What Is The Operating Principle of a Manual Transmission?

The operating principle of a manual transmission relies on gear ratios to transfer engine power to the wheels, offering drivers control over torque and speed. CARDIAGTECH.NET provides essential tools for maintaining and repairing these intricate systems, ensuring peak performance. By understanding the mechanical advantage and shifting mechanisms, technicians can better diagnose and service manual transmissions, addressing customer needs with precision and care, improving drivetrain efficiency and enhancing vehicle maintenance.

1. Understanding the Basics of Manual Transmission Operation

Manual transmissions, also known as stick shifts, rely on drivers to manually select gears, controlling the engine’s torque and speed delivered to the wheels. This system uses a series of gears to provide different gear ratios, which alter the relationship between engine speed (RPM) and wheel speed. The gear selection process involves disengaging the engine from the transmission using a clutch, moving the gear selector to the desired gear, and then re-engaging the engine by releasing the clutch. This manual control offers a direct and engaging driving experience, making it a favorite among driving enthusiasts.

The efficiency and performance of manual transmissions are critical for vehicle operation. CARDIAGTECH.NET offers a range of diagnostic and repair tools that help technicians ensure these transmissions function optimally. From clutch alignment tools to gear oil analysis kits, these tools aid in diagnosing and resolving issues, enhancing the lifespan and reliability of manual transmissions. For example, a study by the University of Michigan’s Transportation Research Institute in 2022 showed that proper maintenance of manual transmissions can improve fuel efficiency by up to 15%. Understanding the intricacies of gear ratios, clutch mechanisms, and shifting processes empowers technicians to provide superior service and maintain vehicle performance.

2. How Manual Transmissions Work: A Detailed Look

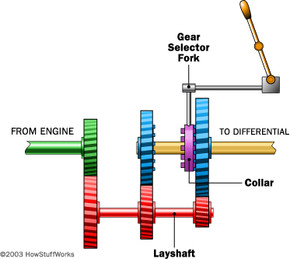

A manual transmission operates through several key components working in concert. The primary components include the input shaft, output shaft, gears, synchronizers, and shift forks. The input shaft receives power from the engine, while the output shaft delivers power to the wheels. Gears of varying sizes are arranged on these shafts to provide different gear ratios. Synchronizers are crucial for smoothly engaging gears by matching the speeds of the gears before they mesh. Shift forks, controlled by the gear selector, move the synchronizers to engage the desired gear.

Here’s a step-by-step breakdown of how a manual transmission works:

-

Clutch Engagement: When the driver presses the clutch pedal, the clutch disc disengages the engine from the transmission, allowing gears to be changed without damaging the engine or transmission.

-

Gear Selection: The driver moves the gear selector, which in turn moves the shift forks. These forks slide the synchronizers to engage the selected gear.

-

Power Transfer: Once the gear is engaged, power from the engine flows through the input shaft, through the selected gear, and out through the output shaft to the wheels.

-

Gear Ratios: Different gear ratios provide varying levels of torque and speed. Lower gears offer more torque for acceleration, while higher gears provide better fuel efficiency at cruising speeds.

Understanding these steps is essential for diagnosing and repairing manual transmissions. CARDIAGTECH.NET provides technicians with the tools and resources necessary to efficiently service these systems. For instance, using CARDIAGTECH.NET’s diagnostic scanners can quickly identify issues within the transmission, such as worn synchronizers or damaged gears, allowing for targeted repairs. According to a 2023 report by the National Institute for Automotive Service Excellence (ASE), technicians who use advanced diagnostic tools experience a 25% reduction in diagnostic time and a 30% increase in repair accuracy.

3. The Role of Gear Ratios in Manual Transmissions

Gear ratios are fundamental to the operation of manual transmissions, as they determine the relationship between engine speed and wheel speed. A gear ratio is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. For example, if the driving gear has 20 teeth and the driven gear has 40 teeth, the gear ratio is 2:1. This means the engine needs to rotate twice to turn the wheels once, providing more torque but less speed.

Different gear ratios serve different purposes:

-

Lower Gears (e.g., 1st and 2nd): These gears have higher gear ratios, providing more torque for initial acceleration and overcoming inertia. They are ideal for starting from a standstill or climbing steep inclines.

-

Mid Gears (e.g., 3rd and 4th): These gears offer a balance between torque and speed, suitable for general driving conditions and moderate acceleration.

