How To Fix Bearings On A Car: A Complete Guide

Fixing car bearings involves understanding the issue, acquiring the right tools, and following a detailed process. At CARDIAGTECH.NET, we provide the resources and guidance you need to ensure a smooth and safe repair. Whether it’s wheel bearing replacement, diagnosing bearing noise, or understanding the function of bearings, we’ve got you covered with expert insights and superior tools.

1. Identifying Wheel Bearing Problems

Recognizing the signs of a failing wheel bearing early can prevent more significant damage and costly repairs. Wheel bearings are crucial components that allow your car’s wheels to rotate smoothly, supporting the vehicle’s weight and facilitating movement. Understanding what to look for can help you address issues promptly.

1.1 Common Symptoms of a Bad Wheel Bearing

Several symptoms indicate potential problems with your wheel bearings. Being attentive to these signs can help you diagnose issues early.

- Unusual Noises: One of the most common indicators is a grinding, humming, or rumbling noise coming from the wheels. This noise often changes in intensity with speed.

- Vibration: You might feel vibrations in the steering wheel or the car’s floor. These vibrations can be subtle but become more noticeable as speed increases.

- Looseness or Play: If you lift the car and try to wiggle the wheel, excessive play indicates a potential bearing issue.

- Uneven Tire Wear: A faulty wheel bearing can cause the tire to wear unevenly because of the instability in wheel alignment.

- ABS Malfunction: In some cases, a bad wheel bearing can trigger the ABS (Anti-lock Braking System) light due to the sensor being affected.

1.2 Diagnosing the Source of the Noise

Pinpointing the exact wheel bearing causing the problem can save time and effort. Here’s how to effectively diagnose the source of the noise:

- Road Test: Drive the vehicle at varying speeds to identify when the noise is most prominent. Note whether it increases or decreases during turns.

- Turning Test: Turn the steering wheel sharply to the left and then to the right while driving. If the noise gets louder when turning in one direction, the bearing on the opposite side is likely the culprit.

- Lift and Spin: Safely lift the vehicle with a jack and secure it with jack stands. Spin each wheel by hand and listen for any grinding or rough sounds. Also, check for any play by wiggling the wheel.

- Visual Inspection: Remove the wheel and inspect the bearing hub for any signs of damage, such as rust, discoloration, or grease leaks.

- Professional Inspection: If you are unsure, take your vehicle to a trusted mechanic for a thorough inspection. Mechanics can use specialized tools to accurately diagnose the problem.

Alt text: Inspecting a wheel bearing hub for signs of damage and wear

1.3 Understanding Different Types of Wheel Bearings

Familiarizing yourself with the different types of wheel bearings can aid in proper diagnosis and replacement. Here are some common types:

- Ball Bearings: These are used in many passenger vehicles and are designed to handle radial loads.

- Tapered Roller Bearings: Commonly found in heavier vehicles, these bearings can handle both radial and axial loads.

- Hub Assembly Bearings: These are pre-packaged units that include the bearing, hub, and sometimes the ABS sensor. They simplify the replacement process.

- Sealed Bearings: These bearings are designed to keep contaminants out and lubricant in, extending their lifespan.

| Bearing Type | Common Application | Load Handling | Lifespan |

|---|---|---|---|

| Ball Bearings | Passenger Vehicles | Radial Loads | Moderate |

| Tapered Roller | Heavy Vehicles | Radial and Axial Loads | Long |

| Hub Assembly Bearings | Modern Cars | Pre-set Loads | Variable |

| Sealed Bearings | Various Applications | Protected | Extended |

By understanding the types and symptoms associated with wheel bearings, you can better diagnose and address issues, ensuring vehicle safety and performance.

2. Essential Tools and Materials for Bearing Replacement

Having the right tools and materials is crucial for a successful wheel bearing replacement. Using appropriate equipment not only simplifies the process but also ensures the job is done safely and effectively. CARDIAGTECH.NET provides a wide range of high-quality tools to meet your needs.

2.1 List of Necessary Tools

To replace a wheel bearing, you’ll need a specific set of tools. Here’s a comprehensive list:

- Jack and Jack Stands: To safely lift and secure the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

- Lug Wrench: To remove the wheel nuts.

