What Is the Operating Principle of a Hydraulic Power Steering System?

The operating principle of a hydraulic power steering (HPS) system is to use pressurized hydraulic fluid to assist the driver in steering the vehicle more easily. Want to experience superior control and maneuverability? CARDIAGTECH.NET offers top-of-the-line hydraulic power steering components that enhance your driving experience. By understanding hydraulic power assist, fluid dynamics, and the importance of a well-maintained system, you’ll appreciate the evolution of power steering.

1. Unveiling Hydraulic Power Steering: A Comprehensive Guide

What is the operating principle of a hydraulic power steering system? The operating principle of a hydraulic power steering (HPS) system lies in its ability to leverage pressurized hydraulic fluid to provide power assistance to the driver, significantly reducing the effort required to steer the vehicle. This system enhances maneuverability, making driving smoother and safer.

Hydraulic power steering is a sophisticated system designed to make steering easier for drivers, especially in larger vehicles. It works by using hydraulic pressure to amplify the force applied to the steering wheel, allowing for smoother and more controlled turns. This system is comprised of several key components that work together seamlessly.

Key Components of a Hydraulic Power Steering System:

- Hydraulic Pump: The heart of the system, driven by the engine, provides the necessary hydraulic pressure.

- Fluid Reservoir: Stores the hydraulic fluid and ensures a constant supply to the pump.

- Control Valve: Regulates the flow of fluid to the appropriate side of the steering gear based on steering wheel input.

- Power Cylinder: Uses hydraulic pressure to assist in moving the steering linkage.

- Hoses: Connect all the components, allowing for the transfer of hydraulic fluid.

Understanding these components is essential for grasping the entire operating principle of a hydraulic power steering system.

2. Breaking Down the “Hydraulic Power Steering” Terminology

Why is it called hydraulic power steering? The term “hydraulic power steering” is descriptive of its function, combining “hydraulic,” indicating the use of fluid power, with “power steering,” highlighting the assistance provided in steering. This system uses hydraulic fluid under pressure to amplify the driver’s steering input.

Let’s dissect the terminology to gain a clearer understanding:

- Hydraulic: Refers to the use of a liquid, in this case, hydraulic fluid, to transmit power. This fluid is pressurized and used to perform work.

- Power: Indicates that the system provides assistance, reducing the amount of physical effort required from the driver to turn the steering wheel.

- Steering: Simply refers to the act of controlling the direction of the vehicle.

Therefore, “hydraulic power steering” accurately describes a system that utilizes pressurized hydraulic fluid to provide power assistance for steering.

3. Delving into the Operational Mechanics of Hydraulic Power Steering

How does a hydraulic power steering system operate mechanically? Mechanically, a hydraulic power steering system operates through a series of interconnected components, beginning with the steering wheel’s input activating a control valve, which directs pressurized hydraulic fluid to a power cylinder. This assistance reduces steering effort.

The operational mechanics can be broken down into several key steps:

- Driver Input: The driver turns the steering wheel, initiating the steering action.

- Control Valve Activation: The rotation of the steering wheel activates a control valve within the steering gear.

- Fluid Direction: The control valve directs high-pressure hydraulic fluid to one side of the power cylinder.

- Power Assistance: The hydraulic pressure assists the movement of the power cylinder, which in turn moves the steering linkage.

- Wheel Turning: The movement of the steering linkage causes the wheels to turn, allowing the vehicle to change direction.

- Feedback: As the wheels turn, feedback is provided to the control valve, which modulates the hydraulic pressure to provide appropriate assistance.

This mechanical operation ensures that the driver experiences a smooth and responsive steering feel, with minimal effort required.

4. Exploring the Historical Roots of Hydraulic Power Steering

When was hydraulic power steering first introduced? Hydraulic power steering was first introduced in automobiles in 1951 with the Chrysler Imperial. This marked a significant advancement in automotive technology, offering drivers enhanced control and reduced steering effort, especially in larger vehicles.

The history of hydraulic power steering can be traced back to earlier innovations:

- Early Patents: The concept of power steering was patented as early as 1876, but practical implementation took time.

