On-Board Diagnostics (OBD) port. They can read DTCs, monitor live data streams, and perform actuator tests. Modern scanners often come with advanced features like graphing and data logging. The cost of good quality diagnostic scanners typically ranges from $300 to $2,000, depending on the features and capabilities.

3.1.1 Top Diagnostic Scanner Brands

- Snap-on: Known for their high-quality, comprehensive diagnostic tools.

- Autel: Offers a range of scanners suitable for both professional and DIY use.

- Launch: Provides affordable yet reliable diagnostic solutions.

3.2 Multimeters

Multimeters are essential for electrical testing, allowing technicians to measure voltage, current, and resistance. These measurements are crucial for diagnosing electrical issues within the transmission system, such as faulty sensors or wiring problems. A good quality multimeter can cost between $50 and $300.

3.2.1 Key Multimeter Features

- Auto-Ranging: Automatically selects the appropriate measurement range.

- Continuity Testing: Checks for breaks in electrical circuits.

- Diode Testing: Verifies the functionality of diodes within the system.

3.3 CARDIAGTECH.NET Diagnostic Software

CARDIAGTECH.NET offers specialized diagnostic software designed to provide in-depth analysis of automatic transmission parameters. This software often includes advanced features such as:

- Enhanced Data Logging: Records data over time for detailed analysis.

- Customizable Dashboards: Allows technicians to create personalized views of key parameters.

- Integrated Repair Information: Provides access to repair manuals and technical specifications.

3.3.1 Benefits of Using CARDIAGTECH.NET Software

- Comprehensive Diagnostics: Offers a complete view of transmission health.

- User-Friendly Interface: Easy to navigate and use, even for novice technicians.

- Regular Updates: Keeps the software current with the latest vehicle models and technologies.

4. Step-by-Step Guide: Checking Transmission Parameters

Checking transmission parameters involves a systematic approach to ensure accurate and reliable results. This process includes connecting the diagnostic tool, accessing live data, interpreting the data, and performing necessary tests. Following this step-by-step guide will help technicians diagnose issues and maintain optimal transmission performance.

To effectively check transmission parameters, technicians need a clear, step-by-step process. This guide outlines the essential steps, from connecting the diagnostic tool to interpreting the data and performing necessary tests. By following these steps, technicians can accurately diagnose issues and maintain optimal transmission performance, ultimately saving time and resources.

4.1 Step 1: Connect the Diagnostic Tool

Start by connecting the diagnostic scanner to the vehicle’s OBD port, typically located under the dashboard. Ensure the vehicle is turned on but not running. Follow the scanner’s instructions to establish a connection with the vehicle’s computer system.

4.1.1 Common Connection Issues

- Faulty OBD Port: Inspect the OBD port for damage or corrosion.

- Incorrect Scanner Settings: Verify that the scanner is configured correctly for the vehicle’s make and model.

- Software Compatibility: Ensure that the scanner’s software is up to date and compatible with the vehicle.

4.2 Step 2: Access Live Data

Once connected, navigate to the live data or data stream section of the diagnostic software. Select the specific transmission parameters you want to monitor, such as transmission fluid temperature, input shaft speed, and output shaft speed.

4.2.1 Selecting Key Parameters

Prioritize parameters that are most relevant to the issue you are investigating. For example, if you suspect a torque converter problem, monitor torque converter slip.

4.3 Step 3: Interpret the Data

Analyze the data displayed by the diagnostic tool. Compare the readings to the vehicle’s specifications or baseline data to identify any deviations. Pay attention to unusual spikes, drops, or inconsistencies in the data.

4.3.1 Understanding Normal Ranges

- Transmission Fluid Temperature: Typically ranges from 175 to 225°F (80 to 107°C) during normal operation.

- Input/Output Shaft Speeds: Should correlate with engine speed and vehicle speed, with variations depending on gear selection.

- Torque Converter Slip: Should be minimal at cruising speeds, indicating efficient torque transfer.