- Socket Set: Various sizes to remove bolts and nuts.

- Wrench Set: For additional fasteners.

- Torque Wrench: To tighten bolts to the manufacturer’s specifications.

- Hammer: To gently tap components into place.

- Pry Bar: To help separate parts that are stuck.

- Wheel Bearing Press Kit: Essential for pressing out the old bearing and pressing in the new one.

- Slide Hammer with Hub Puller Attachment: To remove stubborn hubs.

- Punch and Chisel: To help remove retaining clips and stubborn parts.

- Gloves and Safety Glasses: For personal protection.

2.2 Required Materials

In addition to tools, you’ll need specific materials to complete the job:

- New Wheel Bearing: Ensure it’s the correct part for your vehicle.

- Grease: High-quality grease for lubricating the new bearing.

- Brake Cleaner: To clean the hub and surrounding components.

- Penetrating Oil: To loosen rusted or stuck bolts.

- Shop Rags: To wipe away dirt and grease.

- Threadlocker: To secure bolts and prevent them from loosening.

2.3 Selecting the Right Wheel Bearing Press Kit

A wheel bearing press kit is indispensable for replacing bearings. When selecting a kit, consider the following:

- Compatibility: Ensure the kit is compatible with your vehicle’s make and model.

- Quality: Opt for a kit made from high-quality steel for durability and reliability.

- Versatility: Choose a kit with multiple adapters to accommodate different bearing sizes and types.

- Ease of Use: Look for a kit with a user-friendly design and clear instructions.

CARDIAGTECH.NET offers wheel bearing press kits designed for both professional mechanics and DIY enthusiasts, ensuring you have the right tool for the job.

Alt text: Components of a wheel bearing press kit

**2.4 Safety Equipment

Safety should be a top priority when working on any automotive repair. Essential safety equipment includes:

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands from grease, oil, and sharp edges.

- Hearing Protection: If using power tools that generate loud noise.

- Proper Ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes.

Investing in the right tools and materials, along with adhering to safety precautions, ensures a smooth and safe wheel bearing replacement process. CARDIAGTECH.NET is your trusted partner for providing the equipment and resources needed for successful auto repairs.

3. Step-by-Step Guide to Replacing a Wheel Bearing

Replacing a wheel bearing requires careful attention to detail. This step-by-step guide will walk you through the process. Always consult your vehicle’s repair manual for specific instructions.

3.1 Preparation and Safety Measures

Before starting, ensure the vehicle is safely secured and you have all the necessary tools and materials.

- Secure the Vehicle: Park the vehicle on a level surface, engage the parking brake, and use wheel chocks behind the rear wheels.

- Loosen Lug Nuts: Use a lug wrench to loosen the lug nuts on the wheel of the affected bearing.

- Lift the Vehicle: Use a jack to lift the vehicle and place jack stands securely under the frame. Never work under a vehicle supported only by a jack.

- Remove the Wheel: Fully unscrew the lug nuts and remove the wheel.

3.2 Removing the Old Wheel Bearing

Removing the old wheel bearing can be challenging, especially if it’s rusted or seized.

- Remove Brake Components: Disconnect the brake caliper and rotor. Secure the caliper out of the way to avoid damaging the brake line.

- Remove the Hub: Depending on the vehicle, you may need to use a slide hammer with a hub puller attachment to remove the hub.

- Access the Bearing: Once the hub is removed, you’ll have access to the wheel bearing.

- Use a Wheel Bearing Press: Position the hub in a wheel bearing press and use the appropriate adapters to press out the old bearing. Ensure the hub is properly supported to avoid damage.

- Clean the Hub: Thoroughly clean the hub with brake cleaner to remove any dirt, rust, or debris.

Alt text: Utilizing a wheel bearing press to remove the old wheel bearing

3.3 Installing the New Wheel Bearing

Installing the new wheel bearing requires precision to ensure proper fit and function.

- Prepare the New Bearing: Apply a thin layer of high-quality grease to the new bearing.

