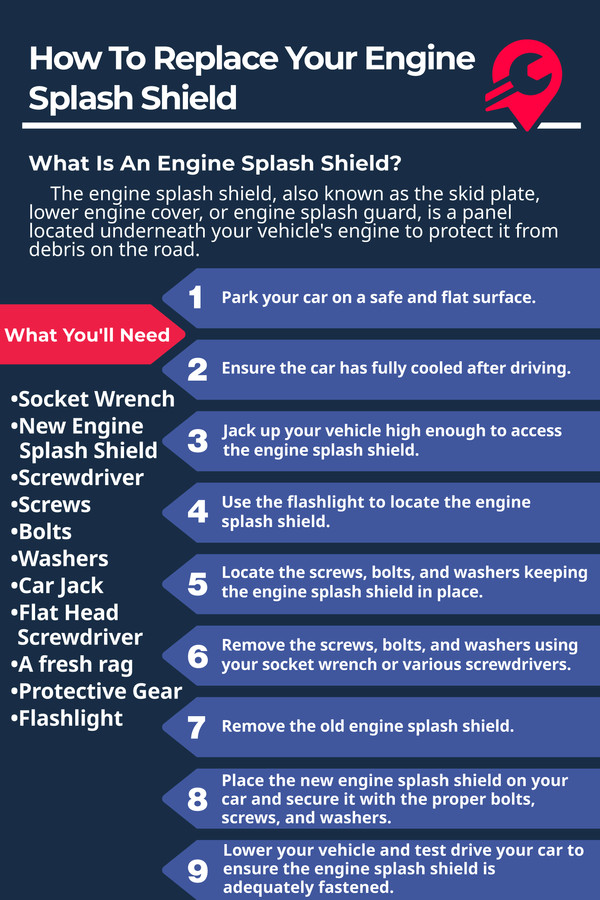

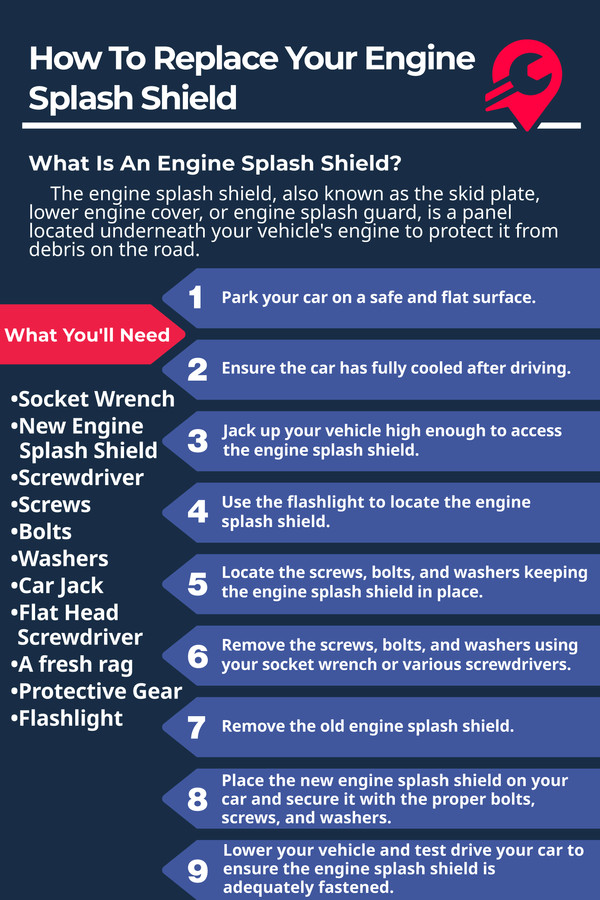

How To Fix Splash Shield Under Car: A Comprehensive Guide

Replacing your car’s splash shield is crucial for protecting vital components from road debris. CARDIAGTECH.NET offers a range of tools and equipment to make this task easier and more efficient. This guide provides step-by-step instructions and expert advice to help you successfully replace your splash shield, ensuring optimal protection and performance for your vehicle. Discover related auto repair solutions today.

1. Understanding the Importance of a Splash Shield

The splash shield, also known as the engine splash shield, skid plate, or lower engine cover, plays a vital role in protecting your vehicle’s undercarriage. It’s a panel typically made of plastic or metal, located beneath the engine compartment. Its primary function is to safeguard essential components from road hazards.