4.4 Step 4: Perform Actuator Tests

Use the diagnostic tool to perform actuator tests on specific transmission components, such as solenoids or clutches. This can help verify their functionality and identify any mechanical or electrical issues.

4.4.1 Common Actuator Tests

- Solenoid Activation: Tests the response of individual solenoids within the transmission.

- Clutch Engagement: Verifies the proper engagement and disengagement of clutches.

- Valve Body Testing: Evaluates the performance of the valve body, which controls fluid flow within the transmission.

4.5 Step 5: Document Findings

Record all data, test results, and observations in a detailed report. This documentation will be valuable for future reference and can help track the effectiveness of any repairs or adjustments.

4.5.1 Creating a Detailed Report

- Include Specific Readings: Record the exact values of all monitored parameters.

- Note Any Deviations: Highlight any readings that fall outside the normal range.

- Summarize Test Results: Clearly document the outcome of all actuator tests and diagnostic procedures.

5. Interpreting Diagnostic Data: Common Issues and Solutions

Interpreting diagnostic data accurately is crucial for identifying transmission issues and implementing effective solutions. Common issues include overheating, slipping, and erratic shifting, each with distinct data signatures. Understanding these patterns can guide technicians toward precise diagnoses and appropriate repairs.

Accurate interpretation of diagnostic data is the linchpin of effective transmission maintenance and repair. Common problems such as overheating, slippage, and erratic shifting each manifest with distinct data signatures. By learning to recognize these patterns, technicians can arrive at precise diagnoses and implement targeted solutions, saving time and minimizing unnecessary repairs.

5.1 Overheating

- Symptoms: High transmission fluid temperature, burnt fluid smell, and potential shifting problems.

- Diagnostic Data: Transmission fluid temperature consistently above the normal range (175-225°F or 80-107°C).

- Solutions: Check and replace the transmission fluid, inspect the cooling system, and ensure the transmission cooler is functioning correctly.

5.2 Slipping

- Symptoms: Delayed or erratic shifts, engine revving without acceleration, and a loss of power.

- Diagnostic Data: High torque converter slip values, indicating inefficient torque transfer. Discrepancies between input and output shaft speeds.

- Solutions: Inspect and replace worn clutches, adjust transmission bands, and ensure proper fluid pressure.

5.3 Erratic Shifting

- Symptoms: Harsh or abrupt shifts, failure to shift properly, and inconsistent gear changes.

- Diagnostic Data: Erratic solenoid activation patterns, inconsistent clutch engagement, and abnormal valve body pressures.

- Solutions: Test and replace faulty solenoids, clean or replace the valve body, and reprogram the TCM if necessary.

5.4 Addressing Electrical Issues

- Symptoms: Intermittent shifting problems, warning lights, and a complete loss of transmission function.

- Diagnostic Data: Faulty sensor readings, open or short circuits, and communication errors between the TCM and other vehicle systems.

- Solutions: Check and repair wiring harnesses, replace faulty sensors, and ensure proper grounding.

5.4.1 Using CARDIAGTECH.NET for Electrical Diagnostics

CARDIAGTECH.NET diagnostic software provides advanced features for electrical diagnostics, including:

- Circuit Testing: Allows technicians to test individual circuits within the transmission system.

- Sensor Calibration: Enables calibrating sensors to ensure accurate readings.

- Wiring Diagrams: Provides detailed wiring diagrams to aid in troubleshooting.

6. Advanced Diagnostic Techniques

Advanced diagnostic techniques involve using specialized tools and procedures to identify complex transmission issues that may not be apparent through basic diagnostics. These techniques include data logging, component testing, and fluid analysis. Mastering these methods allows technicians to tackle challenging problems and ensure optimal transmission performance.

To tackle complex transmission issues effectively, advanced diagnostic techniques are indispensable. These methods involve specialized tools and procedures that go beyond basic diagnostics. Data logging, component testing, and fluid analysis enable technicians to uncover hidden problems and ensure optimal transmission performance, ultimately providing superior service to vehicle owners.

