What Are The Types of Drum Brake Systems? A Comprehensive Guide

Are you curious about the different types of drum brake systems? Drum brake systems are a classic and reliable braking technology, and at CARDIAGTECH.NET, we’re here to provide you with a comprehensive understanding. This guide explores the various types, their functionality, and how they compare to modern braking solutions, ensuring you’re well-informed about these essential automotive components. Let’s explore this traditional braking technology and discover the best tools and equipment for their maintenance and repair, available at CARDIAGTECH.NET.

1. Understanding Drum Brake Systems: An Overview

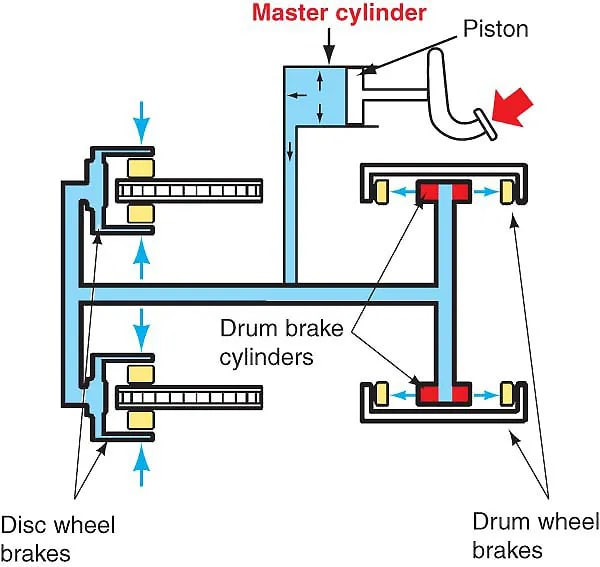

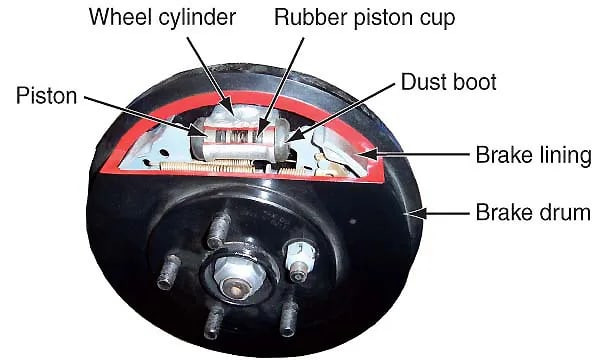

What is a drum brake system and how does it work? A drum brake system is a type of braking system where brake shoes press against the inside surface of a rotating drum to create friction and slow or stop a vehicle. Drum brakes, still found in many vehicles, primarily on the rear wheels, are a reliable technology.

- Simple Operation: Drum brakes operate using hydraulic pressure to push brake shoes against the drum, creating friction.

- Cost-Effective: Generally less expensive to manufacture than disc brakes, making them a budget-friendly option.

- Self-Energizing Effect: Some designs offer a self-energizing effect, where the friction helps to increase the braking force.

2. Key Components of a Drum Brake System

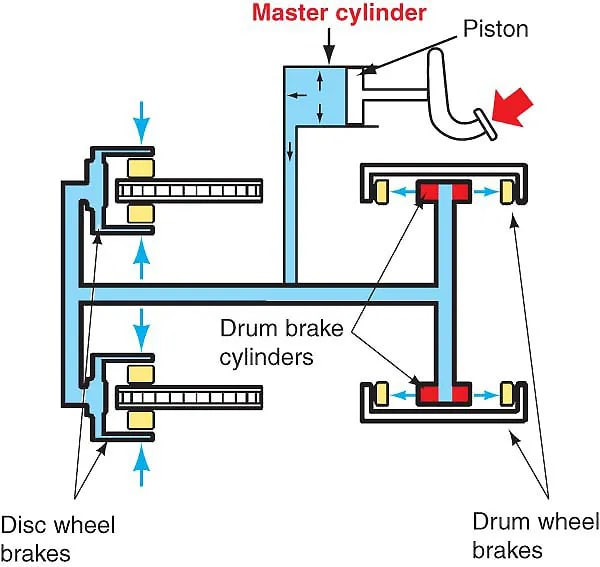

What parts make up a drum brake system? The main components include the brake drum, brake shoes, wheel cylinder, backing plate, and various springs and levers. Understanding these parts is crucial for maintenance and repair.

