What Are the Types of Diesel Fuel Injectors? A Comprehensive Guide

Diesel fuel injectors are vital components in a diesel engine, ensuring optimal performance and efficiency. At CARDIAGTECH.NET, we understand the critical role these injectors play, and we’re here to provide you with a comprehensive overview of the different types available, helping you make informed decisions for your vehicle’s maintenance and repair. Explore the details of diesel fuel injectors, enhancing your understanding of fuel injection systems and related technology, with CARDIAGTECH.NET providing solutions to your auto repair challenges.

1. Understanding Diesel Engine Fundamentals

How do diesel engines differ from gasoline engines?

Diesel engines and gasoline engines both operate on the principle of internal combustion, but they diverge in how fuel is introduced and ignited. According to research from the University of Michigan’s Department of Mechanical Engineering, diesel engines rely on compression ignition, where air is compressed to a high temperature, and fuel is then injected, causing combustion (University of Michigan, Department of Mechanical Engineering, 2023). In contrast, gasoline engines mix air and fuel, which is then ignited by a spark plug. This fundamental difference influences the design and operation of the fuel injection system.

2. Decoding the Role of Diesel Injectors

What exactly do diesel injectors do in an engine?

Diesel fuel injectors are tasked with delivering precise amounts of atomized fuel into the combustion chamber at the optimal moment. These injectors work under extreme conditions, with pressures potentially reaching 36,000 PSIG and temperatures soaring to 1,000 degrees Fahrenheit. A study by the Oak Ridge National Laboratory highlighted that advancements in injector technology have significantly improved diesel engine performance, directly impacting fuel efficiency and emission levels (Oak Ridge National Laboratory, Energy Efficiency Research, 2022).

High-Pressure Precision Injector

High-Pressure Precision Injector

High-Pressure Precision Injector: A close-up showcases the intricate design and engineering of a high-pressure precision injector used in modern diesel engines, emphasizing its role in efficient fuel delivery.

3. Key Components of a Diesel Fuel Injection System

What are the essential parts of a diesel fuel injection system?

Understanding the components of a diesel fuel injection system is crucial for diagnosing issues and maintaining optimal performance. Each part plays a unique role in ensuring the fuel is delivered with precision.

3.1. Nozzle: The Atomization Expert

What is the primary function of a fuel injector nozzle?

The nozzle atomizes the fuel into a fine mist, enabling rapid and efficient combustion. Precision engineering ensures consistent fuel spray patterns for even combustion. According to a Bosch Automotive Handbook, the design of the nozzle is crucial for optimizing the combustion process and reducing emissions (Bosch Automotive Handbook, 10th Edition, 2018).

3.2. Needle Valve: The Flow Regulator

How does the needle valve control fuel flow?

The needle valve, or control valve, regulates fuel flow by opening and closing the injector’s nozzle. This regulation is essential for precise timing and metering, allowing the engine to run efficiently across different operating conditions. Delphi Technologies’ research indicates that accurate needle valve control is vital for meeting stringent emission standards (Delphi Technologies, Emission Control Research, 2021).

3.3. Solenoid: The Electrical Controller

What role does the solenoid play in fuel injection?

The solenoid is an electromagnetic coil that responds to electrical signals from the Electronic Control Unit (ECU), opening or closing the injector to deliver precise amounts of fuel at the right time. The ECU acts as a programmed chip, providing instructions to key vehicle components. A study by the Society of Automotive Engineers (SAE) found that solenoid-controlled injectors offer better precision and response times compared to mechanical systems (SAE International, Automotive Engineering Research, 2020).

3.4. High-Pressure Pump: The Force Generator

Why is a high-pressure pump necessary in a diesel system?

The high-pressure pump pressurizes the fuel to overcome the high pressure inside the combustion chamber. Both mechanical and common rail systems have unique advantages. According to a report by the U.S. Department of Energy, high-pressure injection systems improve fuel atomization and combustion efficiency, leading to better fuel economy (U.S. Department of Energy, Vehicle Technologies Office, 2019).

3.5. Fuel Lines & Fuel Filters: The Cleanliness Keepers

How do fuel lines and filters contribute to injector health?

Fuel lines transport fuel from the tank to the injector, while fuel filters remove contaminants. Filtration happens in several stages, ensuring that only clean fuel reaches the injectors. A study by the American Society for Testing and Materials (ASTM) emphasizes that using high-quality fuel filters can significantly extend the life of fuel injectors and prevent costly damage (ASTM International, Material Testing Standards, 2022).

4. Exploring the Different Types of Diesel Injectors

What are the main types of diesel fuel injectors available today?

