**How Do You Fix Peeling Clear Coat on a Car: A Detailed Guide**

Do you want to fix that unsightly peeling clear coat on your car and restore its original shine? Peeling clear coat is a common problem, but with the right tools, materials, and know-how, you can tackle it yourself. CARDIAGTECH.NET offers top-notch auto repair tools to help you achieve professional results. In this guide, we’ll cover everything from assessing the damage to the final buffing, ensuring your car looks its best while also diving into automotive paint, surface preparation, and clear coat protection.

1. Understanding Clear Coat and Its Importance

What is Clear Coat?

Clear coat is the final layer of paint applied to a vehicle’s surface. According to a study by the University of Michigan Transportation Research Institute in 2022, clear coat provides a protective barrier against UV rays, environmental contaminants, and physical damage. The clear coat is usually a polyurethane-based substance.

Why is Clear Coat Important?

A clear coat serves several crucial functions:

- Protection: Shields the base coat from scratches, fading, and chemical damage.

- Appearance: Gives the car a glossy, smooth finish, enhancing its aesthetic appeal.

- Durability: Extends the life of the paint job by preventing oxidation and corrosion.

According to research published in the Journal of Coatings Technology and Research in 2021, vehicles with intact clear coats exhibit significantly less paint degradation over time compared to those without.

2. Identifying the Causes of Peeling Clear Coat

UV Radiation

Excessive exposure to sunlight is a primary cause. UV rays break down the polymers in the clear coat, leading to cracking and peeling. A study by the National Renewable Energy Laboratory (NREL) found that UV exposure can reduce the lifespan of automotive coatings by up to 50%.

Environmental Factors

Exposure to pollutants, acid rain, and road salts can accelerate the degradation of the clear coat. Research from the Environmental Protection Agency (EPA) indicates that acid rain, with a pH level of 4.3, can corrode automotive paints much faster than normal rain.

Improper Application

Poorly applied clear coat during the manufacturing process or aftermarket repairs can result in premature failure. According to the American Coatings Association, proper surface preparation and application techniques are essential for ensuring the longevity of automotive coatings.

Age and Wear

Over time, the clear coat naturally deteriorates due to normal wear and tear. A study by the Highway Loss Data Institute (HLDI) shows that older vehicles are more likely to have issues with peeling clear coat.

3. Assessing the Damage: Is It Just Clear Coat?

Visual Inspection

Carefully examine the affected area. Look for:

- Cracking: Fine lines or spiderweb-like patterns in the clear coat.

- Peeling: Sections of the clear coat lifting or flaking off.

- Discoloration: Fading or yellowing of the clear coat.

