How Long to Fix Brakes on Car: Expert Guide & Time Breakdown

Fixing brakes on a car typically takes around 1.5 to 2 hours for a complete brake job, but the exact duration depends on several factors. CARDIAGTECH.NET is here to provide an expert guide, offering insights into the time involved, potential costs, and essential maintenance for your vehicle’s braking system. Addressing the crucial aspects of brake repair, including brake pad replacement and rotor maintenance, ensures optimal performance and safety while driving, with resources to equip auto repair professionals with the tools they need to succeed.

1. Understanding the Basics: Brake Pads and Rotors

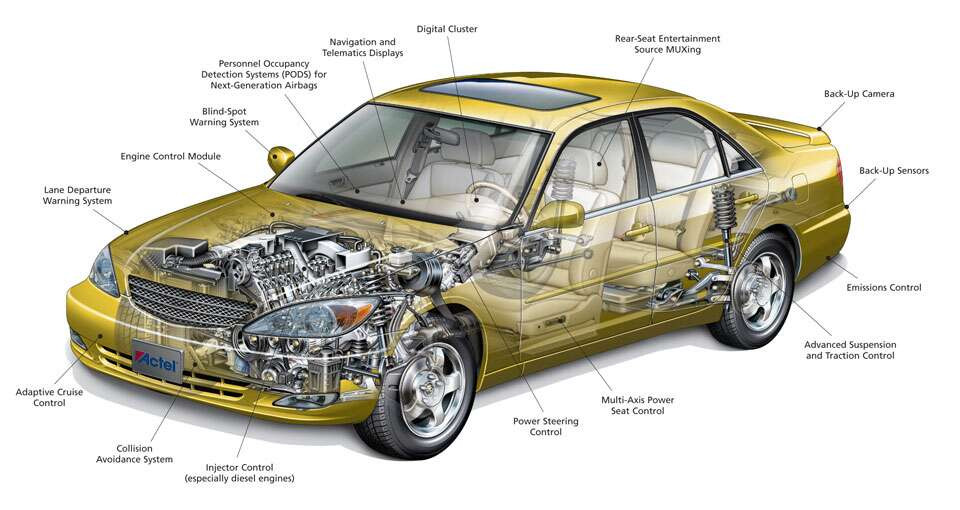

The braking system in your car is a crucial safety feature, consisting mainly of brake pads and rotors. These components work together to slow down or stop your vehicle. Knowing the difference between them is essential for proper maintenance and repair.

1.1. Brake Rotors

Brake rotors are discs connected to each wheel, spinning at the same speed. When you apply the brakes, calipers compress brake pads against these rotors, creating friction that slows down the vehicle. According to a study by the University of California, Berkeley, the efficiency of brake rotors is directly related to their condition; worn rotors can significantly reduce braking performance.

1.2. Brake Pads

Brake pads are steel plates with friction material bonded to their surface. When you brake, these pads press against the rotors. This constant friction causes the pads to wear down over time, requiring periodic replacement. Research from the Society of Automotive Engineers (SAE) indicates that the type of material used in brake pads greatly affects their lifespan and performance.

2. Average Time to Fix Brakes on Car

So, how long to fix brakes on car? The time it takes to fix brakes can vary, but here’s a general breakdown:

2.1. Brake Pad Replacement

Replacing brake pads typically takes about 30 minutes per wheel. This involves removing the old pads, cleaning the brake calipers, and installing new brake pads.

2.2. Brake Rotor Replacement

Replacing brake rotors can take between 30 to 60 minutes per wheel. This process includes removing the wheel, detaching the caliper, removing the old rotor, and installing the new one.

2.3. Complete Brake Job

A complete brake job, which includes replacing both the brake pads and rotors on all four wheels, usually takes around 1.5 to 2 hours. This timeframe can vary based on the mechanic’s experience, the tools available, and the specific make and model of the vehicle. CARDIAGTECH.NET provides a range of tools that can help reduce this time.

3. Factors Affecting Brake Repair Time

Several factors can influence how long it takes to fix your car’s brakes. Being aware of these can help you better estimate the time needed for repairs.

