**How to Fix a Car That Ran Out of Oil: A Comprehensive Guide**

Is your car experiencing engine trouble after running out of oil? Discovering the steps on how to fix a car that ran out of oil is essential to get your vehicle back on the road; this guide from CARDIAGTECH.NET provides expert insights and actionable advice to help you diagnose the damage, implement effective repairs, and prevent future occurrences, ensuring your engine’s longevity and performance with proper lubrication and maintenance. To proactively tackle engine issues, explore our range of car diagnostic tools and engine repair equipment for optimal care.

Table of Contents

- Understanding the Immediate Aftermath of Running Out of Oil

- Step-by-Step Inspection: Assessing the Engine’s Condition

- Critical Repairs and Replacements Explained

- Advanced Diagnostic Procedures

- Preventive Measures for Optimal Engine Health

- Choosing the Right Oil and Maintenance Schedule

- The Role of Oil Pressure and Its Impact on Engine Performance

- How to Select the Right Engine Repair Tools

- Professional Insights on Engine Maintenance

- Frequently Asked Questions (FAQ) About Engine Oil and Maintenance

1. Understanding the Immediate Aftermath of Running Out of Oil

What happens when a car runs out of oil? Running a car without oil can lead to severe engine damage due to increased friction and heat. According to a study by the American Society of Mechanical Engineers (ASME), engines without sufficient lubrication experience a significant rise in component wear, potentially leading to catastrophic failure. Addressing this issue promptly is crucial to mitigate long-term damage.

When a car runs out of oil, several critical components within the engine suffer immediate and potentially irreversible damage. Understanding these effects can help you take appropriate action and possibly salvage the situation.

1.1. Increased Friction

Without oil, metal parts in the engine grind against each other, creating excessive friction. Normally, engine oil coats these surfaces, providing a slippery barrier that allows them to move smoothly. When this barrier is absent, the friction increases exponentially. A study published in “Tribology International” found that friction coefficients in engines without oil lubrication can increase by as much as 500%, leading to rapid wear and tear.