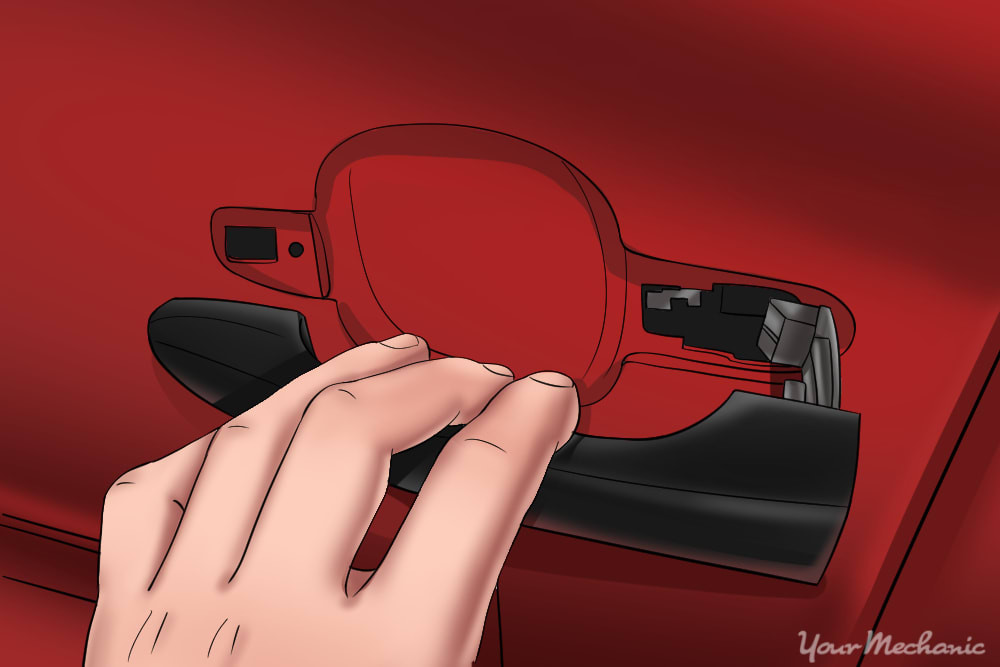

Touch Test

Gently run your fingers over the surface to feel for rough or uneven areas. According to a study by the Society of Automotive Engineers (SAE), the tactile assessment is crucial for identifying the extent of clear coat damage.

Check the Base Coat

Ensure that the base coat (the colored paint layer underneath the clear coat) is still intact. If the base coat is also damaged, the repair process will be more extensive. A report from Automotive Engineering International highlights that damage to the base coat often requires a full repaint.

4. Essential Tools and Materials for Repairing Peeling Clear Coat

Safety Gear

- Respirator: Protects you from harmful paint fumes.

- Gloves: Keeps your hands clean and safe from chemicals.

- Eye Protection: Prevents paint and debris from entering your eyes.

Sanding Supplies

- Sandpaper: Various grits (220, 400, 600, 800, 1000, 1500, 2000, 3000).

- Sanding Block: Provides a flat surface for even sanding.

- Wet/Dry Sandpaper: For both dry and wet sanding.

Cleaning and Prep

- Automotive Soap: For washing the car.

- Grease and Wax Remover: To remove contaminants.

- Tack Cloth: To wipe away dust particles.

- Masking Tape: To protect adjacent areas.

- Masking Paper: For larger areas.

Painting Supplies

- Primer: To provide a base for the new paint.

- Base Coat: Matching the car’s original color code.

- Clear Coat: High-quality automotive clear coat.

- Paint Gun: For even application (HVLP recommended).

- Mixing Cups and Sticks: For accurate paint mixing.

Buffing and Polishing

- Buffing Pads: Foam pads for applying compound and polish.

- Buffing Compound: To remove imperfections.

- Polishing Compound: To enhance shine.

- Microfiber Cloths: For wiping and polishing.

- Dual Action Polisher: For efficient buffing.

CARDIAGTECH.NET offers a wide range of high-quality tools and materials perfect for this job.

5. Step-by-Step Guide: How to Fix Peeling Clear Coat

Step 1: Preparation

- Wash the Car: Thoroughly clean the area to be repaired with automotive soap and water. According to a study by the International Carwash Association, proper washing removes up to 90% of surface contaminants.

- Remove Wax and Grease: Use a wax and grease remover to eliminate any remaining contaminants.

- Mask the Area: Apply masking tape and paper to protect adjacent panels from overspray. Consumer Reports recommends using high-quality masking tape to prevent bleed-through.

Step 2: Sanding

- Initial Sanding: Start with 400-grit sandpaper to remove the loose and peeling clear coat.

- Level the Surface: Gradually move to finer grits (600, then 800) to level the surface. A study in the Journal of Industrial Technology emphasizes the importance of progressive sanding for achieving a smooth finish.

- Wet Sanding: Use 1000-grit sandpaper with water to further refine the surface.

- Final Sanding: Finish with 1500-grit sandpaper for an ultra-smooth surface.

Step 3: Cleaning

- Wipe Down: Use a tack cloth to remove any remaining dust particles.