- Pre-War Efforts: In the 1920s, inventors like Francis Davis worked on hydraulic power steering systems, but these were not commercially viable.

- World War II: The demands of military vehicles during World War II spurred rapid development and adoption of hydraulic power steering for heavy-duty applications.

- Post-War Commercialization: Following the war, Chrysler introduced the first commercial hydraulic power steering system in the 1951 Imperial, setting the stage for widespread adoption across the automotive industry.

This timeline highlights the evolution from initial concepts to practical applications, revolutionizing vehicle handling and driver comfort.

Francis Davis is the father of hydraulic power steering.

Francis Davis is the father of hydraulic power steering.

Francis Davis is the father of hydraulic power steering.

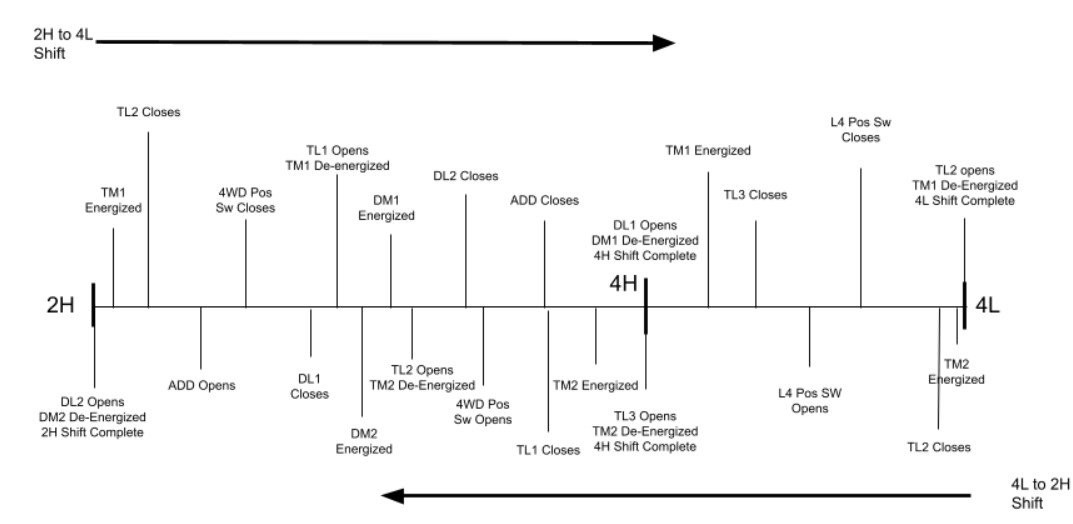

5. Understanding the Hydraulic Power Steering System Diagram

What does a typical hydraulic power steering system diagram illustrate? A typical hydraulic power steering system diagram illustrates the interconnected components, including the fluid reservoir, hydraulic pump, control valve, power cylinder, and connecting hoses. It maps the flow of hydraulic fluid and the mechanical linkages that provide steering assistance.

A detailed diagram provides a visual representation of how each component contributes to the overall function of the system. Key elements to look for in a diagram include:

- Fluid Reservoir: Shows the storage location of the hydraulic fluid.

- Hydraulic Pump: Depicts the pump’s connection to the engine and its role in pressurizing the fluid.

- Control Valve: Illustrates how the valve directs fluid flow based on steering wheel input.

- Power Cylinder: Shows how hydraulic pressure assists in moving the steering linkage.

- Hoses: Indicates the pathways through which hydraulic fluid flows between components.

By studying the diagram, one can understand the sequence of operations and the interaction between different parts of the system.

6. Identifying the Core Components of a Hydraulic Power Steering System

What are the main parts of a hydraulic power steering system? The main parts of a hydraulic power steering system include the hydraulic pump, fluid reservoir, control valve, power cylinder, and connecting hoses. Each component plays a crucial role in delivering power assistance for easier steering.

Let’s examine each component in detail:

- Hydraulic Pump: Driven by the engine, the hydraulic pump pressurizes the hydraulic fluid, creating the force needed for power assistance.