1.1. What Does a Splash Shield Protect?

The splash shield defends against:

- Debris: Rocks, gravel, salt, and other road debris that can be kicked up and cause damage.

- Water and Moisture: Protects against water splashes that can lead to corrosion and electrical issues.

- Dust and Dirt: Prevents accumulation of dirt and dust, which can affect the performance of various components.

- Snow and Ice: In colder climates, it provides a barrier against snow and ice buildup.

Source: National Highway Traffic Safety Administration (NHTSA) emphasizes the importance of vehicle maintenance and safety, which includes protecting undercarriage components.

1.2. Critical Components Protected by the Splash Shield

- Engine: Shields the engine block from impacts and debris.

- Oil Pan: Protects the oil pan from punctures and damage, preventing oil leaks.

- Transmission: Guards the transmission case from road hazards.

- Belts and Hoses: Prevents debris from interfering with the operation of belts and hoses.

- Electrical Wiring: Protects sensitive wiring from moisture and physical damage.

- Exhaust System: Provides some shielding to exhaust components, reducing exposure to corrosive elements.

1.3. The Consequences of Driving Without a Splash Shield

Driving without a properly functioning splash shield can lead to serious consequences:

- Increased Risk of Damage: The undercarriage is exposed to potential damage from road debris.

- Corrosion: Exposure to water, salt, and other corrosive elements can accelerate rust and corrosion.

- Component Failure: Critical components like the oil pan or transmission can be damaged, leading to costly repairs.

- Safety Issues: Damaged wiring or hoses can create safety hazards.

- Reduced Vehicle Lifespan: Long-term exposure to harsh conditions can reduce the overall lifespan of your vehicle.

According to the Bureau of Automotive Repair, California: Regular inspection and maintenance of undercarriage components, including the splash shield, is crucial for vehicle longevity and safety.

2. Identifying When Your Splash Shield Needs Fixing

Recognizing the signs of a damaged or failing splash shield is essential for timely replacement and preventing further damage to your vehicle. Here are common indicators that your splash shield needs attention:

2.1. Common Signs of a Damaged Splash Shield

- Visible Damage: Cracks, holes, or tears in the splash shield material.

- Hanging or Loose Shield: The splash shield is sagging or dragging underneath the car.

- Unusual Noises: Rattling, scraping, or flapping sounds coming from under the vehicle while driving.

- Oil or Fluid Leaks: Evidence of oil or other fluid leaks near the splash shield area.

- Debris Accumulation: Excessive buildup of dirt, rocks, or other debris on top of the splash shield.

2.2. Factors Contributing to Splash Shield Damage

- Road Hazards: Impact from rocks, potholes, speed bumps, and other road debris.

- Weather Conditions: Exposure to extreme temperatures, salt, and moisture.

- Wear and Tear: Gradual degradation of the material over time.

- Accidents: Minor collisions or impacts with objects on the road.

- Improper Installation: If the splash shield was not correctly installed during a previous repair.

2.3. Inspection Checklist

Regularly inspect your splash shield for any signs of damage. Use this checklist to guide your inspection:

- Visual Inspection: Look for cracks, holes, or tears in the splash shield material.

- Check Attachment Points: Ensure that all screws, bolts, and clips are securely fastened.

- Examine for Sagging: Check if the splash shield is sagging or hanging loose.

- Listen for Unusual Noises: Pay attention to any unusual sounds coming from under the vehicle while driving.

- Look for Leaks: Check for any signs of oil or fluid leaks near the splash shield area.

Source: AAA (American Automobile Association) emphasizes the importance of regular vehicle inspections to identify and address potential maintenance issues.

Damaged splash shield hanging loose under a car

Damaged splash shield hanging loose under a car

2.4. Tools Available at CARDIAGTECH.NET for Inspection

CARDIAGTECH.NET offers a range of tools to aid in inspecting your splash shield:

- Inspection Mirrors: For viewing hard-to-reach areas.

- Flashlights/Work Lights: To improve visibility during inspections.

- Jack Stands: To safely lift the vehicle for a thorough inspection.

3. Choosing the Right Replacement Splash Shield

Selecting the appropriate replacement splash shield is crucial for ensuring proper fit, protection, and longevity. Here’s what you need to consider:

3.1. Material Types: Plastic vs. Metal

- Plastic Splash Shields:

- Pros:

- Affordable: Generally less expensive than metal options.

