How to Fix a Frame on a Car Professionally

Frame damage compromises your vehicle’s structural integrity after a significant impact. While hoping to avoid such incidents, minor accidents and the resulting repairs are part of car ownership. At CARDIAGTECH.NET, we provide the tools and know-how to restore your vehicle’s frame safely and effectively, offering peace of mind on the road. Remember, proper alignment and structural integrity are key, enhanced by precision measuring.

1. Understanding the Car Frame and Its Importance

Think of your car’s frame as its backbone. It’s much more than just a part; it ensures the doors align perfectly when closed, supports the engine and bumpers, and provides a robust foundation for the entire vehicle. A damaged or bent frame, often resulting from collisions, significantly impacts road safety and can render your car undrivable without professional intervention.

Modern vehicles incorporate “crumple zones” designed to absorb impact during accidents, safeguarding passengers. However, depending on the severity of the incident, the frame may still sustain damage, leading you to consider repair options. Let’s explore how to address this issue effectively.

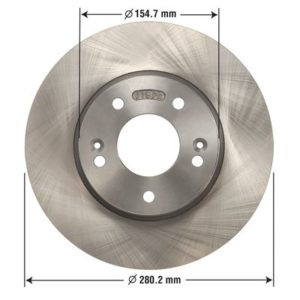

Car frame showing its importance

Car frame showing its importance

2. Assessing DIY Car Frame Repair: When is it Acceptable?

Tackling car frame repair yourself might seem tempting, but safety should always be your top priority. Minor damage like dents, dings, or a slightly crumpled hood might be manageable with the right tools and approach. However, proceed with caution and consider the potential risks.

Having professional-grade tools can significantly improve the outcome and safety of your DIY attempts. Consider using a frame straightener, along with accessories like a pulling post, chains, clamps, and anchor pots. These tools, available at CARDIAGTECH.NET, can help you achieve better results while minimizing the risk of further damage.

Remember, while minor cosmetic issues are often manageable, any structural damage or concerns about internal components like the radiator, brakes, or steering necessitate professional attention. Never compromise safety for the sake of DIY repair.

3. Identifying Situations Requiring Professional Car Frame Straightening

Most instances of car frame damage necessitate the expertise of a qualified auto body repair professional. Internal issues with brakes, steering, or the radiator could pose significant safety risks if not addressed correctly. Entrusting the repair to professionals ensures a comprehensive assessment and precise restoration.

Auto body shops employ specialized tools like frame racks and computerized measuring equipment to restore the damaged frame to its original specifications. Achieving proper alignment requires meticulous measurements and expertise. Attempting to straighten a severely bent frame without these resources can lead to further complications and compromise the vehicle’s safety.

4. Essential Tools and Equipment for Professional Car Frame Repair

For auto body shops aiming to expand their frame straightening capabilities, CARDIAGTECH.NET offers a comprehensive range of tools and equipment. These include:

- Frame Racks: Providing a stable platform for aligning and straightening frames.

- Measuring Equipment: Ensuring accurate measurements for precise restoration.

- Pulling Posts: Facilitating controlled pulling and straightening of damaged areas.

- Chains and Clamps: Securing the frame and applying force for realignment.

- Welding Equipment: For repairing cracks and reinforcing weakened areas.

Investing in high-quality tools from CARDIAGTECH.NET enables auto body shops to deliver reliable and safe frame repair services, restoring vehicles to their pre-accident condition.

5. Step-by-Step Guide to Fixing a Frame on a Car

Fixing a car frame requires precision, expertise, and the right equipment. Here’s a simplified step-by-step guide for professionals:

- Assessment: Thoroughly inspect the damage, identifying all affected areas and hidden issues.

- Measurement: Utilize computerized measuring systems to determine the extent of misalignment and establish reference points.

- Anchoring: Secure the vehicle to a frame rack, ensuring stability and proper alignment.

- Pulling: Employ pulling posts, chains, and clamps to gradually straighten the frame, following precise measurements.

- Welding: Repair any cracks or weakened areas using professional welding techniques.

- Realignment: Re-measure the frame to verify alignment with factory specifications.

- Finishing: Apply corrosion protection and refinishing to restore the frame’s appearance and durability.

This process demands meticulous attention to detail and adherence to safety protocols. Auto body professionals rely on their skills and experience to execute each step effectively, ensuring the vehicle’s structural integrity is fully restored.