3.1. Mechanic’s Experience

An experienced mechanic can often complete brake repairs more quickly than someone less experienced. Their familiarity with various car models and braking systems allows them to work efficiently. According to a survey by the National Institute for Automotive Service Excellence (ASE), certified technicians typically complete repairs 30% faster than non-certified technicians.

3.2. Tools Available

Having the right tools can significantly reduce repair time. Specialized tools for brake work, such as caliper compressors and brake spring pliers, can speed up the process. CARDIAGTECH.NET offers a wide array of high-quality tools designed to make brake repairs more efficient.

3.3. Vehicle Make and Model

The make and model of your vehicle can also affect repair time. Some cars have more complex braking systems that require additional steps or specialized knowledge. European cars, for example, may have electronic brake pad sensors that need to be reset after replacement, adding to the overall time.

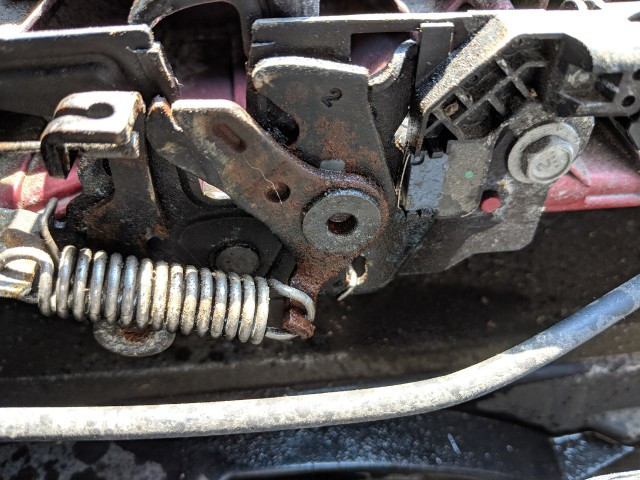

3.4. Condition of the Brakes

If the brakes are severely worn or damaged, it may take longer to repair them. Rust, corrosion, or seized components can make disassembly more difficult, increasing the time required for the job.

3.5. Additional Issues

Sometimes, during a brake repair, additional issues may be discovered that need to be addressed. For example, a damaged brake hose or a leaking caliper may require replacement, adding to the overall repair time.

4. DIY vs. Professional Brake Repair

Deciding whether to fix your brakes yourself or hire a professional mechanic is an important consideration. Both options have their pros and cons.

4.1. DIY Brake Repair

Pros:

- Cost Savings: Doing it yourself can save you money on labor costs.

- Flexibility: You can work on your car at your own pace and schedule.

- Learning Experience: It can be a rewarding experience to learn about your car’s braking system.

Cons:

- Time Commitment: It can take significantly longer to do it yourself, especially if you are not experienced.

- Risk of Mistakes: Making mistakes can lead to safety issues and additional repair costs.

- Tool Investment: You may need to purchase specialized tools.

4.2. Professional Brake Repair

Pros:

- Expertise: Professional mechanics have the knowledge and experience to do the job correctly.

- Efficiency: They can complete the repairs quickly and efficiently.

- Warranty: Many shops offer warranties on their work.

Cons:

- Higher Cost: Labor costs can be significant.

- Scheduling: You may need to schedule an appointment and wait for the repair to be completed.

According to data from AAA, the average cost of a brake repair at a professional shop is between $350 and $800 per axle.

5. Signs You Need Brake Repair

Recognizing the signs that your brakes need repair is essential for maintaining your vehicle’s safety. Here are some common indicators:

5.1. Squealing or Squeaking Noises

One of the most common signs of worn brake pads is a squealing or squeaking noise when you apply the brakes. This noise is often caused by a built-in wear indicator on the brake pads.

5.2. Grinding Noises

A grinding noise when braking can indicate that your brake pads are completely worn down and the metal backing is rubbing against the rotors. This can cause significant damage to the rotors.

5.3. Vibration or Pulsation

If you feel a vibration or pulsation in the brake pedal when braking, it could be a sign of warped rotors.