- Lightweight: Doesn’t add significant weight to the vehicle.

- Corrosion-Resistant: Not susceptible to rust.

- Cons:

- Less Durable: More prone to cracking and damage from impacts.

- Shorter Lifespan: May need to be replaced more frequently.

- Pros:

- Metal Splash Shields:

- Pros:

- Highly Durable: Provides superior protection against impacts and road hazards.

- Longer Lifespan: Lasts longer than plastic options.

- Cons:

- More Expensive: Higher initial cost.

- Heavier: Adds more weight to the vehicle.

- Susceptible to Corrosion: Can rust if not properly coated or treated.

- Pros:

3.2. Factors to Consider When Choosing

- Vehicle Type: Different makes and models require specific splash shield designs.

- Driving Conditions: If you frequently drive on rough roads or in areas with harsh weather, a metal splash shield may be a better choice.

- Budget: Plastic splash shields are more budget-friendly, while metal options offer better long-term value.

- Climate: In areas with heavy snow or salt use, consider a corrosion-resistant metal or plastic option.

- Ease of Installation: Some splash shields are designed for easier installation than others.

3.3. Ensuring Compatibility

- Check Vehicle Specifications: Consult your vehicle’s manual or a reliable online database to determine the correct splash shield for your make and model.

- Verify Part Numbers: Match the part number of the original splash shield with the replacement to ensure compatibility.

- Consult a Professional: If you’re unsure, seek advice from a qualified mechanic or auto parts specialist.

3.4. Where to Buy

- CARDIAGTECH.NET: Offers a variety of tools and equipment to assist with splash shield replacement.

- Local Auto Parts Stores: Provide a wide selection of splash shields and expert advice.

- Online Retailers: Offer competitive pricing and convenient shopping options.

According to Consumer Reports: Comparing prices and reading reviews from multiple sources can help you find the best value for your replacement splash shield.

4. Essential Tools for Splash Shield Replacement from CARDIAGTECH.NET

Having the right tools is crucial for a successful and efficient splash shield replacement. CARDIAGTECH.NET offers a comprehensive selection of high-quality tools to make the job easier.

4.1. List of Necessary Tools

- Socket Wrench Set: For removing and installing bolts and nuts.

- Screwdriver Set: Including flathead and Phillips head screwdrivers for various fasteners.

- Car Jack: To safely lift the vehicle.

- Jack Stands: To support the vehicle once it’s lifted.

- Pliers: For removing clips and fasteners.

- Trim Removal Tool: To remove plastic trim pieces without damage.

- Flashlight/Work Light: To provide adequate lighting.

- Gloves: To protect your hands.

- Safety Glasses: To protect your eyes.

- Torque Wrench: To tighten bolts to the correct specifications.

4.2. Tool Recommendations from CARDIAGTECH.NET

- Socket Wrench Set: A high-quality socket wrench set with various sizes is essential for removing and installing fasteners. Look for a set with both metric and SAE sockets.

- Car Jack and Jack Stands: Ensure that your car jack has sufficient weight capacity for your vehicle. Invest in sturdy jack stands to safely support the vehicle.

- Trim Removal Tool Set: These tools are designed to remove plastic trim pieces and fasteners without causing damage. A good set will include various shapes and sizes to accommodate different types of trim.

- Work Light: A bright, portable work light is essential for providing adequate lighting while working under the vehicle.

4.3. Optional but Helpful Tools

- Penetrating Oil: To loosen corroded bolts and nuts.

- Impact Wrench: To quickly remove stubborn fasteners.

- Magnetic Parts Tray: To keep track of small parts and prevent them from getting lost.

- Mechanic’s Creeper: To comfortably work under the vehicle.

4.4. Why Choose CARDIAGTECH.NET Tools?

- Durability: CARDIAGTECH.NET tools are made from high-quality materials for long-lasting performance.

- Reliability: Our tools are designed to withstand the rigors of automotive repair.

- Comprehensive Selection: We offer a wide range of tools to meet all your automotive needs.

5. Step-by-Step Guide to Fixing Your Splash Shield

Replacing your splash shield can be a straightforward task if you follow these step-by-step instructions. Ensure you have all the necessary tools and safety equipment before starting.

5.1. Preparation and Safety Measures

- Gather Your Tools: Ensure you have all the necessary tools listed above.

- Park on a Level Surface: Park your vehicle on a flat, level surface and engage the parking brake.