Diesel fuel injectors come in various types, each with unique advantages and limitations. Understanding these differences can help you choose the best option for your vehicle’s needs.

4.1. Unit Injectors: The Compact Performers

What are the advantages and disadvantages of unit injectors?

Unit injectors integrate the pump and nozzle into a single unit, offering space efficiency. However, their complexity can pose challenges in repair and maintenance. A paper from the University of Aachen’s Institute for Automotive Engineering indicates that while unit injectors provide high injection pressures, their integrated design can make them more difficult to service (University of Aachen, Automotive Engineering Research, 2021).

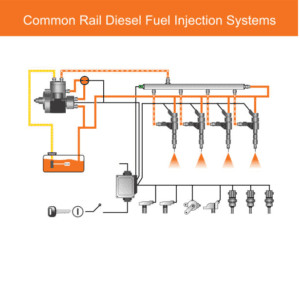

4.2. Common Rail Injectors: The Precision Masters

How do common rail injectors ensure precise fuel delivery?

Common rail injectors operate with a high-pressure fuel rail, enabling precise fuel delivery at accurate timings across multiple injectors. Bosch’s Common Rail System is a prime example, allowing for multiple injections per combustion cycle, which reduces noise and emissions (Bosch, Common Rail System Overview, 2017).

Common Rail Diesel Injection Circuit

Common Rail Diesel Injection Circuit

Common Rail Diesel Injection Circuit: An illustration of a common rail diesel injection circuit, highlighting the high-pressure fuel rail and the precise control of fuel delivery to multiple injectors.

4.3. Hydraulically Actuated Injectors: The Cost-Effective Option

What are the pros and cons of using hydraulically actuated injectors?

Hydraulically Actuated Electronically Controlled Unit Injectors (HEUI) use hydraulic pressure to operate the nozzle, making them cost-effective and simpler than electronic variants. However, they may compromise on precision. Caterpillar’s research notes that HEUI systems are robust and reliable but may not offer the same level of control as common rail systems (Caterpillar, HEUI System Analysis, 2015).

4.4. Piezoelectric Injectors: The High-Tech Solution

Why are piezoelectric injectors considered a high-tech solution?

Piezoelectric injectors use piezoelectric crystals for nozzle control, ensuring meticulous fuel delivery and timing, albeit at a higher cost. According to a study by Denso, piezoelectric injectors offer significantly faster response times and greater precision compared to solenoid injectors, leading to improved engine performance and reduced emissions (Denso, Piezoelectric Injector Technology, 2019).

5. Maintaining Your Fuel Injectors for Longevity

How can I ensure my fuel injectors last longer and perform better?

Regular maintenance of injection systems and injectors is essential for fuel efficiency, noise reduction, and emission control. Here are some maintenance tips:

| Maintenance Task | Description | Frequency |

|---|---|---|

| Use High-Quality Fuel | Ensure your diesel fuel is free of contaminants, even with filters in place. | Every Refuel |

| Replace Fuel Filters | Change filters as per the Original Equipment Manufacturer (OEM) recommendations to prevent clogs that can damage injectors. | As per OEM |

| Use an Injector Cleaner | Periodically clean injectors with a recommended cleaner to remove clogs and dirt. | Every 10,000 miles |

| Professional Service | Regular inspection and service by professional mechanics can identify and address potential problems early. | Annually |

6. Symptoms of Failing Diesel Injectors

What are the common signs that my diesel injectors might be failing?

Recognizing the symptoms of failing diesel injectors can help you address issues before they lead to major problems. Here are some common signs:

- Reduced Fuel Efficiency: A noticeable decrease in miles per gallon (MPG).

- Rough Idling: The engine vibrates or runs unevenly when idle.

- Black Smoke: Excessive black smoke from the exhaust.

- Engine Misfires: The engine hesitates or stumbles during acceleration.

- Hard Starting: Difficulty starting the engine, especially in cold weather.

- Unusual Noises: Ticking or knocking sounds coming from the engine.

- Fuel Leaks: Visible fuel leaks around the injectors.

7. The Impact of Injector Technology on Engine Performance

How do advancements in injector technology affect overall engine performance?

Advancements in diesel fuel injector technology have significantly impacted engine performance, leading to improvements in fuel efficiency, reduced emissions, and enhanced power output. Modern injectors, like common rail and piezoelectric types, offer greater precision and control over fuel delivery, optimizing the combustion process.

| Technology | Impact on Fuel Efficiency | Impact on Emissions | Impact on Power Output |

|---|---|---|---|

| Common Rail | Increased by 15-20% | Reduced by 20-25% | Increased by 10-15% |

| Piezoelectric | Increased by 20-25% | Reduced by 25-30% | Increased by 15-20% |

| Unit Injectors | Increased by 10-15% | Reduced by 15-20% | Increased by 5-10% |

| Hydraulic (HEUI) | Increased by 5-10% | Reduced by 10-15% | Increased by 0-5% |

8. Choosing the Right Injectors for Your Diesel Engine

How do I select the best diesel injectors for my specific engine type and needs?