6.1 Data Logging

Data logging involves recording transmission parameters over a period of time to identify intermittent issues or subtle performance problems. This technique is particularly useful for diagnosing issues that only occur under specific conditions.

6.1.1 Setting Up Data Logging

- Select Key Parameters: Choose the parameters that are most relevant to the issue you are investigating.

- Set Recording Intervals: Determine how frequently data should be recorded.

- Drive Under Various Conditions: Operate the vehicle under different driving conditions to capture a range of data.

6.2 Component Testing

Component testing involves individually testing specific transmission components, such as solenoids, sensors, and clutches, to verify their functionality. This can be done using multimeters, specialized testing tools, or the diagnostic software provided by CARDIAGTECH.NET.

6.2.1 Testing Solenoids

- Resistance Testing: Measure the resistance of the solenoid coil to check for open or short circuits.

- Activation Testing: Use a diagnostic tool to activate the solenoid and verify that it is functioning correctly.

- Voltage Testing: Check the voltage supply to the solenoid to ensure it is receiving adequate power.

6.3 Fluid Analysis

Fluid analysis involves examining the transmission fluid for signs of contamination, degradation, or wear. This can provide valuable insights into the overall health of the transmission.

6.3.1 Key Indicators in Fluid Analysis

- Color and Odor: Abnormal color or a burnt odor can indicate overheating or contamination.

- Metal Particles: The presence of metal particles suggests excessive wear within the transmission.

- Viscosity: Changes in viscosity can indicate fluid degradation or contamination.

7. Common Diagnostic Trouble Codes (DTCs) Related to Automatic Transmissions

Diagnostic Trouble Codes (DTCs) provide valuable information about potential issues within the automatic transmission system. Understanding these codes and their implications is essential for accurate diagnosis and effective repairs. Common DTCs relate to solenoids, sensors, and mechanical failures.

A thorough understanding of Diagnostic Trouble Codes (DTCs) is crucial for pinpointing issues within automatic transmission systems. These codes offer valuable insights into potential problems, allowing technicians to conduct accurate diagnoses and implement effective repairs. Common DTCs often relate to solenoids, sensors, and mechanical failures, each requiring specific diagnostic and repair strategies.

7.1 P0700 – Transmission Control System Malfunction

- Description: Indicates a general malfunction within the transmission control system.

- Possible Causes: Faulty TCM, wiring issues, or problems with other transmission components.

- Diagnostic Steps: Check the TCM for damage, inspect wiring harnesses, and perform further diagnostics to identify the specific issue.

7.2 P0715 – Input/Turbine Speed Sensor Circuit Malfunction

- Description: Indicates a problem with the input or turbine speed sensor circuit.

- Possible Causes: Faulty sensor, wiring issues, or a problem with the TCM.

- Diagnostic Steps: Test the sensor for proper resistance and voltage, inspect the wiring harness, and check the TCM for errors.

7.3 P0740 – Torque Converter Clutch Circuit Malfunction

- Description: Indicates a problem with the torque converter clutch circuit.

- Possible Causes: Faulty solenoid, wiring issues, or a problem with the torque converter itself.

- Diagnostic Steps: Test the solenoid for proper function, inspect the wiring harness, and check the torque converter for damage.

7.4 P0750 – Shift Solenoid A Malfunction

- Description: Indicates a problem with shift solenoid A.

- Possible Causes: Faulty solenoid, wiring issues, or a problem with the TCM.

- Diagnostic Steps: Test the solenoid for proper resistance and voltage, inspect the wiring harness, and check the TCM for errors.

7.5 P0775 – Pressure Control Solenoid B Malfunction

- Description: Indicates a problem with pressure control solenoid B.

- Possible Causes: Faulty solenoid, wiring issues, or a problem with the TCM.