5.4. Longer Stopping Distance

If your car takes longer to stop than usual, it could be a sign of worn brake pads or other braking system issues.

5.5. Brake Warning Light

The brake warning light on your dashboard can indicate a variety of issues, including low brake fluid, a problem with the anti-lock braking system (ABS), or worn brake pads.

5.6. Leaking Brake Fluid

If you notice brake fluid leaking from your car, it’s essential to have it checked immediately. Brake fluid leaks can reduce braking performance and pose a safety hazard.

6. How Often Should You Change Brakes?

Determining how often you should change your brakes depends on several factors, including your driving habits, the type of brake pads you use, and the conditions in which you drive.

6.1. Mileage

On average, brake pads need to be replaced every 25,000 to 70,000 miles. Brake rotors typically last longer, needing replacement every 50,000 to 70,000 miles.

6.2. Driving Habits

Aggressive driving habits, such as hard braking and frequent stops, can wear down brake pads more quickly. City driving, with its stop-and-go traffic, also puts more strain on brakes than highway driving.

6.3. Brake Pad Material

The type of material used in your brake pads can affect their lifespan. Organic brake pads tend to wear down faster than ceramic or metallic pads.

6.4. Environmental Conditions

Driving in mountainous areas or in harsh weather conditions can also shorten the lifespan of your brakes.

7. Cost to Fix Brakes on Car

The cost to fix brakes on car can vary widely depending on the type of repair needed, the make and model of your vehicle, and the labor rates in your area.

7.1. Brake Pad Replacement Cost

The average cost to replace brake pads is between $100 and $300 per axle. This includes the cost of the brake pads and the labor to install them.

7.2. Brake Rotor Replacement Cost

The average cost to replace brake rotors is between $200 and $400 per axle. This includes the cost of the rotors and the labor to install them.

7.3. Complete Brake Job Cost

A complete brake job, including replacing both the brake pads and rotors, can cost between $300 and $800 per axle.

7.4. Additional Costs

Additional costs may include replacing brake calipers, brake hoses, or other components of the braking system. These repairs can add significantly to the overall cost of the brake job.

8. Choosing the Right Brake Pads

Selecting the right brake pads is crucial for ensuring optimal braking performance and safety. There are several types of brake pads available, each with its own advantages and disadvantages.

8.1. Organic Brake Pads

Organic brake pads are made from natural materials such as rubber, carbon, and fiberglass. They are quiet and produce less dust than other types of brake pads. However, they tend to wear down more quickly and are not suitable for heavy-duty applications.

8.2. Ceramic Brake Pads

Ceramic brake pads are made from ceramic fibers, bonding agents, and fillers. They are durable, quiet, and produce very little dust. They also provide excellent braking performance in a variety of conditions. However, they are typically more expensive than other types of brake pads.

8.3. Metallic Brake Pads

Metallic brake pads are made from a blend of metals such as iron, steel, and copper. They are durable and provide excellent braking performance, especially in high-performance applications. However, they can be noisy and produce more dust than other types of brake pads.

8.4. Choosing the Right Pad

When choosing brake pads, consider your driving habits, the type of vehicle you drive, and your budget. If you do a lot of city driving or heavy braking, ceramic or metallic brake pads may be a better choice. If you are looking for a quiet and affordable option, organic brake pads may be suitable.

9. Maintaining Your Brakes for Longevity

Proper maintenance is essential for extending the life of your brakes and ensuring optimal performance. Here are some tips for maintaining your brakes:

9.1. Regular Inspections

Have your brakes inspected regularly by a qualified mechanic. They can check the condition of your brake pads, rotors, calipers, and brake fluid.

9.2. Brake Fluid Flushes

Brake fluid can absorb moisture over time, which can reduce its effectiveness and damage braking system components. Have your brake fluid flushed and replaced according to your vehicle manufacturer’s recommendations.

9.3. Proper Driving Habits

Avoid aggressive driving habits such as hard braking and tailgating. Gradual braking can help extend the life of your brake pads and rotors.

9.4. Keep Brakes Clean

Keep your brakes clean and free of debris. Use a brake cleaner to remove dirt, dust, and grime from the braking system components.