6. Utilizing Frame Straightening Machines for Precise Repairs

Frame straightening machines are indispensable tools for auto body professionals, offering precise control and accuracy in restoring damaged frames. These machines employ hydraulic power and computerized measuring systems to realign frames to factory specifications.

Benefits of using frame straightening machines include:

- Accuracy: Achieving precise measurements and alignment, ensuring structural integrity.

- Efficiency: Streamlining the repair process, reducing labor time and costs.

- Versatility: Accommodating various vehicle types and frame designs.

- Safety: Providing a controlled environment for safe and effective repairs.

Investing in a high-quality frame straightening machine from CARDIAGTECH.NET empowers auto body shops to deliver superior repair services, earning customer trust and loyalty.

7. Techniques for Straightening Bent Car Frames

Straightening a bent car frame requires a combination of skill, experience, and specialized techniques. Here are some common methods employed by professionals:

- Hydraulic Pulling: Using hydraulic rams and chains to apply controlled force to bent areas, gradually straightening the frame.

- Heat Application: Applying heat to specific areas to soften the metal, making it easier to manipulate and reshape.

- Hammering and Dolly Work: Employing hammers and dollies to reshape minor dents and imperfections, restoring the frame’s original contours.

- Welding and Reinforcement: Welding cracks and reinforcing weakened areas to ensure structural integrity and prevent future failures.

Each technique requires careful consideration and precise execution to avoid causing further damage to the frame. Auto body professionals undergo extensive training to master these methods, ensuring reliable and long-lasting repairs.

8. Ensuring Accurate Measurements and Alignment

Accurate measurements and alignment are paramount in car frame repair. Even slight deviations can compromise the vehicle’s handling, stability, and safety. Professionals employ various tools and techniques to ensure precise alignment, including:

- Computerized Measuring Systems: Utilizing laser scanners and software to create detailed 3D models of the frame, identifying deviations from factory specifications.

- Tram Gauges: Employing mechanical gauges to measure distances between reference points, verifying alignment and symmetry.

- Levels and Plumb Bobs: Using levels and plumb bobs to ensure the frame is square and level, preventing handling issues and uneven tire wear.

By meticulously measuring and aligning the frame, auto body professionals ensure the vehicle’s structural integrity is fully restored, providing customers with a safe and reliable driving experience.

9. Welding Techniques for Car Frame Repair

Welding plays a crucial role in car frame repair, allowing professionals to repair cracks, reinforce weakened areas, and fabricate custom components. Common welding techniques used in frame repair include:

- MIG Welding (Gas Metal Arc Welding): A versatile and efficient process suitable for welding various types of steel, providing strong and clean welds.

- TIG Welding (Gas Tungsten Arc Welding): A precise and controlled process ideal for welding thin materials and creating high-quality welds with minimal spatter.

- Stick Welding (Shielded Metal Arc Welding): A portable and cost-effective process suitable for welding in various conditions, often used for repairing heavy-duty frames.

Each welding technique requires specific equipment and expertise to achieve optimal results. Auto body professionals undergo extensive training to master these methods, ensuring strong and durable welds that restore the frame’s structural integrity.

10. Preventing Future Car Frame Damage

While accidents are often unavoidable, there are steps you can take to minimize the risk of car frame damage:

- Safe Driving Practices: Obeying traffic laws, maintaining a safe following distance, and avoiding distractions while driving.

- Regular Maintenance: Keeping your vehicle properly maintained, including checking tire pressure, brakes, and suspension components.

- Avoiding Hazards: Being aware of road hazards such as potholes, debris, and construction zones, and taking evasive action when necessary.

- Protective Measures: Installing protective accessories such as bumper guards and frame sliders to minimize damage in minor collisions.

By adopting these preventative measures, you can reduce the likelihood of car frame damage and ensure your vehicle remains safe and reliable for years to come.

11. Cost Considerations for Car Frame Repair

The cost of car frame repair can vary significantly depending on the extent of the damage, the type of vehicle, and the labor rates in your area. Factors influencing the cost include:

- Severity of Damage: Minor dents and dings may cost a few hundred dollars to repair, while severe frame damage can cost thousands.

- Vehicle Type: Luxury vehicles and SUVs often have higher repair costs due to specialized parts and labor requirements.

- Labor Rates: Labor rates vary depending on the location and reputation of the auto body shop.

