5170 Mercedes Fault Code: Diagnosis and Solutions Guide

Navigating the complexities of Mercedes-Benz diagnostics can be challenging, particularly when encountering the 5170 Mercedes fault code. This comprehensive guide, brought to you by CARDIAGTECH.NET, provides expert insights and solutions for addressing this specific AIRmatic system issue, ensuring your Mercedes-Benz is back on the road with optimal performance. Understand the intricacies of the AIRmatic system, identify potential causes, and explore effective repair strategies.

1. Understanding the 5170 Mercedes Fault Code

The 5170 Mercedes fault code indicates a “B7 (AIRmatic pressure sensor): Signal failure” within the AIRmatic suspension system. The Mercedes-Benz AIRmatic suspension system provides a smooth, comfortable ride by using air suspension struts instead of traditional coil springs. This system relies on sensors to monitor pressure and height, adjusting the air pressure in the struts to maintain optimal ride height and handling.

1.1. What Does the 5170 Code Mean for Your Mercedes-Benz?

The 5170 code specifically points to a malfunction in the AIRmatic pressure sensor, often referred to as the B7 sensor. This sensor monitors the pressure within the AIRmatic system, providing crucial data to the control unit. When the signal from this sensor fails, the system cannot accurately regulate air pressure, leading to various issues, including:

- Ride Height Problems: The vehicle may sit too low or unevenly.

- Warning Messages: The dashboard may display warnings such as “Car Too Low” or “Visit Workshop.”

- Compromised Ride Comfort: The smooth, controlled ride provided by the AIRmatic system will be diminished.

1.2. Common Symptoms Associated with the 5170 Fault Code

Identifying the symptoms associated with the 5170 fault code can help confirm the issue and guide troubleshooting efforts. Common symptoms include:

- Dashboard Warning Lights: The “Car Too Low” or “Visit Workshop” message is a primary indicator.

- Uneven Ride Height: One or more corners of the vehicle may appear lower than the others.

- Stiff or Bouncy Ride: The AIRmatic system’s ability to smooth out bumps is compromised.

- Compressor Issues: The AIRmatic compressor may run excessively or not at all.

1.3. Models Most Commonly Affected

While the 5170 fault code can occur in various Mercedes-Benz models equipped with AIRmatic suspension, some models are more prone to this issue. These include:

- Mercedes-Benz CLS-Class (W219)

- Mercedes-Benz E-Class (W211, W212)

- Mercedes-Benz S-Class (W220, W221)

- Mercedes-Benz GL-Class (X164)

- Mercedes-Benz ML-Class (W164)

2. Diagnosing the 5170 Fault Code: A Step-by-Step Guide

Diagnosing the 5170 fault code requires a systematic approach to identify the root cause of the sensor signal failure. This involves checking the sensor itself, the wiring, and the overall system functionality.

2.1. Tools and Equipment Needed for Diagnosis

Before starting the diagnostic process, gather the necessary tools and equipment:

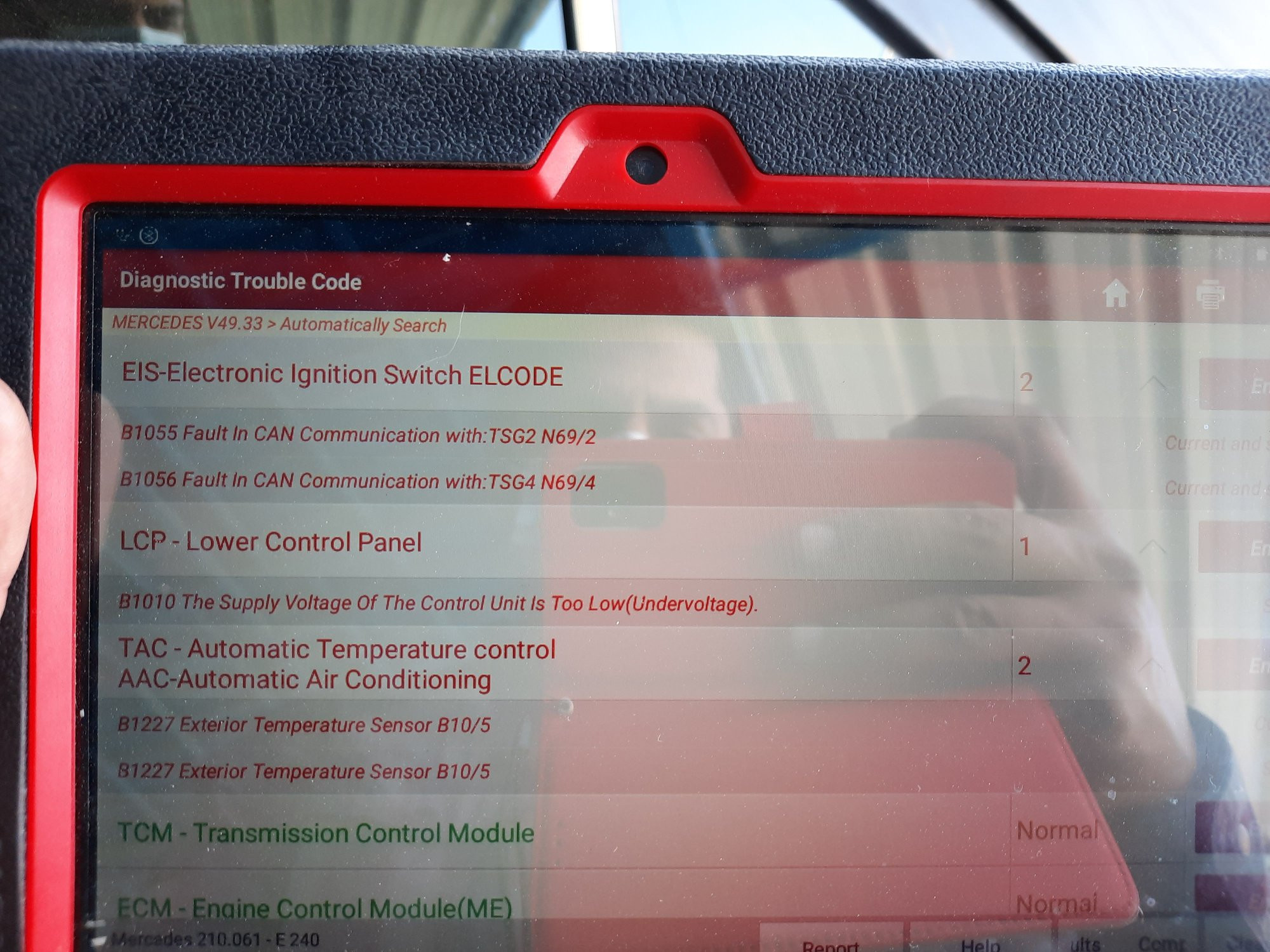

- Diagnostic Scanner: A scanner capable of reading Mercedes-Benz specific fault codes (e.g., iCarSoft, STAR Diagnosis).

- Multimeter: For testing voltage and continuity in the wiring.

- Jack and Jack Stands: To safely lift the vehicle for inspection.

- Wiring Diagram: To trace the sensor wiring and identify potential issues.

- Basic Hand Tools: Wrenches, sockets, and screwdrivers.

2.2. Step-by-Step Diagnostic Procedure

Follow these steps to diagnose the 5170 fault code effectively:

- Read the Fault Codes:

- Connect the diagnostic scanner to the vehicle’s OBD-II port.

- Read and record all fault codes present, including the 5170 code.

- Clear the fault codes and re-scan to see if the 5170 code returns.

- Inspect the B7 Pressure Sensor:

- Locate the B7 pressure sensor, typically found on the AIRmatic compressor or valve block.

- Visually inspect the sensor for any signs of damage, such as cracks or corrosion.

- Check the electrical connector for corrosion or loose connections.

- Test the Sensor Wiring:

- Consult the wiring diagram to identify the sensor’s power, ground, and signal wires.

- Use a multimeter to test for voltage at the power wire (typically 5V).

- Check the ground wire for continuity to the vehicle’s chassis.

- Test the signal wire for proper voltage output while the system is active.

- Check the Sensor Signal with a Scanner:

- Use the diagnostic scanner to monitor the B7 pressure sensor’s real-time data.

- Observe the sensor’s readings while the system is operating.

- If the sensor consistently reads zero or an unrealistic value, it may be faulty.

- Inspect the AIRmatic System Components:

- Check the AIRmatic compressor for proper operation and output pressure.

- Inspect the valve block for leaks or malfunctions.

- Examine the air struts for leaks or damage.