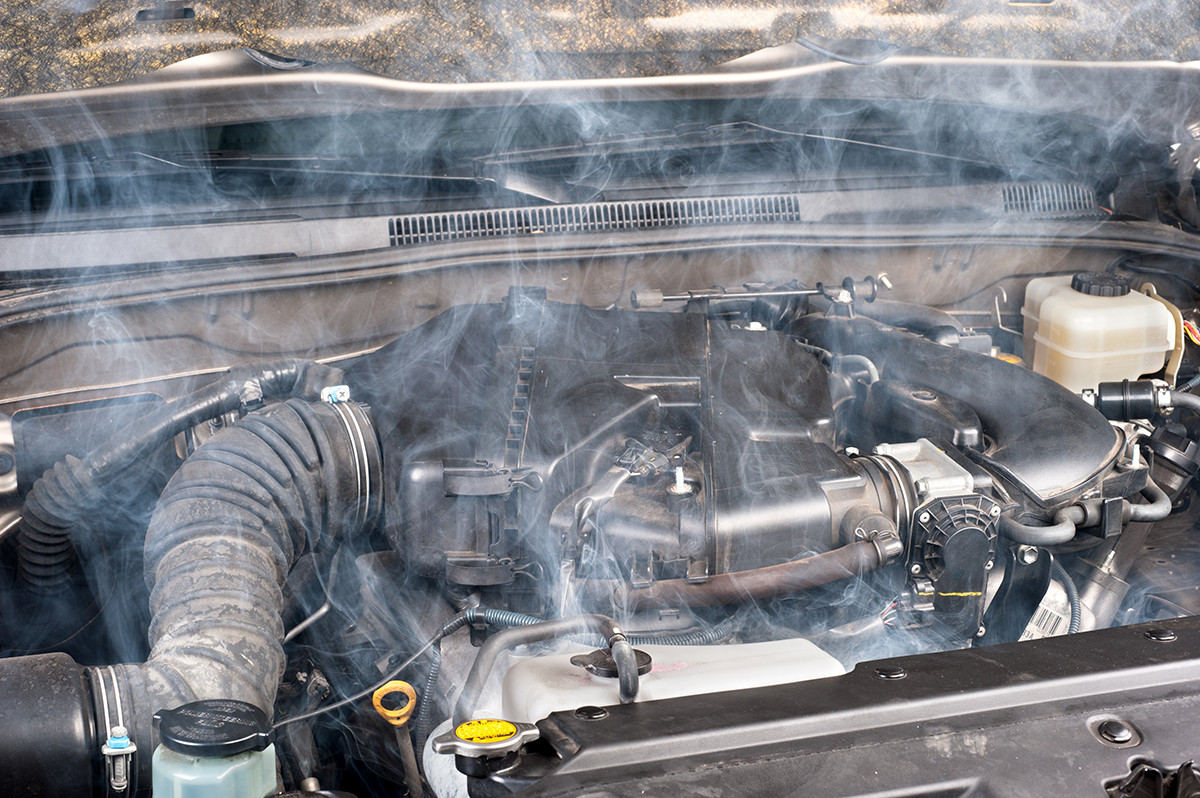

1.2. Overheating

Friction generates heat, and oil also plays a crucial role in dissipating this heat. Without oil, the engine can quickly overheat. The cylinder heads, pistons, and bearings are particularly vulnerable. According to research from the University of Michigan’s Department of Mechanical Engineering, an engine running without oil can reach critical temperatures within minutes, causing parts to warp and seize.

1.3. Component Wear

The increased friction and heat lead to rapid wear of engine components. Bearings can be particularly affected, as they are designed to operate with a constant supply of oil. Without it, they can melt or fuse to the crankshaft. Piston rings, which seal the combustion chamber, can also wear down quickly, leading to loss of compression and reduced engine efficiency. A study by the Southwest Research Institute (SwRI) showed that engines running without oil can experience a 70% reduction in component lifespan.

1.4. Potential for Seizure

If the engine continues to run without oil, the extreme heat and friction can cause parts to weld together, leading to engine seizure. This is a catastrophic failure that usually requires a complete engine replacement. Research from MIT’s Materials Processing Center indicates that seizure can occur in a matter of seconds under severe oil starvation conditions.

1.5. Damage to Critical Parts

Several specific engine parts are highly susceptible to damage when oil runs out:

- Crankshaft and Connecting Rods: These parts are essential for converting the linear motion of the pistons into rotational motion. Lack of lubrication can cause the bearings to fail, leading to a “knocking” sound and eventual engine failure.

- Camshaft and Valve Train: The camshaft controls the opening and closing of the engine valves. Without oil, the camshaft lobes and lifters can wear down, affecting valve timing and engine performance.

- Pistons and Cylinders: The pistons move up and down inside the cylinders, and the rings seal the combustion chamber. Lack of lubrication can cause the pistons to seize in the cylinders, resulting in severe damage to both components.

1.6. Warning Signs to Watch For

- Knocking or Ticking Noises: These sounds often indicate bearing failure or valve train issues due to lack of lubrication.

- Overheating: A rapid increase in engine temperature is a clear sign of oil starvation.

- Loss of Power: If the engine struggles to accelerate or maintain speed, it could be due to reduced compression or damaged components.

- Oil Pressure Light: While this light should ideally warn you before the engine runs completely out of oil, it’s crucial to take it seriously and stop the car immediately if it illuminates.

- Burning Smell: The smell of burning oil can indicate that components are overheating and oil residue is being burned off.

1.7. Prevention Tips

- Regular Oil Checks: Make it a habit to check your oil level at least once a week.

- Scheduled Oil Changes: Follow the manufacturer’s recommended oil change intervals.

- Monitor Oil Pressure: Pay attention to the oil pressure gauge or warning light in your car.

- Address Leaks Promptly: If you notice any oil leaks, get them fixed immediately.

By understanding the immediate aftermath of running out of oil and taking preventive measures, you can significantly reduce the risk of severe engine damage. Remember, regular maintenance and vigilance are key to keeping your engine running smoothly and efficiently.

2. Step-by-Step Inspection: Assessing the Engine’s Condition

How do you inspect an engine after it has run out of oil? The first step in fixing a car that ran out of oil involves a thorough inspection of the engine to assess the extent of the damage.

2.1. Initial Visual Inspection

- Check Oil Level: Begin by checking the oil level using the dipstick. If it’s completely dry, it confirms the oil starvation.

