**New Genius 37 Pin Diagnostic Connector For MAN Trucks**

The New Genius 37 Pin Diagnostic Connector for MAN Trucks is an essential tool for automotive technicians, particularly those specializing in MAN commercial vehicles, and CARDIAGTECH.NET offers premium solutions. This connector, with advanced diagnostic capabilities, ensures efficient and precise vehicle maintenance. Invest in reliable diagnostic tools to enhance your repair services and stay ahead in the automotive industry.

1. Understanding the New Genius Diagnostic Tool

The New Genius diagnostic tool is a standalone ECU programmer designed to read and write data from a vehicle’s Engine Control Unit (ECU) without the need for a computer. It’s widely used in the automotive industry for chiptuning, performance enhancement, and diagnostics. The New Genius tool supports a broad range of vehicle makes and models through various connectors and cables. Its user-friendly interface and portable design make it a favorite among automotive technicians.

1.1. Key Features of the New Genius Tool

- Standalone Operation: No computer required for reading and writing ECU data.

- User-Friendly Interface: Intuitive navigation for easy operation.

- Broad Vehicle Support: Compatible with numerous vehicle makes and models.

- Portable Design: Lightweight and easy to carry for on-site diagnostics.

- Regular Updates: Software updates ensure compatibility with new vehicles.

- Data Logging: Ability to record and analyze vehicle performance data.

- ECU Cloning: Allows for ECU duplication for replacement purposes.

- Recovery Mode: Helps restore ECU to its original state after failed programming.

1.2. Benefits of Using the New Genius Tool

- Increased Efficiency: Faster ECU reading and writing compared to traditional methods.

- Improved Accuracy: Reduces the risk of errors during reprogramming.

- Enhanced Performance: Enables performance tuning for improved vehicle output.

- Cost Savings: Reduces the need for expensive dealership visits.

- Versatility: Supports a wide range of diagnostic and tuning tasks.

- Time Savings: Streamlines the diagnostic process, saving valuable time.

- Better Diagnostics: Provides in-depth analysis of vehicle systems.

- Customer Satisfaction: Enhances service quality and customer satisfaction.

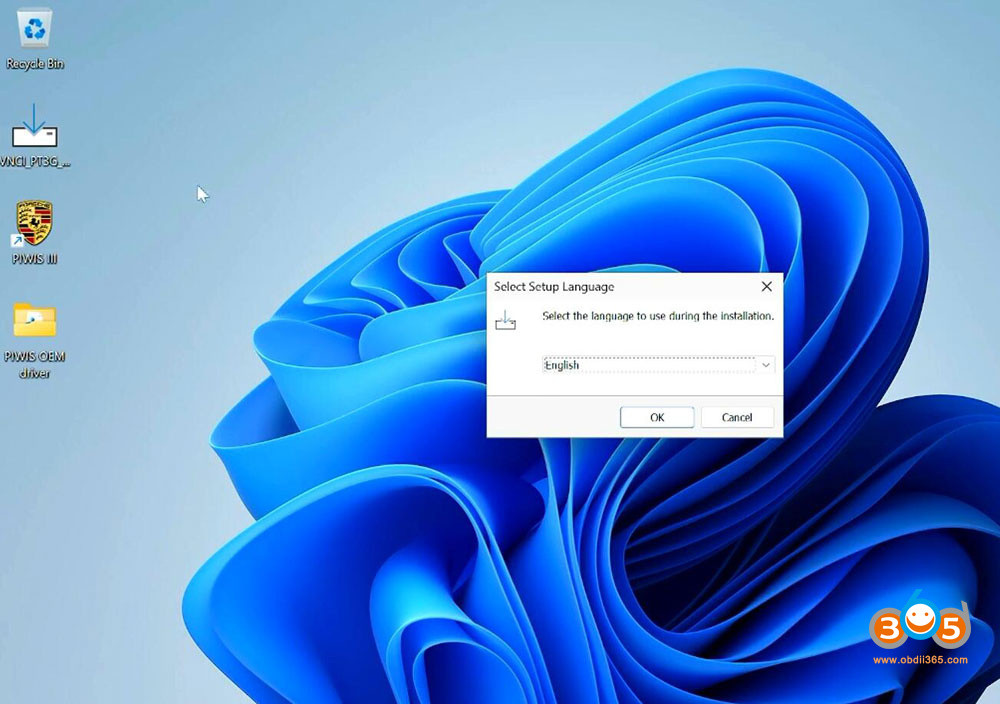

Alt: New Genius diagnostic tool interface displaying vehicle selection options for various truck models.

