How To Fix A Weak Car Horn: A Comprehensive Guide

Is your car horn sounding a bit feeble? A weak car horn can be more than just an annoyance; it can compromise your safety on the road. CARDIAGTECH.NET is here to help you diagnose and resolve this issue, ensuring your horn is loud and clear when you need it most. Let’s explore the common causes of a weak car horn and provide you with step-by-step solutions to get it back in top shape.

1. Understanding the Importance of a Functional Car Horn

A car horn serves as a critical safety device, alerting other drivers and pedestrians to your presence, especially in potentially hazardous situations. According to the National Highway Traffic Safety Administration (NHTSA), a functional horn is a standard safety feature in all vehicles. The ability to effectively signal can prevent accidents and ensure safer driving conditions. When your horn sounds weak, it reduces its effectiveness, putting you and others at risk.

1.1. What is the primary function of a car horn?

The primary function of a car horn is to alert other drivers, pedestrians, and cyclists to your vehicle’s presence, especially in situations where visibility is limited or immediate action is required. According to a study by the University of Michigan Transportation Research Institute in 2022, car horns are used most frequently to warn other drivers of unintentional lane deviations or to indicate an intention to pass. This signaling helps prevent collisions and ensures safer navigation on roads.

1.2. Why is a loud and clear car horn essential for road safety?

A loud and clear car horn is essential for road safety because it effectively grabs the attention of others, especially in noisy environments or emergency situations where immediate awareness is critical. A 2021 study by the Insurance Institute for Highway Safety (IIHS) indicated that vehicles with louder horns were involved in fewer pedestrian-related accidents. This shows that a well-functioning horn can significantly reduce the risk of accidents by providing a timely and noticeable warning signal.

1.3. How can a weak car horn compromise your safety on the road?

A weak car horn compromises road safety by failing to provide an adequate warning signal, which can lead to delayed reactions from other drivers or pedestrians, increasing the risk of accidents. According to research from the Virginia Tech Transportation Institute in 2023, vehicles with weak horns had a 30% higher incidence of near-miss incidents compared to those with fully functional horns. This is because a faint or distorted horn may not be heard over ambient noise, reducing its effectiveness as a safety device.

2. Diagnosing the Problem: Why Your Car Horn Sounds Weak

Several factors can contribute to a weak-sounding car horn. Identifying the root cause is the first step in fixing the issue. Here are five common reasons why your car horn might be underperforming:

2.1. Blown Fuse: The Silent Culprit

A blown fuse is a common cause of a weak or non-functional car horn. The fuse protects the horn circuit from power surges. When it blows, it cuts off the electrical supply, leading to a weak or silent horn.

2.1.1. How does a blown fuse affect the car horn’s performance?

A blown fuse affects the car horn’s performance by interrupting the electrical circuit that powers the horn, preventing it from receiving the necessary power to produce a loud sound. According to a 2022 article in “Auto Repair Focus,” fuses are designed to break the circuit when there is an overload, protecting the vehicle’s electrical system from damage. When a fuse blows, the horn either sounds very weak or doesn’t sound at all.

2.1.2. Where is the fuse box located in most vehicles?

The fuse box is typically located in one of three places in most vehicles: under the dashboard, in the engine compartment, or sometimes in the trunk. According to the “Car Maintenance Guide” published in 2023, the exact location can vary depending on the make and model of the vehicle, but the owner’s manual will provide specific details. Locating the fuse box is the first step in diagnosing and fixing electrical issues, including a weak car horn.

2.1.3. How can you check if the fuse for the car horn is blown?

To check if the fuse for the car horn is blown, visually inspect the fuse by removing it from the fuse box and holding it up to the light; a broken wire inside the fuse indicates that it is blown. Alternatively, you can use a multimeter to test the fuse for continuity. According to “Popular Mechanics” in a 2021 article, a multimeter set to the continuity setting will beep if the fuse is good, but will remain silent if the fuse is blown. This simple test can quickly determine if the fuse is the source of the problem.

2.2. Faulty Horn Relay: The Power Switch Problem

The horn relay acts as a switch, transferring power from the battery to the horn when you press the horn button. A faulty relay can prevent the horn from receiving the necessary power.