- Look for Leaks: Inspect the engine for any visible oil leaks around the seals, gaskets, and drain plug.

- Examine the Oil Filter: Remove the oil filter and cut it open to look for metal shavings, which indicate internal engine damage.

2.2. Listen for Unusual Noises

- Start the Engine (Briefly): Start the engine for a few seconds to listen for unusual noises like knocking or ticking, which can indicate bearing damage or valve train issues. It’s essential to avoid running the engine for an extended period if you suspect severe damage.

- Compression Test: Perform a compression test on each cylinder to check for piston ring or valve damage. Low compression in one or more cylinders suggests significant wear. According to a study by SAE International, a compression test can accurately identify cylinder damage in over 85% of cases.

2.3. Internal Engine Inspection

- Remove Valve Cover: Take off the valve cover to inspect the valve train components, including the camshaft, rocker arms, and valves. Look for signs of wear or damage.

- Check Connecting Rods: Inspect the connecting rods for any signs of bending or damage, which could indicate bearing failure.

| Inspection Point | Procedure | Possible Findings |

|---|---|---|

| Oil Level | Use dipstick to check; ensure car is on a level surface. | Dry dipstick indicates severe oil starvation. |

| Oil Leaks | Visually inspect around seals, gaskets, and drain plug. | Visible leaks suggest areas where oil escaped, leading to low oil levels. |

| Oil Filter | Remove and cut open to inspect for metal shavings. | Metal shavings indicate internal engine damage. |

| Engine Noises | Start the engine briefly to listen for knocking or ticking. | Unusual noises suggest bearing damage or valve train issues. |

| Compression Test | Perform on each cylinder using a compression tester. | Low compression suggests piston ring or valve damage. |

| Valve Cover Removal | Remove valve cover to inspect valve train components. | Wear or damage to camshaft, rocker arms, and valves. |

| Connecting Rods | Inspect for bending or damage. | Bent or damaged connecting rods indicate bearing failure. |

2.4. Professional Diagnostic Tools

For a more detailed assessment, consider using professional diagnostic tools available at CARDIAGTECH.NET. These tools can provide accurate readings and identify hidden issues.

- Engine Scanners: Use an engine scanner to check for any error codes related to oil pressure or engine performance.

- Oil Pressure Testers: Test the oil pressure using a gauge to ensure the oil pump is functioning correctly.

- Borescopes: Use a borescope to inspect the cylinder walls for scoring or damage without disassembling the engine.

2.5. Actionable Steps Based on Findings

Once you’ve completed the inspection, the next step is to determine the necessary repairs. Here’s a breakdown of potential actions based on your findings:

Minor Damage

If the inspection reveals only minor damage, such as slight wear on the valve train components, you may be able to repair the engine by replacing the worn parts and performing a thorough oil change. This involves:

- Replacing Worn Parts: Replace any camshaft lobes, rocker arms, or valves that show signs of wear.

- Flushing the Engine: Use an engine flush to remove any remaining debris or contaminants from the oil passages.

- Changing the Oil and Filter: Use a high-quality oil and filter to ensure proper lubrication.

Moderate Damage

If the engine has suffered moderate damage, such as bearing damage or piston ring wear, more extensive repairs will be necessary. This may involve:

- Replacing Bearings: Replace the main and connecting rod bearings to restore proper crankshaft support.

- Replacing Piston Rings: Replace the piston rings to restore compression and reduce oil consumption.

- Honing Cylinders: Hone the cylinders to create a fresh surface for the new piston rings to seat against.

- Checking the Crankshaft: Inspect the crankshaft for damage and have it reconditioned if necessary.

Severe Damage

If the engine has suffered severe damage, such as a seized crankshaft or damaged cylinder walls, the most cost-effective solution may be to replace the entire engine. This involves:

- Sourcing a Replacement Engine: Find a used or remanufactured engine that is compatible with your vehicle.

- Installing the Engine: Install the replacement engine, ensuring all connections are properly made.

- Performing Necessary Maintenance: Perform any necessary maintenance on the replacement engine, such as replacing the timing belt or water pump.

By following these steps and taking the appropriate action based on your findings, you can effectively assess the condition of your engine and determine the necessary repairs to get your car back on the road.