- Position the Hub: Place the hub in the wheel bearing press, ensuring it is properly aligned.

- Press in the New Bearing: Use the press to carefully press the new bearing into the hub. Make sure it is seated correctly and fully.

- Reinstall the Hub: Reattach the hub to the vehicle, ensuring it is properly aligned.

- Reinstall Brake Components: Reattach the brake rotor and caliper, tightening the bolts to the manufacturer’s specifications.

- Reattach the Wheel: Mount the wheel back onto the hub and tighten the lug nuts by hand.

- Lower the Vehicle: Carefully lower the vehicle and remove the jack stands.

- Torque Lug Nuts: Use a torque wrench to tighten the lug nuts to the specified torque.

3.4 Final Checks and Adjustments

After installing the new wheel bearing, perform these checks to ensure everything is working correctly.

- Test Drive: Take the vehicle for a short test drive to check for any unusual noises or vibrations.

- Inspect the Bearing: After the test drive, inspect the bearing for any signs of leaks or overheating.

- Check ABS Functionality: If your vehicle has ABS, ensure the system is functioning correctly.

- Re-torque Lug Nuts: After driving a short distance, re-torque the lug nuts to ensure they are properly tightened.

3.5 Professional Tips for a Smooth Replacement

- Use Penetrating Oil: If bolts are rusted or stuck, apply penetrating oil and let it soak for a few minutes before attempting to remove them.

- Inspect Surrounding Components: Check the condition of the brake components, suspension parts, and other related items while the wheel is off.

- Follow Torque Specifications: Always tighten bolts to the manufacturer’s specified torque to prevent damage or failure.

- Cleanliness is Key: Keep the work area clean to prevent contaminants from entering the new bearing.

Following these steps and tips will help you successfully replace a wheel bearing, ensuring the safety and performance of your vehicle. CARDIAGTECH.NET is here to support you with quality tools and expert advice throughout the process.

4. Diagnosing and Addressing Common Issues After Replacement

Even with careful installation, issues can sometimes arise after replacing a wheel bearing. Knowing how to diagnose and address these problems can save you time and frustration.

4.1 Identifying Unusual Noises

One of the most common post-replacement issues is unusual noise.

- Grinding Noise: This could indicate that the bearing wasn’t pressed in straight or that there’s debris inside the hub.

- Humming Noise: This might suggest that the bearing is too tight or that it’s not properly lubricated.

- Clicking Noise: Clicking sounds, especially when turning, could mean that the axle nut is not properly tightened or that there’s an issue with the CV joint.

4.2 Dealing with Vibration

Vibration can also occur after a wheel bearing replacement.

- Check Wheel Balance: Ensure the wheels are properly balanced to eliminate vibration.

- Inspect Tire Condition: Uneven tire wear or tire damage can cause vibration.

- Verify Bearing Installation: Double-check that the bearing is correctly seated and that all bolts are tightened to the proper torque.

4.3 ABS Light Activation

If the ABS light comes on after replacing the wheel bearing, consider these steps:

- Check ABS Sensor: Ensure the ABS sensor is properly connected and not damaged.

- Inspect Sensor Wire: Look for any breaks or damage in the sensor wire.

- Scan for Codes: Use an OBD-II scanner to check for ABS-related error codes.

Alt text: Inspecting the ABS sensor after replacing a wheel bearing

4.4 Troubleshooting Bearing Overheating

Overheating can lead to premature bearing failure.

- Ensure Proper Lubrication: Verify that the bearing is adequately lubricated with high-quality grease.

- Check for Over-tightening: Make sure the bearing is not over-tightened, as this can cause excessive friction and heat.

- Inspect Brake Components: A sticking brake caliper can cause excessive heat.

4.5 Addressing Loose Wheel Bearings

A loose wheel bearing can compromise safety and performance.

- Check Axle Nut Torque: Ensure the axle nut is tightened to the manufacturer’s specified torque.

- Inspect Bearing Seat: Examine the bearing seat in the hub for any damage or wear.

- Replace Damaged Components: If the hub or spindle is damaged, replace them to ensure proper bearing fit.