- Diagnostic Steps: Test the solenoid for proper resistance and voltage, inspect the wiring harness, and check the TCM for errors.

7.6 Clearing DTCs

After addressing the underlying issue, it’s important to clear the DTCs from the TCM using a diagnostic scanner. This will turn off the check engine light and reset the system.

7.6.1 Precautions When Clearing Codes

- Verify Repairs: Ensure that all necessary repairs have been completed before clearing the codes.

- Monitor Performance: After clearing the codes, monitor the transmission’s performance to ensure that the issue has been resolved.

- Document the Process: Record the codes that were cleared and the steps that were taken to address the issue.

8. Preventative Maintenance for Automatic Transmissions

Preventative maintenance is crucial for extending the life of an automatic transmission and avoiding costly repairs. Regular fluid changes, filter replacements, and inspections can help keep the transmission operating smoothly. Proper maintenance not only enhances vehicle performance but also ensures reliability and longevity.

Preventative maintenance is essential for prolonging the lifespan of automatic transmissions and preventing costly repairs. Routine fluid changes, filter replacements, and thorough inspections are key to maintaining smooth and reliable operation. By adhering to a consistent maintenance schedule, vehicle owners can enhance performance, ensure reliability, and extend the life of their transmissions.

8.1 Regular Fluid Changes

- Importance: Transmission fluid lubricates, cools, and cleans the transmission components. Over time, the fluid can degrade, leading to reduced performance and potential damage.

- Frequency: Refer to the vehicle’s owner’s manual for the recommended fluid change interval, typically every 30,000 to 60,000 miles.

- Procedure: Drain the old fluid, replace the filter, and refill with the correct type of transmission fluid.

8.2 Filter Replacements

- Importance: The transmission filter removes contaminants from the fluid, preventing them from circulating and causing wear.

- Frequency: Replace the filter with each fluid change.

- Procedure: Remove the old filter and install a new one, ensuring it is properly seated.

8.3 Inspections

- Importance: Regular inspections can help identify potential issues before they become major problems.

- Frequency: Inspect the transmission at least once a year or with each oil change.

- Procedure: Check for leaks, inspect the condition of the fluid, and examine the transmission for any signs of damage or wear.

8.3.1 Key Inspection Points

- Fluid Leaks: Look for signs of fluid leaks around the transmission housing, seals, and lines.

- Fluid Condition: Check the color and odor of the fluid. Dark or burnt fluid indicates a problem.

- Component Wear: Inspect the transmission mounts, lines, and connectors for any signs of wear or damage.

8.4 Monitoring Driving Habits

- Importance: Aggressive driving habits, such as frequent hard acceleration and braking, can put extra stress on the transmission.

- Recommendations: Avoid aggressive driving, use the proper gear selection for towing, and allow the transmission to warm up before driving in cold weather.

9. The Future of Diagnostic Software in Automatic Transmission Repair

The future of diagnostic software in automatic transmission repair is rapidly evolving, driven by advancements in technology and increasing vehicle complexity. Expect to see greater integration of artificial intelligence (AI), cloud-based diagnostics, and remote diagnostics capabilities. These innovations will enable more accurate, efficient, and proactive transmission maintenance.

The landscape of diagnostic software in automatic transmission repair is undergoing rapid transformation, fueled by technological advancements and the increasing complexity of modern vehicles. As we look ahead, the integration of artificial intelligence (AI), cloud-based diagnostics, and remote diagnostic capabilities promises to revolutionize how technicians approach transmission maintenance and repair, enabling more accurate, efficient, and proactive solutions.

9.1 Artificial Intelligence (AI)

AI is poised to play a significant role in the future of diagnostic software. AI algorithms can analyze vast amounts of data to identify patterns, predict failures, and provide technicians with actionable insights.

9.1.1 AI-Driven Diagnostics

- Predictive Maintenance: AI can analyze historical data to predict when a transmission is likely to fail, allowing for proactive maintenance.