- Fluid Reservoir: The reservoir stores the hydraulic fluid, ensuring a constant supply to the pump. It also allows for air bubbles to escape from the fluid.

- Control Valve: The control valve, also known as the rotary valve, directs the high-pressure fluid to the appropriate side of the power cylinder based on the driver’s steering input.

- Power Cylinder: The power cylinder uses hydraulic pressure to assist in moving the steering linkage, reducing the effort required from the driver.

- Hoses: The hoses connect all the components, allowing for the transfer of hydraulic fluid throughout the system.

These components work together to provide a seamless and efficient steering experience.

7. The Role of Hydraulic Fluid in Power Steering Operations

What is the purpose of hydraulic fluid in a power steering system? Hydraulic fluid serves as the lifeblood of a power steering system, transmitting pressure generated by the pump to the power cylinder. This fluid enables the system to amplify the driver’s steering input, making it easier to turn the wheels.

Hydraulic fluid performs several critical functions:

- Power Transmission: It transmits the pressure generated by the hydraulic pump to the power cylinder, providing the force needed for power assistance.

- Lubrication: The fluid lubricates the moving parts within the system, reducing friction and wear.

- Cooling: It helps dissipate heat generated by the system, preventing overheating and maintaining optimal performance.

- Protection: It protects the components from corrosion and contamination.

Proper maintenance and the use of the correct type of hydraulic fluid are essential for the longevity and efficiency of the power steering system.

8. Exploring the Hydraulic Power Steering Pump Function

How does a hydraulic power steering pump work? A hydraulic power steering pump works by drawing hydraulic fluid from the reservoir and pressurizing it before sending it to the control valve. Driven by the engine, it ensures a consistent flow of high-pressure fluid, enabling the power steering system to function effectively.

The operation of the hydraulic power steering pump can be explained in the following steps:

- Intake: The pump draws hydraulic fluid from the reservoir through an inlet port.

- Pressurization: Inside the pump, a rotating mechanism, such as vanes or gears, compresses the fluid, increasing its pressure.

- Delivery: The high-pressure fluid is then delivered to the control valve through an outlet port.

- Regulation: Some pumps have a pressure relief valve to prevent over-pressurization, ensuring the system operates within safe limits.

The pump’s ability to maintain a consistent flow of high-pressure fluid is crucial for the smooth and responsive operation of the power steering system.

9. Decoding the Control Valve Mechanism in Hydraulic Steering

What is the function of the control valve in a hydraulic power steering system? The control valve directs the flow of high-pressure hydraulic fluid to either side of the power cylinder based on the driver’s steering input. This mechanism determines the direction and amount of power assistance provided, ensuring precise and responsive steering.

The control valve operates as follows:

- Neutral Position: When the steering wheel is not being turned, the control valve is in a neutral position, allowing fluid to circulate back to the pump with minimal assistance.

- Turning Input: When the driver turns the steering wheel, the control valve shifts, directing fluid to one side of the power cylinder.

- Direction Control: The direction of fluid flow determines which way the power cylinder will move, assisting the driver in turning the wheels.

- Proportional Assistance: The amount of fluid directed to the power cylinder is proportional to the amount of steering wheel input, providing variable assistance based on driving conditions.

This precise control ensures that the driver receives the appropriate level of assistance, enhancing both maneuverability and driving comfort.

10. The Role of the Power Cylinder in Hydraulic Steering Assistance

How does the power cylinder contribute to hydraulic steering assistance? The power cylinder uses hydraulic pressure to push or pull the steering linkage, providing the primary force that assists the driver in turning the wheels. By amplifying the driver’s input, it significantly reduces the effort required to steer, especially at low speeds.

The power cylinder’s operation can be summarized as follows:

- Fluid Input: High-pressure hydraulic fluid enters the power cylinder from the control valve.

- Piston Movement: The fluid pressure acts on a piston inside the cylinder, causing it to move.

- Linkage Connection: The piston is connected to the steering linkage, transferring the force to the wheels.

- Assisted Steering: As the piston moves, it pushes or pulls the steering linkage, assisting the driver in turning the wheels.

