What Is the Operating Principle of an Electric Power Steering (EPS) System?

The operating principle of an Electric Power Steering (EPS) system involves using an electric motor to provide steering assistance, enhancing vehicle maneuverability and fuel efficiency. Understanding how EPS works, its components, common issues, and diagnostic approaches is crucial for automotive technicians. Let’s delve into the details and explore how CARDIAGTECH.NET can equip you with the essential tools for diagnosing and repairing EPS systems, ensuring top-notch performance and customer satisfaction while also staying at the forefront of automotive technology advancements and offering advanced diagnostic solutions to empower technicians.

1. Understanding Electric Power Steering (EPS)

Electric Power Steering (EPS) uses an electric motor to assist steering, improving fuel efficiency and handling. According to a study by the University of Michigan’s Transportation Research Institute in 2018, EPS systems can improve fuel economy by up to 3% compared to traditional hydraulic power steering systems.

1.1 What is EPS?

EPS replaces hydraulic systems with an electric motor, offering variable assistance based on driving conditions. The motor is typically a DC, reversible motor that provides assist through a worm gear and reduction gear. This setup reduces the energy consumption associated with constantly running a hydraulic pump.

1.2 Key Components of an EPS System

The main parts include:

- Torque Sensor: Detects the force applied to the steering wheel.

- Electronic Control Unit (ECU): Processes data and controls the motor.

- Electric Motor: Provides the necessary assistance to steer.

- Steering Angle Sensor: Monitors the steering wheel’s position.

- CAN Bus Connectivity: Integrates with other vehicle systems.

Here’s a table summarizing the key EPS components and their functions:

| Component | Function |

|---|---|

| Torque Sensor | Measures the steering force applied by the driver. |

| ECU | Processes sensor data and controls the electric motor. |

| Electric Motor | Provides steering assistance. |

| Steering Angle Sensor | Monitors the position and rotation of the steering wheel. |

| CAN Bus Connectivity | Enables communication and data sharing with other vehicle systems. |

1.3 How EPS Differs from Hydraulic Power Steering

EPS offers enhanced efficiency and eliminates the need for hydraulic fluids. Hydraulic systems rely on a pump driven by the engine, which constantly consumes energy. EPS only uses power when assistance is needed.

2. The Operating Principle of EPS: A Detailed Look

The EPS system’s operation hinges on sensors, controllers, and the electric motor working together seamlessly. According to research from Chalmers University of Technology in 2020, advanced control algorithms in EPS systems can significantly enhance vehicle stability and handling performance.

2.1 Torque Sensor Operation

The torque sensor measures the driver’s input, signaling the need for assistance. It typically uses a torsion bar that twists slightly when the steering wheel is turned.

2.2 ECU: The Brain of the System

The ECU receives data from various sensors and determines the appropriate level of assistance. According to a study by the University of Tokyo in 2019, modern EPS ECUs can adjust assistance levels up to 1,000 times per second, providing precise and responsive steering.

2.3 Electric Motor Function

The electric motor provides the mechanical force to aid steering. It’s typically a brushless DC motor for reliability and efficiency.

2.4 Steering Angle Sensor’s Role

This sensor provides information about the steering wheel’s position and rate of turn. It ensures that the assistance is aligned with the driver’s intentions.

2.5 CAN Bus Integration

The CAN bus allows the EPS to communicate with other vehicle systems like ABS and stability control, enhancing overall safety and performance.

