How to Fix a Car Running Lean: Symptoms, Causes & Solutions

Fixing a car running lean involves identifying the symptoms, understanding the causes, and implementing effective solutions. CARDIAGTECH.BIZ can equip you with the diagnostic tools and equipment necessary to accurately pinpoint the problem and restore your engine’s optimal performance. Let’s explore how to identify and fix a lean-running engine, addressing issues such as air-fuel mixture, engine performance, and potential damage.

1. Understanding a Lean Engine Condition

Is your car’s engine running lean? A lean condition means your engine isn’t getting enough fuel relative to the amount of air it’s taking in. This imbalance can cause a range of problems, from reduced performance to serious engine damage. Identifying the symptoms and understanding the causes are the first steps in fixing a lean-running engine.

-

Definition of a Lean Engine: An engine runs lean when the air-to-fuel ratio is higher than the ideal stoichiometric ratio (around 14.7:1 for gasoline engines). This means there’s too much air and not enough fuel in the combustion mixture.

-

Why a Lean Engine is Bad: A lean mixture can lead to increased combustion temperatures, causing knocking, pinging, and potentially melting pistons or damaging valves. It can also result in poor fuel economy and increased emissions.

2. Recognizing the Symptoms of a Lean-Running Engine

What are the signs that your engine is running lean? Spotting the symptoms early can save you from costly repairs down the road. Here’s what to watch out for:

-

Poor Engine Performance: A noticeable decrease in power, sluggish acceleration, and overall poor drivability.

-

Rough Idling: The engine may idle roughly or stall, especially when cold.

-

Hesitation During Acceleration: The engine may hesitate or stumble when you try to accelerate.