4.6 Common Mistakes to Avoid

- Using Incorrect Tools: Always use the correct tools, such as a wheel bearing press, to avoid damaging the bearing or hub.

- Neglecting Lubrication: Proper lubrication is essential for bearing longevity.

- Ignoring Torque Specifications: Always tighten bolts and nuts to the manufacturer’s specified torque.

- Skipping Safety Precautions: Always wear safety glasses and gloves, and ensure the vehicle is properly secured.

By carefully diagnosing and addressing these common post-replacement issues, you can ensure that your new wheel bearing performs optimally. CARDIAGTECH.NET offers the tools and resources you need to troubleshoot and resolve any problems effectively.

5. Maximizing the Lifespan of Wheel Bearings

Extending the life of your wheel bearings involves proactive maintenance and careful driving habits. By following these tips, you can ensure your wheel bearings last longer and perform optimally.

5.1 Regular Maintenance Practices

- Proper Lubrication: Ensure that wheel bearings are adequately lubricated. Periodically check and replenish grease as needed.

- Regular Inspections: Inspect wheel bearings during routine maintenance checks for any signs of wear, damage, or play.

- Torque Checks: Regularly check and re-torque axle nuts and hub assembly bolts to ensure they are tightened to the manufacturer’s specifications.

- Wheel Alignment: Maintain proper wheel alignment to prevent uneven wear on the bearings.

5.2 Driving Habits That Affect Bearing Life

Your driving habits significantly impact the lifespan of wheel bearings.

- Avoid Potholes: Reduce impacts by avoiding potholes and rough road surfaces.

- Smooth Driving: Practice smooth acceleration and braking to minimize stress on the bearings.

- Avoid Overloading: Do not exceed the vehicle’s maximum load capacity to prevent excessive strain on the bearings.

- Gentle Cornering: Take corners at a moderate speed to reduce lateral forces on the wheel bearings.

5.3 Choosing High-Quality Replacement Parts

- Select Reputable Brands: Opt for wheel bearings from reputable manufacturers known for quality and durability. CARDIAGTECH.NET offers a range of high-quality wheel bearings to meet your needs.

- Correct Specifications: Ensure that the replacement bearings match the exact specifications for your vehicle make and model.

- Consider Material Quality: Look for bearings made from high-quality steel and designed with advanced sealing technology.

Alt text: A high-quality wheel bearing replacement part

5.4 Environmental Factors

- Road Salt: Minimize exposure to road salt and corrosive materials, which can accelerate bearing wear.

- Water Exposure: Avoid driving through deep water, as water can contaminate the bearing lubricant.

- Regular Cleaning: Periodically clean the undercarriage of your vehicle to remove accumulated dirt and debris.

5.5 Storage Tips for Seasonal Vehicles

If you store your vehicle for extended periods, follow these tips to protect the wheel bearings:

- Elevate the Vehicle: Place the vehicle on jack stands to take the weight off the wheels and bearings.

- Cover the Wheels: Cover the wheels to protect them from the elements.

- Apply Grease: Before storage, apply a thin layer of grease to the bearings to prevent corrosion.

5.6 Benefits of Proactive Bearing Maintenance

- Extended Bearing Life: Proactive maintenance can significantly extend the life of your wheel bearings.

- Improved Safety: Well-maintained wheel bearings ensure safe and reliable vehicle operation.

- Cost Savings: Preventing bearing failure can save you money on costly repairs and replacements.

- Enhanced Performance: Properly maintained wheel bearings contribute to smoother and more efficient vehicle performance.

By implementing these maintenance practices and adopting careful driving habits, you can maximize the lifespan of your wheel bearings and enjoy a safer and more reliable driving experience. CARDIAGTECH.NET is committed to providing you with the products and information you need to keep your vehicle in top condition.

6. The Role of CARDIAGTECH.NET in Your Auto Repair Journey

CARDIAGTECH.NET is dedicated to providing comprehensive support for all your auto repair needs. From high-quality tools to expert guidance, we are your trusted partner in ensuring successful and safe vehicle maintenance.

6.1 High-Quality Tools and Equipment

CARDIAGTECH.NET offers an extensive selection of tools and equipment specifically designed for automotive repairs.