9.5. Address Issues Promptly

Address any brake issues promptly. Ignoring problems can lead to more extensive damage and higher repair costs.

10. Tools and Equipment for Brake Repair

Having the right tools and equipment is essential for performing brake repairs safely and efficiently. CARDIAGTECH.NET offers a wide range of high-quality tools for brake repair, including:

10.1. Brake Pad Spreader

A brake pad spreader is used to compress the brake caliper pistons, making it easier to install new brake pads.

10.2. Brake Caliper Piston Tool

A brake caliper piston tool is used to retract the pistons in the brake calipers, allowing you to remove and replace the brake pads.

10.3. Brake Rotor Wrench

This tool provides extra leverage when removing stubborn or seized brake rotors.

10.4. Brake Bleeder Kit

A brake bleeder kit is used to remove air from the brake lines after a brake repair.

10.5. Torque Wrench

A torque wrench is used to tighten bolts and nuts to the correct specifications, ensuring that the braking system components are properly secured.

10.6. Jack and Jack Stands

A jack and jack stands are used to safely lift and support the vehicle while you are working on the brakes.

10.7. Wheel Chocks

Wheel chocks are used to prevent the vehicle from rolling while you are working on the brakes.

11. Safety Precautions for Brake Repair

Safety should always be your top priority when performing brake repairs. Here are some safety precautions to keep in mind:

11.1. Wear Safety Glasses

Wear safety glasses to protect your eyes from brake dust, debris, and brake fluid.

11.2. Wear Gloves

Wear gloves to protect your hands from brake dust, grease, and brake fluid.

11.3. Work in a Well-Ventilated Area

Work in a well-ventilated area to avoid breathing in brake dust and fumes.

11.4. Use Jack Stands

Always use jack stands to support the vehicle when it is lifted. Never work under a vehicle that is only supported by a jack.

11.5. Dispose of Brake Fluid Properly

Dispose of used brake fluid properly. Do not pour it down the drain or onto the ground. Take it to a recycling center or hazardous waste collection facility.

11.6. Follow Manufacturer’s Instructions

Follow the vehicle manufacturer’s instructions and torque specifications when performing brake repairs.

12. How CARDIAGTECH.NET Can Help

CARDIAGTECH.NET is your trusted partner for all your automotive diagnostic and repair needs. We offer a wide range of products and services to help you keep your vehicle running smoothly and safely.

12.1. High-Quality Tools

We offer a wide selection of high-quality tools for brake repair, including brake pad spreaders, brake caliper piston tools, torque wrenches, and more. Our tools are designed to make brake repairs easier and more efficient.

12.2. Diagnostic Equipment

We offer a range of diagnostic equipment to help you identify and diagnose brake system problems. Our diagnostic tools can help you pinpoint the source of the problem and make the necessary repairs.

12.3. Expert Advice

Our team of experienced technicians can provide expert advice and support to help you with your brake repairs. We can answer your questions, offer guidance, and help you troubleshoot any problems you may encounter.

12.4. Training Resources

We offer a variety of training resources to help you improve your brake repair skills. Our training resources include online tutorials, videos, and hands-on workshops.

12.5. Contact Us

Don’t let brake issues slow you down. Contact CARDIAGTECH.NET today for expert advice and quality tools. Our friendly staff is ready to assist you with all your automotive repair needs. Visit us at 276 Reock St, City of Orange, NJ 07050, United States, call us at +1 (641) 206-8880, or visit our website at CARDIAGTECH.NET. Let us help you keep your vehicle running safely and efficiently.

13. Common Brake Repair Mistakes to Avoid

Even experienced mechanics can sometimes make mistakes during brake repairs. Here are some common mistakes to avoid:

13.1. Not Cleaning the Hub

Failing to clean the hub before installing new rotors can cause runout, which can lead to vibration and premature wear.

13.2. Over-Tightening Lug Nuts

Over-tightening lug nuts can warp the rotors and damage the wheel studs. Use a torque wrench to tighten the lug nuts to the correct specifications.

13.3. Not Lubricating Brake Components

Failing to lubricate the brake caliper slides and other moving parts can cause them to bind and wear prematurely.