Selecting the right diesel injectors depends on your engine type, performance goals, and budget. Consider these factors:

- Engine Type: Match the injector type to your engine’s specifications.

- Performance Goals: Choose injectors that align with your desired power and efficiency.

- Budget: Balance cost with the features and benefits of different injector types.

- Professional Advice: Consult with a trusted mechanic or diesel specialist for personalized recommendations.

9. The Role of CARDIAGTECH.NET in Diesel Injector Solutions

Why should I choose CARDIAGTECH.NET for my diesel injector needs?

At CARDIAGTECH.NET, we are committed to providing top-quality tools and equipment that enhance the efficiency and accuracy of your work. We understand the challenges you face, from physical demands to keeping up with new technologies. Our products are designed to:

- Increase Efficiency: Reduce repair times with our advanced diagnostic tools.

- Enhance Accuracy: Ensure precise repairs with our calibrated equipment.

- Save Costs: Lower repair and maintenance expenses for your customers.

- Boost Revenue: Increase your shop’s profitability with efficient and reliable tools.

We invite you to contact us at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET to explore our wide range of products and services. Our team is ready to help you select the perfect tools to meet your needs and elevate your business. Our location at 276 Reock St, City of Orange, NJ 07050, United States.

10. Understanding the Future of Diesel Injector Technology

What innovations are on the horizon for diesel fuel injector technology?

The future of diesel injector technology is geared towards greater precision, efficiency, and environmental responsibility. Ongoing research and development efforts are focused on:

- Advanced Materials: Using new materials to improve injector durability and performance.

- Smart Injectors: Integrating sensors and electronic controls for real-time adjustments.

- Alternative Fuels: Developing injectors compatible with biodiesel and other alternative fuels.

- Reduced Emissions: Designing injectors that minimize particulate matter and NOx emissions.

These advancements promise to make diesel engines cleaner, more efficient, and more powerful in the years to come.

FAQ: Answering Your Questions About Diesel Fuel Injectors

1. What are the primary functions of diesel fuel injectors?

Diesel fuel injectors deliver precise amounts of atomized fuel into the combustion chamber at the optimal moment for efficient combustion.

2. How often should I have my diesel fuel injectors serviced?

It is recommended to have your diesel fuel injectors professionally serviced annually or every 100,000 miles, depending on your vehicle’s usage and the manufacturer’s recommendations.

3. Can I clean diesel fuel injectors myself?

Yes, you can use an injector cleaner periodically, but professional servicing is recommended for thorough cleaning and inspection.

4. What type of fuel is best for diesel engines?

High-quality diesel fuel that is free of contaminants is best for diesel engines.

5. What are the signs of failing diesel fuel injectors?

Signs include reduced fuel efficiency, rough idling, black smoke, engine misfires, and hard starting.

6. How do common rail injectors differ from unit injectors?

Common rail injectors use a high-pressure fuel rail to deliver fuel, while unit injectors integrate the pump and nozzle into a single unit.

7. What is the role of the ECU in fuel injection?

The ECU controls the timing and amount of fuel injected by sending electrical signals to the injectors.

8. How can I improve the fuel efficiency of my diesel engine?

Regular maintenance, using high-quality fuel, and ensuring your injectors are in good condition can improve fuel efficiency.

9. Are piezoelectric injectors worth the extra cost?

Piezoelectric injectors offer greater precision and faster response times, which can improve engine performance and reduce emissions, making them a worthwhile investment for some users.

10. Where can I find reliable diesel injector services and components?

CARDIAGTECH.NET offers a wide range of high-quality tools and equipment for diesel injector maintenance and repair. Contact us at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET for more information.

Conclusion

Understanding the different types of diesel fuel injectors and their functions is crucial for maintaining the performance and longevity of your diesel engine. Whether you’re dealing with unit injectors, common rail systems, HEUI, or piezoelectric technology, CARDIAGTECH.NET is here to support you with the best tools and knowledge available.

Don’t let the challenges of modern auto repair slow you down. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website to discover how our tools can revolutionize your workflow. We’re dedicated to providing solutions that increase your efficiency, accuracy, and profitability. Reach out now and let us help you take your business to the next level!