- Wheel Bearing Press Kits: Our wheel bearing press kits are engineered for durability and precision, making bearing replacement easier and safer.

- Socket and Wrench Sets: We provide a variety of socket and wrench sets to handle any fastener on your vehicle.

- Torque Wrenches: Ensure accurate tightening with our range of torque wrenches, calibrated to meet industry standards.

- Specialty Tools: Find specialized tools like slide hammers, hub pullers, and bearing separators to tackle even the most challenging tasks.

6.2 Expert Guidance and Support

We offer expert guidance and support to help you navigate your auto repair projects.

- Detailed Guides and Tutorials: Access our library of detailed guides and tutorials that walk you through various repair processes step-by-step.

- Technical Support: Contact our knowledgeable technical support team for assistance with tool selection, troubleshooting, and repair advice.

- Online Resources: Explore our online resources, including FAQs, product manuals, and technical specifications.

6.3 Ensuring Safety and Efficiency

CARDIAGTECH.NET prioritizes safety and efficiency in all our products and services.

- Safety Equipment: We offer a range of safety equipment, including safety glasses, gloves, and hearing protection, to keep you safe during repairs.

- Ergonomic Designs: Our tools are designed with ergonomics in mind, reducing fatigue and improving efficiency.

- Durable Materials: We use high-quality materials to ensure our tools withstand the rigors of automotive repair.

Mechanic using tools purchased from CARDIAGTECH.NET

Mechanic using tools purchased from CARDIAGTECH.NET

Alt text: A mechanic utilizing quality tools purchased from CARDIAGTECH.NET

6.4 Customer Satisfaction

Your satisfaction is our top priority.

- Quality Assurance: We stand behind the quality of our products with comprehensive warranties and quality assurance programs.

- Easy Returns: If you’re not completely satisfied with your purchase, take advantage of our hassle-free return policy.

- Customer Reviews: Read customer reviews and testimonials to learn about the experiences of other CARDIAGTECH.NET users.

6.5 Building a Community of Auto Enthusiasts

CARDIAGTECH.NET is more than just a supplier; we’re building a community of auto enthusiasts.

- Forums and Discussions: Join our online forums to connect with other mechanics, share tips, and ask questions.

- Workshops and Training: Attend our workshops and training sessions to enhance your skills and knowledge.

- Social Media: Follow us on social media for the latest updates, product announcements, and automotive tips.

By choosing CARDIAGTECH.NET, you’re investing in high-quality tools, expert guidance, and a commitment to your success. Let us be your trusted partner in your auto repair journey.

7. Understanding the Cost of Wheel Bearing Replacement

Knowing the costs associated with wheel bearing replacement helps you budget effectively and make informed decisions. Several factors influence the overall cost, including parts, labor, and vehicle type.

7.1 Factors Influencing the Cost

- Vehicle Make and Model: The make and model of your vehicle significantly impact the cost of wheel bearing replacement. Some vehicles require more specialized parts or labor, increasing the overall expense.

- Type of Wheel Bearing: Different types of wheel bearings, such as hub assembly bearings versus individual bearings, have varying costs. Hub assembly bearings are generally more expensive but can simplify the replacement process.

- Labor Costs: Labor costs vary depending on the mechanic’s hourly rate and the complexity of the job.

- Location: Prices can differ based on geographic location. Urban areas tend to have higher labor rates compared to rural areas.

- Additional Repairs: If other components, such as the hub, spindle, or ABS sensor, need replacement, this will add to the overall cost.

7.2 Average Cost Breakdown

- Parts Cost: The cost of a wheel bearing typically ranges from $50 to $200 per bearing, depending on the brand and type.

- Labor Cost: Labor costs can range from $150 to $500 per wheel, depending on the complexity of the job and the mechanic’s hourly rate.

- Total Cost: The total cost to replace a wheel bearing can range from $200 to $700 per wheel.