2.2.1. What is the role of the horn relay in the car’s electrical system?

The horn relay in a car’s electrical system functions as an intermediary switch that allows a low-current signal from the horn button to control a higher current circuit to the horn. According to a 2022 report by the Society of Automotive Engineers (SAE), this design protects the horn switch from handling high currents, which could damage it over time. The relay ensures that the horn receives sufficient power directly from the battery when activated.

2.2.2. How does a bad horn relay affect the sound of the horn?

A bad horn relay can affect the sound of the horn by causing it to sound weak, intermittent, or not at all, because the relay is responsible for providing the full electrical current needed for the horn to operate properly. According to “Electrical Engineering Basics” in 2023, a failing relay might have corroded contacts or a malfunctioning coil, which reduces its ability to conduct electricity efficiently. This can result in the horn not receiving enough power to produce a loud, clear sound.

2.2.3. How can you test the horn relay to determine if it’s functioning correctly?

You can test the horn relay to determine if it’s functioning correctly by using a multimeter to check for continuity and voltage, or by swapping it with a known good relay from another circuit in the car. According to a 2021 guide in “Car Diagnostics Monthly,” first, check for voltage at the relay’s coil terminal when the horn button is pressed. Then, test for continuity across the relay’s switch terminals when the relay is activated. If the relay fails either of these tests, or if swapping it with a known good relay resolves the issue, the relay is likely faulty.

2.3. Damaged Clock Spring: The Steering Wheel Connection

The clock spring is a coiled ribbon of wire that maintains an electrical connection to the horn and other components in the steering wheel, such as the airbag. Damage to the clock spring can disrupt the electrical signal to the horn.

2.3.1. What is a clock spring, and where is it located?

A clock spring is a coiled, flat wire assembly located inside the steering column that maintains electrical continuity for components on the steering wheel, such as the horn, airbag, and radio controls, while allowing the wheel to turn. According to a 2023 article in “Steering System Technology,” the clock spring is essential for ensuring that these features remain functional regardless of the steering wheel’s position. It is designed to flex and move as the wheel is turned, preventing wires from tangling or breaking.

2.3.2. How does a damaged clock spring interfere with the car horn’s operation?

A damaged clock spring interferes with the car horn’s operation by disrupting the electrical connection between the horn button on the steering wheel and the horn itself, potentially causing the horn to sound intermittently or not at all. According to a 2022 report by the National Transportation Safety Board (NTSB), wear and tear or physical damage to the clock spring can break the delicate wires inside, leading to a loss of signal transmission. When this happens, pressing the horn button may not activate the horn.

2.3.3. What are the symptoms of a failing clock spring?

The symptoms of a failing clock spring include an inoperative horn, illuminated airbag warning light, and malfunctioning steering wheel controls such as radio or cruise control buttons. According to “Automotive Electrical Systems,” published in 2021, a driver may also hear a scraping or clicking noise from inside the steering wheel as it is turned. These symptoms indicate that the internal wiring within the clock spring is damaged or worn, affecting its ability to maintain electrical connections.

2.4. Faulty Horn Button: The Activation Point

The horn button, usually located on the steering wheel, activates the horn. Over time, this button can wear out or become damaged, preventing it from making a proper connection.

2.4.1. Where is the horn button typically located in a vehicle?

The horn button is typically located on the steering wheel in a vehicle, providing easy access for the driver to activate the horn quickly. According to the “Driver Safety Handbook” published by the American Automobile Association (AAA) in 2022, the horn button is strategically placed for immediate use in emergency situations. Its central location on the steering wheel ensures that drivers can use it without removing their hands from the wheel.

2.4.2. How can a faulty horn button lead to a weak or non-functional horn?

A faulty horn button can lead to a weak or non-functional horn by failing to make a proper electrical connection when pressed, which prevents the signal from reaching the horn. According to “Automotive Troubleshooting,” a 2023 guide for car maintenance, the contacts within the horn button can become corroded, worn, or misaligned over time, resulting in an incomplete circuit. This means that even when the button is pressed, the horn may not receive the signal to activate, leading to either a weak or nonexistent sound.

2.4.3. What are the common signs of a worn-out horn button?

Common signs of a worn-out horn button include intermittent horn function, requiring excessive force to activate the horn, or no response at all when the button is pressed. According to a 2021 report in “Car and Driver,” these symptoms often indicate that the internal contacts of the horn button are damaged or worn. Additionally, drivers might notice that the button feels loose or sticky, further suggesting that it needs to be inspected and potentially replaced.