2. Importance of Diagnostic Connectors in Modern Trucks

Diagnostic connectors are essential components in modern trucks, serving as the interface between diagnostic tools and the vehicle’s electronic control systems. These connectors allow technicians to access critical data, diagnose issues, and perform necessary repairs. Without reliable diagnostic connectors, troubleshooting complex problems in modern trucks would be significantly more challenging.

2.1. Functions of Diagnostic Connectors

- Data Access: Provides access to real-time data from various vehicle systems.

- Fault Code Reading: Retrieves Diagnostic Trouble Codes (DTCs) to identify issues.

- System Testing: Allows technicians to perform component and system tests.

- Reprogramming: Enables ECU reprogramming and software updates.

- Parameter Adjustment: Allows adjustment of vehicle parameters for optimal performance.

- Module Configuration: Configures new or replacement modules to vehicle specifications.

- Communication Interface: Facilitates communication between diagnostic tools and vehicle ECUs.

- Data Logging: Records vehicle data for analysis and diagnostics.

2.2. Types of Diagnostic Connectors in Trucks

- OBD-II Connectors: Standardized connectors for basic diagnostics.

- J1939 Connectors: Used in heavy-duty vehicles for network communication.

- Proprietary Connectors: Manufacturer-specific connectors for advanced diagnostics.

- Deutsch Connectors: Rugged connectors used in harsh environments.

- Round Pin Connectors: Older style connectors found in some trucks.

- Pin-Out Specific Connectors: Connectors with specific pin configurations for certain systems.

- CAN Bus Connectors: For Controller Area Network communication.

- Ethernet Connectors: Used for high-speed data transfer and diagnostics.

3. The MAN Truck Diagnostic System

MAN trucks incorporate advanced diagnostic systems to monitor and manage various vehicle functions. These systems rely on a network of sensors, control units, and diagnostic connectors to ensure optimal performance and reliability. Understanding the specifics of the MAN truck diagnostic system is crucial for effective diagnostics and repairs.

3.1. Overview of MAN Truck Electronic Systems

- Engine Management System (EMS): Controls fuel injection, ignition, and emissions.

- Transmission Control System (TCS): Manages gear shifting and transmission functions.

- Brake System (EBS/ABS): Regulates braking force and prevents wheel lock-up.

- Suspension System (ECAS): Controls air suspension for ride comfort and stability.

- Body Control Module (BCM): Manages lighting, wipers, and other body functions.

- Instrument Cluster: Displays vehicle information such as speed, RPM, and fuel level.

- HVAC System: Controls heating, ventilation, and air conditioning.

- Telematics System: Provides vehicle tracking, diagnostics, and communication features.

3.2. Diagnostic Protocols Used in MAN Trucks

- CAN Bus (Controller Area Network): Primary communication protocol for vehicle systems.

- K-Line: Older diagnostic protocol used for some systems.

- SAE J1939: Communication protocol for heavy-duty vehicles.

- ISO 15765 (Diagnostic on CAN): Standard for diagnostic communication over CAN bus.

- UDS (Unified Diagnostic Services): Advanced diagnostic protocol for modern ECUs.

- OBD-II (On-Board Diagnostics II): Standardized diagnostic protocol for emissions-related issues.

- Keyword Protocol 2000 (KWP2000): Older protocol used in some MAN trucks.

- Local Interconnect Network (LIN): Communication protocol for low-speed devices.

4. Deep Dive into the New Genius 37 Pin Diagnostic Connector

The New Genius 37 Pin Diagnostic Connector is specifically designed for MAN trucks, providing a reliable and secure connection for diagnostic and programming tasks. This connector ensures compatibility with MAN truck’s diagnostic systems, allowing technicians to perform a wide range of functions with precision.

4.1. Pin Configuration and Functions

- Pin 1: Ground (GND): Provides a common ground reference for the connector.

- Pin 2: CAN High (CAN_H): Transmits high-level CAN bus signals.

- Pin 3: CAN Low (CAN_L): Transmits low-level CAN bus signals.

- Pin 4: K-Line (ISO 9141): Used for K-Line diagnostic communication.

- Pin 5: L-Line (ISO 9141): Used for L-Line diagnostic communication.

- Pin 6: Battery Voltage (VBAT): Provides power supply to the diagnostic tool.