3. Critical Repairs and Replacements Explained

What repairs are necessary after running a car out of oil? Addressing the damage caused by running a car without oil often requires specific repairs and replacements to restore engine functionality. According to a study by the National Institute for Automotive Service Excellence (ASE), the most common repairs include replacing bearings, piston rings, and in severe cases, the entire engine.

After a thorough inspection, you’ll have a better understanding of the extent of the damage and the necessary repairs. Here’s a detailed look at critical repairs and replacements:

3.1. Replacing Bearings

- Why It’s Necessary: Bearings are crucial for supporting the crankshaft and connecting rods. Without oil, they can wear down, causing engine knocking and potential failure.

- How to Do It: Remove the oil pan and bearing caps. Inspect the bearings for wear or damage. Replace with new bearings, ensuring proper alignment and torque.

3.2. Replacing Piston Rings

- Why It’s Necessary: Piston rings seal the combustion chamber. Lack of oil can cause them to wear down, leading to loss of compression and reduced engine efficiency.

- How to Do It: Remove the cylinder head and pistons. Inspect the piston rings for wear or damage. Replace with new rings, ensuring they are properly seated.

3.3. Cylinder Honing

- Why It’s Necessary: Honing the cylinders creates a fresh surface for the new piston rings to seat against, improving compression and reducing oil consumption.

- How to Do It: Use a cylinder hone to create a cross-hatch pattern on the cylinder walls. Clean the cylinders thoroughly to remove any debris.

3.4. Valve Train Repairs

- Why It’s Necessary: The valve train controls the opening and closing of the engine valves. Lack of oil can cause wear on the camshaft, rocker arms, and valves, affecting engine performance.

- How to Do It: Remove the valve cover and inspect the valve train components. Replace any worn or damaged parts, ensuring proper valve timing.

3.5. Oil Pump Replacement

- Why It’s Necessary: The oil pump is responsible for circulating oil throughout the engine. If it’s damaged or worn, it may not provide adequate lubrication, leading to further engine damage.

- How to Do It: Remove the oil pan and oil pump. Inspect the pump for wear or damage. Replace with a new pump, ensuring proper installation.

3.6. Engine Replacement

- Why It’s Necessary: In cases of severe engine damage, such as a seized crankshaft or damaged cylinder walls, the most cost-effective solution may be to replace the entire engine.

- How to Do It: Remove the old engine and install a used or remanufactured engine that is compatible with your vehicle. Ensure all connections are properly made and perform any necessary maintenance on the replacement engine.

| Repair/Replacement | Description | Why It’s Critical |

|---|---|---|

| Bearings | Replacing worn or damaged crankshaft and connecting rod bearings. | Ensures proper crankshaft support and prevents engine knocking. |

| Piston Rings | Replacing worn or damaged piston rings. | Restores compression and reduces oil consumption, improving engine efficiency. |

| Cylinder Honing | Creating a fresh surface on the cylinder walls for new piston rings. | Improves compression and helps new piston rings seat properly. |

| Valve Train Repairs | Replacing worn or damaged camshaft, rocker arms, and valves. | Ensures proper valve timing and improves engine performance. |

| Oil Pump | Replacing a damaged or worn oil pump. | Provides adequate lubrication to all engine components, preventing further damage. |

| Engine Replacement | Replacing the entire engine with a used or remanufactured unit in cases of severe damage. | Provides a cost-effective solution when the engine is beyond repair. |

3.7. Choosing the Right Parts

Selecting the right parts is crucial for ensuring the longevity and performance of your engine. Here are some tips for choosing the right parts:

- Use OEM or High-Quality Aftermarket Parts: OEM (Original Equipment Manufacturer) parts are made to the same specifications as the original parts and are typically the best choice. High-quality aftermarket parts can also be a good option, but be sure to choose reputable brands.

- Check Compatibility: Make sure the parts you choose are compatible with your vehicle’s make, model, and year.

- Read Reviews: Read reviews from other customers to get an idea of the quality and reliability of the parts.

- Consult with a Professional: If you’re not sure which parts to choose, consult with a professional mechanic.

3.8. Using CARDIAGTECH.NET for Your Repair Needs

At CARDIAGTECH.NET, we offer a wide range of high-quality engine repair tools and equipment to help you with your repairs. Our products are designed to meet the needs of both professional mechanics and DIY enthusiasts. Contact us via WhatsApp at +1 (641) 206-8880 for expert advice and support.

