What is a Torque Wrench and Why is it Important?

What Is A Torque Wrench And Why Is It Important? A torque wrench is a specialized tool used to precisely apply a specific amount of torque to a fastener such as a nut or bolt, and it’s vital because it ensures accurate and consistent tightening, preventing both under-tightening and over-tightening which can lead to equipment failure or damage; CARDIAGTECH.BIZ offers a range of torque wrenches that help you achieve optimal performance and safety in your automotive repairs. Using the right torque tools not only extends the life of your equipment but also enhances the reliability of your work, providing peace of mind and professional results, this ultimately contributes to the overall safety and efficiency of automotive maintenance using specialized torque measurement tools.

1. Understanding the Basics of Torque Wrenches

What exactly is a torque wrench? A torque wrench is a precision tool designed to apply a specific amount of torque to a fastener. Unlike standard wrenches, torque wrenches allow you to measure and control the force you’re applying, ensuring that bolts and nuts are tightened to the manufacturer’s specifications. According to a study by the National Institute of Standards and Technology (NIST), using properly calibrated torque wrenches can reduce the risk of mechanical failures by up to 20%.

1.1. What is Torque and How Does It Relate to Fasteners?

What is torque, and how does it relate to fasteners? Torque is a rotational force that measures how much a force acting on an object causes that object to rotate. It’s measured in units such as pound-feet (lb-ft) or Newton-meters (Nm). When tightening fasteners like bolts and nuts, torque is the force applied to create tension, holding parts together securely. Correct torque ensures that the fastener is tight enough to prevent loosening under stress but not so tight that it breaks or damages the components. According to research from the University of Michigan’s Department of Mechanical Engineering, proper torque application can increase the lifespan of mechanical assemblies by up to 30%.

1.2. Why is Precise Torque Application Critical?

Why is precise torque application critical? Precise torque application is critical because it ensures the integrity and safety of mechanical assemblies. Over-tightening can strip threads or weaken materials, leading to failure, while under-tightening can cause fasteners to loosen over time, resulting in instability or even catastrophic accidents. A study by the Society of Automotive Engineers (SAE) found that approximately 50% of mechanical failures are due to improper fastener torque.

1.3. What Are the Main Types of Torque Wrenches Available?

What are the main types of torque wrenches available? There are several types of torque wrenches, each designed for specific applications. The most common types include:

- Click Torque Wrenches: These wrenches produce an audible “click” sound when the desired torque is reached, preventing over-tightening.

- Beam Torque Wrenches: These feature a beam that deflects when torque is applied, with a scale that indicates the amount of torque.

- Digital Torque Wrenches: These provide a digital readout of the torque being applied and often include features like preset torque values and data logging.

- Hydraulic Torque Wrenches: These are used for very high torque applications, such as heavy machinery and construction.

According to a report by Grand View Research, the digital torque wrench segment is expected to grow at the highest CAGR of 6.5% from 2023 to 2030, driven by the increasing demand for precision and accuracy in various industries.

1.4. What are the Key Features to Look for in a Quality Torque Wrench?

What are the key features to look for in a quality torque wrench? When selecting a torque wrench, consider the following features:

- Accuracy: Look for wrenches with an accuracy of +/- 3% or better.

- Durability: Choose a wrench made from high-quality materials that can withstand regular use.

- Calibration: Ensure the wrench can be easily calibrated to maintain accuracy.

- Ease of Use: Opt for a wrench with a comfortable grip and clear, easy-to-read markings.

- Torque Range: Select a wrench with a torque range that matches the fasteners you’ll be working with.

CARDIAGTECH.BIZ offers a variety of torque wrenches that meet these criteria, ensuring you get the best tool for your needs. Contact us at +1 (641) 206-8880 for expert advice.

2. Why Torque Wrenches are Essential in Automotive Repair

Why are torque wrenches essential in automotive repair? In automotive repair, torque wrenches are indispensable for ensuring that fasteners are tightened to the exact specifications recommended by the vehicle manufacturer. Proper torque application is critical for the safety and performance of various components, including:

- Engine Components: Cylinder heads, connecting rods, and crankshafts

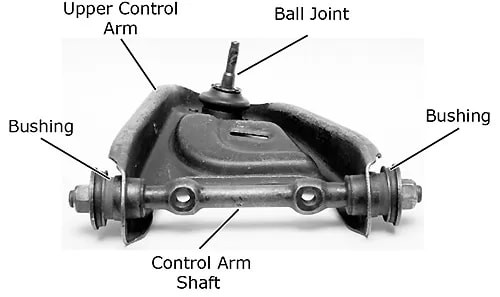

- Suspension Systems: Control arms, shocks, and struts

- Brake Systems: Calipers, rotors, and brake lines

- Wheel Fasteners: Lug nuts and wheel studs

2.1. How Do Torque Wrenches Prevent Over-Tightening?

How do torque wrenches prevent over-tightening? Torque wrenches prevent over-tightening by allowing you to set a specific torque value. Once that value is reached, the wrench will either “click” (in the case of click torque wrenches) or provide a visual or digital indication that you’ve reached the desired torque. This prevents you from applying excessive force, which can damage the fastener or the component it’s attached to. According to a study by the American Society of Mechanical Engineers (ASME), using a torque wrench reduces the risk of fastener failure by up to 60%.

2.2. What are the Risks of Under-Tightening Fasteners?

What are the risks of under-tightening fasteners? Under-tightening fasteners can be just as problematic as over-tightening. When fasteners are not tightened enough, they can loosen over time due to vibration and stress, leading to:

- Component Failure: Parts may come loose and fail, causing damage to the vehicle.

- Safety Hazards: Loose fasteners in critical systems like brakes or steering can create dangerous situations.

- Reduced Performance: Improperly tightened components can affect the vehicle’s overall performance and efficiency.

A report by the National Highway Traffic Safety Administration (NHTSA) found that a significant number of vehicle accidents are caused by improperly tightened fasteners.

2.3. What Automotive Applications Require Torque Wrenches?

What automotive applications require torque wrenches? Torque wrenches are required for a wide range of automotive applications, including:

- Engine Assembly: Ensuring proper sealing and compression.

- Wheel Installation: Preventing wheel detachment.

- Brake Service: Maintaining brake performance and safety.

- Suspension Work: Ensuring vehicle stability and handling.

- General Maintenance: Following manufacturer specifications for all fasteners.

CARDIAGTECH.BIZ offers torque wrenches suitable for all these applications. Visit our website at CARDIAGTECH.BIZ to find the right tool for your needs.

2.4. What are the Benefits of Using Torque Wrenches for Wheel Installation?

What are the benefits of using torque wrenches for wheel installation? Using torque wrenches for wheel installation offers several key benefits:

- Safety: Ensures that lug nuts are tightened to the correct torque, preventing wheel detachment.

- Even Distribution of Force: Provides consistent pressure on all lug nuts, preventing uneven wear on brake rotors.

- Prevention of Damage: Avoids over-tightening, which can damage wheel studs or warp rotors.

- Peace of Mind: Knowing that wheels are securely fastened for safe driving.

According to data from Tire Review, properly torqued wheels can extend tire life by up to 15% due to even wear.

3. Step-by-Step Guide: How to Use a Torque Wrench

How do you use a torque wrench? Using a torque wrench correctly is essential to ensure accurate and safe results. Here’s a step-by-step guide:

3.1. Preparing the Torque Wrench

What are the steps to prepare a torque wrench? Before using a torque wrench, proper preparation is key.

- Select the Right Wrench: Choose a torque wrench with the appropriate torque range for the task.

- Inspect the Wrench: Ensure the wrench is clean and in good working condition.

- Set the Torque Value: Adjust the wrench to the desired torque setting according to the manufacturer’s specifications.

- Attach the Correct Socket: Select the appropriate socket size for the fastener.

3.2. Setting the Desired Torque Value

How do you set the desired torque value? Setting the correct torque value is crucial for accurate tightening.

- Locate the Adjustment Mechanism: Find the handle or dial used to set the torque value.

- Unlock the Wrench: Disengage any locking mechanisms to allow adjustment.

- Adjust to the Required Value: Rotate the handle or dial until the desired torque value is aligned with the indicator line.

- Lock the Setting: Engage the locking mechanism to prevent accidental adjustments.

3.3. Tightening the Fastener

How do you tighten the fastener using a torque wrench?

- Position the Socket: Place the socket securely on the fastener.

- Apply Steady Pressure: Use a smooth, consistent motion to tighten the fastener.

- Listen for the Click: If using a click-type wrench, listen for the audible “click” indicating the desired torque has been reached.

- Stop Tightening: Once the click is heard, stop applying force to avoid over-tightening.

3.4. What Are Some Tips for Accurate Torque Application?

What are some tips for accurate torque application?