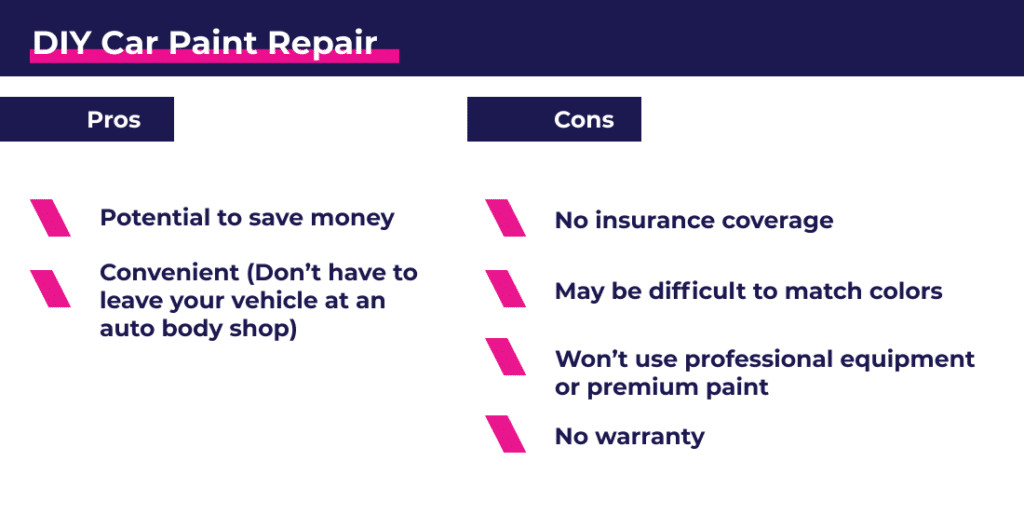

7.3 DIY vs. Professional Replacement

- DIY Advantages: Doing it yourself can save you money on labor costs. However, it requires the right tools, skills, and time.

- Professional Advantages: Hiring a professional ensures the job is done correctly and often comes with a warranty on parts and labor.

| Task | DIY | Professional |

|---|---|---|

| Cost | Lower (parts only) | Higher (parts and labor) |

| Time | More (learning curve) | Less (experience and efficiency) |

| Skill Required | Moderate to High | Low |

| Tools Required | Yes (may need to purchase) | No (provided by the mechanic) |

| Warranty | No | Yes (on parts and labor) |

7.4 Tips for Saving Money on Wheel Bearing Replacement

- Get Multiple Quotes: Obtain quotes from several mechanics to compare prices.

- Use Quality Parts: Invest in high-quality replacement parts to ensure longevity and prevent future repairs.

- Consider DIY: If you have the skills and tools, consider doing the job yourself to save on labor costs.

- Routine Maintenance: Regular maintenance can prevent premature wheel bearing failure and reduce the need for costly replacements.

- Check for Coupons: Look for coupons or discounts from local auto repair shops.

7.5 Long-Term Cost Benefits

- Improved Safety: Replacing a worn wheel bearing enhances vehicle safety and handling.

- Reduced Wear on Other Parts: A faulty wheel bearing can cause excessive wear on other components, such as tires and brakes. Replacing it promptly can prevent these issues.

- Better Fuel Efficiency: A properly functioning wheel bearing contributes to smoother vehicle operation and better fuel efficiency.

Understanding the costs associated with wheel bearing replacement empowers you to make informed decisions and budget effectively. Whether you choose to DIY or hire a professional, CARDIAGTECH.NET is here to support you with quality parts, tools, and expert advice.

8. Understanding Wheel Bearing Function and Importance

Wheel bearings are essential components in your vehicle’s wheel assembly. Understanding their function and importance helps you appreciate their role in ensuring smooth, safe, and efficient driving.

8.1 Basic Function of Wheel Bearings

- Enabling Wheel Rotation: Wheel bearings allow the wheels to rotate freely with minimal friction, enabling smooth vehicle movement.

- Supporting Vehicle Weight: They support the vehicle’s weight and distribute the load evenly across the wheel assembly.

- Reducing Friction: By minimizing friction, wheel bearings prevent overheating and wear on the wheels and axles.

- Ensuring Stability: Wheel bearings contribute to vehicle stability by maintaining proper wheel alignment and reducing play.