- Effort Reduction: By providing this additional force, the power cylinder significantly reduces the effort required from the driver.

This assistance is particularly noticeable when parking or maneuvering in tight spaces.

11. Exploring Different Types of Hydraulic Power Steering Systems

Are there different types of hydraulic power steering systems? Yes, there are variations of hydraulic power steering systems, including conventional HPS, speed-proportional HPS, and integrated hydraulic power steering (IHPS). Each type offers unique features to enhance steering performance and efficiency.

Let’s examine the different types:

- Conventional HPS: This is the most common type, providing constant power assistance regardless of vehicle speed.

- Speed-Proportional HPS: This system adjusts the amount of power assistance based on vehicle speed. At higher speeds, assistance is reduced to provide a firmer steering feel, while at lower speeds, assistance is increased for easier maneuverability.

- Integrated Hydraulic Power Steering (IHPS): This system integrates the power steering pump with other hydraulic systems, such as braking and suspension, to improve overall efficiency and performance.

Each type offers specific advantages depending on the vehicle’s design and intended use.

12. Benefits of Using Hydraulic Power Steering in Vehicles

What are the advantages of using a hydraulic power steering system in vehicles? The primary advantages of hydraulic power steering include reduced steering effort, improved maneuverability, and enhanced vehicle control. These benefits contribute to a safer and more comfortable driving experience.

Let’s explore these advantages in detail:

- Reduced Steering Effort: Hydraulic power steering significantly reduces the amount of physical effort required to turn the steering wheel, especially at low speeds.

- Improved Maneuverability: The power assistance makes it easier to maneuver the vehicle in tight spaces, such as parking lots or city streets.

- Enhanced Vehicle Control: The system provides a more precise and responsive steering feel, improving overall vehicle control.

- Increased Comfort: By reducing the physical strain of steering, hydraulic power steering enhances driver comfort, especially on long journeys.

- Safety: Enhanced control and reduced effort contribute to safer driving conditions, allowing drivers to react more quickly and effectively to changing road conditions.

These advantages have made hydraulic power steering a standard feature in most modern vehicles.

13. Potential Issues and Problems with Hydraulic Power Steering

What are some common problems associated with hydraulic power steering systems? Common issues with hydraulic power steering systems include fluid leaks, pump failures, worn hoses, and control valve malfunctions. These problems can lead to reduced steering assistance, noise, and potential safety hazards.

Let’s examine these issues in more detail:

- Fluid Leaks: Leaks can occur at hoses, fittings, or seals, leading to a loss of hydraulic pressure and reduced steering assistance.

- Pump Failures: The hydraulic pump can fail due to wear, contamination, or overheating, resulting in a loss of power assistance.

- Worn Hoses: Hoses can deteriorate over time, becoming brittle or cracked, leading to leaks and reduced performance.

- Control Valve Malfunctions: The control valve can become clogged or damaged, leading to erratic steering behavior or a complete loss of power assistance.

- Noise: Unusual noises, such as whining or groaning, can indicate problems with the pump or other components.

Regular maintenance and prompt repairs are essential to prevent these issues and ensure the safe and reliable operation of the hydraulic power steering system.

Fluid leak is one of steering rack most common and easily detected symptoms.

Fluid leak is one of steering rack most common and easily detected symptoms.

Fluid leak is one of steering rack most common and easily detected symptoms.

14. Essential Maintenance Tips for Hydraulic Power Steering Systems

How should I maintain a hydraulic power steering system to ensure its longevity? To maintain a hydraulic power steering system, regularly check and replenish fluid levels, inspect hoses and connections for leaks, and flush the system periodically to remove contaminants. Proper maintenance ensures optimal performance and extends the system’s lifespan.

Here are some essential maintenance tips:

- Check Fluid Levels: Regularly check the hydraulic fluid level in the reservoir and replenish as needed, using the correct type of fluid specified by the vehicle manufacturer.

- Inspect Hoses and Connections: Inspect hoses and connections for leaks, cracks, or damage. Replace any worn or damaged components immediately.