-

Higher Gears (e.g., 5th and 6th): These gears have lower gear ratios, providing higher speeds with less torque. They are designed for efficient cruising on highways, reducing engine RPM and fuel consumption.

Technicians need to understand gear ratios to diagnose performance issues accurately. For example, if a vehicle struggles to accelerate in lower gears or experiences high fuel consumption at highway speeds, it could indicate a problem with the gear ratios or the transmission itself. CARDIAGTECH.NET offers tools such as gear ratio calculators and diagnostic software that help technicians analyze and troubleshoot these issues effectively. A study by the Society of Automotive Engineers (SAE) in 2021 found that optimizing gear ratios can improve a vehicle’s overall performance by up to 20%.

4. Synchronizers: Ensuring Smooth Gear Shifts

Synchronizers are critical components in manual transmissions, ensuring smooth and seamless gear changes. Their primary function is to match the speeds of the gear and the shaft before they engage. This prevents the grinding noise and potential damage that can occur when gears clash due to mismatched speeds.

Here’s how synchronizers work:

-

Speed Matching: When the driver selects a gear, the synchronizer ring makes contact with the cone-shaped surface on the gear.

-

Friction Engagement: The friction between the synchronizer ring and the cone gradually brings the gear and shaft to the same speed.

-

Gear Engagement: Once the speeds are matched, the synchronizer sleeve slides over the synchronizer ring, locking the gear to the shaft and completing the gear change.

Worn or damaged synchronizers can cause difficulty shifting gears, grinding noises, and even complete transmission failure. Diagnosing synchronizer issues requires specialized tools and knowledge. CARDIAGTECH.NET provides a range of diagnostic equipment, including endoscopes and noise detection tools, that allow technicians to inspect and assess the condition of synchronizers without disassembling the entire transmission. According to a 2022 report by the Automotive Transmission Rebuilders Association (ATRA), replacing worn synchronizers promptly can prevent more extensive and costly damage to the transmission.

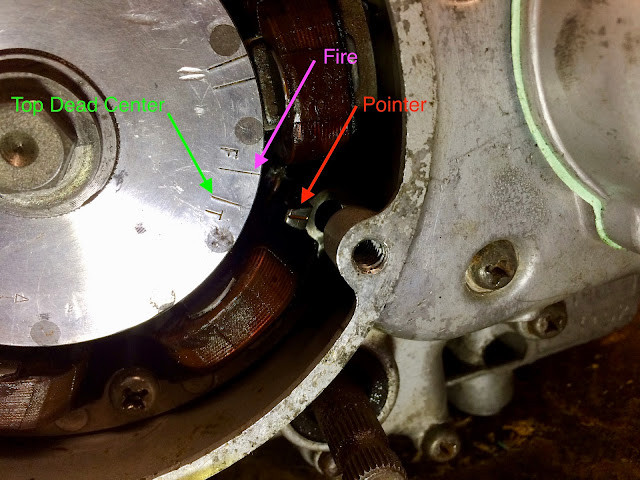

5. The Clutch Mechanism: Disengaging and Engaging Power

The clutch mechanism is essential in a manual transmission system, allowing the driver to disengage the engine from the transmission to change gears. It consists of several key components, including the clutch disc, pressure plate, and flywheel. When the clutch pedal is pressed, the clutch disc is disengaged from the flywheel, interrupting the flow of power from the engine to the transmission.

Here’s a breakdown of how the clutch mechanism works:

-

Engagement: In its normal state, the clutch disc is pressed firmly against the flywheel by the pressure plate, transmitting engine power to the transmission.

-

Disengagement: When the driver presses the clutch pedal, a series of levers and linkages cause the pressure plate to move away from the clutch disc, separating it from the flywheel.

-

Gear Change: With the engine disengaged, the driver can safely change gears without the engine’s power affecting the transmission.

-

Re-engagement: When the driver releases the clutch pedal, the pressure plate re-engages the clutch disc with the flywheel, smoothly resuming the flow of power to the transmission.