- Safety Gear: Wear safety glasses and gloves to protect your eyes and hands.

- Consult Manual: Refer to your vehicle’s service manual for specific instructions and torque specifications.

- Disconnect Battery (Optional): Disconnecting the negative battery terminal can prevent electrical accidents.

5.2. Step-by-Step Instructions

- Loosen Lug Nuts: Use a lug wrench to loosen the lug nuts on the front wheels.

- Jack Up the Vehicle: Place the car jack under the designated jacking points on the vehicle frame. Lift the vehicle high enough to provide ample working space.

- Secure with Jack Stands: Place jack stands under the vehicle frame near the jacking points. Ensure the jack stands are securely positioned before lowering the vehicle onto them.

- Locate the Splash Shield: Identify the splash shield under the engine compartment.

- Remove Fasteners: Use a socket wrench, screwdriver, or trim removal tool to remove all screws, bolts, and clips securing the splash shield.

- Support the Shield: As you remove the last fasteners, support the splash shield to prevent it from falling.

- Remove the Old Shield: Carefully remove the old splash shield from the vehicle.

- Clean the Area: Use a clean rag to wipe down the area where the splash shield was located.

- Position the New Shield: Align the new splash shield with the mounting points on the vehicle.

- Install Fasteners: Install the screws, bolts, and clips to secure the new splash shield. Tighten the fasteners to the specified torque using a torque wrench.

- Lower the Vehicle: Carefully raise the vehicle with the car jack to remove the jack stands. Then, slowly lower the vehicle to the ground.

- Tighten Lug Nuts: Use a torque wrench to tighten the lug nuts to the specified torque.

5.3. Visual Aids

- Consult online videos or diagrams for visual guidance.

- Refer to your vehicle’s service manual for detailed illustrations.

5.4. Post-Installation Checks

- Inspect the Shield: Ensure that the splash shield is securely attached and properly aligned.

- Test Drive: Take the vehicle for a short test drive to check for any unusual noises or issues.

- Re-torque Fasteners: After the test drive, re-torque the fasteners to ensure they are still properly tightened.

According to Popular Mechanics: Proper installation and regular inspection of the splash shield are crucial for protecting your vehicle’s undercarriage.

6. Common Mistakes to Avoid When Changing a Splash Shield

Replacing a splash shield is a relatively simple task, but it’s essential to avoid common mistakes that can lead to problems. Here’s what to watch out for:

6.1. Incorrect Tools

Using the wrong tools can damage fasteners or the splash shield itself. Always use the correct size socket wrench, screwdriver, or trim removal tool. CARDIAGTECH.NET provides the right tools for the job.

6.2. Stripped or Broken Fasteners

Applying too much force can strip or break fasteners. Use penetrating oil to loosen corroded fasteners and avoid over-tightening.

6.3. Incorrect Alignment

Improperly aligning the splash shield can cause it to rub against other components or come loose. Ensure the splash shield is correctly aligned with the mounting points before tightening the fasteners.

6.4. Over-Tightening Fasteners

Over-tightening fasteners can damage the splash shield or the mounting points. Use a torque wrench to tighten fasteners to the specified torque.

6.5. Neglecting Safety Measures

Failing to use safety glasses or gloves can lead to injuries. Always wear appropriate safety gear when working on your vehicle.

6.6. Using the Wrong Replacement Part

Using the wrong replacement part can result in poor fit and inadequate protection. Always verify the part number and vehicle specifications to ensure compatibility.

6.7. Forgetting to Re-torque Fasteners

Forgetting to re-torque fasteners after a test drive can cause them to loosen and the splash shield to come loose. Always re-torque the fasteners after a test drive.

6.8. Not Supporting the Vehicle Properly

Failing to use jack stands to support the vehicle can be extremely dangerous. Always use jack stands to securely support the vehicle before working underneath it.

6.9. Ignoring Warning Signs

Ignoring warning signs such as unusual noises or sagging can lead to further damage. Address any issues promptly to prevent more costly repairs.

Source: The Family Handyman provides helpful tips and advice for avoiding common mistakes in DIY auto repair projects.

7. Maintenance Tips for Prolonging the Life of Your Splash Shield

Proper maintenance can significantly extend the life of your splash shield and protect your vehicle’s undercarriage. Here are some essential maintenance tips:

7.1. Regular Inspections

- Frequency: Inspect your splash shield at least twice a year, or more often if you frequently drive on rough roads.