8.2 Types of Wheel Bearings

- Ball Bearings: These are typically used in lighter vehicles and consist of a series of balls that roll between two races.

- Tapered Roller Bearings: Commonly found in heavier vehicles, these bearings use tapered rollers to handle both radial and axial loads.

- Needle Roller Bearings: These use cylindrical rollers and are suitable for high-load applications.

- Sealed Bearings: These are designed with seals to protect the bearing from contaminants and retain lubricant.

8.3 Components of a Wheel Bearing Assembly

- Inner Race: The inner ring that fits onto the axle or spindle.

- Outer Race: The outer ring that fits into the hub or housing.

- Rolling Elements: The balls, rollers, or needles that roll between the races.

- Cage: The component that separates and holds the rolling elements in place.

- Seals: The protective barriers that keep out contaminants and retain lubricant.

Alt text: A detailed diagram illustrating a wheel bearing assembly

8.4 Importance of Properly Functioning Wheel Bearings

- Safety: Properly functioning wheel bearings are crucial for vehicle safety, ensuring stable handling and braking.

- Performance: They contribute to smooth and efficient vehicle performance by minimizing friction and ensuring proper wheel rotation.

- Fuel Efficiency: Reduced friction leads to better fuel efficiency, saving you money on gas.

- Reduced Wear: Properly maintained wheel bearings prevent excessive wear on other components, such as tires and brakes.

8.5 Signs of Wheel Bearing Failure

- Unusual Noises: Grinding, humming, or rumbling noises coming from the wheels.

- Vibration: Vibrations in the steering wheel or car floor.

- Looseness or Play: Excessive play when wiggling the wheel.

- Uneven Tire Wear: Uneven wear patterns on the tires.

- ABS Malfunction: The ABS light coming on due to sensor issues.

8.6 Consequences of Neglecting Wheel Bearing Issues

- Increased Risk of Accidents: Worn wheel bearings can lead to unstable handling and increased risk of accidents.

- Damage to Other Components: Neglecting wheel bearing issues can cause damage to other components, such as tires, brakes, and axles.

- Costly Repairs: Over time, neglecting wheel bearing issues can result in more extensive and costly repairs.

8.7 Proactive Maintenance Tips

- Regular Inspections: Inspect wheel bearings during routine maintenance checks.

- Proper Lubrication: Ensure that wheel bearings are adequately lubricated.

- Torque Checks: Regularly check and re-torque axle nuts and hub assembly bolts.

- Careful Driving: Avoid potholes and rough road surfaces.

By understanding the function and importance of wheel bearings, you can take proactive steps to maintain them and ensure the safety and performance of your vehicle. CARDIAGTECH.NET is dedicated to providing you with the knowledge and tools you need to keep your vehicle in top condition.

9. Advanced Techniques for Diagnosing Wheel Bearing Issues

For accurate diagnosis of wheel bearing issues, advanced techniques can provide valuable insights beyond basic inspections. These techniques often involve specialized tools and a deeper understanding of automotive systems.

9.1 Using a Chassis Ear

A chassis ear is a diagnostic tool that allows you to listen to different parts of the vehicle while it is in motion.

- How It Works: The chassis ear consists of multiple microphones that you can attach to different points on the vehicle, such as the wheel hub, suspension components, and axle.

- Pinpointing the Source: While driving, you can switch between the microphones to listen for unusual noises. This helps pinpoint the exact source of the noise, even if it is subtle.

- Interpreting Sounds: Grinding, humming, or clicking noises can indicate wheel bearing issues. By listening closely, you can differentiate between bearing noise and other potential sources of noise, such as the brakes or suspension.

9.2 Performing a Runout Test

A runout test measures the amount of wobble or deviation in the wheel hub or axle.

- Tools Needed: You’ll need a dial indicator and a magnetic base to perform a runout test.

- Procedure: Attach the magnetic base to a fixed point on the suspension and position the dial indicator against the wheel hub. Rotate the hub by hand and observe the dial indicator reading.

- Interpreting Results: Excessive runout can indicate a bent hub or axle, which can cause premature wheel bearing failure. Consult your vehicle’s service manual for acceptable runout specifications.