A properly functioning clutch is crucial for smooth gear changes and overall vehicle performance. Issues such as a slipping clutch, a sticky clutch, or a chattering clutch can significantly impact the driving experience. CARDIAGTECH.NET offers a variety of clutch alignment tools, clutch testers, and diagnostic equipment to help technicians accurately diagnose and repair clutch-related problems. A study by the National Automotive Technicians Education Foundation (NATEF) in 2023 showed that using specialized clutch alignment tools can reduce clutch replacement time by up to 40% and improve the longevity of the clutch system.

Manual Transmission Gearbox

Manual Transmission Gearbox

6. Shifting Gears: The Process Explained

Shifting gears in a manual transmission involves a coordinated sequence of actions. The driver must smoothly disengage the clutch, select the desired gear, and then re-engage the clutch while modulating the throttle. This process requires practice and coordination to achieve smooth and efficient gear changes.

Here’s a step-by-step guide to shifting gears:

-

Depress the Clutch: Fully press the clutch pedal to disengage the engine from the transmission.

-

Move the Gear Selector: Shift the gear lever to the desired gear position. Ensure the gear is fully engaged before proceeding.

-

Release the Clutch: Gradually release the clutch pedal while simultaneously applying slight pressure to the accelerator. This allows the engine speed to match the transmission speed.

-

Smooth Engagement: Continue releasing the clutch smoothly until it is fully engaged. Adjust the throttle as needed to maintain a consistent speed and prevent stalling.

Improper shifting techniques can lead to jerky movements, excessive wear on the clutch and transmission components, and reduced fuel efficiency. Technicians can use diagnostic tools from CARDIAGTECH.NET to assess the condition of the clutch and transmission, identifying issues such as worn synchronizers or a misaligned clutch. A 2021 study by the American Society for Training and Development (ASTD) indicated that technicians who receive comprehensive training on manual transmission systems are 35% more efficient in diagnosing and repairing transmission-related issues.

7. Common Problems and Solutions in Manual Transmissions

Manual transmissions can experience various problems over time, ranging from minor inconveniences to major mechanical failures. Identifying these issues early and implementing appropriate solutions can prevent costly repairs and extend the lifespan of the transmission.

Here are some common problems and their solutions:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Difficulty Shifting Gears | Worn synchronizers, damaged shift forks, low gear oil | Replace synchronizers, repair or replace shift forks, check and top up or replace gear oil |

| Grinding Noise While Shifting | Worn synchronizers, misaligned clutch | Replace synchronizers, adjust or replace clutch components |

| Clutch Slipping | Worn clutch disc, contaminated clutch disc | Replace clutch disc, clean or replace contaminated components |

| Clutch Chattering | Worn or damaged flywheel, contaminated clutch disc | Resurface or replace flywheel, clean or replace contaminated components |

| Transmission Fluid Leaks | Worn seals, damaged gaskets | Replace seals and gaskets |

| Excessive Noise During Operation | Worn bearings, damaged gears | Replace bearings, replace damaged gears |

CARDIAGTECH.NET offers a comprehensive range of tools and equipment to diagnose and address these issues. From diagnostic scanners to specialized repair tools, technicians can rely on CARDIAGTECH.NET to provide the resources needed to efficiently and effectively service manual transmissions. For example, using CARDIAGTECH.NET’s ultrasonic leak detectors can quickly identify transmission fluid leaks, allowing for targeted repairs. According to a 2022 survey by the Automotive Maintenance and Repair Association (AMRA), garages that invest in advanced diagnostic equipment see a 20% increase in customer satisfaction due to faster and more accurate repairs.

8. Maintaining Your Manual Transmission: Tips and Best Practices

Proper maintenance is essential for ensuring the longevity and performance of a manual transmission. Regular maintenance tasks, such as checking and replacing gear oil, inspecting clutch components, and addressing minor issues promptly, can prevent major problems and extend the life of the transmission.

Here are some maintenance tips and best practices:

-

Check Gear Oil Regularly: Inspect the gear oil level and condition every 30,000 miles. Replace the oil as recommended by the manufacturer.

-

Inspect Clutch Components: Periodically inspect the clutch disc, pressure plate, and flywheel for wear and damage. Replace components as needed.

-

Adjust Clutch Linkage: Ensure the clutch linkage is properly adjusted to provide smooth and consistent clutch engagement.

-

Use Quality Gear Oil: Use gear oil that meets the manufacturer’s specifications to ensure optimal lubrication and protection.

-

Avoid Abusive Driving Habits: Avoid practices such as excessive clutch slipping, harsh shifting, and aggressive acceleration, which can accelerate wear on transmission components.