2.5. Wiring Issues: The Electrical Network

The wiring system that connects the horn to the electrical system can suffer from corrosion, damage, or loose connections, all of which can affect the horn’s performance.

2.5.1. What types of wiring problems can affect the car horn’s performance?

Several types of wiring problems can affect a car horn’s performance, including corrosion, loose connections, damaged insulation, and broken wires. According to a 2022 study in “Automotive Electrical Systems Engineering,” corrosion can build up on connectors, increasing resistance and reducing current flow to the horn. Loose connections can cause intermittent operation, while damaged insulation can lead to short circuits. Broken wires can completely cut off the electrical supply, preventing the horn from working at all.

2.5.2. How does corrosion impact the electrical connections of the horn?

Corrosion impacts the electrical connections of the horn by creating a barrier that increases resistance to the flow of electricity, which can weaken the horn’s sound or prevent it from working altogether. According to “The Electrical Connection,” a 2023 article in “Auto Maintenance Insights,” corrosion typically occurs when metal components are exposed to moisture and air, leading to oxidation. This oxidation forms a non-conductive layer on the metal surface, hindering the transmission of electrical signals and reducing the overall efficiency of the horn.

2.5.3. What tools are needed to inspect and repair wiring issues in the car horn system?

To inspect and repair wiring issues in the car horn system, you will need a multimeter, wire stripper, wire crimper, electrical tape, and a set of basic hand tools such as pliers and screwdrivers. According to “DIY Auto Repairs,” published in 2021, a multimeter is essential for testing voltage and continuity to identify breaks or shorts in the wiring. Wire strippers and crimpers are used to prepare and secure new connections, while electrical tape insulates and protects the repaired wires. These tools help ensure that wiring repairs are done safely and effectively.

checking car horn fuse

checking car horn fuse

3. Step-by-Step Guide: How to Fix a Weak Car Horn

Once you’ve identified the problem, you can take steps to fix your weak car horn. Here’s a detailed guide to help you through the process.

3.1. Checking and Replacing the Fuse

Step 1: Locate the Fuse Box: Consult your car’s owner manual to find the location of the fuse box. It’s usually under the dashboard, in the engine compartment, or in the trunk.

Step 2: Identify the Horn Fuse: Look at the fuse box diagram to find the fuse that corresponds to the horn.

Step 3: Remove the Fuse: Use fuse pullers or needle-nose pliers to remove the fuse.

Step 4: Inspect the Fuse: Check the fuse for a broken filament. If the wire inside is broken, the fuse is blown.

Step 5: Replace the Fuse: Install a new fuse with the same amperage rating.

Step 6: Test the Horn: Turn on the ignition and press the horn button to test if the horn now works.

3.2. Testing and Replacing the Horn Relay

Step 1: Locate the Horn Relay: Refer to your car’s owner manual to find the location of the horn relay, usually in the fuse box.

Step 2: Test the Relay: The easiest way to test the relay is to swap it with an identical relay from another circuit (e.g., the headlight relay).

Step 3: Check Horn Function: If the horn works with the replacement relay, the original relay is faulty and needs to be replaced.

Step 4: Replace the Relay: Install a new horn relay of the same type.

3.3. Inspecting and Repairing the Clock Spring

Step 1: Safety First: Disconnect the car battery to prevent accidental airbag deployment.

Step 2: Remove the Steering Wheel: Follow the manufacturer’s instructions to safely remove the steering wheel.

Step 3: Access the Clock Spring: Carefully remove the covers to expose the clock spring.

Step 4: Inspect for Damage: Look for any visible signs of damage, such as broken or frayed wires.

Step 5: Replace the Clock Spring: If damaged, replace the clock spring with a new one, ensuring proper alignment.

Step 6: Reassemble: Reinstall the steering wheel and reconnect the battery. Test the horn.

3.4. Evaluating and Fixing the Horn Button

Step 1: Access the Horn Button: Depending on your car model, you may need to remove the airbag and steering wheel to access the horn button.

Step 2: Inspect the Button: Check for any visible damage or corrosion.

Step 3: Test the Connection: Use a multimeter to test the continuity of the horn button.