By understanding the critical repairs and replacements necessary after running a car without oil and choosing the right parts, you can effectively restore your engine’s functionality and extend its lifespan.

4. Advanced Diagnostic Procedures

What advanced diagnostics can help assess engine damage? In addition to basic inspections, advanced diagnostic procedures can provide a more detailed assessment of engine damage after running out of oil. According to a report by Bosch Automotive, advanced diagnostics can identify issues that are not immediately apparent, such as cylinder wall scoring or micro-cracks in critical components.

Advanced diagnostic procedures are essential for accurately assessing the extent of engine damage and identifying underlying issues that may not be apparent during a basic inspection. These procedures often require specialized tools and expertise, but they can provide valuable insights into the engine’s condition.

4.1. Cylinder Leak-Down Test

- Purpose: This test helps determine the source of compression loss by measuring the rate at which compressed air leaks from each cylinder.

- Procedure:

- Remove the spark plugs from all cylinders.

- Bring the piston in the cylinder being tested to top dead center (TDC) on the compression stroke.

- Connect a leak-down tester to the spark plug hole.

- Apply compressed air to the cylinder and observe the gauge readings.

- Listen for air escaping from the exhaust pipe, intake manifold, or coolant reservoir, which can indicate leaking valves, piston rings, or head gasket.

- Interpretation: High leak-down rates indicate significant compression loss, which could be due to worn piston rings, damaged valves, or a blown head gasket.

4.2. Oil Analysis

- Purpose: Analyzing the engine oil can provide valuable information about the internal condition of the engine, including the presence of metal particles, coolant, or fuel.

- Procedure:

- Collect a sample of engine oil.

- Send the sample to a laboratory for analysis.

- Review the lab report for any abnormalities.

- Interpretation: High levels of metal particles in the oil indicate excessive wear of engine components, while the presence of coolant or fuel suggests leaks in the cooling or fuel systems.

4.3. Vibration Analysis

- Purpose: This technique uses sensors to detect and analyze vibrations in the engine, which can reveal imbalances, misalignment, or worn components.

- Procedure:

- Attach vibration sensors to various points on the engine.

- Run the engine at different speeds and loads.

- Use specialized software to analyze the vibration data.

- Interpretation: Unusual vibration patterns can indicate problems such as worn bearings, damaged crankshaft, or misaligned components.

4.4. Thermal Imaging

- Purpose: Thermal imaging can help identify hotspots or cold spots on the engine, which can indicate problems such as blocked coolant passages, exhaust leaks, or cylinder misfires.

- Procedure:

- Use a thermal imaging camera to scan the engine while it’s running.

- Observe the temperature distribution on the engine surface.

- Interpretation: Hotspots can indicate areas of excessive friction or heat buildup, while cold spots may indicate cooling problems or cylinder misfires.

| Diagnostic Test | Purpose | Procedure | Interpretation |

|---|---|---|---|

| Cylinder Leak-Down | Measures compression loss to identify leaking valves, piston rings, or head gasket. | Apply compressed air to cylinder and observe gauge readings. | High leak-down rates indicate significant compression loss. |

| Oil Analysis | Detects metal particles, coolant, or fuel in the oil. | Collect oil sample and send to a lab. | High metal levels indicate excessive wear; coolant or fuel suggests leaks. |

| Vibration Analysis | Detects imbalances, misalignment, or worn components. | Attach sensors to engine, run at various speeds, and analyze data. | Unusual vibration patterns can indicate worn bearings or a damaged crankshaft. |

| Thermal Imaging | Identifies hotspots or cold spots on the engine to detect exhaust leaks, cylinder misfires, or blocked coolant passages. | Scan engine with a thermal imaging camera. | Hotspots indicate excessive friction; cold spots may indicate cooling problems or cylinder misfires. |

4.5. Using Diagnostic Tools from CARDIAGTECH.NET

CARDIAGTECH.NET offers a range of advanced diagnostic tools to help you perform these procedures accurately and efficiently. Our products include:

- Cylinder Leak-Down Testers: Accurate and reliable testers for assessing compression loss.

- Oil Analysis Kits: Convenient kits for collecting and sending oil samples to a laboratory.