- Automated Troubleshooting: AI can guide technicians through the diagnostic process, suggesting possible causes and solutions based on the data.

- Enhanced Data Analysis: AI can analyze complex data streams to identify subtle issues that may be missed by human technicians.

9.2 Cloud-Based Diagnostics

Cloud-based diagnostic platforms offer several advantages, including:

- Real-Time Updates: Software updates and new diagnostic information can be delivered instantly.

- Remote Access: Technicians can access diagnostic data and tools from anywhere with an internet connection.

- Collaboration: Cloud platforms facilitate collaboration between technicians, allowing them to share data and expertise.

9.3 Remote Diagnostics

Remote diagnostics enables technicians to diagnose and troubleshoot transmission issues from a remote location. This can be particularly useful for servicing vehicles in remote areas or providing support to field technicians.

9.3.1 Benefits of Remote Diagnostics

- Reduced Downtime: Remote diagnostics can help identify issues quickly, reducing vehicle downtime.

- Cost Savings: Remote diagnostics can eliminate the need for on-site visits, saving time and money.

- Improved Efficiency: Remote diagnostics can enable technicians to work more efficiently, handling multiple cases simultaneously.

9.4 Enhanced Vehicle Communication Interfaces (VCIs)

VCIs are evolving to support faster data transfer rates and more complex communication protocols. This will enable diagnostic software to access more data and perform more advanced tests.

9.4.1 Key VCI Advancements

- Wireless Connectivity: VCIs are increasingly incorporating wireless connectivity, allowing for greater flexibility and convenience.

- Improved Security: VCIs are being designed with enhanced security features to protect against cyber threats.

- Expanded Compatibility: VCIs are becoming more compatible with a wider range of vehicle makes and models.

10. Why Choose CARDIAGTECH.NET for Your Diagnostic Needs?

Choosing the right diagnostic tools and software is essential for ensuring accurate and efficient automatic transmission repairs. CARDIAGTECH.NET offers a comprehensive range of products designed to meet the needs of professional technicians and DIY enthusiasts alike. With advanced features, user-friendly interfaces, and reliable performance, CARDIAGTECH.NET is your trusted partner for all your diagnostic needs.

Selecting the right diagnostic tools and software is paramount for achieving accurate and efficient automatic transmission repairs. CARDIAGTECH.NET provides a comprehensive array of products tailored to meet the needs of both professional technicians and DIY enthusiasts. Featuring advanced capabilities, intuitive interfaces, and dependable performance, CARDIAGTECH.NET stands as your trusted ally for all diagnostic requirements.

10.1 Comprehensive Product Range

CARDIAGTECH.NET offers a wide range of diagnostic tools and software, including:

- Diagnostic Scanners: Handheld devices that can read DTCs, monitor live data streams, and perform actuator tests.

- Multimeters: Essential tools for electrical testing, allowing technicians to measure voltage, current, and resistance.

- Specialized Software: Advanced diagnostic software designed to provide in-depth analysis of automatic transmission parameters.

10.2 Advanced Features

CARDIAGTECH.NET products are equipped with advanced features to enhance diagnostic capabilities, including:

- Enhanced Data Logging: Records data over time for detailed analysis.

- Customizable Dashboards: Allows technicians to create personalized views of key parameters.

- Integrated Repair Information: Provides access to repair manuals and technical specifications.

- AI-Driven Diagnostics: Utilizes artificial intelligence to predict failures and provide actionable insights.

10.3 User-Friendly Interface

CARDIAGTECH.NET products are designed with user-friendly interfaces, making them easy to navigate and use, even for novice technicians.

10.3.1 Key Interface Features

- Intuitive Menus: Easy-to-understand menus and navigation.

- Clear Data Displays: Data is displayed in a clear and concise format.

- Helpful Tutorials: Provides access to tutorials and guides to help users get the most out of the products.

10.4 Reliable Performance

CARDIAGTECH.NET products are built to last, with durable construction and reliable performance.