-

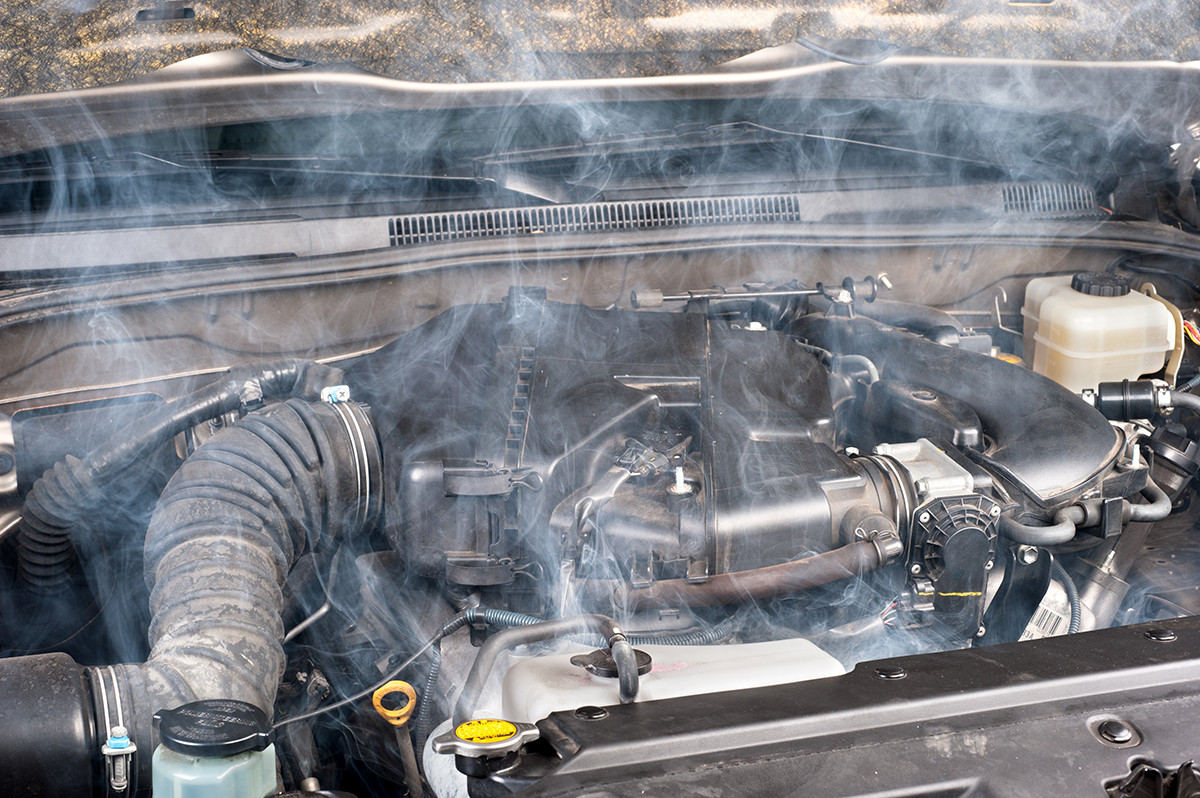

Increased Engine Temperature: Higher than normal engine temperatures due to the lean mixture burning hotter.

-

Check Engine Light: The check engine light may illuminate, often accompanied by diagnostic trouble codes (DTCs) related to lean conditions.

-

Pinging or Knocking: A metallic pinging or knocking sound from the engine, especially under load.

-

Poor Fuel Economy: Surprisingly, although counterintuitive, a lean condition can sometimes worsen fuel economy as the engine struggles to maintain power.

3. Common Causes of a Lean Engine

What could be causing your engine to run lean? Several factors can contribute to this issue, and pinpointing the exact cause is crucial for effective repair. Here are some common culprits:

3.1. Vacuum Leaks

What role do vacuum leaks play in a lean engine? Vacuum leaks are a frequent cause of lean conditions, as they allow unmetered air to enter the engine.

- How Vacuum Leaks Cause Lean Conditions: Vacuum leaks introduce extra air into the intake manifold after the mass airflow sensor (MAF) has already measured the incoming air. This excess air leans out the air-fuel mixture.

- Common Locations for Vacuum Leaks:

- Intake manifold gaskets

- Vacuum hoses

- Throttle body gaskets

- PCV valve hoses

- Brake booster hose

- Detecting Vacuum Leaks:

- Visual Inspection: Check for cracked, loose, or disconnected hoses.

- Smoke Test: Introduce smoke into the intake system and look for smoke escaping from leak points.

- Carburetor Cleaner/Starting Fluid: Spray small amounts of carburetor cleaner or starting fluid around potential leak areas. If the engine RPM increases, you’ve found a leak. (Caution: Use sparingly and avoid spraying on hot surfaces.)

3.2. Fuel System Issues

Can fuel system problems lead to a lean engine? Absolutely. Any issue that restricts fuel delivery can cause a lean condition.

- Clogged Fuel Filter: A restricted fuel filter can limit the amount of fuel reaching the engine.

- Weak Fuel Pump: A failing fuel pump may not provide adequate fuel pressure to the injectors. According to a study by the National Highway Traffic Safety Administration (NHTSA) in 2022, fuel pump failures are a common cause of engine performance issues, leading to lean conditions in many vehicles.

- Faulty Fuel Injectors: Dirty or malfunctioning fuel injectors may not deliver the correct amount of fuel.

- Fuel Pressure Regulator: A malfunctioning fuel pressure regulator can cause low fuel pressure, resulting in a lean mixture.

- Testing the Fuel System:

- Fuel Pressure Test: Use a fuel pressure gauge to check if the fuel pump is delivering the correct pressure.

- Fuel Injector Test: Use an oscilloscope or multimeter to check the injector pulse width and resistance. Injectors can also be removed and tested/cleaned professionally.

3.3. Sensor Malfunctions

How do faulty sensors contribute to a lean engine? Several sensors play a critical role in maintaining the correct air-fuel ratio, and a malfunction can disrupt this balance.

- Mass Airflow (MAF) Sensor: The MAF sensor measures the amount of air entering the engine. If it’s dirty or faulty, it can send incorrect data to the engine control unit (ECU), leading to a lean condition. According to a 2021 report by the EPA, faulty MAF sensors are a significant contributor to increased emissions and poor fuel economy due to incorrect air-fuel mixtures.

- Cleaning the MAF Sensor: Use a specialized MAF sensor cleaner to remove dirt and debris from the sensor element.

- Testing the MAF Sensor: Use a multimeter to check the sensor’s output voltage or frequency.