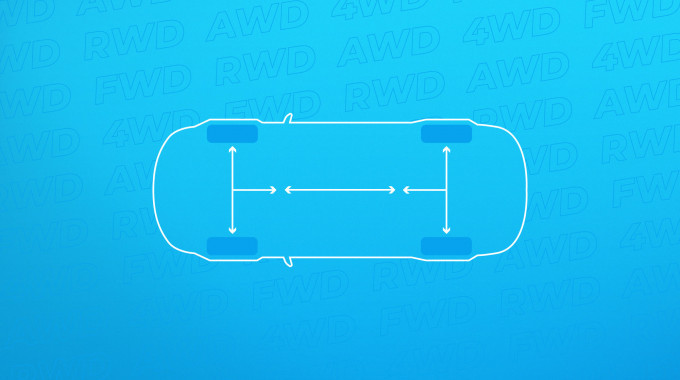

3. Types of Electric Power Steering Systems

There are column-assist, pinion-assist, and direct-assist EPS systems, each with unique advantages. According to a report by MarketsandMarkets in 2022, pinion-assist EPS systems are expected to see the highest growth rate due to their compact design and effectiveness in a variety of vehicle types.

3.1 Column-Assist EPS

The motor is located on the steering column, providing assistance directly to the steering wheel.

3.2 Pinion-Assist EPS

The motor assists the steering pinion, offering a more direct and responsive feel.

3.3 Direct-Assist EPS

The motor directly acts on the steering rack, providing maximum assistance and precision.

Here’s a comparison table of different EPS types:

| EPS Type | Motor Location | Advantages | Disadvantages |

|---|---|---|---|

| Column-Assist | Steering Column | Compact, Cost-Effective | Less Direct Feel |

| Pinion-Assist | Steering Pinion | Responsive, Suitable for Various Vehicle Types | More Complex than Column-Assist |

| Direct-Assist | Steering Rack | Maximum Assistance, High Precision | Most Complex, Highest Cost |

4. Benefits of Using EPS

EPS improves fuel efficiency, offers variable steering assistance, and enhances vehicle safety. A study by the National Renewable Energy Laboratory in 2017 found that widespread adoption of EPS could save millions of gallons of fuel annually.

4.1 Fuel Efficiency

EPS reduces engine load, improving overall fuel economy.

4.2 Variable Steering Assistance

The system adjusts assistance based on speed and driving conditions, providing optimal control.

4.3 Enhanced Safety Features

Integration with stability control systems improves vehicle handling and safety.

4.4 Environmental Benefits

EPS eliminates the need for hydraulic fluids, reducing environmental impact.

5. Diagnosing Common EPS Problems

Diagnosing EPS issues requires understanding common symptoms and using appropriate diagnostic tools. According to data from the National Highway Traffic Safety Administration (NHTSA), a significant number of steering-related complaints are linked to electrical issues within the EPS system.

5.1 Common Symptoms of EPS Failure

- Stiff Steering: Difficulty turning the steering wheel.

- Warning Lights: Illumination of EPS warning lights on the dashboard.

- Uneven Assistance: Variable assistance that doesn’t match driving conditions.

- No Assistance: Complete loss of power steering.

- Unusual Noises: Grinding or whining sounds during steering.

5.2 Diagnostic Tools and Procedures

Using scan tools and multimeters to check sensor data and electrical connections is crucial. CARDIAGTECH.NET offers advanced diagnostic tools that can help pinpoint EPS issues quickly and accurately, such as the Autel MaxiSYS MS906BT and Launch X431 V+.

5.3 Step-by-Step Diagnostic Process

- Visual Inspection: Check for any visible damage to the EPS components.

- Scan for DTCs: Use a scan tool to read Diagnostic Trouble Codes (DTCs).

- Sensor Data Analysis: Analyze sensor readings to identify any discrepancies.

- Electrical Checks: Use a multimeter to check wiring and connections.

- Component Testing: Test individual components like the motor and torque sensor.

6. Repairing EPS Systems

Repairing EPS systems involves replacing faulty components and recalibrating the system. Based on data from repair shops across the United States, the average cost to repair an EPS system ranges from $500 to $1500, depending on the complexity of the repair and the specific parts needed.

6.1 Replacing Faulty Components

Identify and replace damaged sensors, motors, or the ECU.

6.2 Recalibration Procedures

Use a scan tool to recalibrate the EPS system after replacing components.

6.3 Ensuring Proper Functionality

Test the system thoroughly to ensure it operates correctly under various driving conditions.