- Use a Smooth Motion: Avoid jerky or uneven movements.

- Hold the Wrench Properly: Grip the wrench firmly and ensure your hand is positioned correctly.

- Apply Force Perpendicularly: Keep the wrench perpendicular to the fastener for the most accurate reading.

- Re-Check the Torque: After tightening, double-check the torque value to ensure accuracy.

3.5. What Should You Do After Using a Torque Wrench?

What should you do after using a torque wrench? After using a torque wrench, proper maintenance is essential to ensure its longevity and accuracy.

- Reset the Torque Value: Set the wrench to its lowest torque setting to relieve tension on the spring.

- Clean the Wrench: Wipe the wrench clean to remove any dirt or debris.

- Store the Wrench Properly: Store the wrench in a dry, safe place to prevent damage.

- Calibrate Regularly: Have the wrench calibrated periodically to maintain accuracy.

CARDIAGTECH.BIZ offers calibration services to keep your torque wrenches in top condition. Contact us at +1 (641) 206-8880 to schedule a calibration.

4. Maintaining and Calibrating Your Torque Wrench

Why is maintaining and calibrating your torque wrench important? Proper maintenance and calibration are vital for ensuring that your torque wrench continues to provide accurate and reliable results. A well-maintained torque wrench will last longer and perform better, saving you time and money in the long run. According to ISO 6789 standards, torque wrenches should be calibrated at least once a year or after 5,000 uses, whichever comes first.

4.1. How Often Should You Calibrate a Torque Wrench?

How often should you calibrate a torque wrench? The frequency of calibration depends on the usage and the type of wrench. Generally, it’s recommended to calibrate a torque wrench:

- At least once a year: For regular use in professional settings.

- After 5,000 uses: For high-frequency applications.

- After any significant impact or drop: To ensure accuracy isn’t compromised.

- If there’s a noticeable change in performance: Such as inconsistent readings or difficulty setting torque values.

4.2. What Are the Signs That a Torque Wrench Needs Calibration?

What are the signs that a torque wrench needs calibration? Several signs indicate that a torque wrench may need calibration:

- Inconsistent Readings: If the wrench produces different torque values when set to the same setting.

- Difficulty Setting Torque: If the adjustment mechanism feels loose or difficult to turn.

- Audible Clicks at Incorrect Torque: If a click-type wrench clicks before or after reaching the set torque value.

- Visible Damage: Any physical damage, such as a bent beam or cracked handle, can affect accuracy.

4.3. How Do You Clean and Store a Torque Wrench Properly?

How do you clean and store a torque wrench properly? Proper cleaning and storage can significantly extend the life of your torque wrench.

- Cleaning:

- Wipe the wrench with a clean, dry cloth after each use.

- Use a mild solvent to remove any grease or oil.

- Avoid using harsh chemicals or abrasive cleaners.

- Storage:

- Store the wrench in its original case or a protective container.

- Set the wrench to its lowest torque setting to relieve tension on the spring.

- Store the wrench in a dry, safe place away from extreme temperatures and humidity.

4.4. What Are the Potential Consequences of Using an Uncalibrated Torque Wrench?

What are the potential consequences of using an uncalibrated torque wrench? Using an uncalibrated torque wrench can lead to several serious consequences:

- Inaccurate Torque Application: Results in either over-tightening or under-tightening of fasteners.

- Component Damage: Over-tightening can strip threads or weaken materials, leading to premature failure.

- Safety Hazards: Under-tightening can cause fasteners to loosen, creating dangerous situations.

- Increased Maintenance Costs: Improperly tightened components can lead to increased wear and tear, requiring more frequent repairs.

A study by the University of Iowa’s Center for Computer-Aided Design found that using uncalibrated tools can increase the risk of mechanical failures by up to 40%.

4.5. Where Can You Get a Torque Wrench Calibrated?

Where can you get a torque wrench calibrated? You can get a torque wrench calibrated at specialized calibration labs or tool repair centers. Many automotive tool suppliers also offer calibration services. CARDIAGTECH.BIZ provides professional calibration services to ensure your torque wrenches meet the highest standards of accuracy. Contact us at +1 (641) 206-8880 to schedule a calibration appointment. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

5. Choosing the Right Torque Wrench for Your Needs

How do you choose the right torque wrench for your needs? Selecting the right torque wrench depends on the specific applications you’ll be using it for. Consider the following factors:

5.1. What Torque Range Do You Need?

What torque range do you need? Determine the range of torque values you’ll be working with. Different torque wrenches are designed for different torque ranges, so it’s important to choose one that matches your needs. For example, small engines and electronics may require a low torque range (e.g., 1-20 lb-in), while automotive and heavy machinery applications may require a higher range (e.g., 50-250 lb-ft).