- Flush the System: Periodically flush the hydraulic power steering system to remove contaminants, such as dirt, debris, and worn fluid.

- Listen for Unusual Noises: Pay attention to any unusual noises, such as whining or groaning, which can indicate problems with the pump or other components.

- Follow Manufacturer Recommendations: Follow the vehicle manufacturer’s recommendations for maintenance intervals and fluid types.

By following these tips, you can keep your hydraulic power steering system in good working condition and prevent costly repairs.

15. Understanding the Costs Associated with Hydraulic Power Steering Repairs

What is the average cost to repair a hydraulic power steering system? The average cost to repair a hydraulic power steering system can vary widely depending on the specific issue, the vehicle’s make and model, and the labor rates of the repair shop. Common repairs can range from $200 to $800 or more.

Here’s a breakdown of potential repair costs:

- Fluid Leak Repair: Repairing a fluid leak can range from $100 to $300, depending on the location and severity of the leak.

- Hose Replacement: Replacing a worn or damaged hose can cost between $80 and $200, including parts and labor.

- Pump Replacement: Replacing the hydraulic pump can be one of the more expensive repairs, ranging from $300 to $600 or more.

- Control Valve Repair/Replacement: Repairing or replacing the control valve can cost between $200 and $500, depending on the complexity of the system.

- System Flush: Flushing the system to remove contaminants can cost between $80 and $150.

These costs are estimates and can vary based on your specific situation.

16. Comparing Hydraulic Power Steering to Electric Power Steering Systems

How does hydraulic power steering compare to electric power steering (EPS) systems? Hydraulic power steering (HPS) relies on engine-driven hydraulic pumps, while electric power steering (EPS) uses electric motors for assistance. EPS systems are generally more efficient, lighter, and offer variable assistance, making them a popular choice in modern vehicles.

Let’s compare the two systems:

| Feature | Hydraulic Power Steering (HPS) | Electric Power Steering (EPS) |

|---|---|---|

| Power Source | Engine-driven hydraulic pump | Electric motor |

| Efficiency | Lower, as it constantly draws power from the engine | Higher, as it only uses power when steering assistance is needed |

| Weight | Heavier, due to the pump, hoses, and fluid | Lighter, as it eliminates the need for a hydraulic pump and fluid |

| Assistance | Constant assistance regardless of speed | Variable assistance based on speed and driving conditions |

| Maintenance | Requires regular fluid checks and potential leak repairs | Lower maintenance, as there are fewer moving parts |

| Environmental Impact | Higher, due to potential fluid leaks and lower fuel efficiency | Lower, with no fluid leaks and improved fuel efficiency |

EPS systems are becoming increasingly common due to their efficiency and performance benefits.

17. The Environmental Impact of Hydraulic Power Steering Systems

What is the environmental impact of hydraulic power steering systems? Hydraulic power steering systems can have a negative environmental impact due to potential fluid leaks and lower fuel efficiency compared to electric systems. Fluid leaks can contaminate soil and water, while the constant power draw reduces overall fuel economy.

Here are some key points regarding the environmental impact:

- Fluid Leaks: Hydraulic fluid leaks can contaminate soil and water, posing a threat to ecosystems.

- Lower Fuel Efficiency: The constant power draw from the engine reduces overall fuel efficiency, leading to higher emissions.

- Disposal Issues: Improper disposal of hydraulic fluid can also contribute to environmental pollution.

- Recycling: Efforts to recycle hydraulic fluid can help mitigate some of the environmental impact.

Switching to electric power steering systems can significantly reduce the environmental impact associated with power steering.

18. Addressing Common Misconceptions About Hydraulic Power Steering

What are some misconceptions about hydraulic power steering systems? Common misconceptions include the belief that HPS systems require no maintenance, that all power steering fluid is the same, and that any noise indicates imminent failure. Understanding the truth can prevent costly repairs and ensure safe operation.

Let’s debunk some common myths:

- Myth: HPS systems require no maintenance.

- Fact: HPS systems require regular fluid checks, hose inspections, and periodic system flushes to ensure optimal performance and longevity.

- Myth: All power steering fluid is the same.