- Pin 7: Ignition Sense: Detects when the ignition is switched on.

- Pin 8: J1939+: Transmits J1939 positive signals.

- Pin 9: J1939-: Transmits J1939 negative signals.

- Pin 10: Reserved: Typically not used, reserved for future functions.

- Pin 11: ECU Reset: Resets the ECU during programming.

- Pin 12: Programming Voltage: Provides voltage for ECU programming.

- Pins 13-37: Various control and data lines specific to MAN truck systems.

4.2. Compatibility with MAN Truck Models

The New Genius 37 Pin Diagnostic Connector is compatible with a wide range of MAN truck models, including:

| Model | Year Range | Engine Type | ECU Type |

|---|---|---|---|

| TGA | 2000-2007 | Diesel | EDC7, EDC16 |

| TGL | 2005-2013 | Diesel | EDC7, EDC17 |

| TGM | 2005-2013 | Diesel | EDC7, EDC17 |

| TGS | 2007-2020 | Diesel | EDC7, EDC17, MS6 |

| TGX | 2007-2020 | Diesel | EDC7, EDC17, MS6 |

| TGE | 2017-2024 | Diesel, Gasoline | EDC17, ME17 |

| Bus Chassis | 2000-2024 | Diesel, CNG | EDC7, EDC17, MS6 |

| Coach | 2000-2024 | Diesel | EDC7, EDC17, MS6 |

| Construction | 2000-2024 | Diesel | EDC7, EDC17, MS6 |

| Special Trucks | 2000-2024 | Diesel | EDC7, EDC17, MS6 |

4.3. Advantages of Using the 37 Pin Connector

- Secure Connection: Ensures a stable and reliable connection during diagnostics.

- Full System Access: Provides access to all MAN truck electronic systems.

- Fast Data Transfer: Enables rapid data transfer for efficient diagnostics.

- Durable Design: Built to withstand the rigors of automotive environments.

- Easy to Use: Simple plug-and-play design for quick connection.

- Reduced Downtime: Speeds up the diagnostic process, reducing vehicle downtime.

- Cost-Effective: Eliminates the need for multiple connectors for different systems.

- Improved Accuracy: Enhances diagnostic accuracy, reducing repair errors.

5. Step-by-Step Guide to Using the New Genius 37 Pin Connector

Using the New Genius 37 Pin Diagnostic Connector correctly is essential for accurate diagnostics and programming. Follow this step-by-step guide to ensure proper usage and avoid potential issues.

5.1. Preparing for the Diagnostic Process

- Gather Necessary Tools: Ensure you have the New Genius diagnostic tool, the 37 Pin Diagnostic Connector, and any required software or updates from CARDIAGTECH.NET.

- Vehicle Identification: Identify the specific MAN truck model and year to ensure compatibility.

- Safety Precautions: Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Battery Check: Ensure the vehicle’s battery is fully charged to prevent interruptions during the diagnostic process.

- Workspace Preparation: Work in a well-lit and clean environment to avoid accidents and ensure clear visibility.

- Software Updates: Verify that the New Genius tool has the latest software updates installed for optimal performance.

- Data Backup: Back up any existing ECU data before making changes to prevent data loss.

- Read Vehicle Manual: Consult the vehicle’s service manual for any specific diagnostic procedures or requirements.

5.2. Connecting the Connector to the MAN Truck

- Locate Diagnostic Port: Find the 37 Pin diagnostic port in the MAN truck, typically located in the cab or engine compartment.

- Inspect Connector: Check the connector and port for any signs of damage or corrosion.

- Align Connector: Align the 37 Pin Diagnostic Connector with the diagnostic port.

- Secure Connection: Firmly push the connector into the port until it clicks or locks into place.

- Verify Connection: Ensure the connection is secure and stable to prevent data interruptions.

- Power On Tool: Turn on the New Genius diagnostic tool and allow it to initialize.

- Check Communication: Verify that the tool is communicating with the vehicle’s ECU.

- Address Potential Issues: If the connection fails, recheck the connector and port for damage, and ensure proper alignment.

5.3. Performing Diagnostics and Programming

- Select Vehicle: Choose the correct MAN truck model from the New Genius tool’s menu.

- Read Fault Codes: Retrieve any stored Diagnostic Trouble Codes (DTCs) from the ECU.

- Interpret Codes: Use the tool’s database or a service manual to interpret the fault codes.