- Insurance Coverage: If the damage is covered by insurance, your out-of-pocket expenses may be limited to your deductible.

Obtaining multiple estimates from reputable auto body shops can help you compare prices and ensure you’re getting a fair deal.

12. Choosing the Right Auto Body Shop for Frame Repair

Selecting the right auto body shop for frame repair is crucial for ensuring a safe and reliable outcome. Consider the following factors when making your decision:

- Reputation: Look for shops with positive reviews, testimonials, and certifications from industry organizations.

- Experience: Choose a shop with extensive experience in frame repair, particularly with your vehicle’s make and model.

- Equipment: Ensure the shop has state-of-the-art frame straightening equipment and computerized measuring systems.

- Warranty: Inquire about warranties on parts and labor, providing peace of mind and protection against future issues.

By carefully evaluating these factors, you can select an auto body shop that meets your needs and delivers exceptional results.

13. Understanding Frame Straightening Techniques and Equipment

Frame straightening is a complex process that requires specialized techniques and equipment. Here’s an overview of the tools and methods used by professionals:

| Equipment | Description |

|---|---|

| Frame Racks | Provides a stable platform for anchoring and aligning vehicles during frame repair. |

| Pulling Posts | Used to apply controlled force to bent areas, gradually straightening the frame. |

| Chains and Clamps | Secures the frame and applies tension for realignment. |

| Measuring Systems | Utilizes laser scanners and software to measure frame dimensions and identify deviations from factory specifications. |

| Welding Equipment | Repairs cracks and reinforces weakened areas, ensuring structural integrity. |

| Hydraulic Rams | Used to apply controlled force to bend the metal back into shape. |

Understanding these techniques and equipment can help you communicate effectively with auto body professionals and make informed decisions about your vehicle’s repair.

14. Restoring Structural Integrity with Frame Repair

The primary goal of car frame repair is to restore the vehicle’s structural integrity, ensuring it meets safety standards and performs as intended. By straightening bent frames, repairing cracks, and reinforcing weakened areas, auto body professionals ensure the vehicle can withstand impact and provide occupants with adequate protection in the event of a collision.

Restoring structural integrity also improves the vehicle’s handling, stability, and ride quality, providing a safe and comfortable driving experience. Entrusting frame repair to qualified professionals ensures your vehicle is restored to its pre-accident condition, providing peace of mind and confidence on the road.

15. Benefits of Professional Car Frame Straightening

Choosing professional car frame straightening offers numerous benefits compared to DIY attempts or subpar repairs:

- Safety: Ensuring the vehicle meets safety standards and provides occupants with adequate protection.

- Accuracy: Achieving precise alignment and measurements, restoring the vehicle’s handling and stability.

- Durability: Repairing cracks and reinforcing weakened areas, preventing future failures and extending the vehicle’s lifespan.

- Value: Maintaining the vehicle’s resale value by restoring it to its pre-accident condition.

Investing in professional car frame straightening is a worthwhile investment that protects your safety, preserves your vehicle’s value, and provides peace of mind on the road.

16. The Importance of Frame Alignment for Vehicle Safety

Proper frame alignment is critical for vehicle safety, affecting handling, stability, and overall performance. Misaligned frames can lead to:

- Uneven Tire Wear: Causing premature tire wear and reducing traction.

- Handling Issues: Making the vehicle difficult to steer and control, particularly in emergency situations.

- Suspension Problems: Straining suspension components and reducing their lifespan.

- Compromised Safety: Reducing the vehicle’s ability to withstand impact and protect occupants in a collision.

Ensuring proper frame alignment is essential for maintaining vehicle safety and preventing accidents. Auto body professionals use specialized equipment and techniques to verify and correct frame alignment, providing customers with a safe and reliable driving experience.

17. Advanced Car Frame Repair Techniques

Advanced car frame repair techniques push the boundaries of traditional methods, offering innovative solutions for complex damage scenarios. These techniques include:

- Unibody Repair: Restoring the structural integrity of unibody vehicles, which rely on a single integrated structure for strength and stability.

- Sectioning: Replacing damaged sections of the frame with new or salvaged components, preserving the integrity of the remaining structure.

- Carbon Fiber Repair: Repairing carbon fiber frames using specialized techniques and materials, maintaining the vehicle’s lightweight and high-performance characteristics.

- 3D Printing: Utilizing 3D printing technology to create custom repair components and jigs, enabling precise and efficient repairs.