- Fact: Different vehicles require different types of power steering fluid. Using the wrong type can damage the system.

- Myth: Any noise indicates imminent failure.

- Fact: While unusual noises can indicate a problem, they don’t always mean the system is about to fail. Prompt diagnosis can often prevent major damage.

- Myth: HPS systems improve fuel efficiency.

- Fact: HPS systems typically reduce fuel efficiency compared to manual steering or electric power steering.

Addressing these misconceptions can help vehicle owners make informed decisions about maintenance and repairs.

19. Upgrading and Enhancing Your Hydraulic Power Steering System

Can I upgrade or enhance my hydraulic power steering system for better performance? Yes, you can upgrade or enhance your hydraulic power steering system by installing a high-performance pump, upgrading to stainless steel hoses, or adding a fluid cooler. These upgrades can improve responsiveness, reduce fluid temperatures, and extend the system’s lifespan.

Here are some potential upgrades:

- High-Performance Pump: A high-performance pump can provide more consistent pressure and flow, improving steering responsiveness.

- Stainless Steel Hoses: Stainless steel hoses are more durable and resistant to leaks than rubber hoses, extending the system’s lifespan.

- Fluid Cooler: A fluid cooler can help reduce fluid temperatures, preventing overheating and improving performance.

- Control Valve Upgrade: Upgrading the control valve can provide more precise steering control and feedback.

Consulting with a professional mechanic can help you determine the best upgrades for your specific vehicle and driving needs.

20. Choosing the Right Hydraulic Power Steering Fluid for Your Vehicle

How do I choose the correct hydraulic power steering fluid for my vehicle? To select the right hydraulic power steering fluid, consult your vehicle’s owner’s manual for the manufacturer’s recommended fluid type. Using the correct fluid ensures optimal performance and prevents damage to the system.

Here are some key considerations:

- Manufacturer Recommendations: Always follow the vehicle manufacturer’s recommendations for fluid type.

- Fluid Specifications: Check the fluid specifications, such as DEXRON, MERCON, or specific OEM standards.

- Fluid Type: Determine whether your vehicle requires conventional power steering fluid, synthetic fluid, or a specific blend.

- Compatibility: Ensure that the fluid is compatible with the materials used in your power steering system.

- Quality: Choose a high-quality fluid from a reputable brand to ensure optimal performance and protection.

Using the wrong fluid can lead to leaks, pump damage, and reduced steering performance.

21. Understanding Power Steering Assist and Its Impact on Handling

What is power steering assist and how does it affect vehicle handling? Power steering assist refers to the amount of force provided by the power steering system to aid the driver in turning the wheels. The level of assist affects steering feel, responsiveness, and overall vehicle handling.

Here’s how power steering assist impacts handling:

- Low Speed: At low speeds, higher levels of assist make it easier to maneuver the vehicle in tight spaces.

- High Speed: At high speeds, lower levels of assist provide a firmer steering feel, improving stability and control.

- Variable Assist: Some systems offer variable assist, adjusting the level of assistance based on vehicle speed and driving conditions.

- Steering Feel: The level of assist affects the steering feel, with higher levels providing a lighter, more responsive feel and lower levels providing a heavier, more direct feel.

- Driver Preference: The ideal level of assist depends on driver preference and the intended use of the vehicle.

Understanding the impact of power steering assist can help drivers choose a system that meets their specific needs and preferences.

22. The Relationship Between Steering Ratio and Hydraulic Power Steering

How does steering ratio relate to hydraulic power steering systems? Steering ratio, the measure of how far the steering wheel must turn to achieve a certain turn of the wheels, works in conjunction with hydraulic power steering to optimize steering effort and responsiveness. A lower ratio means less turning is needed, enhancing maneuverability with the help of hydraulic assistance.

Here’s how steering ratio and hydraulic power steering interact:

- Lower Steering Ratio: A lower steering ratio means that less steering wheel movement is required to achieve a given turn of the wheels. This reduces steering effort, especially when combined with hydraulic power assistance.