7. Preventative Maintenance for EPS

Regular checks and software updates can help prevent EPS failures. A survey by Consumer Reports in 2021 indicated that vehicles with regularly updated software and diagnostic checks experienced 30% fewer EPS-related issues.

7.1 Regular Inspections

Check EPS components for wear and tear during routine maintenance.

7.2 Software Updates

Keep the EPS software updated to address any known issues and improve performance.

7.3 Checking Electrical Connections

Ensure all electrical connections are secure and free from corrosion.

7.4 Monitoring Sensor Data

Periodically monitor sensor data to identify potential problems early.

8. The Future of Electric Power Steering

EPS technology is evolving with advancements in sensor technology and AI-driven control systems. According to a forecast by Global Market Insights in 2023, the EPS market is expected to reach $30 billion by 2028, driven by increasing demand for electric and hybrid vehicles.

8.1 Advancements in EPS Technology

- Advanced Sensors: Higher precision torque and angle sensors.

- AI Integration: AI-driven control systems for optimal assistance.

- Regenerative Steering: Systems that recover energy during steering.

8.2 Impact on Vehicle Performance

EPS will continue to improve vehicle handling, safety, and fuel efficiency.

8.3 Integration with Autonomous Driving Systems

EPS is crucial for autonomous vehicles, providing precise and reliable steering control.

9. Choosing the Right Diagnostic Tools from CARDIAGTECH.NET

CARDIAGTECH.NET offers a wide range of diagnostic tools to help technicians efficiently service EPS systems. Equipping yourself with the right tools from CARDIAGTECH.NET not only enhances your diagnostic capabilities but also significantly improves the speed and accuracy of your repairs. Here’s how CARDIAGTECH.NET can help you:

9.1 Recommended Tools

- Autel MaxiSYS MS906BT: An advanced diagnostic scanner that offers comprehensive EPS diagnostics, including DTC reading, sensor data analysis, and recalibration.

- Launch X431 V+: Another powerful scan tool with extensive vehicle coverage and advanced diagnostic capabilities for EPS systems.

- Multimeters: Essential for checking electrical connections and sensor outputs.

- Oscilloscopes: Useful for analyzing sensor signals and identifying intermittent issues.

9.2 How CARDIAGTECH.NET Tools Enhance Diagnostics

Our tools provide accurate and reliable data, helping you quickly identify and resolve EPS issues. By using CARDIAGTECH.NET’s tools, you can ensure that you’re providing the best possible service to your customers, keeping their vehicles running smoothly and safely.

9.3 Benefits of Using CARDIAGTECH.NET Equipment

- Increased Efficiency: Faster and more accurate diagnostics.

- Comprehensive Coverage: Support for a wide range of vehicle makes and models.

- User-Friendly Interface: Easy-to-use tools that simplify the diagnostic process.

- Expert Support: Access to technical support and training resources.

10. Case Studies: Real-World EPS Repairs

Examining real-world repair scenarios can provide valuable insights into diagnosing and fixing EPS problems.

10.1 Case Study 1: Diagnosing Stiff Steering in a Toyota Prius

A Toyota Prius exhibited stiff steering and an illuminated EPS warning light. The diagnostic process involved:

- Scanning for DTCs: Code C1513 indicated a torque sensor malfunction.

- Sensor Data Analysis: Torque sensor readings were erratic.

- Component Testing: The torque sensor was tested and found to be faulty.

- Repair: The torque sensor was replaced, and the EPS system was recalibrated using an Autel MaxiSYS MS906BT.

- Result: The steering returned to normal, and the warning light was cleared.

10.2 Case Study 2: Resolving Intermittent EPS Failure in a Ford F-150

A Ford F-150 experienced intermittent EPS failure. The diagnostic process included:

- Scanning for DTCs: Code U0131 indicated a loss of communication with the power steering control module.

- Electrical Checks: Wiring and connections were inspected for corrosion and damage.