- What to Look For: Check for cracks, holes, tears, sagging, and loose fasteners.

- Tools: Use a flashlight and inspection mirror to thoroughly examine the splash shield.

7.2. Cleaning

- Why Clean: Removing dirt, debris, and salt can prevent corrosion and damage.

- How to Clean: Use a pressure washer or garden hose to rinse off the splash shield. For stubborn dirt, use a mild soap and a brush.

- When to Clean: Clean the splash shield after driving on salted roads or in muddy conditions.

7.3. Fastener Maintenance

- Check Fasteners: Regularly check the fasteners to ensure they are tight and secure.

- Replace Corroded Fasteners: Replace any corroded or damaged fasteners to prevent the splash shield from coming loose.

- Use Anti-Seize Lubricant: Apply anti-seize lubricant to the threads of the fasteners to prevent corrosion and make them easier to remove in the future.

7.4. Protective Coatings

- Rust-Proofing: Apply a rust-proofing coating to metal splash shields to prevent corrosion.

- Undercoating: Consider applying an undercoating to the vehicle’s undercarriage to provide additional protection.

7.5. Driving Habits

- Avoid Road Hazards: Drive carefully to avoid potholes, rocks, and other road hazards that can damage the splash shield.

- Slow Down on Rough Roads: Reduce your speed when driving on rough roads to minimize the impact on the splash shield.

7.6. Professional Maintenance

- Schedule Regular Checkups: Have your splash shield inspected by a qualified mechanic during routine maintenance visits.

- Address Issues Promptly: Address any issues with the splash shield promptly to prevent further damage.

According to J.D. Power: Regular maintenance and prompt repairs are essential for maintaining the reliability and longevity of your vehicle.

8. Benefits of Using CARDIAGTECH.NET for Your Auto Repair Needs

Choosing CARDIAGTECH.NET for your auto repair needs comes with numerous benefits that can save you time, money, and hassle. Here are some key advantages:

8.1. High-Quality Tools and Equipment

- Wide Selection: CARDIAGTECH.NET offers a comprehensive selection of high-quality tools and equipment for all your auto repair needs.

- Durability: Our tools are made from durable materials and designed to withstand the rigors of automotive repair.

- Reliability: You can rely on CARDIAGTECH.NET tools to perform accurately and consistently.

8.2. Expert Advice and Support

- Knowledgeable Staff: Our knowledgeable staff can provide expert advice and guidance to help you choose the right tools and equipment for your needs.

- Technical Support: We offer technical support to help you troubleshoot any issues you may encounter during your repairs.

- Online Resources: Access our online resources, including how-to guides and videos, to help you with your auto repair projects.

8.3. Competitive Pricing

- Affordable Prices: CARDIAGTECH.NET offers competitive pricing on all our tools and equipment.

- Special Offers: Take advantage of our special offers and discounts to save even more money.

- Value for Money: Our high-quality tools and equipment provide excellent value for money.

8.4. Convenient Shopping Experience

- Online Store: Shop conveniently from the comfort of your own home with our easy-to-use online store.

- Fast Shipping: We offer fast and reliable shipping to get your tools and equipment to you quickly.

- Easy Returns: Our easy return policy ensures that you can return any items that don’t meet your expectations.

8.5. Customer Satisfaction

- Excellent Customer Service: We are committed to providing excellent customer service and ensuring your satisfaction.

- Positive Reviews: Read our positive customer reviews to see why so many people trust CARDIAGTECH.NET for their auto repair needs.

- Long-Term Relationships: We strive to build long-term relationships with our customers by providing exceptional products and service.

8.6. Focus on Innovation

- Cutting-Edge Technology: CARDIAGTECH.NET stays up-to-date with the latest advancements in automotive technology to offer innovative tools and equipment.

- Continuous Improvement: We continuously improve our products and services to meet the evolving needs of our customers.

According to a study by the Automotive Aftermarket Industry Association (AAIA): Investing in high-quality tools and equipment can significantly improve the efficiency and effectiveness of auto repairs.

9. Real-World Examples of Splash Shield Damage and Repair

Understanding real-world scenarios of splash shield damage and repair can provide valuable insights into the importance of this component and how to address related issues. Here are a few examples:

9.1. Scenario 1: Pothole Impact

- Situation: A driver hits a deep pothole at high speed, causing significant impact to the undercarriage.