- Higher Steering Ratio: A higher steering ratio means that more steering wheel movement is required to achieve the same turn of the wheels. This provides more precise control but requires more effort without power assistance.

- Combined Effect: Hydraulic power steering compensates for a higher steering ratio by reducing the effort required to turn the wheels, while a lower steering ratio maximizes the benefits of power assistance.

- Vehicle Design: The choice of steering ratio and power steering system depends on the vehicle’s design and intended use, with performance vehicles often using lower ratios and more responsive power steering systems.

The combination of steering ratio and hydraulic power steering is carefully calibrated to provide optimal handling and driving experience.

23. Symptoms of a Failing Hydraulic Power Steering System

What are the telltale signs of a failing hydraulic power steering system? Key symptoms of a failing hydraulic power steering system include difficulty steering, noisy pump operation, fluid leaks, and a stiff or unresponsive steering wheel. These signs indicate that the system requires immediate inspection and potential repair.

Here are some specific symptoms to watch for:

- Difficulty Steering: The most common symptom is difficulty turning the steering wheel, especially at low speeds.

- Noisy Pump Operation: Unusual noises, such as whining or groaning, can indicate problems with the hydraulic pump.

- Fluid Leaks: Visible fluid leaks around the pump, hoses, or steering gear are a clear sign of a problem.

- Stiff or Unresponsive Steering Wheel: The steering wheel may feel stiff or unresponsive, requiring more effort to turn.

- Erratic Steering Behavior: The steering may feel jerky or unpredictable, indicating a problem with the control valve.

- Dashboard Warning Light: Some vehicles have a dashboard warning light that illuminates when there is a problem with the power steering system.

Addressing these symptoms promptly can prevent further damage and ensure safe driving.

24. Is It Possible to Convert to Electric Power Steering?

Can I convert my car’s hydraulic power steering to an electric power steering (EPS) system? Yes, it is possible to convert a car’s hydraulic power steering (HPS) to an electric power steering (EPS) system, although it can be a complex and costly modification. The conversion involves removing the hydraulic components and installing an electric motor and control unit.

Here are some considerations:

- Complexity: The conversion requires significant mechanical and electrical modifications.

- Cost: The cost can range from several hundred to several thousand dollars, depending on the vehicle and the complexity of the installation.

- Compatibility: Ensuring compatibility between the EPS system and the vehicle’s existing systems is crucial.

- Performance: EPS systems can offer improved fuel efficiency and variable assist, but the performance benefits may not justify the cost and effort for some vehicles.

- Professional Installation: It is highly recommended to have the conversion performed by a qualified mechanic.

While a conversion to EPS is possible, it’s essential to weigh the costs and benefits carefully.

25. The Future Innovations in Power Steering Technology

What innovations are on the horizon for power steering technology? Future innovations in power steering technology include advanced electric power steering (EPS) systems with enhanced feedback, steer-by-wire technology, and integration with autonomous driving systems. These advancements aim to improve efficiency, safety, and driving experience.

Here are some key trends:

- Enhanced EPS Systems: Advanced EPS systems offer improved feedback, more precise control, and integration with driver-assistance systems.

- Steer-by-Wire Technology: Steer-by-wire systems eliminate the mechanical connection between the steering wheel and the wheels, providing greater flexibility and control.

- Integration with Autonomous Driving: Power steering systems are being integrated with autonomous driving systems to enable automated steering and navigation.

- Energy Efficiency: Future systems will focus on improving energy efficiency and reducing environmental impact.

- Customization: Advanced systems will offer greater customization, allowing drivers to adjust the steering feel and response to their preferences.

These innovations promise to revolutionize the driving experience, making vehicles safer, more efficient, and more enjoyable to drive.

Hydraulic power steering is a cornerstone of modern vehicle handling, offering essential assistance that enhances safety and driving comfort. Understanding its operating principles, maintenance needs, and potential issues is critical for vehicle owners.

Ready to enhance your vehicle’s steering performance? Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or WhatsApp +1 (641) 206-8880 for expert advice and top-quality hydraulic power steering components. Don’t wait—experience the difference today! Visit CARDIAGTECH.NET now for all your automotive needs.