- Oxygen (O2) Sensor: The O2 sensor monitors the amount of oxygen in the exhaust. A faulty O2 sensor can provide incorrect feedback to the ECU, causing it to lean out the mixture.

- Testing the O2 Sensor: Use a scan tool to monitor the O2 sensor’s voltage readings. The sensor should switch rapidly between high and low voltage.

- Manifold Absolute Pressure (MAP) Sensor: The MAP sensor measures the pressure in the intake manifold. If it’s inaccurate, it can cause the ECU to miscalculate the air-fuel ratio.

- Testing the MAP Sensor: Use a scan tool to monitor the MAP sensor’s readings. The pressure should change with engine load.

3.4. Exhaust Leaks

Can exhaust leaks affect the air-fuel ratio? Surprisingly, yes. Exhaust leaks, especially those located before the oxygen sensor, can introduce extra oxygen into the exhaust stream.

- How Exhaust Leaks Cause Lean Readings: The O2 sensor detects the extra oxygen and signals the ECU to reduce fuel, resulting in a lean condition.

- Checking for Exhaust Leaks:

- Visual Inspection: Look for signs of exhaust leaks, such as soot or corrosion around exhaust joints.

- Listening: Listen for hissing or puffing sounds coming from the exhaust system.

- Smoke Test: Introduce smoke into the exhaust system and look for smoke escaping from leak points.

3.5. EGR Valve Issues

How does the EGR valve affect the air-fuel mixture? A malfunctioning EGR valve can contribute to a lean condition.

- EGR Valve Stuck Open: If the EGR valve is stuck open, it allows too much exhaust gas to recirculate into the intake manifold, which can lean out the mixture.

- Testing the EGR Valve:

- Visual Inspection: Check for carbon buildup or damage to the valve.

- Scan Tool: Use a scan tool to monitor the EGR valve’s position and operation.

4. Step-by-Step Guide to Fixing a Car Running Lean

How do you fix a lean-running engine? Follow these steps to diagnose and resolve the issue.

Step 1: Initial Inspection

- Check Engine Light: Use a scan tool to retrieve any diagnostic trouble codes (DTCs). Record the codes and research their meaning.

- Visual Inspection: Inspect all vacuum hoses, fuel lines, and electrical connections for signs of damage or leaks.

Step 2: Vacuum Leak Test

- Inspect Vacuum Hoses: Check all vacuum hoses for cracks, leaks, or disconnections. Replace any damaged hoses.

- Smoke Test: Perform a smoke test to identify any hidden vacuum leaks in the intake manifold or other components.

- Carburetor Cleaner Method: Spray small amounts of carburetor cleaner around potential leak areas. If the engine RPM increases, you’ve found a leak.

Step 3: Fuel System Diagnosis

- Fuel Pressure Test: Use a fuel pressure gauge to check the fuel pressure at the fuel rail. Compare the reading to the manufacturer’s specifications.

- Fuel Filter Inspection: Inspect the fuel filter for clogs or restrictions. Replace the filter if necessary.

- Fuel Injector Test: Use an oscilloscope or multimeter to check the injector pulse width and resistance. Clean or replace any faulty injectors.

Step 4: Sensor Testing

- MAF Sensor Test: Clean the MAF sensor with a specialized cleaner. Use a multimeter to check the sensor’s output voltage or frequency. Replace the sensor if it’s faulty.

- O2 Sensor Test: Use a scan tool to monitor the O2 sensor’s voltage readings. Replace the sensor if it’s not switching properly.

- MAP Sensor Test: Use a scan tool to monitor the MAP sensor’s readings. Replace the sensor if it’s inaccurate.

Step 5: Exhaust System Inspection

- Visual Inspection: Inspect the exhaust system for leaks, especially before the oxygen sensor.

- Smoke Test: Perform a smoke test to identify any exhaust leaks.

Step 6: EGR Valve Inspection

- Visual Inspection: Check the EGR valve for carbon buildup or damage.

- Scan Tool Test: Use a scan tool to monitor the EGR valve’s position and operation. Clean or replace the valve if necessary.