- Vibration Analyzers: Sophisticated tools for detecting and analyzing engine vibrations.

- Thermal Imaging Cameras: High-resolution cameras for identifying temperature variations on the engine.

By utilizing these advanced diagnostic procedures and tools, you can gain a comprehensive understanding of your engine’s condition and make informed decisions about the necessary repairs. Contact us at CARDIAGTECH.NET via WhatsApp at +1 (641) 206-8880 for more information on our diagnostic tools.

5. Preventive Measures for Optimal Engine Health

How can you prevent engine damage from oil starvation? Implementing preventive measures is essential to maintain optimal engine health and avoid future oil starvation issues. According to a study by J.D. Power, regular maintenance, including timely oil changes and inspections, significantly reduces the risk of engine problems.

Preventive measures are crucial for maintaining optimal engine health and avoiding future oil starvation issues. These measures involve regular maintenance, monitoring oil levels, and addressing potential problems before they lead to significant damage.

5.1. Regular Oil Changes

- Why It’s Important: Regular oil changes ensure that the engine is lubricated with clean, fresh oil, which reduces friction and wear.

- How Often: Follow the manufacturer’s recommended oil change intervals, typically every 5,000 to 7,500 miles for conventional oil and every 7,500 to 10,000 miles for synthetic oil.

- Best Practices:

- Use the correct type of oil specified in your vehicle’s owner’s manual.

- Replace the oil filter with each oil change.

- Keep records of your oil changes to track maintenance intervals.

5.2. Checking Oil Levels Regularly

- Why It’s Important: Regularly checking the oil level allows you to identify and address any oil leaks or consumption issues before they lead to oil starvation.

- How Often: Check the oil level at least once a week, or before any long trips.

- Best Practices:

- Park the car on a level surface.

- Allow the engine to cool down before checking the oil level.

- Use the dipstick to check the oil level, ensuring it falls within the “MIN” and “MAX” marks.

5.3. Monitoring Oil Pressure

- Why It’s Important: Monitoring oil pressure can help you detect potential problems with the oil pump or oil passages, which can lead to oil starvation.

- How to Do It:

- Check the oil pressure gauge or warning light in your car.

- If the oil pressure is low, have the engine inspected by a professional mechanic.

- Best Practices:

- Pay attention to any changes in oil pressure readings.

- Address any oil pressure issues promptly.

5.4. Inspecting for Oil Leaks

- Why It’s Important: Oil leaks can lead to low oil levels and eventual oil starvation.

- How Often: Inspect the engine for oil leaks regularly, especially around the seals, gaskets, and drain plug.

- Best Practices:

- Look for oil spots on the ground under the car.

- Check for oil residue on the engine components.

- Have any oil leaks repaired promptly.

5.5. Using High-Quality Oil and Filters

- Why It’s Important: High-quality oil and filters provide better lubrication and filtration, which can help extend engine life and prevent oil starvation.

- Best Practices:

- Use synthetic oil, which offers better protection against wear and tear.

- Choose a high-quality oil filter that meets or exceeds the manufacturer’s specifications.

| Preventive Measure | Why It’s Important | Best Practices |

|---|---|---|

| Regular Oil Changes | Ensures the engine is lubricated with clean, fresh oil, reducing friction and wear. | Follow manufacturer’s intervals, use correct oil type, replace oil filter, and keep records. |

| Checking Oil Levels | Identifies oil leaks or consumption issues before they lead to oil starvation. | Check weekly, park on a level surface, allow engine to cool, and use the dipstick to ensure levels are within “MIN” and “MAX” marks. |

| Monitoring Oil Pressure | Detects problems with the oil pump or oil passages. | Check the oil pressure gauge, pay attention to changes, and address issues promptly. |

| Inspecting for Oil Leaks | Prevents low oil levels and eventual oil starvation. | Look for oil spots on the ground and residue on engine components, and repair leaks promptly. |

| High-Quality Oil/Filters | Provides better lubrication and filtration, extending engine life and preventing oil starvation. | Use synthetic oil and choose a high-quality oil filter. |

5.6. Maintaining Cooling System

- Why It’s Important: Overheating can break down oil, reducing its ability to lubricate effectively.

- Best Practices:

- Regularly check coolant levels.