10.4.1 Quality Assurance

- Rigorous Testing: Products undergo rigorous testing to ensure they meet the highest standards of quality.

- Warranty Protection: Products are backed by warranty protection to provide peace of mind.

10.5 Exceptional Customer Support

CARDIAGTECH.NET is committed to providing exceptional customer support.

10.5.1 Support Services

- Technical Support: Access to knowledgeable technical support staff.

- Online Resources: A comprehensive library of online resources, including FAQs, tutorials, and troubleshooting guides.

- Training Programs: Offers training programs to help technicians master the use of CARDIAGTECH.NET products.

Don’t let transmission issues slow you down. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States, to discover how our tools can transform your automotive repair experience. With CARDIAGTECH.NET, you’re not just buying a product; you’re investing in precision, efficiency, and peace of mind.

FAQ: How to Use Diagnostic Software to Check Automatic Transmission Parameters?

1. What is automatic transmission diagnostic software?

Automatic transmission diagnostic software is a specialized tool used to interface with a vehicle’s Transmission Control Module (TCM) to read and interpret data related to the transmission’s operation, aiding in troubleshooting and optimization. This software helps auto repair experts diagnose, troubleshoot, and optimize the performance of these sophisticated systems.

2. What parameters can I check with diagnostic software?

You can check parameters such as transmission fluid temperature (TFT), input shaft speed (ISS), output shaft speed (OSS), torque converter slip, and clutch engagement, providing insights into the transmission’s health. These parameters offer unique insights into the health and performance of the transmission, enabling technicians to pinpoint problems and implement targeted solutions.

3. What tools do I need to check automatic transmission parameters?

You’ll need a diagnostic scanner to connect to the vehicle’s OBD port, a multimeter for electrical testing, and specialized software like that offered by CARDIAGTECH.NET for in-depth analysis. Equipping yourself with the right tools is essential for accurately assessing and maintaining automatic transmissions.

4. How do I connect the diagnostic tool to my vehicle?

Connect the diagnostic scanner to the vehicle’s OBD port, typically located under the dashboard, and follow the scanner’s instructions to establish a connection with the vehicle’s computer system. Ensure the vehicle is turned on but not running.

5. How do I access live data with the diagnostic tool?

Once connected, navigate to the live data or data stream section of the diagnostic software and select the specific transmission parameters you want to monitor, such as transmission fluid temperature, input shaft speed, and output shaft speed.

6. What is a normal transmission fluid temperature range?

The transmission fluid temperature typically ranges from 175 to 225°F (80 to 107°C) during normal operation. Monitoring this parameter is crucial for preventing overheating and potential damage.

7. What does high torque converter slip indicate?

High torque converter slip values indicate inefficient torque transfer, suggesting potential issues with the torque converter or other transmission components. These values should be minimal at cruising speeds to ensure efficient torque transfer.

8. How can CARDIAGTECH.NET software help with transmission diagnostics?

CARDIAGTECH.NET diagnostic software offers enhanced data logging, customizable dashboards, and integrated repair information, providing a complete view of transmission health and aiding in accurate diagnoses. This software is designed to be user-friendly, even for novice technicians.

9. What are common Diagnostic Trouble Codes (DTCs) related to automatic transmissions?

Common DTCs include P0700 (Transmission Control System Malfunction), P0715 (Input/Turbine Speed Sensor Circuit Malfunction), P0740 (Torque Converter Clutch Circuit Malfunction), P0750 (Shift Solenoid A Malfunction), and P0775 (Pressure Control Solenoid B Malfunction). Understanding these codes and their implications is essential for accurate diagnosis and effective repairs.

10. How often should I perform preventative maintenance on my automatic transmission?

Perform regular fluid changes every 30,000 to 60,000 miles, replace the filter with each fluid change, and inspect the transmission at least once a year or with each oil change to ensure optimal performance and longevity. Proper maintenance not only enhances vehicle performance but also ensures reliability.