9.3 Analyzing Vibration Frequencies

Vibration analysis involves measuring and analyzing the frequencies of vibrations in the vehicle.

- Tools Needed: This technique requires a vibration analyzer, which can measure the amplitude and frequency of vibrations.

- Procedure: Attach the vibration analyzer to different points on the suspension and run the vehicle on a lift. The analyzer will measure the vibrations and display them as a frequency spectrum.

- Identifying Issues: Specific vibration frequencies can indicate wheel bearing issues. For example, a frequency that increases with speed may suggest a worn bearing.

9.4 Checking Bearing Temperature

Monitoring the temperature of the wheel bearings can provide insights into their condition.

- Tools Needed: An infrared thermometer is used to measure the temperature of the wheel hub.

- Procedure: After driving the vehicle for a short distance, use the infrared thermometer to measure the temperature of each wheel hub.

- Interpreting Results: A significantly higher temperature on one wheel hub compared to the others can indicate a failing wheel bearing.

9.5 Evaluating ABS Sensor Signals

The ABS (Anti-lock Braking System) sensor can provide information about the condition of the wheel bearing.

- Tools Needed: An oscilloscope or scan tool that can read ABS sensor data is required.

- Procedure: Connect the oscilloscope or scan tool to the ABS sensor and monitor the signal while rotating the wheel.

- Analyzing Signals: An irregular or weak signal can indicate a problem with the ABS sensor or the wheel bearing. Some ABS sensors are integrated into the wheel bearing assembly, so a failing bearing can affect the sensor signal.

9.6 Utilizing Diagnostic Software

Modern diagnostic software can provide detailed information about the vehicle’s systems, including the wheel bearings.

- Capabilities: Diagnostic software can read error codes, monitor sensor data, and perform diagnostic tests.

- Interpreting Data: By analyzing the data provided by the software, you can identify potential wheel bearing issues and other related problems.

By utilizing these advanced diagnostic techniques, you can accurately identify wheel bearing issues and perform targeted repairs. CARDIAGTECH.NET offers a range of diagnostic tools and equipment to help you with your automotive repair needs.

Is your car making strange noises? Experiencing unusual vibrations? Don’t wait until it’s too late. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET for expert advice and the highest quality tools. Our team is ready to help you diagnose and fix your wheel bearing issues efficiently and safely. Located at 276 Reock St, City of Orange, NJ 07050, United States, we are here to provide the solutions you need. Reach out now and let CARDIAGTECH.NET get you back on the road with confidence.

FAQ: How to Fix Bearings on a Car

-

What are the signs of a bad wheel bearing?

Signs include grinding noises, vibrations, looseness in the wheel, uneven tire wear, and ABS light activation.

-

What tools do I need to replace a wheel bearing?

You’ll need a jack, jack stands, lug wrench, socket set, wrench set, torque wrench, hammer, pry bar, wheel bearing press kit, and safety glasses.

-

How do I diagnose which wheel bearing is bad?

Perform a road test, turning test, lift and spin each wheel, and visually inspect the bearing hub for damage.

-

Can I replace a wheel bearing myself?

Yes, if you have the right tools and mechanical skills. Otherwise, it’s best to have a professional do it.

-

How much does it cost to replace a wheel bearing?

The cost ranges from $200 to $700 per wheel, including parts and labor.

-

What is a wheel bearing press kit used for?

A wheel bearing press kit is used to safely press the old bearing out of the hub and press the new bearing in.

-

How can I extend the life of my wheel bearings?

Regularly lubricate the bearings, avoid potholes, practice smooth driving, and maintain proper wheel alignment.

-

What happens if I ignore a bad wheel bearing?

Ignoring a bad wheel bearing can lead to unstable handling, damage to other components, and increased risk of accidents.

-

How do I check the torque on the axle nut?

Use a torque wrench and tighten the axle nut to the manufacturer’s specified torque.

-

Where can I buy high-quality wheel bearings and tools?

You can find a wide selection of high-quality wheel bearings and tools at CARDIAGTECH.NET.