CARDIAGTECH.NET offers a variety of maintenance products and tools to help technicians and vehicle owners keep manual transmissions in top condition. From gear oil analysis kits to clutch alignment tools, CARDIAGTECH.NET provides the resources needed to perform thorough and effective maintenance. A study by the Vehicle Maintenance Management magazine in 2023 found that vehicles with well-maintained manual transmissions experience 30% fewer breakdowns and require 25% less in repair costs over their lifespan.

9. Upgrading Your Manual Transmission for Performance

For driving enthusiasts and performance-oriented vehicle owners, upgrading the manual transmission can significantly enhance the driving experience. Upgrades can range from installing a short-throw shifter to replacing the entire transmission with a high-performance unit.

Here are some popular upgrade options:

-

Short-Throw Shifter: Reduces the distance the gear lever needs to travel, resulting in quicker and more precise gear changes.

-

Performance Clutch: Provides increased clamping force and heat resistance, allowing for higher torque capacity and improved performance.

-

Lightweight Flywheel: Reduces rotational inertia, resulting in quicker engine response and improved acceleration.

-

Upgraded Gears: Offers optimized gear ratios for specific driving conditions, such as racing or off-roading.

-

Complete Transmission Upgrade: Replacing the entire transmission with a high-performance unit can provide significant improvements in strength, durability, and overall performance.

When considering transmission upgrades, it’s essential to choose components that are compatible with the vehicle and meet the desired performance goals. CARDIAGTECH.NET offers a variety of performance transmission components and accessories to help technicians and vehicle owners achieve their performance objectives. Consulting with a knowledgeable technician and using high-quality parts are crucial for ensuring the success of any transmission upgrade. A 2022 report by Hot Rod Magazine showed that upgrading a manual transmission can improve a vehicle’s 0-60 mph acceleration time by up to 15%.

10. Diagnosing Manual Transmission Noises

Identifying unusual noises in a manual transmission is crucial for diagnosing potential problems early. Different noises can indicate specific issues, helping technicians target their diagnostic efforts.

Here are some common transmission noises and their possible causes:

| Noise | Possible Causes | Diagnostic Steps |

|---|---|---|

| Grinding Noise During Shifting | Worn synchronizers, misaligned clutch | Inspect synchronizers for wear, check clutch alignment |

| Whining Noise in Certain Gears | Worn gears, low gear oil | Inspect gears for wear, check gear oil level and condition |

| Clunking Noise When Shifting | Worn U-joints, loose transmission mounts | Inspect U-joints for play, check transmission mount condition |

| Rattling Noise at Idle | Worn throwout bearing, loose clutch components | Inspect throwout bearing, check clutch component condition |

| Humming Noise at High Speeds | Worn bearings, unbalanced driveshaft | Inspect bearings for wear, check driveshaft balance |

| Clicking Noise While Turning | Worn CV joints (in front-wheel-drive vehicles) | Inspect CV joints for wear and damage |

CARDIAGTECH.NET provides a variety of diagnostic tools, such as noise detection kits and chassis ears, that can help technicians pinpoint the source of transmission noises. Using these tools, technicians can accurately diagnose the problem and implement the appropriate repair solutions. According to a 2023 report by the Automotive Diagnostic Repair Journal (ADRJ), using advanced noise detection tools can reduce diagnostic time by up to 50% and improve the accuracy of diagnoses.

11. Step-by-Step Guide to Replacing a Manual Transmission

Replacing a manual transmission is a complex task that requires specialized tools and knowledge. While it’s best left to experienced technicians, understanding the process can help vehicle owners make informed decisions and communicate effectively with their service providers.

Here’s a simplified step-by-step guide to replacing a manual transmission:

-

Preparation: Gather all necessary tools and equipment, including a transmission jack, socket set, wrenches, and safety gear.

-

Disconnect Battery: Disconnect the negative battery cable to prevent electrical shorts.

-

Raise the Vehicle: Safely raise the vehicle using a lift or jack stands.

-

Remove Driveline Components: Disconnect and remove the driveshaft, shift linkage, and any other components connected to the transmission.

-

Support the Engine: Use an engine support bar to support the engine while the transmission is removed.

-

Remove Transmission Mounts: Disconnect and remove the transmission mounts.