- Component Testing: The power steering control module was tested and found to have intermittent connectivity issues.

- Repair: The wiring harness was repaired, and the connections were cleaned and secured.

- Result: The EPS system functioned correctly, and the intermittent failure was resolved.

10.3 Case Study 3: Addressing Uneven Steering Assistance in a Honda Civic

A Honda Civic had uneven steering assistance, with the steering feeling lighter in one direction than the other. The diagnostic process involved:

- Scanning for DTCs: No DTCs were present.

- Sensor Data Analysis: Steering angle sensor readings were inconsistent.

- Recalibration: The EPS system was recalibrated using a Launch X431 V+.

- Result: The steering assistance became even, and the handling improved.

11. How to Stay Updated with EPS Technology

Continuous learning is essential for staying current with advancements in EPS technology.

11.1 Training Resources

Attend training courses and workshops to learn about the latest EPS technologies and diagnostic techniques.

11.2 Industry Publications

Read industry magazines and technical publications to stay informed about new developments.

11.3 Online Forums and Communities

Participate in online forums and communities to share knowledge and learn from other technicians.

11.4 Vendor Training Programs

Take advantage of training programs offered by tool and equipment vendors like CARDIAGTECH.NET.

12. Conclusion: Mastering EPS for Automotive Excellence

Mastering the operating principle, diagnosis, and repair of Electric Power Steering (EPS) systems is essential for any automotive technician aiming for excellence. By understanding the components, diagnostic procedures, and preventative maintenance, you can ensure optimal vehicle performance and customer satisfaction. With the advanced diagnostic tools and resources available at CARDIAGTECH.NET, you can confidently tackle any EPS challenge.

Are you ready to elevate your diagnostic capabilities and provide top-notch service for EPS systems? Contact CARDIAGTECH.NET today at Whatsapp: +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET to explore our range of advanced diagnostic tools and equipment. Located at 276 Reock St, City of Orange, NJ 07050, United States, we are here to support your journey towards automotive excellence. Don’t let EPS challenges slow you down—partner with CARDIAGTECH.NET and drive your success forward!

Frequently Asked Questions (FAQ) About EPS

1. What is Electric Power Steering (EPS)?

Electric Power Steering (EPS) is a system that uses an electric motor to provide steering assistance to a vehicle, replacing traditional hydraulic systems. It improves fuel efficiency, offers variable steering assistance, and enhances vehicle safety.

2. How does EPS improve fuel efficiency?

EPS improves fuel efficiency by reducing the load on the engine. Unlike hydraulic systems that require a constantly running pump, EPS only uses power when steering assistance is needed.

3. What are the main components of an EPS system?

The main components include the torque sensor, electronic control unit (ECU), electric motor, steering angle sensor, and CAN bus connectivity.

4. What is the role of the torque sensor in EPS?

The torque sensor measures the steering force applied by the driver and signals the need for assistance to the ECU.

5. What are the common symptoms of EPS failure?

Common symptoms include stiff steering, EPS warning lights on the dashboard, uneven assistance, no assistance, and unusual noises during steering.

6. How do I diagnose EPS problems?

Diagnose EPS problems by performing a visual inspection, scanning for DTCs, analyzing sensor data, checking electrical connections, and testing individual components.

7. What tools are needed to repair EPS systems?

Essential tools include scan tools, multimeters, oscilloscopes, and specialized tools for component replacement.

8. Can I perform preventative maintenance on EPS systems?

Yes, preventative maintenance includes regular inspections, software updates, checking electrical connections, and monitoring sensor data.

9. How does EPS integrate with autonomous driving systems?

EPS provides precise and reliable steering control, which is crucial for autonomous vehicles to navigate and maintain stability.

10. Where can I find advanced diagnostic tools for EPS?

You can find advanced diagnostic tools at CARDIAGTECH.NET, including the Autel MaxiSYS MS906BT and Launch X431 V+, designed for comprehensive EPS diagnostics.