- Brake Drum: A hollow, cylindrical component that rotates with the wheel.

- Brake Shoes: Curved friction material that presses against the drum to create braking force.

- Wheel Cylinder: Hydraulic cylinder that pushes the brake shoes outward.

- Backing Plate: Provides a foundation for the brake assembly and supports the other components.

- Springs and Levers: Ensure proper shoe return and adjustment.

3. Types of Drum Brake Systems

What are the different designs of drum brake systems? Drum brake systems come in several designs, each with unique characteristics and applications. These include leading/trailing shoe, twin leading shoe, duo-servo, and auto-reverse brakes.

3.1. Leading/Trailing Shoe Brakes

What are leading/trailing shoe drum brakes? Leading/trailing shoe brakes feature one shoe that is “leading” (self-energizing) and another that is “trailing” (less self-energizing), providing balanced braking force. This design is common in many passenger vehicles.

- Operation: The leading shoe is more effective when the drum rotates in one direction, while the trailing shoe is more effective in the opposite direction.

- Balance: Provides a balanced braking force in both forward and reverse directions.

- Application: Commonly found on the rear wheels of many vehicles.

3.2. Twin Leading Shoe Brakes

What are twin leading shoe drum brakes? Twin leading shoe brakes have two leading shoes, both self-energizing, which increases braking efficiency in one direction. This design is often used in the front wheels of older vehicles or specialized applications.

- Enhanced Braking: Offers increased braking power in the forward direction due to both shoes being self-energizing.

- Directional: More effective in one direction of rotation.

- Application: Often used in the front wheels of older vehicles or specialized applications.

3.3. Duo-Servo Brakes

What are duo-servo drum brakes? Duo-servo brakes use a primary and secondary shoe, where the primary shoe’s force is amplified by the secondary shoe, resulting in high braking power. This design is common in many rear drum brake systems.

- Amplified Force: The primary shoe’s force is amplified by the secondary shoe, providing significant braking power.

- High Efficiency: Offers high braking efficiency with relatively low input force.

- Application: Commonly used in rear drum brake systems.

3.4. Auto-Reverse Brakes

What are auto-reverse drum brakes? Auto-reverse brakes are designed to provide equal braking force in both forward and reverse directions, typically using a specialized lever or cam system. This design ensures consistent performance regardless of the vehicle’s direction.

- Consistent Performance: Provides equal braking force in both forward and reverse directions.

- Specialized Design: Utilizes a specialized lever or cam system.

- Application: Ensures consistent performance regardless of the vehicle’s direction.

Different drum brake systems

Different drum brake systems

4. How Drum Brakes Work: A Detailed Explanation

How do drum brakes function? Drum brakes use hydraulic pressure to force brake shoes against the rotating drum, creating friction that slows or stops the vehicle. This process involves several key steps and components working in harmony.

- Hydraulic Pressure: When the brake pedal is pressed, the master cylinder sends hydraulic pressure to the wheel cylinders.

- Wheel Cylinder Activation: The wheel cylinders convert hydraulic pressure into mechanical force, pushing the brake shoes outward.

- Friction Creation: The brake shoes press against the inner surface of the drum, creating friction.

- Vehicle Slowing: The friction slows the rotation of the drum and, consequently, the wheel, bringing the vehicle to a stop.

- Release: When the brake pedal is released, springs pull the brake shoes back to their original position, releasing the pressure on the drum.

5. Advantages and Disadvantages of Drum Brakes

What are the pros and cons of using drum brakes? Drum brakes have distinct advantages and disadvantages compared to disc brakes, influencing their application in modern vehicles.

5.1. Advantages

- Cost-Effective: Generally cheaper to manufacture and maintain.

- Self-Energizing Effect: Some designs offer a self-energizing effect, reducing the force needed on the brake pedal.

- Parking Brake Integration: Easier to integrate a parking brake mechanism.