- Perform Tests: Conduct any necessary component or system tests to diagnose the issue.

- Clear Fault Codes: Clear the fault codes after the repair is completed.

- Reprogram ECU: If necessary, reprogram the ECU with updated software or parameters.

- Verify Operation: After programming, verify that the vehicle systems are functioning correctly.

- Document Results: Record all diagnostic and programming results for future reference.

6. Troubleshooting Common Issues

Even with proper usage, issues can arise when using the New Genius 37 Pin Diagnostic Connector. Here are some common problems and how to troubleshoot them.

6.1. Connection Problems

- Issue: The diagnostic tool fails to connect to the vehicle’s ECU.

- Possible Causes:

- Damaged or corroded connector pins.

- Incorrect connector alignment.

- Faulty wiring in the diagnostic port.

- Software incompatibility.

- Insufficient power supply.

- Troubleshooting Steps:

- Inspect connector pins for damage or corrosion and clean if necessary.

- Ensure the connector is properly aligned and securely connected.

- Check the wiring in the diagnostic port for continuity and shorts.

- Verify that the diagnostic tool has the latest software updates.

- Ensure the vehicle’s battery is fully charged.

6.2. Communication Errors

- Issue: The diagnostic tool displays communication errors during data transfer.

- Possible Causes:

- Interference from other electronic devices.

- Faulty CAN bus communication.

- ECU malfunction.

- Incorrect diagnostic protocol.

- Troubleshooting Steps:

- Move away from potential sources of electronic interference.

- Check the CAN bus wiring for continuity and shorts.

- Try resetting the ECU.

- Verify that the correct diagnostic protocol is selected in the tool’s settings.

6.3. Software Issues

- Issue: The diagnostic tool is not functioning correctly due to software problems.

- Possible Causes:

- Corrupted software installation.

- Outdated software version.

- Software incompatibility.

- Driver issues.

- Troubleshooting Steps:

- Reinstall the diagnostic tool’s software.

- Update the software to the latest version from CARDIAGTECH.NET.

- Ensure the software is compatible with the vehicle model and ECU type.

- Check for and update any necessary drivers.

7. Maintaining Your New Genius 37 Pin Connector

Proper maintenance is essential to prolong the life and reliability of your New Genius 37 Pin Diagnostic Connector. Follow these maintenance tips to keep your connector in top condition.

7.1. Cleaning and Storage

- Cleaning:

- Regularly clean the connector pins with a soft, dry cloth.

- Use contact cleaner to remove stubborn dirt or corrosion.

- Avoid using abrasive cleaners or solvents that could damage the connector.

- Storage:

- Store the connector in a clean, dry place away from extreme temperatures.

- Use a protective case or cover to prevent damage.

- Avoid storing the connector in direct sunlight or near corrosive materials.

7.2. Regular Inspections

- Pin Inspection:

- Inspect the connector pins regularly for damage, bending, or corrosion.

- Replace the connector if any pins are severely damaged.

- Cable Inspection:

- Check the cable for cuts, fraying, or exposed wires.

- Replace the cable if it is damaged to prevent short circuits.

- Functionality Test:

- Periodically test the connector with a known good vehicle to ensure it is functioning correctly.

- Address any issues promptly to prevent further damage.

7.3. Preventing Damage

- Proper Handling:

- Handle the connector with care to avoid bending or breaking the pins.

- Avoid dropping the connector or exposing it to excessive force.

- Correct Usage:

- Use the connector only with compatible vehicles and diagnostic tools.

- Follow the manufacturer’s instructions for proper usage.

- Environmental Protection:

- Protect the connector from moisture, dust, and extreme temperatures.

- Avoid using the connector in wet or hazardous environments.

8. Benefits of Purchasing from CARDIAGTECH.NET

When it comes to diagnostic tools and connectors, purchasing from a reputable supplier like CARDIAGTECH.NET offers numerous benefits.

8.1. Quality and Reliability

- High-Quality Products: CARDIAGTECH.NET offers only high-quality, reliable diagnostic tools and connectors.

- Tested Products: All products are rigorously tested to ensure they meet industry standards.

- Warranty: Products come with a warranty to protect against defects and malfunctions.

- Genuine Components: CARDIAGTECH.NET uses genuine components to ensure optimal performance.

8.2. Expert Support and Guidance

- Technical Support: Access to expert technical support for troubleshooting and assistance.

- Product Training: Training resources to help you get the most out of your diagnostic tools.