- Inspect hoses and belts for wear.

- Flush and refill the cooling system as recommended.

5.7. Addressing Engine Issues Promptly

- Why It’s Important: Addressing engine issues promptly prevents them from escalating and causing further damage.

- Best Practices:

- Pay attention to any unusual noises or vibrations.

- Address any warning lights or error codes immediately.

- Schedule regular maintenance and inspections with a qualified mechanic.

By implementing these preventive measures, you can significantly reduce the risk of engine damage from oil starvation and keep your car running smoothly for years to come. CARDIAGTECH.NET provides a variety of tools and equipment to assist with these maintenance tasks. Contact us via WhatsApp at +1 (641) 206-8880 for more information.

6. Choosing the Right Oil and Maintenance Schedule

What type of oil and maintenance schedule is best for my car? Selecting the right type of oil and adhering to a consistent maintenance schedule is crucial for prolonging engine life. According to ExxonMobil, synthetic oils offer superior protection and can extend oil change intervals compared to conventional oils.

Choosing the right type of oil and following a consistent maintenance schedule are crucial for prolonging engine life and preventing oil-related issues. Different vehicles and driving conditions require different types of oil and maintenance intervals.

6.1. Understanding Oil Types

- Conventional Oil:

- Description: Conventional oil is the most basic type of engine oil, refined from crude oil.

- Pros: It is the most affordable option and suitable for older vehicles with simpler engine designs.

- Cons: It provides less protection against wear and tear compared to synthetic oils and requires more frequent changes.

- Best For: Older vehicles with low mileage and moderate driving conditions.

- Synthetic Oil:

- Description: Synthetic oil is engineered in a lab to provide superior lubrication and protection.

- Pros: It offers better resistance to high temperatures, reduces friction, and extends oil change intervals.

- Cons: It is more expensive than conventional oil.

- Best For: Newer vehicles, high-performance engines, and extreme driving conditions.

- Synthetic Blend:

- Description: Synthetic blend oil is a mixture of conventional and synthetic oils.

- Pros: It offers a balance between cost and performance, providing better protection than conventional oil at a lower price than full synthetic oil.

- Cons: It does not offer the same level of protection as full synthetic oil.

- Best For: Vehicles that require better protection than conventional oil but don’t necessarily need full synthetic oil.

- High Mileage Oil:

- Description: High mileage oil is formulated for vehicles with over 75,000 miles.

- Pros: It contains additives that help reduce oil leaks, condition seals, and clean sludge deposits.

- Cons: It is not necessary for vehicles with low mileage.

- Best For: Vehicles with over 75,000 miles.

| Oil Type | Description | Pros | Cons |

|---|---|---|---|

| Conventional | Refined from crude oil. | Most affordable option. | Less protection; requires more frequent changes. |

| Synthetic | Engineered in a lab for superior lubrication. | Better resistance to high temperatures; reduces friction; extends oil change intervals. | More expensive. |

| Synthetic Blend | Mixture of conventional and synthetic oils. | Balance between cost and performance. | Less protection than full synthetic. |

| High Mileage | Formulated for vehicles with over 75,000 miles; contains additives to reduce leaks, condition seals, and clean sludge. | Reduces oil leaks; conditions seals; cleans sludge deposits. | Not necessary for low mileage vehicles. |

6.2. Determining the Right Oil

- Consult Your Owner’s Manual: The owner’s manual specifies the recommended oil type and viscosity for your vehicle.

- Consider Your Driving Conditions: If you drive in extreme conditions, such as hot weather, cold weather, or heavy traffic, you may need to use a higher-quality oil.

- Talk to a Professional Mechanic: A professional mechanic can recommend the best oil for your vehicle based on its age, condition, and driving conditions.

6.3. Establishing a Maintenance Schedule

- Follow Manufacturer Recommendations: The manufacturer’s recommended maintenance schedule provides guidelines for oil changes, filter replacements, and other essential maintenance tasks.

- Adjust for Driving Conditions: If you drive in extreme conditions, you may need to perform maintenance more frequently.

- Keep Records: Keep records of all maintenance performed on your vehicle, including oil changes, filter replacements, and other repairs.