5.2. Disadvantages

- Heat Dissipation: Less efficient at dissipating heat, leading to brake fade under heavy use.

- Water Sensitivity: Can be affected by water and debris, reducing braking efficiency.

- Maintenance: Requires more frequent maintenance due to enclosed design.

6. Common Issues and Troubleshooting

What problems commonly occur with drum brakes and how can they be fixed? Common issues include brake fade, noise, uneven wear, and sticking brakes. Addressing these problems promptly is crucial for maintaining vehicle safety.

- Brake Fade: Caused by overheating, reducing braking efficiency. Solution: Allow brakes to cool or upgrade to more efficient components.

- Noise: Squealing or grinding noises indicate worn shoes or drum damage. Solution: Replace worn parts and inspect the drum for damage.

- Uneven Wear: Uneven wear on brake shoes can cause pulling or reduced braking performance. Solution: Replace shoes and inspect the wheel cylinder and springs.

- Sticking Brakes: Caused by corroded or damaged components, preventing the shoes from releasing. Solution: Clean and lubricate moving parts or replace damaged components.

7. Maintenance Tips for Drum Brake Systems

How can drum brakes be properly maintained to ensure longevity and performance? Regular inspection and maintenance are crucial for ensuring the longevity and optimal performance of drum brake systems.

- Regular Inspection: Check brake shoes, drums, and hardware for wear and damage.

- Cleaning: Clean brake components to remove dust and debris.

- Lubrication: Lubricate moving parts to ensure smooth operation.

- Adjustment: Adjust brake shoes to maintain proper clearance.

- Fluid Check: Inspect and replace brake fluid as needed.

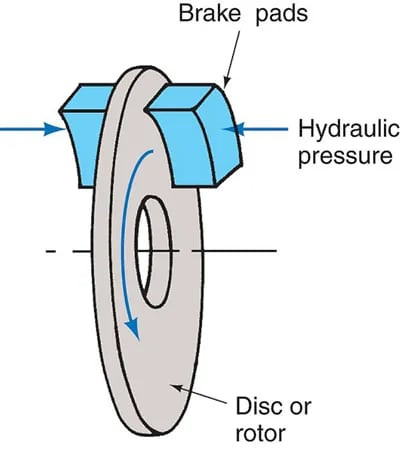

8. Drum Brakes vs. Disc Brakes: A Comparison

How do drum brakes compare to disc brakes in terms of performance, cost, and maintenance? Understanding the differences between drum and disc brakes is essential for making informed decisions about vehicle maintenance and upgrades.

- Performance: Disc brakes generally offer better stopping power and heat dissipation compared to drum brakes.

- Cost: Drum brakes are typically less expensive to manufacture and maintain.

- Maintenance: Disc brakes often require less frequent maintenance due to their open design and self-cleaning properties.

According to a study by the National Highway Traffic Safety Administration (NHTSA), disc brakes provide a 20-30% shorter stopping distance compared to drum brakes in emergency situations.

9. Upgrading Your Drum Brake System

Can drum brakes be upgraded for improved performance? Yes, several upgrades can enhance the performance of drum brake systems, including high-performance brake shoes, improved wheel cylinders, and enhanced drum materials.

- High-Performance Brake Shoes: Offer improved friction and heat resistance.

- Improved Wheel Cylinders: Provide more consistent and reliable operation.

- Enhanced Drum Materials: Offer better heat dissipation and durability.

10. Tools and Equipment for Drum Brake Repair at CARDIAGTECH.NET

What tools and equipment are essential for repairing drum brake systems, and where can they be purchased? CARDIAGTECH.NET offers a wide range of tools and equipment specifically designed for drum brake repair.

- Brake Spring Pliers: For easy removal and installation of brake springs.

- Brake Shoe Retaining Spring Tool: For removing and installing retaining springs.

- Brake Cylinder Hone: For resurfacing wheel cylinder bores.

- Brake Drum Micrometer: For measuring drum diameter and ensuring proper fit.

- Brake Bleeder Kit: For removing air from the brake lines after repairs.

Investing in high-quality tools from CARDIAGTECH.NET ensures efficient and accurate drum brake repairs, saving time and improving the quality of your work.