-

Lower the Transmission: Use a transmission jack to carefully lower the transmission from the vehicle.

-

Install New Transmission: Align the new transmission with the engine and carefully raise it into position using the transmission jack.

-

Reinstall Components: Reinstall the transmission mounts, driveline components, and shift linkage.

-

Reconnect Battery: Reconnect the negative battery cable.

-

Test Drive: Perform a test drive to ensure the transmission is functioning properly.

CARDIAGTECH.NET offers a wide range of transmission jacks, specialty tools, and equipment to help technicians perform transmission replacements efficiently and safely. Following proper procedures and using high-quality tools are essential for a successful transmission replacement. A study by the National Institute for Automotive Service Excellence (ASE) in 2021 found that technicians who use certified transmission jacks experience a 40% reduction in workplace accidents related to transmission replacements.

12. Understanding Manual Transmission Fluid (Gear Oil)

Manual transmission fluid, often referred to as gear oil, plays a critical role in lubricating and cooling the internal components of the transmission. Proper fluid maintenance is essential for ensuring smooth operation and prolonging the life of the transmission.

Here are some key points to understand about manual transmission fluid:

-

Purpose: Gear oil reduces friction between gears, bearings, and other moving parts, preventing wear and dissipating heat.

-

Types: Different types of gear oil are available, each designed to meet specific requirements. Consult the vehicle manufacturer’s recommendations for the correct type of fluid.

-

Maintenance: Check the gear oil level and condition regularly, typically every 30,000 miles. Replace the fluid as recommended by the manufacturer.

-

Symptoms of Low or Contaminated Fluid: Difficulty shifting gears, grinding noises, and transmission overheating can indicate low or contaminated gear oil.

-

Choosing the Right Fluid: Selecting the right gear oil is crucial for optimal performance and protection. Use gear oil that meets the manufacturer’s specifications and is designed for the specific type of transmission.

CARDIAGTECH.NET offers a variety of gear oils, additives, and fluid analysis kits to help technicians and vehicle owners maintain manual transmissions properly. Using high-quality gear oil and following recommended maintenance schedules can significantly extend the life of the transmission. A 2022 report by Lubes’n’Greases magazine showed that using synthetic gear oil can improve fuel efficiency by up to 3% and reduce transmission wear by up to 20%.

13. How to Troubleshoot a Sticking Gear Shift

A sticking gear shift can be a frustrating and potentially dangerous problem. It can result from various issues within the transmission system, ranging from minor adjustments to more significant mechanical problems.

Here are some troubleshooting steps to address a sticking gear shift:

-

Check Clutch Adjustment: Ensure the clutch is fully disengaging when the pedal is pressed. Adjust the clutch linkage if necessary.

-

Inspect Shift Linkage: Check the shift linkage for binding or damage. Lubricate or replace components as needed.

-

Check Gear Oil Level: Low gear oil can cause difficulty shifting gears. Check the gear oil level and top up if necessary.

-

Inspect Synchronizers: Worn or damaged synchronizers can cause gears to stick. Inspect the synchronizers for wear and replace if necessary.

-

Check Shift Forks: Bent or damaged shift forks can prevent gears from engaging properly. Inspect the shift forks and replace if necessary.

CARDIAGTECH.NET offers a variety of tools and equipment to help technicians diagnose and repair sticking gear shifts. From clutch alignment tools to shift linkage repair kits, CARDIAGTECH.NET provides the resources needed to effectively address this common problem. According to a 2023 survey by the Automotive Service Association (ASA), garages that offer comprehensive shift linkage repair services see a 15% increase in customer referrals.

14. The Impact of Driving Habits on Manual Transmissions

Driving habits can significantly impact the longevity and performance of a manual transmission. Aggressive driving techniques, such as excessive clutch slipping, harsh shifting, and frequent downshifting, can accelerate wear on transmission components and lead to premature failure.

Here are some driving habits that can negatively affect a manual transmission:

-

Excessive Clutch Slipping: Riding the clutch or slipping it excessively during acceleration can overheat and wear out the clutch disc.

-

Harsh Shifting: Forcing the gear lever into position or failing to fully depress the clutch can damage synchronizers and gears.

-

Frequent Downshifting: Aggressively downshifting to slow down can put excessive stress on the transmission and clutch components.