Step 7: Final Steps

- Clear DTCs: After completing the repairs, clear the diagnostic trouble codes (DTCs) with a scan tool.

- Test Drive: Test drive the vehicle to ensure the lean condition has been resolved and the engine is running smoothly.

- Monitor Performance: Monitor the engine’s performance and fuel economy to ensure the issue doesn’t return.

5. Essential Tools and Equipment from CARDIAGTECH.BIZ

What tools do you need to fix a car running lean, and how can CARDIAGTECH.BIZ help? Having the right tools and equipment is essential for diagnosing and repairing a lean-running engine. Here are some must-have items available at CARDIAGTECH.BIZ:

| Tool/Equipment | Description | Benefits |

|---|---|---|

| Scan Tool | Reads and clears diagnostic trouble codes (DTCs), monitors sensor data. | Accurate diagnosis, saves time and money, identifies potential issues early. |

| Fuel Pressure Gauge | Measures fuel pressure at the fuel rail. | Determines if the fuel pump is delivering adequate pressure, identifies fuel system problems. |

| Vacuum Gauge | Measures vacuum in the intake manifold. | Detects vacuum leaks, assesses engine condition. |

| Multimeter | Tests electrical components, such as sensors and fuel injectors. | Diagnoses electrical issues, verifies sensor functionality, identifies faulty components. |

| Smoke Machine | Introduces smoke into the intake or exhaust system to detect leaks. | Quickly locates vacuum and exhaust leaks, improves diagnostic accuracy. |

| Fuel Injector Cleaner | Cleans fuel injectors to restore proper fuel delivery. | Improves fuel economy, restores engine performance, reduces emissions. |

| MAF Sensor Cleaner | Cleans MAF sensors to ensure accurate air flow readings. | Maintains accurate air-fuel ratio, improves engine performance, reduces emissions. |

| Socket Set & Wrenches | For removing and installing various engine components. | Essential for disassembly and reassembly, ensures proper torque. |

| OBD-II Extension Cable | Allows for easier access to the OBD-II port, especially in tight spaces. | Convenient for diagnostics, reduces strain on the OBD-II port. |

| Work Gloves | Protects hands from dirt, grease, and chemicals. | Enhances safety and comfort, prevents skin irritation. |

| Mechanic’s Creeper | Provides comfortable support while working under the vehicle. | Reduces fatigue, improves access to undercarriage components. |

| Protective Eyewear | Protects eyes from debris and chemicals. | Ensures safety, prevents eye injuries. |

| Jack and Jack Stands | Safely lifts and supports the vehicle for undercarriage access. | Essential for accessing undercarriage components, ensures safety during repairs. |

| Wheel Chocks | Prevents the vehicle from rolling while lifted. | Enhances safety, prevents accidents. |

| Torque Wrench | Ensures bolts and nuts are tightened to the manufacturer’s specified torque. | Prevents over-tightening or under-tightening, ensures proper component assembly. |

| Inspection Mirror | Helps to see hard-to-reach areas. | Improves visibility, aids in locating leaks and damage. |

| Parts Tray | Keeps small parts organized during disassembly. | Prevents lost parts, streamlines the reassembly process. |

| Service Manual | Provides detailed information on vehicle-specific diagnostic and repair procedures. | Ensures accurate repairs, provides torque specifications and troubleshooting guides. |

| Code Reader | Quickly retrieves diagnostic trouble codes (DTCs). | Provides a quick and easy way to diagnose engine problems. |

| Jumper Cables | Provides a temporary connection to start a car with a dead battery. | Helps in situations where the car won’t start due to a weak or dead battery. |

| Battery Terminal Cleaner | Cleans corrosion from battery terminals for better electrical connection. | Ensures proper electrical flow, prevents starting issues. |

| Circuit Tester | Tests electrical circuits for voltage, continuity, and ground. | Helps diagnose electrical problems quickly and accurately. |

These tools can significantly enhance your ability to diagnose and fix a lean-running engine effectively. Investing in quality tools from CARDIAGTECH.BIZ ensures that you’re well-equipped to tackle any automotive repair challenge.