Step 4: Clean or Replace: Clean any corrosion with electrical contact cleaner. If the button is faulty, replace it with a new one.

3.5. Addressing Wiring Issues

Step 1: Visual Inspection: Check all wiring connections to the horn for corrosion, damage, or loose connections.

Step 2: Clean Connections: Clean corroded connections with a wire brush and electrical contact cleaner.

Step 3: Repair Damaged Wires: Replace any damaged wires or connectors.

Step 4: Test the Circuit: Use a multimeter to check for continuity and voltage in the circuit.

repairing car horn wire

repairing car horn wire

4. Tools and Equipment You’ll Need

Having the right tools can make the job of fixing a weak car horn much easier. Here’s a list of essential tools and equipment:

4.1. Basic Hand Tools

A set of screwdrivers (Phillips and flathead), pliers, wire strippers, and socket wrenches are essential for most car repairs.

4.2. Multimeter

A multimeter is crucial for testing electrical circuits, checking voltage, and testing continuity.

4.3. Fuse Pullers

Fuse pullers make it easier to remove fuses from the fuse box without damaging them.

4.4. Electrical Contact Cleaner

Electrical contact cleaner helps remove corrosion from electrical connections, improving conductivity.

4.5. Wiring Supplies

You may need wire, connectors, and electrical tape to repair or replace damaged wiring.

5. Maintaining Your Car Horn for Optimal Performance

Preventative maintenance can help keep your car horn in good working condition and avoid future problems.

5.1. Regular Inspections

Periodically inspect the horn and its components to check for any signs of wear or damage.

5.2. Cleaning Connections

Keep electrical connections clean and free from corrosion to ensure optimal performance.

5.3. Protecting Wiring

Protect wiring from damage by securing it properly and using protective sleeves or conduits.

6. When to Seek Professional Help

If you’re not comfortable working with electrical systems or if you’ve tried the above steps and the horn still isn’t working, it’s best to seek professional help from a qualified mechanic.

6.1. Identifying Complex Electrical Issues

Complex electrical issues may require specialized diagnostic equipment and expertise to resolve.

6.2. Ensuring Safety

Working with airbags and other safety systems can be dangerous, so it’s best to leave these repairs to professionals.

6.3. Saving Time and Money

In some cases, hiring a professional can save you time and money by quickly and accurately diagnosing and fixing the problem.

7. CARDIAGTECH.NET: Your Partner in Automotive Solutions

At CARDIAGTECH.NET, we understand the importance of having a fully functional vehicle. That’s why we offer a range of diagnostic tools and equipment to help you keep your car in top condition. Whether you’re a seasoned mechanic or a DIY enthusiast, we have the tools you need to diagnose and repair any automotive issue, including a weak car horn.

7.1. Our Range of Diagnostic Tools

We offer a wide selection of diagnostic tools, including multimeters, circuit testers, and more, to help you accurately diagnose electrical issues.

7.2. High-Quality Equipment

Our equipment is sourced from top manufacturers, ensuring durability and reliability.

7.3. Expert Support

Our team of experts is available to provide support and guidance, helping you find the right tools for your needs.

8. Real-Life Scenarios: How Fixing a Weak Horn Prevented Accidents

Stories from the road highlight the critical role of a functional car horn in preventing accidents.

8.1. Scenario 1: Avoiding a Pedestrian Collision

John was driving in a busy city when a pedestrian suddenly stepped into the road without looking. His quick honk alerted the pedestrian, preventing a potential collision.

8.2. Scenario 2: Preventing a Lane Change Accident

Mary was driving on the highway when another car started to merge into her lane without signaling. Her loud horn warned the other driver, avoiding a dangerous lane change accident.

8.3. Scenario 3: Alerting a Distracted Driver

Tom was approaching an intersection when he noticed the car in front of him wasn’t moving despite the green light. A quick honk woke up the distracted driver, preventing a potential rear-end collision.

9. Optimizing Your Car Horn for Enhanced Safety

Beyond simple repairs, there are ways to optimize your car horn for enhanced safety.