- Knowledge Base: A comprehensive knowledge base with articles, FAQs, and tutorials.

- Customer Service: Dedicated customer service team to address any questions or concerns.

8.3. Competitive Pricing and Value

- Competitive Prices: CARDIAGTECH.NET offers competitive prices on all diagnostic tools and connectors.

- Value for Money: High-quality products and expert support provide excellent value for your investment.

- Discounts and Promotions: Regular discounts and promotions to save you money.

- Financing Options: Flexible financing options to make purchasing easier.

9. Future Trends in Truck Diagnostics

The field of truck diagnostics is constantly evolving, with new technologies and trends emerging regularly. Staying up-to-date with these trends is crucial for automotive technicians and shop owners.

9.1. Remote Diagnostics

- Overview: Remote diagnostics allows technicians to diagnose and repair vehicles remotely using telematics and cloud-based software.

- Benefits:

- Reduced downtime.

- Faster diagnostics.

- Cost savings.

- Improved customer service.

- Applications:

- Fleet management.

- On-site repairs.

- Preventive maintenance.

9.2. Artificial Intelligence (AI) in Diagnostics

- Overview: AI is being used to analyze diagnostic data and provide technicians with insights and recommendations.

- Benefits:

- Improved diagnostic accuracy.

- Faster troubleshooting.

- Reduced repair costs.

- Enhanced efficiency.

- Applications:

- Fault code analysis.

- Predictive maintenance.

- Automated diagnostics.

9.3. Wireless Diagnostics

- Overview: Wireless diagnostic tools allow technicians to connect to vehicles wirelessly using Bluetooth or Wi-Fi.

- Benefits:

- Increased mobility.

- Improved flexibility.

- Enhanced convenience.

- Applications:

- On-site repairs.

- Roadside assistance.

- Vehicle inspections.

10. Frequently Asked Questions (FAQs)

1. What is the New Genius 37 Pin Diagnostic Connector?

The New Genius 37 Pin Diagnostic Connector is a specialized connector designed for MAN trucks, used with diagnostic tools to read and write data from the vehicle’s electronic control units (ECUs).

2. Which MAN truck models are compatible with this connector?

The connector is compatible with various MAN truck models, including TGA, TGL, TGM, TGS, TGX, and TGE, as well as bus chassis, coaches, construction trucks, and special trucks manufactured between 2000 and 2024.

3. What diagnostic protocols does the New Genius 37 Pin Connector support?

It supports CAN Bus, K-Line, SAE J1939, ISO 15765, UDS, OBD-II, KWP2000, and LIN protocols.

4. Where can I find the 37 Pin diagnostic port in a MAN truck?

The diagnostic port is typically located in the cab or engine compartment of the truck.

5. What are the common issues encountered when using the connector?

Common issues include connection problems, communication errors, and software issues. Troubleshooting steps involve inspecting the connector, checking wiring, and updating software.

6. How should I maintain the New Genius 37 Pin Connector?

Maintain the connector by regularly cleaning it with a soft cloth, storing it in a dry place, and inspecting it for damage or corrosion.

7. What are the benefits of purchasing from CARDIAGTECH.NET?

Purchasing from CARDIAGTECH.NET ensures quality, reliability, expert support, competitive pricing, and access to the latest diagnostic tools and software.

8. Can the New Genius tool be used for ECU cloning?

Yes, the New Genius tool allows for ECU duplication for replacement purposes.

9. Does the New Genius tool require a computer for operation?

No, the New Genius tool is a standalone device and does not require a computer for reading and writing ECU data.

10. What future trends are expected in truck diagnostics?

Future trends include remote diagnostics, the use of artificial intelligence (AI) in diagnostics, and wireless diagnostic tools.

In conclusion, the New Genius 37 Pin Diagnostic Connector is an indispensable tool for servicing MAN trucks, and CARDIAGTECH.NET is your trusted source for high-quality diagnostic solutions. By understanding the features, functions, and maintenance of this connector, you can ensure efficient and accurate vehicle diagnostics. Stay ahead in the automotive industry by investing in reliable diagnostic tools and staying informed about emerging trends.

Ready to enhance your diagnostic capabilities? Contact CARDIAGTECH.NET today at Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880 or visit our website: CARDIAGTECH.NET for expert advice and premium diagnostic tools that meet your specific needs. Don’t let challenging repairs slow you down – let CARDIAGTECH.NET help you achieve peak performance.