Drum brake parts

Drum brake parts

11. Step-by-Step Guide to Replacing Drum Brakes

How can drum brakes be replaced safely and effectively? Replacing drum brakes involves several steps, including removing the wheel, disconnecting the brake hardware, and installing new components.

- Preparation: Gather necessary tools and parts, and ensure the vehicle is safely supported.

- Wheel Removal: Remove the wheel to access the brake drum.

- Drum Removal: Remove the brake drum, which may require tapping or using a drum puller.

- Hardware Disconnection: Disconnect the brake springs, shoes, and wheel cylinder.

- Component Inspection: Inspect the wheel cylinder, springs, and backing plate for wear and damage.

- New Component Installation: Install new brake shoes, springs, and wheel cylinder if necessary.

- Adjustment: Adjust the brake shoes to the proper clearance.

- Drum Reinstallation: Reinstall the brake drum and wheel.

- Testing: Test the brakes to ensure proper operation.

12. Safety Precautions When Working with Drum Brakes

What safety measures should be taken when working on drum brake systems? Working with drum brakes involves handling various components and fluids, making safety a top priority.

- Wear Safety Glasses: Protect your eyes from brake dust and debris.

- Use Gloves: Protect your hands from brake fluid and sharp edges.

- Work in a Well-Ventilated Area: Avoid inhaling brake dust, which can be harmful.

- Proper Disposal: Dispose of used brake fluid and components properly.

- Secure Vehicle: Ensure the vehicle is properly supported before starting work.

13. Understanding Brake Shoe Materials

What are the different types of materials used in brake shoes? Brake shoes are made from various materials, each offering different performance characteristics.

- Organic: Made from organic materials like rubber, glass, and resins. They are quiet but wear quickly.

- Semi-Metallic: Contain a mix of metal and organic materials, offering a good balance of performance and durability.

- Ceramic: Made from ceramic fibers, providing excellent heat resistance and long life.

14. The Role of Springs in Drum Brake Systems

Why are springs important in drum brake systems? Springs play a crucial role in ensuring proper brake operation by returning the shoes to their original position and maintaining proper tension.

- Return Springs: Pull the brake shoes back when the brake pedal is released.

- Hold-Down Springs: Secure the brake shoes to the backing plate.

- Adjuster Springs: Maintain proper tension on the self-adjusting mechanism.

15. Adjusting Drum Brakes for Optimal Performance

How should drum brakes be adjusted to ensure optimal performance? Proper adjustment ensures that the brake shoes have the correct clearance, providing optimal braking performance and preventing premature wear.

- Locate Adjuster: Find the adjuster wheel or star wheel on the backing plate.

- Tighten Adjuster: Use a brake adjusting tool to tighten the adjuster, expanding the shoes until they lightly drag on the drum.

- Loosen Adjuster: Back off the adjuster slightly until the shoes no longer drag.

- Test Brakes: Test the brakes to ensure they operate smoothly and effectively.

16. Diagnosing Brake Drum Problems

How can problems with brake drums be identified? Common issues include scoring, cracking, and out-of-round conditions, which can affect braking performance.

- Scoring: Grooves or scratches on the drum surface caused by worn brake shoes.

- Cracking: Cracks in the drum can weaken its structure and reduce braking efficiency.

- Out-of-Round: The drum is not perfectly round, causing vibrations and uneven braking.

17. The Future of Drum Brake Technology

Are drum brakes still relevant in modern vehicles? While disc brakes are more common, drum brakes continue to be used in certain applications due to their cost-effectiveness and simplicity.

- Cost Savings: Drum brakes remain a cost-effective option for rear brake systems in many vehicles.

- Simplicity: Their simple design makes them reliable and easy to maintain.

- Electric Vehicles: Some electric vehicles use drum brakes on the rear wheels to reduce drag and improve efficiency.

According to a report by Global Market Insights, the drum brake market is expected to see steady growth in developing regions due to their affordability and ease of maintenance.

18. Maintaining Your Drum Brakes for Longevity

How can drum brakes be maintained to extend their lifespan? Regular maintenance and timely repairs can significantly extend the lifespan of drum brakes.