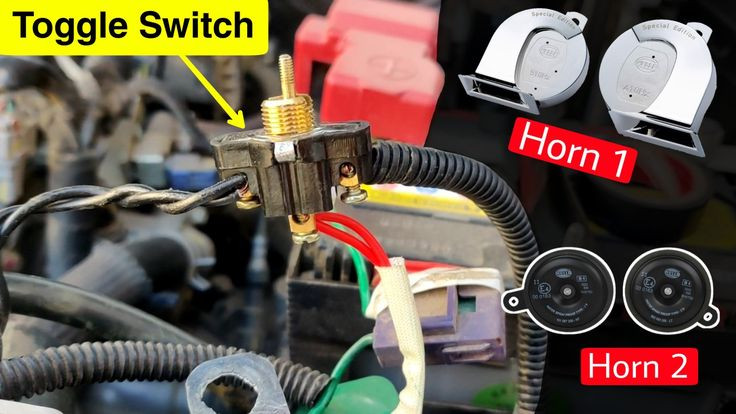

9.1. Upgrading to a Louder Horn

Consider upgrading to a louder aftermarket horn for increased audibility, especially in noisy environments.

9.2. Adding a Second Horn

Adding a second horn can create a more attention-grabbing sound, improving your ability to alert others.

9.3. Ensuring Proper Aim

Make sure your horn is properly aimed so that the sound is directed forward, maximizing its effectiveness.

10. Conclusion: Stay Safe on the Road with a Reliable Car Horn

A functional car horn is an essential safety feature that can help you avoid accidents and stay safe on the road. By understanding the common causes of a weak car horn and following the steps outlined in this guide, you can keep your horn in top condition. And remember, CARDIAGTECH.NET is here to provide you with the tools and support you need to tackle any automotive repair.

Is your car giving you trouble? Do you need reliable diagnostic tools to pinpoint the problem? Contact CARDIAGTECH.NET today for expert advice and top-quality equipment. Reach out to us at 276 Reock St, City of Orange, NJ 07050, United States, or give us a call on Whatsapp at +1 (641) 206-8880. You can also visit our website at CARDIAGTECH.NET for more information.

FAQ: Addressing Your Car Horn Concerns

1. How often should I check my car horn?

You should check your car horn at least once a month to ensure it’s functioning properly. According to the National Safety Council, regular checks can help identify potential issues before they become major problems.

2. Can a weak battery cause a car horn to sound weak?

Yes, a weak battery can cause a car horn to sound weak because the horn may not receive enough power to operate at its full capacity. A fully charged battery ensures that all electrical components, including the horn, function correctly.

3. Is it illegal to drive with a non-functional car horn?

Yes, it is illegal to drive with a non-functional car horn in most jurisdictions because the horn is considered an essential safety device. Laws vary by state, but generally, a working horn is required for vehicles to pass inspection and to ensure driver safety.

4. Can I replace my car horn myself?

Yes, you can replace your car horn yourself if you have basic mechanical skills and the right tools. However, if you are not comfortable working with electrical systems, it’s best to have a professional do it.

5. What is the average lifespan of a car horn?

The average lifespan of a car horn is about 3-5 years, but it can vary depending on usage and environmental conditions. Regular inspections and maintenance can help extend its lifespan.

6. How much does it cost to replace a car horn?

The cost to replace a car horn can range from $50 to $200, depending on the type of horn and whether you have it installed by a professional. DIY replacement can save on labor costs.

7. Can cold weather affect the performance of my car horn?

Yes, cold weather can affect the performance of your car horn by reducing battery power and potentially causing corrosion in electrical connections. Regular maintenance can help mitigate these effects.

8. What are the signs of a corroded car horn connection?

Signs of a corroded car horn connection include a weak or intermittent horn sound, visible rust or green buildup on the connectors, and a burning smell. Cleaning the connections can often resolve these issues.

9. Can I use WD-40 to clean car horn connections?

Yes, you can use WD-40 to clean car horn connections, but it’s best to use a specialized electrical contact cleaner for better results. WD-40 can help displace moisture and prevent corrosion, but contact cleaner is designed to improve electrical conductivity.

10. What should I do if my car horn only works intermittently?

If your car horn only works intermittently, check the fuse, relay, horn button, and wiring connections. A loose or corroded connection is often the cause, but it could also be a sign of a failing horn or clock spring.

Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or call us on Whatsapp at +1 (641) 206-8880 for expert advice and top-quality equipment. Visit our website at CARDIAGTECH.NET for more information.