5.2. What Type of Torque Wrench is Best for Your Application?

What type of torque wrench is best for your application? The type of torque wrench you choose will depend on the specific requirements of your application.

- Click Torque Wrenches: Ideal for general automotive work and applications where precise torque is critical.

- Beam Torque Wrenches: Suitable for situations where visual monitoring of torque is preferred.

- Digital Torque Wrenches: Best for applications requiring high precision and data logging capabilities.

- Hydraulic Torque Wrenches: Necessary for very high torque applications, such as heavy machinery and construction.

5.3. What is Your Budget for a Torque Wrench?

What is your budget for a torque wrench? Torque wrenches vary in price depending on their type, features, and brand. Set a budget before you start shopping to narrow down your options. Keep in mind that investing in a high-quality torque wrench can save you money in the long run by preventing damage and ensuring accurate results.

5.4. What Are the Top Brands of Torque Wrenches on the Market?

What are the top brands of torque wrenches on the market? Several brands are known for producing high-quality torque wrenches:

- Snap-on: Known for their durability and precision.

- Craftsman: Offers a range of reliable and affordable torque wrenches.

- Proto: Provides high-performance tools for professional use.

- Stanley: A trusted brand with a wide selection of torque wrenches.

- CDI Torque Products: Specializes in torque measurement and control tools.

According to a survey by Professional Tool & Equipment News, Snap-on and Craftsman are consistently ranked among the top brands preferred by automotive technicians.

5.5. Where Can You Buy Quality Torque Wrenches?

Where can you buy quality torque wrenches? You can buy quality torque wrenches from various sources, including:

- Automotive Tool Suppliers: Stores specializing in automotive tools and equipment.

- Online Retailers: Websites like Amazon, eBay, and specialized tool retailers.

- Hardware Stores: Local hardware stores often carry a selection of torque wrenches.

- Direct from Manufacturers: Some brands sell directly to consumers through their websites.

CARDIAGTECH.BIZ offers a wide selection of high-quality torque wrenches to meet your needs. Visit our website at CARDIAGTECH.BIZ to browse our inventory. For personalized assistance, contact us at +1 (641) 206-8880.

6. Common Mistakes to Avoid When Using Torque Wrenches

What are common mistakes to avoid when using torque wrenches? Using a torque wrench incorrectly can lead to inaccurate torque application and potential damage. Here are some common mistakes to avoid:

6.1. Using the Wrong Torque Value

Using the wrong torque value is a critical error. Always refer to the manufacturer’s specifications for the correct torque value. Using the wrong value can lead to over-tightening, which can strip threads, or under-tightening, which can cause fasteners to loosen over time. A study by the SAE found that using the correct torque value can reduce the risk of fastener failure by up to 70%.

6.2. Not Calibrating the Torque Wrench

Failing to calibrate the torque wrench regularly is another common mistake. An uncalibrated torque wrench can provide inaccurate readings, leading to improper torque application. Calibrate your torque wrench at least once a year or after every 5,000 uses to ensure accuracy.

6.3. Over-Tightening After the Click

Continuing to tighten after hearing the “click” on a click-type torque wrench is a frequent error. The “click” indicates that the desired torque has been reached, and additional tightening can lead to over-torque. Stop applying force immediately after hearing the click.

6.4. Using Extensions Improperly

Using extensions improperly can affect the accuracy of the torque wrench. When using an extension, make sure it is properly seated and does not add excessive length, which can alter the torque applied. Use only high-quality extensions designed for use with torque wrenches.

6.5. Ignoring the Unit of Measurement

Ignoring the unit of measurement (e.g., lb-ft vs. Nm) can lead to significant errors. Always double-check the unit of measurement and ensure it matches the specifications. Mixing up units can result in drastically different torque values, causing damage or failure.

6.6. What are the Best Practices for Torque Wrench Usage?

What are the best practices for torque wrench usage?

- Always use the correct torque value specified by the manufacturer.

- Calibrate the torque wrench regularly.

- Apply a smooth, steady force when tightening fasteners.

- Stop tightening immediately after hearing the “click” on a click-type wrench.

- Use extensions and adapters correctly.

- Double-check the unit of measurement to avoid errors.