13.4. Not Bleeding the Brakes

Failing to bleed the brakes after replacing brake lines or calipers can leave air in the system, which can reduce braking performance.

13.5. Using the Wrong Brake Pads

Using the wrong brake pads can cause noise, vibration, and premature wear. Always use brake pads that are designed for your vehicle.

13.6. Ignoring the Brake Calipers

Ignoring the brake calipers and only replacing the pads and rotors can lead to future problems. Make sure to inspect the calipers for leaks, damage, and proper function.

14. The Importance of Brake Fluid

Brake fluid is a critical component of your vehicle’s braking system. It is responsible for transmitting the force from the brake pedal to the brake calipers, which then apply the brakes.

14.1. Types of Brake Fluid

There are several types of brake fluid available, each with its own specifications and properties. The most common types of brake fluid are DOT 3, DOT 4, and DOT 5.

14.2. Brake Fluid Maintenance

Brake fluid can absorb moisture over time, which can reduce its effectiveness and damage braking system components. It is important to have your brake fluid checked and replaced according to your vehicle manufacturer’s recommendations.

14.3. Signs of Contaminated Brake Fluid

Signs of contaminated brake fluid include a spongy brake pedal, reduced braking performance, and a change in the color or consistency of the brake fluid.

14.4. Choosing the Right Brake Fluid

When choosing brake fluid, it is important to use the type of fluid that is recommended by your vehicle manufacturer. Using the wrong type of brake fluid can damage the braking system components.

15. The Role of ABS (Anti-lock Braking System)

The anti-lock braking system (ABS) is an important safety feature that helps prevent the wheels from locking up during hard braking. This allows you to maintain steering control and reduce your stopping distance.

15.1. How ABS Works

ABS works by monitoring the speed of each wheel and detecting when a wheel is about to lock up. When a wheel is about to lock up, the ABS modulates the brake pressure to that wheel, preventing it from locking up and allowing you to maintain steering control.

15.2. ABS Maintenance

ABS requires regular maintenance to ensure that it is functioning properly. This includes checking the ABS sensors, wiring, and hydraulic components.

15.3. ABS Warning Light

If the ABS warning light on your dashboard comes on, it could indicate a problem with the ABS system. Have your vehicle checked by a qualified mechanic to diagnose and repair the problem.

16. Preparing for Your Brake Repair Appointment

To ensure a smooth and efficient brake repair appointment, it’s helpful to be prepared. Here’s how:

16.1. Gather Information

Collect any relevant information about your vehicle’s braking issues, such as when the problem started, what noises you hear, and any other symptoms you’ve noticed.

16.2. Schedule an Appointment

Schedule your brake repair appointment in advance to ensure that the shop has the time and resources to properly diagnose and repair your brakes.

16.3. Ask Questions

Don’t hesitate to ask questions about the repair process, the parts being used, and the estimated cost. A reputable shop will be happy to answer your questions and provide you with a detailed estimate.

16.4. Drop Off Your Vehicle

Drop off your vehicle at the scheduled time and provide the shop with any relevant information about your braking issues.

16.5. Follow Up

Follow up with the shop to check on the progress of the repair and ask any additional questions you may have.

17. Why Regular Brake Inspections are Essential

Regular brake inspections are a crucial part of vehicle maintenance and safety. They help identify potential problems before they become major issues.

17.1. Catch Problems Early

Regular inspections can catch problems such as worn brake pads, damaged rotors, and leaking brake fluid before they cause more extensive damage and higher repair costs.

17.2. Ensure Safety

Regular inspections help ensure that your brakes are functioning properly and that you can stop safely in any situation.

17.3. Maintain Performance

Regular inspections help maintain the performance of your braking system, ensuring that you have optimal stopping power and control.

17.4. Extend Lifespan

Regular inspections and maintenance can help extend the lifespan of your brakes, saving you money on costly repairs.

17.5. Peace of Mind

Knowing that your brakes have been inspected and are functioning properly can give you peace of mind while driving.