- Damage: The splash shield cracks and partially detaches from the vehicle.

- Consequences: The engine and oil pan are exposed to road debris, increasing the risk of damage.

- Repair: The splash shield needs to be replaced immediately to protect the engine and other components.

9.2. Scenario 2: Gravel Road Driving

- Situation: A driver frequently travels on gravel roads, where small rocks and debris are constantly kicked up.

- Damage: Over time, the splash shield becomes worn and damaged by the constant bombardment of rocks.

- Consequences: The damaged splash shield no longer provides adequate protection, leading to potential damage to the engine and transmission.

- Repair: Replacing the splash shield with a more durable metal option can provide better protection in this scenario.

9.3. Scenario 3: Winter Salt Exposure

- Situation: A vehicle is driven in an area where roads are heavily salted during the winter months.

- Damage: The salt causes corrosion to the splash shield and its fasteners.

- Consequences: The corroded splash shield becomes weak and may detach from the vehicle.

- Repair: Replacing the splash shield with a corrosion-resistant plastic option and applying rust-proofing to the undercarriage can prevent further damage.

9.4. Scenario 4: Minor Collision

- Situation: A vehicle is involved in a minor collision with a curb, causing damage to the front undercarriage.

- Damage: The splash shield is bent and deformed, affecting its ability to protect the engine.

- Consequences: The damaged splash shield needs to be replaced to ensure proper protection.

- Repair: The splash shield needs to be replaced, and the undercarriage should be inspected for any additional damage.

9.5. Tips for Handling Real-World Damage

- Inspect Regularly: Regularly inspect your splash shield for any signs of damage, especially after driving on rough roads or in harsh weather conditions.

- Address Issues Promptly: Address any issues with the splash shield promptly to prevent further damage.

- Choose the Right Replacement: Choose a replacement splash shield that is appropriate for your vehicle and driving conditions.

According to the Insurance Institute for Highway Safety (IIHS): Damage to vehicle undercarriage components can significantly impact safety and increase the risk of accidents.

10. Frequently Asked Questions (FAQ) About Splash Shields

Here are some frequently asked questions about splash shields, along with detailed answers:

Q1: What is a splash shield and what does it do?

A: A splash shield, also known as an engine splash shield or skid plate, is a panel located under the engine that protects vital components from road debris, water, and dirt.

Q2: Can I drive without a splash shield?

A: While technically possible, it’s not recommended. Driving without a splash shield increases the risk of damage to your engine, oil pan, and other critical components.

Q3: How much does it cost to replace a splash shield?

A: The cost to replace a splash shield varies depending on the vehicle make and model, the type of splash shield (plastic vs. metal), and labor costs. Generally, it can range from $100 to $500.

Q4: Can I replace a splash shield myself?

A: Yes, if you have the necessary tools and mechanical skills, you can replace a splash shield yourself. Follow the step-by-step instructions provided in this guide.

Q5: How do I know if my splash shield is damaged?

A: Look for signs such as cracks, holes, tears, sagging, or unusual noises coming from under the vehicle.

Q6: Are metal splash shields better than plastic ones?

A: Metal splash shields are more durable and provide better protection, but they are also more expensive. Plastic splash shields are more affordable but less durable.

Q7: How often should I replace my splash shield?

A: The lifespan of a splash shield depends on driving conditions and the quality of the part. Inspect it regularly and replace it when you notice signs of damage.

Q8: What tools do I need to replace a splash shield?

A: You will need a socket wrench set, screwdriver set, car jack, jack stands, pliers, trim removal tool, flashlight, gloves, and safety glasses.

Q9: Where can I buy a replacement splash shield?

A: You can buy a replacement splash shield from local auto parts stores, online retailers, or CARDIAGTECH.NET.

Q10: How do I maintain my splash shield?

A: Regularly inspect and clean your splash shield. Replace corroded fasteners and apply rust-proofing coatings to metal splash shields.

By following this comprehensive guide, you can effectively fix or replace your splash shield, ensuring your vehicle’s undercarriage is well-protected. For all your automotive tool needs, remember to visit CARDIAGTECH.NET.

Is your splash shield damaged or missing? Don’t wait until it causes more expensive damage. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 for expert advice and the best tools to get the job done right. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Protect your vehicle’s vital components now visit CARDIAGTECH.NET.