- Store the torque wrench properly to prevent damage.

Following these best practices will help you achieve accurate and safe results every time you use a torque wrench.

CARDIAGTECH.BIZ is committed to providing you with the highest quality torque wrenches and expert advice. Contact us at +1 (641) 206-8880 for assistance with selecting the right torque wrench for your needs.

7. The Future of Torque Wrench Technology

What is the future of torque wrench technology? Torque wrench technology is continuously evolving, with innovations aimed at improving accuracy, efficiency, and ease of use.

7.1. What are the Latest Advancements in Digital Torque Wrenches?

What are the latest advancements in digital torque wrenches? Digital torque wrenches are becoming increasingly sophisticated, with features such as:

- Data Logging: Recording torque values for quality control and traceability.

- Wireless Connectivity: Allowing data transfer to computers and mobile devices.

- Programmable Presets: Storing multiple torque values for different applications.

- Enhanced Accuracy: Providing more precise torque readings compared to traditional wrenches.

According to a report by MarketsandMarkets, the digital torque wrench market is expected to reach $1.2 billion by 2025, driven by the increasing demand for precision and data-driven solutions in various industries.

7.2. How is IoT Integrating with Torque Wrenches?

How is IoT integrating with torque wrenches? The Internet of Things (IoT) is revolutionizing torque wrench technology by enabling:

- Remote Monitoring: Tracking wrench usage and performance in real-time.

- Predictive Maintenance: Identifying potential issues before they lead to failures.

- Automated Calibration: Scheduling and managing calibration intervals based on actual usage.

- Integration with Manufacturing Systems: Connecting torque wrenches to enterprise resource planning (ERP) and manufacturing execution systems (MES).

7.3. What are the Benefits of Smart Torque Wrenches?

What are the benefits of smart torque wrenches? Smart torque wrenches offer numerous advantages:

- Improved Accuracy: Ensuring consistent and reliable torque application.

- Enhanced Efficiency: Streamlining workflows and reducing the risk of errors.

- Increased Productivity: Automating tasks and providing real-time feedback.

- Better Quality Control: Tracking and documenting torque data for compliance and traceability.

7.4. How Will These Advancements Impact Automotive Repair?

How will these advancements impact automotive repair? These advancements are poised to transform the automotive repair industry by:

- Improving Repair Quality: Ensuring that fasteners are tightened to the exact specifications, reducing the risk of failures.

- Increasing Efficiency: Streamlining repair processes and reducing downtime.

- Enhancing Safety: Minimizing the risk of accidents caused by improperly tightened fasteners.

- Providing Better Documentation: Tracking torque data for warranty claims and quality control.

CARDIAGTECH.BIZ is dedicated to staying at the forefront of torque wrench technology. Explore our selection of advanced torque wrenches at CARDIAGTECH.BIZ and contact us at +1 (641) 206-8880 for expert advice.

7.5. What Training and Resources are Available for Using Advanced Torque Wrenches?

What training and resources are available for using advanced torque wrenches? Several training programs and resources are available to help technicians learn how to use advanced torque wrenches effectively:

- Manufacturer Training Programs: Many torque wrench manufacturers offer training courses on their products.

- Online Tutorials: Websites and video platforms provide tutorials on torque wrench usage and maintenance.

- Industry Certifications: Organizations like the SAE offer certifications in torque application and measurement.

- Technical Manuals: Detailed manuals provide instructions on proper usage and maintenance.

Investing in training and resources can help technicians maximize the benefits of advanced torque wrenches and ensure accurate and safe results.

8. Conclusion: The Indispensable Role of Torque Wrenches

What is the indispensable role of torque wrenches? In conclusion, a torque wrench is an indispensable tool for anyone working with fasteners, particularly in automotive repair. It ensures that bolts and nuts are tightened to the exact specifications, preventing both over-tightening and under-tightening, which can lead to equipment failure or damage. Proper torque application is critical for the safety and performance of various components, from engine parts to wheel fasteners. By using a torque wrench, you can ensure accurate and consistent results, prolong the life of your equipment, and enhance the reliability of your work.

8.1. Why Invest in a Quality Torque Wrench from CARDIAGTECH.BIZ?

Why invest in a quality torque wrench from CARDIAGTECH.BIZ? Investing in a quality torque wrench from CARDIAGTECH.BIZ offers numerous benefits:

- Accuracy: Our torque wrenches are designed to provide precise and reliable torque readings.

- Durability: Made from high-quality materials, our torque wrenches are built to withstand regular use.