18. Understanding Brake Caliper Functionality

Brake calipers are a critical part of your vehicle’s braking system. They house the brake pads and use hydraulic pressure to clamp the pads against the rotors, causing the vehicle to slow down or stop.

18.1. How Brake Calipers Work

When you press the brake pedal, hydraulic pressure is applied to the brake calipers. This pressure forces the pistons in the calipers to push the brake pads against the rotors, creating friction that slows down the vehicle.

18.2. Types of Brake Calipers

There are two main types of brake calipers: floating calipers and fixed calipers. Floating calipers have one or two pistons and move along with the rotor as the brakes are applied. Fixed calipers have multiple pistons on both sides of the rotor and do not move.

18.3. Brake Caliper Maintenance

Brake calipers require regular maintenance to ensure that they are functioning properly. This includes lubricating the caliper slides, inspecting the pistons for leaks, and checking the overall condition of the calipers.

18.4. Signs of Caliper Problems

Signs of caliper problems include uneven brake pad wear, a pulling sensation when braking, and a burning odor coming from the brakes.

18.5. Caliper Replacement

If your brake calipers are damaged or malfunctioning, they may need to be replaced. Caliper replacement involves removing the old calipers, installing new calipers, and bleeding the brakes.

19. The Importance of Proper Brake Bleeding

Proper brake bleeding is essential for maintaining a safe and effective braking system. Brake bleeding involves removing air from the brake lines, which can reduce braking performance and cause a spongy brake pedal.

19.1. Why Brake Bleeding is Necessary

Air can enter the brake lines when the brake system is opened for repairs, such as replacing brake pads, rotors, or calipers. Air in the brake lines can compress, reducing the amount of pressure that is transmitted to the brakes.

19.2. How to Bleed Brakes

There are several methods for bleeding brakes, including manual bleeding, pressure bleeding, and vacuum bleeding. Manual bleeding involves opening the bleeder screws on the brake calipers and pumping the brake pedal to force air out of the lines. Pressure bleeding involves using a pressure bleeder to force brake fluid through the lines, pushing out any air. Vacuum bleeding involves using a vacuum pump to draw brake fluid through the lines, removing any air.

19.3. Brake Bleeding Tools

Several tools are available for bleeding brakes, including bleeder wrenches, bleeder bags, pressure bleeders, and vacuum bleeders.

19.4. Safety Precautions

When bleeding brakes, it is important to follow safety precautions to avoid injury. Wear safety glasses and gloves, and be careful not to spill brake fluid on painted surfaces.

20. Ensuring Equal Brake Wear

Ensuring equal brake wear is essential for maintaining a safe and effective braking system. Uneven brake wear can cause pulling, vibration, and reduced braking performance.

20.1. Causes of Uneven Brake Wear

Causes of uneven brake wear include a stuck caliper, a damaged brake hose, and misaligned suspension components.

20.2. How to Prevent Uneven Brake Wear

To prevent uneven brake wear, make sure to maintain your braking system properly. This includes lubricating the caliper slides, inspecting the brake hoses for damage, and aligning the suspension components.

20.3. Addressing Uneven Wear

If you notice uneven brake wear, have your vehicle checked by a qualified mechanic to diagnose and repair the problem. This may involve replacing the calipers, brake hoses, or suspension components.

21. The Long-Term Benefits of Quality Brake Repairs

Investing in quality brake repairs can provide long-term benefits, including improved safety, reduced repair costs, and increased vehicle lifespan.

21.1. Improved Safety

Quality brake repairs help ensure that your brakes are functioning properly, allowing you to stop safely in any situation.

21.2. Reduced Repair Costs

Addressing brake problems promptly and using quality parts can prevent more extensive damage and higher repair costs in the future.

21.3. Increased Vehicle Lifespan

Proper brake maintenance can help extend the lifespan of your vehicle by preventing damage to other components.

21.4. Peace of Mind

Knowing that your brakes have been properly repaired and maintained can give you peace of mind while driving.

22. Addressing Common Brake Noises

Brake noises can be a sign of a problem with your braking system. Understanding the different types of brake noises can help you diagnose and address the issue.