- Regular Cleaning: Remove brake dust and debris to prevent wear and corrosion.

- Proper Lubrication: Lubricate moving parts to ensure smooth operation.

- Timely Repairs: Address any issues promptly to prevent further damage.

19. Choosing the Right Brake Fluid for Drum Brakes

What type of brake fluid is best for drum brake systems? Using the correct brake fluid is crucial for ensuring proper brake operation and preventing corrosion.

- DOT 3: A common type of brake fluid suitable for many drum brake systems.

- DOT 4: Offers higher boiling point and better performance under high temperatures.

- DOT 5.1: Provides even higher boiling point and is suitable for high-performance applications.

Refer to your vehicle’s manufacturer specifications to determine the correct brake fluid for your drum brake system.

20. Understanding Self-Adjusting Mechanisms in Drum Brakes

How do self-adjusting mechanisms work in drum brakes? Self-adjusting mechanisms automatically adjust the brake shoes to maintain proper clearance, ensuring consistent braking performance.

- Star Wheel Adjuster: A common type of self-adjuster that uses a star wheel to adjust the brake shoes.

- Cable Adjuster: Uses a cable connected to the parking brake lever to adjust the brake shoes.

- Automatic Adjustment: The adjuster automatically tightens the brake shoes when they become worn, maintaining proper clearance.

21. Troubleshooting Common Drum Brake Noises

What do different drum brake noises indicate? Identifying the source of brake noises can help diagnose and repair issues quickly.

- Squealing: Often indicates worn brake shoes or a glazed drum surface.

- Grinding: Suggests that the brake shoes are worn down to the metal and damaging the drum.

- Clicking: Can indicate a loose or broken spring.

- Rattling: May be caused by loose brake hardware.

22. The Importance of Professional Brake Service

Why is it important to have drum brakes serviced by a professional? Professional brake service ensures that your drum brakes are properly inspected, maintained, and repaired, ensuring your safety on the road.

- Expertise: Professional technicians have the knowledge and experience to diagnose and repair brake issues accurately.

- Specialized Tools: They have access to specialized tools and equipment for brake service.

- Safety: Proper brake service ensures that your brakes are functioning correctly, reducing the risk of accidents.

23. Understanding Drum Brake Backing Plates

What is the role of the backing plate in a drum brake system? The backing plate provides a foundation for the brake assembly, supporting the wheel cylinder, brake shoes, and springs.

- Support: Provides structural support for the brake components.

- Protection: Protects the brake components from dirt and debris.

- Mounting: Provides a mounting point for the wheel cylinder and other hardware.

24. Choosing the Right Drum Brake Hardware Kit

What should be included in a drum brake hardware kit? A hardware kit typically includes springs, clips, and adjusters needed to properly install and maintain drum brakes.

- Springs: Return springs, hold-down springs, and adjuster springs.

- Clips: Retaining clips for securing the brake shoes.

- Adjusters: Self-adjusting mechanisms for maintaining proper shoe clearance.

25. The Impact of Drum Brake Size on Performance

How does the size of the drum brake affect its performance? Larger drum brakes generally offer better stopping power due to increased friction surface area.

- Friction Surface Area: Larger drums have more surface area, allowing for greater friction and stopping power.

- Heat Dissipation: Larger drums can dissipate heat more effectively, reducing brake fade.

- Vehicle Weight: Larger vehicles typically require larger drum brakes to provide adequate stopping power.

26. Using a Brake Drum Puller for Removal

How does a brake drum puller assist in removing stubborn drums? A brake drum puller provides a safe and effective way to remove drums that are stuck due to rust or corrosion.

- Safe Removal: Prevents damage to the drum and surrounding components.

- Effective: Provides the necessary force to break the drum free from the axle.

- Easy to Use: Simplifies the drum removal process.

27. The Importance of Even Brake Wear in Drum Systems

Why is it important for brake shoes to wear evenly in drum brake systems? Even wear ensures consistent braking performance and prevents premature wear of brake components.

- Consistent Braking: Evenly worn shoes provide balanced braking force.

- Extended Lifespan: Prevents premature wear of brake drums and other components.