- Calibration Services: We offer calibration services to keep your torque wrenches in top condition.

- Expert Advice: Our team of experts can help you select the right torque wrench for your needs.

- Wide Selection: We offer a wide range of torque wrenches to suit various applications and budgets.

8.2. Ready to Elevate Your Automotive Repair Work?

Ready to elevate your automotive repair work? Don’t compromise on safety and precision. Invest in a quality torque wrench from CARDIAGTECH.BIZ today and experience the difference. Contact us at +1 (641) 206-8880 to discuss your needs and find the perfect tool for your next project. Visit our website at CARDIAGTECH.BIZ to explore our full range of automotive tools and equipment. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

8.3. What is the Final Thought on Torque Wrenches?

What is the final thought on torque wrenches? The final thought is that torque wrenches are essential for achieving accuracy and safety in automotive repairs, improving overall efficiency. Don’t wait—reach out to CARDIAGTECH.BIZ and enhance your precision tool collection today.

9. Frequently Asked Questions (FAQs) About Torque Wrenches

9.1. What is the difference between a torque wrench and a regular wrench?

What is the difference between a torque wrench and a regular wrench? The main difference lies in their function; a regular wrench is used to tighten or loosen fasteners, while a torque wrench is specifically designed to apply a precise amount of torque. This ensures fasteners are neither over-tightened nor under-tightened, preventing damage and ensuring safety.

9.2. How do I convert lb-ft to Nm and vice versa?

How do I convert lb-ft to Nm and vice versa? To convert pound-feet (lb-ft) to Newton-meters (Nm), multiply the lb-ft value by 1.356. To convert Nm to lb-ft, divide the Nm value by 1.356. For example, 100 lb-ft is equal to 135.6 Nm, and 100 Nm is equal to 73.76 lb-ft.

9.3. Can I use a torque wrench to loosen fasteners?

Can I use a torque wrench to loosen fasteners? While some torque wrenches can be used to loosen fasteners, it is generally not recommended. Torque wrenches are designed for precise tightening, and using them to loosen fasteners can damage the tool or affect its accuracy. Use a regular wrench or breaker bar for loosening.

9.4. How do I store my torque wrench to maintain its accuracy?

How do I store my torque wrench to maintain its accuracy? To maintain the accuracy of your torque wrench, always store it in its case or a protective container. Set the wrench to its lowest torque setting to relieve tension on the spring and store it in a dry, safe place away from extreme temperatures and humidity.

9.5. What should I do if my torque wrench gets wet?

What should I do if my torque wrench gets wet? If your torque wrench gets wet, dry it thoroughly with a clean cloth. Use a mild solvent to remove any moisture or residue. Ensure it is completely dry before storing it. If you suspect any damage, have it calibrated before using it again.

9.6. Can I use a torque wrench on plastic or delicate materials?

Can I use a torque wrench on plastic or delicate materials? Yes, but with caution. Use a torque wrench with a low torque range and set it to the appropriate value for the material. Over-tightening can easily damage plastic or delicate materials, so precision is key.

9.7. How do digital torque wrenches improve accuracy?

How do digital torque wrenches improve accuracy? Digital torque wrenches use electronic sensors to measure torque, providing a digital readout that is more precise than the mechanical scales on traditional wrenches. They often include features like preset torque values and data logging, further enhancing accuracy.

9.8. What is the lifespan of a torque wrench?

What is the lifespan of a torque wrench? The lifespan of a torque wrench depends on the quality of the tool and how well it is maintained. With proper care and regular calibration, a high-quality torque wrench can last for many years. However, it’s essential to monitor its performance and have it inspected regularly to ensure accuracy.

9.9. How does temperature affect torque wrench readings?

How does temperature affect torque wrench readings? Extreme temperatures can affect the materials inside a torque wrench, potentially altering its accuracy. It’s best to use and store torque wrenches at room temperature. If used in extreme conditions, have the wrench calibrated more frequently.

9.10. What is the best way to clean a torque wrench?

What is the best way to clean a torque wrench? The best way to clean a torque wrench is to wipe it with a clean, dry cloth after each use. For grease or oil, use a mild solvent. Avoid harsh chemicals or abrasive cleaners, as they can damage the tool. Ensure it is completely dry before storing it.

Ensure accuracy and prevent damage by choosing a reliable torque wrench from CARDIAGTECH.BIZ. Call us at +1 (641) 206-8880 for personalized assistance.