22.1. Squealing

Squealing noises are often caused by worn brake pads. Many brake pads have a built-in wear indicator that makes a squealing noise when the pads are worn down to a certain point.

22.2. Grinding

Grinding noises are often caused by metal-on-metal contact, which can occur when the brake pads are completely worn down and the metal backing is rubbing against the rotors.

22.3. Clicking

Clicking noises can be caused by loose brake pads or caliper components.

22.4. Rumbling

Rumbling noises can be caused by warped rotors or damaged wheel bearings.

22.5. Diagnosing Brake Noises

To diagnose brake noises, have your vehicle inspected by a qualified mechanic. They can identify the source of the noise and recommend the appropriate repairs.

23. What to Expect After Brake Repair

After having your brakes repaired, there are a few things you should expect.

23.1. Break-In Period

New brake pads and rotors need a break-in period to properly seat and bed in. During this period, avoid hard braking and sudden stops.

23.2. Initial Performance

Initially, your brakes may not feel as responsive as they will after the break-in period. This is normal and will improve as the pads and rotors seat properly.

23.3. Monitoring Performance

Monitor the performance of your brakes and pay attention to any noises or vibrations. If you notice any problems, have your vehicle checked by a qualified mechanic.

23.4. Follow-Up Inspection

Consider having a follow-up inspection after a few weeks to ensure that the brakes are functioning properly and that there are no leaks or other issues.

24. Future Trends in Brake Technology

The automotive industry is constantly evolving, and brake technology is no exception. Here are some future trends to watch for:

24.1. Electric Brakes

Electric brakes use electric motors to apply the brakes, rather than hydraulic pressure. This can improve efficiency and reduce maintenance requirements.

24.2. Regenerative Braking

Regenerative braking systems capture energy during braking and use it to recharge the vehicle’s battery. This can improve fuel efficiency and reduce emissions.

24.3. Carbon Ceramic Brakes

Carbon ceramic brakes are lightweight, durable, and provide excellent braking performance. They are often used in high-performance vehicles.

24.4. Smart Brakes

Smart brakes use sensors and software to monitor braking performance and adjust brake pressure accordingly. This can improve safety and reduce stopping distance.

25. Brake Repair FAQs

Here are some frequently asked questions about brake repair:

25.1. How Long Do Brakes Last?

Brakes typically last between 25,000 and 70,000 miles, depending on driving habits and the type of brake pads used.

25.2. How Much Does It Cost to Replace Brakes?

The cost to replace brakes can range from $100 to $800 per axle, depending on the type of repair needed and the make and model of your vehicle.

25.3. Can I Replace Brakes Myself?

Yes, you can replace brakes yourself if you have the knowledge, tools, and experience. However, it is important to follow safety precautions and torque specifications.

25.4. What Are the Signs of Worn Brakes?

Signs of worn brakes include squealing noises, grinding noises, vibration, and longer stopping distance.

25.5. How Often Should I Have My Brakes Inspected?

You should have your brakes inspected at least once a year, or more often if you do a lot of city driving or heavy braking.

25.6. Can I Drive with Worn Brakes?

Driving with worn brakes can be dangerous and can damage other components of your braking system. It is important to have your brakes repaired as soon as possible if you notice any problems.

25.7. What is Brake Fluid?

Brake fluid is a hydraulic fluid that transmits the force from the brake pedal to the brake calipers.

25.8. How Often Should I Change Brake Fluid?

You should change your brake fluid every two to three years, or as recommended by your vehicle manufacturer.

25.9. What is ABS?

ABS (anti-lock braking system) is a safety feature that helps prevent the wheels from locking up during hard braking.

25.10. How Do I Know If My ABS is Working?

If your ABS is working properly, you should feel a pulsation in the brake pedal during hard braking. The ABS warning light on your dashboard should also come on briefly when you start the vehicle and then turn off.

By understanding the importance of brake maintenance, the factors that affect brake life, and the potential costs involved, you can make informed decisions about your vehicle’s braking system. Remember, CARDIAGTECH.NET is here to support you with high-quality tools and expert advice. Contact us today to keep your vehicle running safely and efficiently.