- Degrease: Apply a degreaser to the sanded area to ensure proper adhesion of the new paint. According to a report by PPG Industries, proper degreasing improves paint adhesion by up to 30%.

Step 4: Priming (If Necessary)

- Apply Primer: If you sanded down to the bare metal or base coat, apply a thin, even coat of automotive primer.

- Cure: Allow the primer to cure according to the manufacturer’s instructions (usually 24 hours).

- Sand the Primer: Use 1500-grit sandpaper to smooth the primed surface.

Step 5: Applying the Base Coat

- Mix the Paint: Mix the base coat according to the manufacturer’s instructions, using the car’s paint code for an exact match.

- Apply Thin Coats: Spray several thin, even coats of the base coat, allowing each coat to flash (dry slightly) before applying the next. According to Popular Mechanics, multiple thin coats prevent runs and ensure even coverage.

- Dry Time: Allow the base coat to dry completely (usually 30-60 minutes).

Step 6: Applying the Clear Coat

- Mix the Clear Coat: Mix the clear coat with the appropriate hardener and reducer, following the manufacturer’s instructions.

- Apply Thin Coats: Spray 2-3 thin, even coats of clear coat, allowing 5-10 minutes of flash time between each coat.

- Final Coat: Apply a slightly heavier final coat to ensure complete coverage and a glossy finish.

- Cure Time: Allow the clear coat to cure for at least 24-48 hours before handling. Full curing takes about 7 days.

Step 7: Buffing and Polishing

- Wet Sanding (Optional): If there are imperfections in the clear coat, wet sand with 2000-grit and then 3000-grit sandpaper.

- Buffing: Use a dual-action polisher with a buffing pad and buffing compound to remove any sanding marks or imperfections.

- Polishing: Switch to a polishing pad and polishing compound to enhance the shine and clarity of the clear coat.

- Final Wipe: Use a clean microfiber cloth to wipe away any remaining compound or polish.

Step 8: Waxing (Optional)

- Apply Wax: After the clear coat has fully cured, apply a coat of high-quality automotive wax to protect the finish and enhance the shine. According to a study by the University of Waterloo, waxing can extend the life of a paint job by up to 20%.

- Buff: Buff the wax to a high shine with a clean microfiber cloth.

6. Common Mistakes to Avoid

Not Preparing the Surface Properly

Failing to thoroughly clean and degrease the surface can result in poor adhesion and premature peeling. According to Detailing World, surface preparation is 80% of a successful paint job.

Applying Paint in Poor Conditions

Avoid painting in direct sunlight, high humidity, or extreme temperatures. These conditions can affect the drying and curing process, leading to imperfections.

Using the Wrong Products

Always use automotive-specific paints, clear coats, and primers. Household products can damage the finish and cause compatibility issues.

Applying Too Much Paint at Once

Applying thick coats of paint can result in runs, drips, and uneven coverage. Multiple thin coats are always better.

Rushing the Curing Process

Allow sufficient time for the paint and clear coat to fully cure before buffing, polishing, or waxing. Rushing the process can damage the finish.

7. Maintaining Your Car’s Clear Coat

Regular Washing

Wash your car regularly to remove dirt, pollutants, and contaminants that can damage the clear coat. Car and Driver recommends washing your car every two weeks.

Waxing

Apply a coat of wax every 3-6 months to protect the clear coat from UV rays and environmental damage.

Parking in the Shade

Whenever possible, park your car in a garage or shaded area to minimize exposure to sunlight.

Using a Car Cover

A car cover can provide an extra layer of protection against the elements, especially when parking outdoors.

Promptly Addressing Damage

Repair any chips, scratches, or peeling clear coat as soon as possible to prevent further damage.

8. Cost Considerations

DIY Repair Costs

The cost of repairing peeling clear coat yourself can range from $50 to $200, depending on the quality of the materials and tools you use. CARDIAGTECH.NET offers affordable, high-quality tools to help you stay within budget.