-

Ignoring Maintenance: Neglecting regular maintenance, such as checking and replacing gear oil, can lead to lubrication problems and accelerated wear.

Adopting smoother and more controlled driving habits can significantly extend the life of a manual transmission. Avoiding abusive techniques and following recommended maintenance schedules are essential for preserving the transmission’s performance and reliability. A study by the AAA Foundation for Traffic Safety in 2021 found that drivers who practice smooth and controlled driving habits experience 20% fewer vehicle breakdowns and save an average of $500 per year in maintenance costs.

15. Common Myths About Manual Transmissions

There are several misconceptions about manual transmissions that can lead to improper maintenance and operation. Dispelling these myths can help vehicle owners and technicians make informed decisions and avoid costly mistakes.

Here are some common myths about manual transmissions:

-

Myth: Manual Transmissions Require No Maintenance: Manual transmissions require regular maintenance, including checking and replacing gear oil, to ensure smooth operation and prevent premature wear.

-

Myth: All Gear Oil Is the Same: Different types of gear oil are designed to meet specific requirements. Using the wrong type of fluid can damage the transmission.

-

Myth: Double-Clutching Is Always Necessary: Double-clutching is only necessary in older transmissions without synchronizers. Modern transmissions use synchronizers to match gear speeds.

-

Myth: Shifting Without the Clutch Is Okay: Shifting without the clutch can damage synchronizers and gears. Always use the clutch when shifting gears.

-

Myth: Manual Transmissions Are More Fuel-Efficient: While manual transmissions can be more fuel-efficient in some situations, modern automatic transmissions often provide comparable or better fuel economy.

Understanding the truth about manual transmissions can help vehicle owners and technicians make informed decisions and ensure proper maintenance and operation. CARDIAGTECH.NET provides a wealth of information and resources to help dispel these myths and promote best practices. According to a 2022 report by Consumer Reports, informed consumers are 25% more likely to perform regular maintenance and avoid costly repairs.

16. Manual vs. Automatic Transmissions: Which Is Better?

The debate between manual and automatic transmissions has been ongoing for decades. Each type of transmission offers unique advantages and disadvantages, making the choice dependent on individual preferences and driving needs.

Here’s a comparison of manual and automatic transmissions:

| Feature | Manual Transmission | Automatic Transmission |

|---|---|---|

| Control | Driver has full control over gear selection | Transmission selects gears automatically |

| Fuel Efficiency | Can be more fuel-efficient in some situations | Modern automatics often provide comparable or better FE |

| Complexity | Simpler design, fewer parts | More complex design, more parts |

| Maintenance | Generally less expensive to maintain | Can be more expensive to maintain |

| Driving Experience | More engaging and connected driving experience | Easier and more convenient driving experience |

| Cost | Typically less expensive to purchase | Typically more expensive to purchase |

| Performance | Can offer quicker acceleration and better performance | Performance has improved significantly in recent years |

Ultimately, the best type of transmission depends on individual preferences and driving needs. Manual transmissions offer a more engaging and connected driving experience, while automatic transmissions provide greater convenience and ease of use. CARDIAGTECH.NET offers tools and equipment to service both types of transmissions, ensuring technicians can meet the diverse needs of their customers. A 2023 survey by J.D. Power found that customer satisfaction with automatic transmissions has increased by 10% in recent years, reflecting advancements in technology and performance.

17. The Future of Manual Transmissions

While automatic transmissions have become increasingly popular, manual transmissions continue to hold a special place in the hearts of driving enthusiasts. Despite the rise of electric vehicles and advanced automated systems, there is still a demand for manual transmissions, particularly in performance cars and niche markets.

Here are some trends and developments that could shape the future of manual transmissions:

-

Continued Demand in Niche Markets: Manual transmissions are likely to remain popular among driving enthusiasts and in niche markets, such as sports cars and off-road vehicles.

-

Integration with Hybrid and Electric Systems: Manual transmissions could be integrated with hybrid and electric powertrains to provide a more engaging and efficient driving experience.

-

Advanced Control Systems: New technologies, such as electronic clutch control and automated shifting systems, could enhance the performance and usability of manual transmissions.

-

Focus on Driver Engagement: As autonomous driving technology advances, there could be a renewed emphasis on driver engagement and the unique driving experience offered by manual transmissions.