6. Advanced Diagnostic Techniques

What are some advanced methods for diagnosing a lean engine? For complex cases, advanced diagnostic techniques can help pinpoint the root cause.

- Fuel Trim Analysis:

- What it is: Fuel trim refers to the adjustments the ECU makes to the air-fuel mixture to maintain the ideal ratio. Short-term fuel trim (STFT) and long-term fuel trim (LTFT) values can provide valuable insights into the engine’s condition.

- How it Helps: High positive fuel trim values indicate the ECU is adding extra fuel to compensate for a lean condition. By analyzing STFT and LTFT values under different driving conditions, you can identify the source of the problem.

- Example: According to a study by the Society of Automotive Engineers (SAE) in 2023, monitoring fuel trim values can help diagnose vacuum leaks, MAF sensor issues, and fuel delivery problems more accurately.

- Oscilloscope Diagnostics:

- What it is: An oscilloscope is an electronic instrument that displays electrical signals as waveforms. It can be used to analyze the performance of sensors, fuel injectors, and other components.

- How it Helps: By examining the waveforms, you can identify issues such as slow response times, signal dropouts, or incorrect patterns.

- Example: Using an oscilloscope to analyze the O2 sensor waveform can reveal whether the sensor is switching properly or if it’s sluggish and needs replacement.

- In-Cylinder Pressure Analysis:

- What it is: This technique involves using a specialized sensor to measure the pressure inside the engine cylinders during the combustion process.

- How it Helps: Analyzing the pressure waveforms can reveal issues such as compression problems, valve timing errors, or combustion abnormalities.

- Example: In-cylinder pressure analysis can help diagnose a lean condition caused by a leaking intake valve, which allows extra air to enter the cylinder.

- Data Logging:

- What it is: Data logging involves recording sensor data over a period of time while the vehicle is being driven. This data can then be analyzed to identify patterns and anomalies.

- How it Helps: Data logging can reveal intermittent issues that may not be apparent during a static inspection.

- Example: Data logging can help identify a faulty MAF sensor that only malfunctions under certain driving conditions, such as high engine load.

7. Preventing Lean Engine Conditions

How can you prevent your engine from running lean in the first place? Regular maintenance and proactive care can help prevent lean conditions.

- Regular Maintenance:

- Fuel Filter Replacement: Replace the fuel filter according to the manufacturer’s recommended schedule.

- Air Filter Replacement: Replace the air filter regularly to ensure proper airflow to the engine.

- Spark Plug Replacement: Replace the spark plugs according to the manufacturer’s recommended schedule to ensure proper combustion.

- Fuel System Cleaning:

- Fuel Injector Cleaning: Use a fuel injector cleaner periodically to keep the fuel injectors clean and functioning properly.

- Fuel System Additives: Use fuel system additives to help remove deposits and maintain fuel system performance.

- Sensor Maintenance:

- MAF Sensor Cleaning: Clean the MAF sensor periodically to ensure accurate air flow readings.

- O2 Sensor Inspection: Inspect the O2 sensors regularly and replace them if they are not functioning properly.

- Vacuum Hose Inspection:

- Regular Inspection: Inspect vacuum hoses regularly for cracks, leaks, or disconnections.

- Hose Replacement: Replace any damaged or worn vacuum hoses.

- Exhaust System Inspection:

- Regular Inspection: Inspect the exhaust system regularly for leaks, especially before the oxygen sensor.

- Leak Repair: Repair any exhaust leaks promptly.

8. The Role of Air-Fuel Ratio in Engine Performance

Why is the air-fuel ratio so important? Understanding the air-fuel ratio is crucial for diagnosing and fixing engine problems.

- Stoichiometric Ratio: The ideal air-fuel ratio for gasoline engines is approximately 14.7:1. This means that for every 1 part of fuel, there should be 14.7 parts of air.

- Lean vs. Rich:

- Lean: A lean mixture has more air than fuel (e.g., 16:1).

- Rich: A rich mixture has more fuel than air (e.g., 12:1).

- Effects of Air-Fuel Ratio:

- Lean: Can cause overheating, knocking, pinging, and engine damage.

- Rich: Can cause poor fuel economy, increased emissions, and carbon buildup.