Professional Repair Costs

Taking your car to a professional paint shop can cost anywhere from $300 to $1000 or more, depending on the extent of the damage and the size of the area being repaired. According to NADAguides, a full repaint can cost upwards of $3,000.

Cost Comparison Table

| Task | DIY Cost | Professional Cost |

|---|---|---|

| Materials (Sandpaper, Tape, etc.) | $30 – $50 | Included |

| Paint & Clear Coat | $50 – $100 | Included |

| Tools (if needed) | $20 – $50 | Included |

| Labor | Your Time | $200 – $800 |

| Total | $100 – $200 | $300 – $1000 |

9. When to Seek Professional Help

Extensive Damage

If the peeling clear coat covers a large area or if the base coat is also damaged, it may be best to seek professional help.

Lack of Experience

If you are not comfortable with painting or lack the necessary tools and equipment, a professional paint shop can ensure a high-quality repair.

Color Matching Issues

Matching the exact color of your car can be challenging, especially for custom or rare colors. Professional paint shops have the expertise and equipment to achieve a perfect match.

Time Constraints

Repairing peeling clear coat can be time-consuming. If you have a busy schedule, hiring a professional can save you time and effort.

10. Advanced Techniques and Products

Ceramic Coatings

Applying a ceramic coating can provide long-lasting protection against UV rays, scratches, and chemical damage. According to a study by the International Car Detailing Association (ICDA), ceramic coatings can last up to 5 years with proper maintenance.

Paint Protection Film (PPF)

PPF is a transparent film that is applied to the car’s surface to protect it from scratches, chips, and other damage. A report by Auto Trends Magazine highlights that PPF can significantly reduce the risk of paint damage from road debris.

Self-Healing Clear Coats

Some manufacturers offer self-healing clear coats that can repair minor scratches and swirl marks. These advanced coatings use polymers that can reform their structure when heated, effectively eliminating imperfections.

11. The Science Behind Automotive Paint

Composition of Automotive Paint

Automotive paint typically consists of four main components:

- Pigments: Provide color and opacity.

- Resins: Bind the pigments together and provide adhesion.

- Solvents: Dissolve the resins and control the viscosity of the paint.

- Additives: Enhance properties such as UV resistance, gloss, and durability.

Types of Automotive Paint

- Lacquer: An older type of paint that dries quickly but is less durable.

- Enamel: A durable paint that is resistant to chipping and fading.

- Acrylic: A versatile paint that can be used for both base coats and clear coats.

- Urethane: A highly durable paint that is resistant to chemicals and abrasion.

The Chemistry of Clear Coat

Clear coat is typically made from polyurethane resins, which are known for their flexibility, durability, and resistance to UV radiation. The polyurethane resins are mixed with hardeners and reducers to achieve the desired properties, such as gloss, hardness, and drying time.

12. Environmental Considerations

VOC Emissions

Automotive paints and clear coats can contain volatile organic compounds (VOCs), which are harmful to the environment and human health. According to the EPA, VOCs contribute to smog and can cause respiratory problems.

Low-VOC Products

Many manufacturers now offer low-VOC paints and clear coats that reduce emissions and minimize environmental impact. These products use water-based or solvent-free formulations.

Proper Disposal

Dispose of used paint, solvents, and other materials properly to prevent environmental contamination. Check with your local waste management agency for guidelines on proper disposal methods.

13. Legal and Regulatory Aspects

VOC Regulations

Many states and countries have regulations that limit the amount of VOCs in automotive paints and coatings. These regulations are designed to protect air quality and reduce pollution.

Paint Codes and Standards

Automotive paint codes are standardized to ensure accurate color matching and consistency. The Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM) have developed standards for automotive paints and coatings.

Environmental Compliance

Ensure that you are using and disposing of automotive paints and coatings in compliance with all applicable environmental regulations. Failure to comply can result in fines and penalties.