These advanced techniques require specialized training and equipment, representing the cutting edge of car frame repair technology. Auto body shops that invest in these technologies can offer customers innovative solutions for even the most challenging repair scenarios.

18. The Role of Technology in Modern Car Frame Repair

Technology plays an increasingly vital role in modern car frame repair, enhancing accuracy, efficiency, and safety. Advancements in technology include:

- Computerized Measuring Systems: Providing precise measurements and analysis of frame damage, enabling accurate repairs.

- Virtual Reality (VR) Training: Simulating real-world repair scenarios for training purposes, enhancing skills and reducing errors.

- Artificial Intelligence (AI): Assisting in damage assessment and repair planning, optimizing the repair process and reducing costs.

- Robotics: Automating certain repair tasks, such as welding and painting, improving efficiency and consistency.

Embracing technology is essential for auto body shops looking to stay competitive and deliver superior repair services. By investing in cutting-edge tools and training, shops can enhance their capabilities and provide customers with innovative solutions for their car frame repair needs.

19. Choosing the Right Tools for DIY Car Frame Repair

If you decide to tackle minor car frame repair yourself, selecting the right tools is crucial for achieving safe and effective results. Essential tools for DIY frame repair include:

| Tool | Description |

|---|---|

| Hydraulic Jack | Lifts the vehicle safely and provides access to the frame. |

| Pulling Post | Provides an anchor point for pulling and straightening bent areas. |

| Chains and Clamps | Secures the frame and applies tension for realignment. |

| Hammer and Dolly Set | Reshapes minor dents and imperfections. |

| Safety Glasses | Protects your eyes from debris and sparks. |

Before attempting any DIY frame repair, be sure to research proper techniques, follow safety precautions, and assess your skills and capabilities. If in doubt, consult with a professional auto body technician to avoid causing further damage or compromising your safety.

CARDIAGTECH.NET offers a wide selection of high-quality tools for both professional and DIY car frame repair, ensuring you have the right equipment for the job.

20. Maintaining Car Frame Integrity Through Regular Inspections

Regular car frame inspections are essential for identifying potential issues early and preventing costly repairs down the road. During an inspection, technicians should look for:

- Rust and Corrosion: Inspecting the frame for signs of rust and corrosion, which can weaken the metal and compromise its structural integrity.

- Cracks and Bends: Examining the frame for cracks and bends, which can indicate previous damage or stress.

- Loose Components: Checking for loose bolts, brackets, and other components, which can affect the frame’s stability and alignment.

- Damaged Welds: Inspecting welds for cracks or porosity, which can weaken the frame and compromise its strength.

Addressing these issues promptly can prevent further damage and ensure your vehicle remains safe and reliable for years to come.

Don’t let frame damage compromise your vehicle’s safety and performance. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET for expert advice and top-quality tools. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you restore your car’s frame to its original condition and ensure your peace of mind on the road.

FAQ: How to Fix a Frame on a Car

1. What is car frame damage?

Car frame damage refers to any structural compromise to the vehicle’s underlying support system, often resulting from collisions or impacts.

2. Can I fix car frame damage myself?

Minor damage like dents may be repairable DIY, but significant structural damage requires professional expertise.

3. What tools are needed for professional car frame repair?

Essential tools include frame racks, pulling posts, computerized measuring systems, welding equipment, and hydraulic rams.

4. How do professionals straighten a bent car frame?

Professionals use hydraulic pulling, heat application, hammering, and welding techniques to restore the frame’s original shape.

5. How important is accurate measurement in frame repair?

Accurate measurement is critical to ensure proper alignment, handling, and safety of the vehicle.

6. What are the benefits of professional car frame straightening?

Professional straightening ensures safety, accuracy, durability, and maintains the vehicle’s resale value.

7. How can I prevent future car frame damage?

Practice safe driving, maintain regular maintenance, avoid hazards, and consider protective measures.

8. How much does car frame repair typically cost?

Costs vary based on the severity of damage, vehicle type, and labor rates, ranging from a few hundred to several thousand dollars.

9. How do I choose the right auto body shop for frame repair?

Look for shops with a good reputation, experienced technicians, advanced equipment, and warranty options.

10. What is the role of technology in modern car frame repair?

Technology enhances accuracy, efficiency, and safety through computerized measuring systems, VR training, AI, and robotics.