- Monitoring Air-Fuel Ratio:

- O2 Sensors: O2 sensors monitor the amount of oxygen in the exhaust and provide feedback to the ECU.

- Fuel Trim: Fuel trim values indicate how the ECU is adjusting the air-fuel mixture.

- Scan Tools: Scan tools can display real-time air-fuel ratio data.

9. How CARDIAGTECH.BIZ Supports Automotive Technicians

What benefits do automotive technicians get from CARDIAGTECH.BIZ? CARDIAGTECH.BIZ is committed to providing automotive technicians with the tools, equipment, and support they need to excel in their profession.

- High-Quality Tools and Equipment: CARDIAGTECH.BIZ offers a wide range of high-quality tools and equipment from trusted brands, ensuring technicians have the right tools for the job.

- Competitive Prices: CARDIAGTECH.BIZ offers competitive prices on all products, helping technicians save money on essential tools and equipment.

- Expert Support: CARDIAGTECH.BIZ provides expert support to help technicians diagnose and repair automotive problems effectively.

- Training Resources: CARDIAGTECH.BIZ offers training resources and educational materials to help technicians stay up-to-date with the latest automotive technologies.

- Customer Satisfaction: CARDIAGTECH.BIZ is committed to customer satisfaction and strives to provide the best possible service to automotive technicians.

10. Frequently Asked Questions (FAQs) About Lean-Running Engines

Have more questions about lean-running engines? Here are some frequently asked questions to help you better understand the issue:

-

Q1: What does it mean when my car is running lean?

- A1: When your car is running lean, it means there is too much air and not enough fuel in the air-fuel mixture. This can lead to a range of performance issues and potential engine damage.

-

Q2: Can a lean condition damage my engine?

- A2: Yes, a lean condition can cause increased combustion temperatures, leading to knocking, pinging, and potentially melting pistons or damaging valves.

-

Q3: How do I know if my engine is running lean?

- A3: Common symptoms of a lean-running engine include poor performance, rough idling, hesitation during acceleration, increased engine temperature, and the check engine light coming on.

-

Q4: What are the most common causes of a lean engine?

- A4: Common causes include vacuum leaks, fuel system issues, sensor malfunctions, exhaust leaks, and EGR valve problems.

-

Q5: How can I test for vacuum leaks?

- A5: You can test for vacuum leaks using a visual inspection, a smoke test, or by spraying carburetor cleaner around potential leak areas.

-

Q6: What tools do I need to diagnose a lean-running engine?

- A6: Essential tools include a scan tool, fuel pressure gauge, vacuum gauge, multimeter, smoke machine, and fuel injector cleaner.

-

Q7: Can I fix a lean-running engine myself, or do I need to take it to a professional?

- A7: If you have experience working on cars and have the necessary tools, you may be able to fix a lean-running engine yourself. However, if you’re not comfortable working on cars, it’s best to take it to a professional mechanic.

-

Q8: How often should I check my car for potential lean conditions?

- A8: It’s a good idea to have your car checked regularly as part of your routine maintenance. Pay attention to any unusual symptoms, such as poor performance or rough idling, and address them promptly.

-

Q9: Can a dirty air filter cause a lean condition?

- A9: Yes, a severely clogged air filter can restrict airflow and indirectly cause a lean condition by affecting the air-fuel mixture.

-

Q10: How does CARDIAGTECH.BIZ help in diagnosing and fixing a lean-running engine?

- A10: CARDIAGTECH.BIZ provides high-quality diagnostic tools, equipment, and expert support to help automotive technicians accurately diagnose and effectively repair lean-running engines. We offer a wide range of products from trusted brands at competitive prices to ensure you have everything you need for the job.

Is your car showing signs of running lean? Don’t wait for the problem to escalate. Contact CARDIAGTECH.BIZ today at 276 Reock St, City of Orange, NJ 07050, United States, or reach us via WhatsApp at +1 (641) 206-8880, or visit our website CARDIAGTECH.BIZ. Our expert team can help you find the perfect tools and equipment to diagnose and fix the issue, ensuring your engine runs smoothly and efficiently. Get in touch now and let us assist you in maintaining your vehicle’s optimal performance.