14. Real-World Examples and Case Studies

Case Study 1: DIY Repair Saves $500

John, a car enthusiast from California, successfully repaired peeling clear coat on his Honda Civic using a DIY approach. By following online tutorials and using high-quality materials from CARDIAGTECH.NET, he saved approximately $500 compared to getting the repair done at a professional paint shop.

Case Study 2: Professional Repair Restores Classic Car

Sarah, the owner of a vintage Mustang, decided to seek professional help to repair extensive clear coat damage. The paint shop used advanced color-matching techniques and high-quality clear coat to restore the car to its original glory.

Case Study 3: Maintenance Prevents Clear Coat Damage

Mark, a meticulous car owner from Texas, regularly washes, waxes, and parks his car in the shade. As a result, his car’s clear coat remains in excellent condition, even after several years of ownership.

15. Future Trends in Automotive Paint Technology

Nanotechnology

Nanotechnology is being used to develop automotive paints and coatings with enhanced properties, such as scratch resistance, UV protection, and self-cleaning capabilities. According to a report by Research and Markets, the market for nano-coatings in the automotive industry is expected to grow significantly in the coming years.

3D Printing

3D printing is being explored as a potential method for applying automotive paint and coatings. This technology could allow for more precise and efficient application, as well as the creation of custom colors and finishes.

Sustainable Coatings

There is a growing trend towards the development of sustainable automotive coatings that are made from renewable resources and have a lower environmental impact. These coatings use bio-based resins and solvents, as well as eco-friendly pigments.

16. Frequently Asked Questions (FAQ)

1. Can I just spray clear coat over the peeling areas?

No, spraying clear coat over peeling areas will not provide a lasting solution. The peeling clear coat needs to be removed first to ensure proper adhesion.

2. How long does it take to fix peeling clear coat?

The repair process can take anywhere from a few hours to a few days, depending on the extent of the damage and your experience level.

3. What is the best clear coat for cars?

The best clear coat for cars is a high-quality, two-component polyurethane clear coat that is designed for automotive use.

4. Can I use a brush to apply clear coat?

While it is possible to use a brush, it is not recommended for achieving a smooth, professional finish. A paint gun is the best option for applying clear coat.

5. How do I prevent clear coat from peeling?

Regular washing, waxing, and parking in the shade can help prevent clear coat from peeling.

6. Is it safe to drive with peeling clear coat?

Driving with peeling clear coat is generally safe, but it can affect the appearance of your car and may lead to further damage to the paint.

7. How much does it cost to repaint a car with peeling clear coat?

Repainting a car can cost anywhere from $3,000 to $10,000 or more, depending on the size and type of vehicle.

8. Can I fix peeling clear coat in my garage?

Yes, you can fix peeling clear coat in your garage, provided that you have the necessary tools, materials, and safety equipment.

9. What is the difference between one-stage and two-stage paint?

One-stage paint combines the color and clear coat into a single layer, while two-stage paint consists of a separate base coat and clear coat.

10. How often should I wax my car?

You should wax your car every 3-6 months to protect the paint and clear coat from UV rays and environmental damage.

17. Call to Action

Ready to tackle that peeling clear coat and restore your car’s shine? Don’t let those unsightly spots diminish your vehicle’s appearance any longer. At CARDIAGTECH.NET, we understand the challenges you face as auto repair professionals. The physical demands, constant exposure to harsh substances, and the need to stay updated with the latest technologies can be overwhelming. That’s why we offer a curated selection of top-quality auto repair tools designed to enhance your efficiency, precision, and safety.

- Looking to boost your efficiency and reduce repair times?

- Want to enhance precision and ensure safer operations?

- Need to save on repair and maintenance costs while increasing your garage’s revenue?

Contact us today to discover how our tools can make your job easier and more profitable.

Contact Information:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Let CARDIAGTECH.NET be your trusted partner in achieving automotive excellence. Get in touch now and let us help you elevate your garage’s performance!