6.4. Sample Maintenance Schedule

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 to 7,500 miles for conventional oil; every 7,500 to 10,000 miles for synthetic oil. |

| Oil Filter Replacement | With every oil change. |

| Air Filter Replacement | Every 12,000 to 15,000 miles. |

| Spark Plug Replacement | Every 30,000 to 100,000 miles, depending on the type of spark plug. |

| Coolant Flush | Every 30,000 to 50,000 miles. |

| Brake Fluid Flush | Every 2 to 3 years. |

6.5. Oil Viscosity

- Importance: Viscosity is the oil’s resistance to flow. Using the correct viscosity ensures proper lubrication at different temperatures.

- Reading Viscosity Grades:

- Example: 5W-30

- “W”: Stands for Winter. The number before “W” indicates the oil’s viscosity at low temperatures. Lower numbers mean the oil flows more easily in cold weather.

- Second Number: The number after the “W” indicates the oil’s viscosity at high temperatures. Higher numbers mean the oil remains thicker at high temperatures.

- Consulting the Manual: Always use the viscosity grade recommended in your vehicle’s owner’s manual.

6.6. The Role of Additives

- Detergents: Clean engine parts and prevent sludge buildup.

- Dispersants: Keep contaminants suspended in the oil to prevent them from forming deposits.

- Anti-Wear Additives: Reduce friction and wear between engine parts.

- Viscosity Index Improvers: Help maintain oil viscosity over a wide temperature range.

- Friction Modifiers: Improve fuel economy by reducing friction.

6.7. Utilizing CARDIAGTECH.NET Resources

CARDIAGTECH.NET offers a range of resources to help you choose the right oil and maintenance schedule for your vehicle. We provide expert advice, product recommendations, and high-quality tools to assist with your maintenance tasks. Contact us via WhatsApp at +1 (641) 206-8880 for personalized assistance.

By understanding the different types of oil, determining the right oil for your vehicle, and establishing a consistent maintenance schedule, you can prolong engine life and prevent oil-related issues.

7. The Role of Oil Pressure and Its Impact on Engine Performance

How does oil pressure affect engine performance? Maintaining proper oil pressure is vital for optimal engine performance and longevity. According to research from the University of Tokyo, consistent and adequate oil pressure ensures that all engine components receive the necessary lubrication, preventing wear and tear.

Maintaining proper oil pressure is crucial for optimal engine performance and longevity. Oil pressure ensures that all engine components receive the necessary lubrication to prevent wear and tear.

7.1. Understanding Oil Pressure

- Definition: Oil pressure is the force that pushes oil through the engine’s oil passages, ensuring that all moving parts are properly lubricated.

- Importance: Adequate oil pressure is essential for preventing metal-to-metal contact between engine components, reducing friction and wear.

7.2. Factors Affecting Oil Pressure

- Oil Viscosity: Thicker oils tend to produce higher oil pressure, while thinner oils produce lower oil pressure.

- Oil Temperature: As oil temperature increases, viscosity decreases, resulting in lower oil pressure.

- Engine Speed: Oil pressure typically increases with engine speed, as the oil pump spins faster and delivers more oil.

- Oil Pump Condition: A worn or damaged oil pump may not be able to generate adequate oil pressure.

- Oil Leaks: Oil leaks can reduce oil pressure by allowing oil to escape from the engine.

7.3. Symptoms of Low Oil Pressure

- Oil Pressure Warning Light: The oil pressure warning light on the dashboard may illuminate, indicating low oil pressure.

- Engine Noises: Unusual engine noises, such as knocking or ticking, may indicate that engine components are not receiving adequate lubrication.

- Reduced Engine Performance: Low oil pressure can lead to reduced engine power and acceleration.

- Overheating: Insufficient lubrication can cause engine components to overheat.

7.4. Causes of Low Oil Pressure

- Low Oil Level: The most common cause of low oil pressure is simply a low oil level.

- Oil Leaks: Oil leaks can reduce oil pressure by allowing oil to escape from the engine.

- Worn Oil Pump: A worn or damaged oil pump may not be able to generate adequate oil pressure.

- Clogged Oil Filter: A clogged oil filter can restrict oil flow and reduce oil pressure.

- Worn Engine Bearings: Worn engine bearings can increase the clearance between moving parts, reducing oil pressure.

- Incorrect Oil Viscosity: Using an oil with the wrong viscosity can affect oil pressure