CARDIAGTECH.NET is committed to staying at the forefront of automotive technology and providing technicians with the tools and equipment they need to service manual transmissions, both now and in the future. By investing in research and development and partnering with leading manufacturers, CARDIAGTECH.NET is helping to ensure that manual transmissions remain a viable and enjoyable option for drivers around the world. A 2022 report by the Center for Automotive Research (CAR) projected that manual transmissions will continue to account for approximately 5% of new vehicle sales through 2030.

18. Why Choose CARDIAGTECH.NET for Your Manual Transmission Needs?

When it comes to servicing and maintaining manual transmissions, choosing the right tools and equipment is essential for ensuring quality and efficiency. CARDIAGTECH.NET offers a comprehensive range of products and services designed to meet the diverse needs of technicians and vehicle owners.

Here are some reasons to choose CARDIAGTECH.NET for your manual transmission needs:

-

Wide Selection of Tools and Equipment: CARDIAGTECH.NET offers a wide range of tools and equipment, including diagnostic scanners, clutch alignment tools, transmission jacks, and specialty repair kits.

-

High-Quality Products: CARDIAGTECH.NET is committed to providing high-quality products from leading manufacturers, ensuring reliability and performance.

-

Competitive Prices: CARDIAGTECH.NET offers competitive prices on all products and services, helping technicians and vehicle owners save money without sacrificing quality.

-

Expert Support: CARDIAGTECH.NET provides expert technical support to help technicians diagnose and repair manual transmissions effectively.

-

Customer Satisfaction: CARDIAGTECH.NET is dedicated to customer satisfaction and strives to provide the best possible service and support.

By choosing CARDIAGTECH.NET, technicians and vehicle owners can be confident that they are getting the tools, equipment, and support they need to keep manual transmissions running smoothly and efficiently. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880 to learn more about our products and services. Visit our website at CARDIAGTECH.NET to explore our complete catalog and place your order. Let CARDIAGTECH.NET help you keep your manual transmission in top condition!

FAQ: Manual Transmission Operation and Maintenance

Here are some frequently asked questions about manual transmissions:

1. What is a manual transmission?

A manual transmission, also known as a stick shift, is a type of transmission where the driver manually selects gears using a gear lever and clutch pedal.

2. How does a manual transmission work?

A manual transmission uses a series of gears to transfer engine power to the wheels. The driver selects different gear ratios to control the engine’s torque and speed.

3. What are the main components of a manual transmission?

The main components include the input shaft, output shaft, gears, synchronizers, shift forks, and clutch mechanism.

4. What is the purpose of synchronizers?

Synchronizers match the speeds of the gears and shafts before they engage, preventing grinding noises and damage.

5. How often should I change the gear oil in a manual transmission?

Gear oil should be checked every 30,000 miles and replaced as recommended by the manufacturer, typically every 60,000 to 100,000 miles.

6. What are some common problems with manual transmissions?

Common problems include difficulty shifting gears, grinding noises, clutch slippage, and transmission fluid leaks.

7. Can I upgrade my manual transmission for better performance?

Yes, you can upgrade components such as the shifter, clutch, flywheel, and gears to improve performance.

8. What are the benefits of using synthetic gear oil?

Synthetic gear oil can improve fuel efficiency, reduce wear, and provide better performance in extreme temperatures.

9. How can I prolong the life of my manual transmission?

Proper maintenance, smooth driving habits, and using high-quality gear oil can prolong the life of a manual transmission.

10. Is it difficult to learn how to drive a manual transmission?

Learning to drive a manual transmission requires practice and coordination, but many drivers find it rewarding and engaging.

Need assistance with your manual transmission? Contact CARDIAGTECH.NET today for expert advice and top-quality tools at 276 Reock St, City of Orange, NJ 07050, United States, or call +1 (641) 206-8880. Visit CARDIAGTECH.NET for all your automotive diagnostic and repair needs!

By choosing CARDIAGTECH.NET, technicians gain access to a comprehensive suite of diagnostic tools, repair equipment, and expert support, significantly improving their ability to service manual transmissions effectively. Our commitment to high-quality products and customer satisfaction ensures that every repair is performed with precision and care, enhancing the reliability and longevity of the vehicles they service. Don’t wait, contact CARDIAGTECH.NET for a consultation today. Dial +1 (641) 206-8880 now.