- Safety: Ensures reliable braking performance under all conditions.

28. The Effect of Rust on Drum Brake Performance

How does rust affect the performance of drum brakes? Rust can cause the brake shoes to stick, reduce braking efficiency, and damage the drum surface.

- Sticking Brakes: Rust can cause the brake shoes to stick to the drum, preventing them from releasing properly.

- Reduced Efficiency: Rust reduces the friction between the shoes and the drum, decreasing braking power.

- Drum Damage: Rust can damage the drum surface, leading to uneven wear and noise.

29. Inspecting Wheel Cylinders for Leaks and Damage

How should wheel cylinders be inspected for leaks and damage? Regular inspection ensures they are functioning correctly and not compromising the braking system.

- Visual Inspection: Check for leaks around the cylinder body and piston seals.

- Dust Boot Condition: Inspect the dust boots for cracks or damage.

- Piston Movement: Ensure the pistons move smoothly and freely.

30. Enhancing Drum Brake Performance with Better Components from CARDIAGTECH.NET

Looking to enhance your drum brake system? CARDIAGTECH.NET offers a wide range of high-quality components designed to improve braking performance.

- High-Performance Brake Shoes: Provide improved friction and heat resistance.

- Upgraded Wheel Cylinders: Offer more consistent and reliable operation.

- Enhanced Drum Materials: Provide better heat dissipation and durability.

Explore our selection at CARDIAGTECH.NET and find the perfect components to optimize your drum brake system.

Disc brake parts

Disc brake parts

Understanding the various types of drum brake systems, their components, and maintenance is essential for ensuring vehicle safety and performance. CARDIAGTECH.NET is your trusted partner for providing high-quality tools and equipment for all your automotive repair needs.

Don’t let worn-out drum brakes compromise your safety. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our store at 276 Reock St, City of Orange, NJ 07050, United States. Let our experts help you find the perfect tools and components to keep your brakes in top condition. Enhance your repair capabilities with our specialized equipment and ensure every job is done with precision and care.

Frequently Asked Questions (FAQs) About Drum Brake Systems

1. What are the main types of drum brake systems?

The main types of drum brake systems include leading/trailing shoe, twin leading shoe, duo-servo, and auto-reverse brakes, each designed with unique characteristics and applications.

2. How do duo-servo drum brakes work?

Duo-servo brakes use a primary and secondary shoe, where the primary shoe’s force is amplified by the secondary shoe, resulting in high braking power.

3. What are the advantages of drum brakes compared to disc brakes?

Drum brakes are generally more cost-effective, offer a self-energizing effect, and are easier to integrate a parking brake mechanism.

4. What are some common issues with drum brake systems?

Common issues include brake fade, noise, uneven wear, and sticking brakes, all of which can compromise braking performance.

5. How often should drum brakes be inspected?

Drum brakes should be inspected regularly, typically every 12,000 to 15,000 miles, to ensure proper operation and identify any potential issues.

6. What type of brake fluid should I use for my drum brake system?

Refer to your vehicle’s manufacturer specifications to determine the correct brake fluid. DOT 3 is a common type, but DOT 4 or DOT 5.1 may be recommended for higher performance.

7. How do self-adjusting mechanisms work in drum brakes?

Self-adjusting mechanisms automatically adjust the brake shoes to maintain proper clearance, ensuring consistent braking performance as the shoes wear.

8. What does a grinding noise from my drum brakes indicate?

A grinding noise typically indicates that the brake shoes are worn down to the metal and damaging the drum, requiring immediate attention.

9. Why is it important to use a brake drum puller for drum removal?

A brake drum puller provides a safe and effective way to remove drums that are stuck due to rust or corrosion, preventing damage to the drum and surrounding components.

10. Where can I find high-quality tools and components for drum brake repair?

CARDIAGTECH.NET offers a wide range of high-quality tools and components designed for drum brake repair, ensuring efficient and accurate service. Visit us at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880.

By understanding these aspects of drum brake systems, you can ensure their proper maintenance and repair, keeping your vehicle safe and reliable. Trust CARDIAGTECH.NET to provide the tools and knowledge you need for all your automotive needs.