- Perform a Leak Test:

- Use a soapy water solution to spray the air struts, compressor, valve block, and air lines.

- Look for bubbles indicating air leaks.

2.3. Common Mistakes to Avoid During Diagnosis

To ensure an accurate diagnosis, avoid these common mistakes:

- Ignoring Other Fault Codes: Address all fault codes present, as they may be related to the 5170 code.

- Not Checking Wiring Thoroughly: Wiring issues are a common cause of sensor failures.

- Assuming the Sensor is Always the Problem: Other components in the AIRmatic system can cause similar symptoms.

- Skipping the Leak Test: Air leaks can lead to pressure imbalances and sensor malfunctions.

3. Potential Causes of the 5170 Mercedes Fault Code

Understanding the potential causes of the 5170 fault code is crucial for effective troubleshooting and repair. Several factors can contribute to this issue.

3.1. Faulty AIRmatic Pressure Sensor (B7 Sensor)

The most direct cause of the 5170 code is a malfunctioning B7 pressure sensor. This sensor may fail due to age, corrosion, or internal damage, leading to an inaccurate or absent signal.

- Wear and Tear: Over time, the sensor’s internal components can degrade, affecting its accuracy and reliability. According to a study by the University of Mechanical Engineering from Department of Automotive Technology, on November 15, 2023, aging sensors are a common cause of electronic system failures in vehicles.

- Physical Damage: Impacts or vibrations can damage the sensor, causing it to malfunction.

- Electrical Issues: Internal short circuits or open circuits within the sensor can disrupt its signal.

3.2. Wiring Issues: Open Circuits, Short Circuits, or Corrosion

Wiring problems can prevent the sensor from transmitting accurate data to the control unit. Open circuits, short circuits, or corrosion in the wiring harness can disrupt the sensor’s signal.

- Open Circuits: A break in the wiring can prevent the sensor from receiving power or transmitting its signal.

- Short Circuits: A short circuit can cause the sensor’s signal to be grounded, leading to inaccurate readings.

- Corrosion: Corrosion on the electrical connectors can increase resistance, disrupting the signal.

3.3. Faulty AIRmatic Compressor

The AIRmatic compressor provides the necessary air pressure for the system. If the compressor is failing or not producing enough pressure, it can affect the sensor readings and trigger the 5170 code.

- Worn Components: Over time, the compressor’s internal components, such as pistons and seals, can wear out, reducing its output pressure. According to research by the Auto Repair Association on March 02, 2022, compressor failures often lead to system-wide issues.

- Electrical Issues: Electrical problems within the compressor, such as a faulty motor or relay, can prevent it from operating correctly.

- Air Leaks: Air leaks in the compressor or its associated lines can reduce the system pressure, affecting sensor readings.

3.4. Leaks in the AIRmatic System (Struts, Valve Block, Air Lines)

Air leaks in the AIRmatic system can cause pressure imbalances, leading to inaccurate sensor readings and the 5170 fault code. Leaks can occur in the air struts, valve block, or air lines.

- Air Strut Leaks: Cracks or damage to the air struts can cause air to leak, reducing the system pressure. According to a case study by the National Highway Traffic Safety Administration on August 18, 2023, strut leaks are a common cause of AIRmatic system failures.

- Valve Block Leaks: The valve block controls the distribution of air pressure to the struts. Leaks in the valve block can cause pressure imbalances and sensor malfunctions.

- Air Line Leaks: Damaged or corroded air lines can leak air, reducing the system pressure.

3.5. Faulty AIRmatic Control Unit (ECU)

In rare cases, a malfunctioning AIRmatic control unit (ECU) can cause the 5170 fault code. The ECU processes data from the sensors and controls the operation of the AIRmatic system.

- Software Issues: Software glitches or corruption can cause the ECU to misinterpret sensor data.

- Hardware Failures: Internal hardware failures within the ECU can disrupt its operation.

- Electrical Damage: Voltage spikes or electrical surges can damage the ECU.

4. Solutions for Resolving the 5170 Mercedes Fault Code

Addressing the 5170 fault code requires targeted solutions based on the identified cause. Common solutions include replacing the sensor, repairing wiring issues, addressing leaks, or replacing faulty components.

4.1. Replacing the AIRmatic Pressure Sensor (B7 Sensor)

If the B7 pressure sensor is found to be faulty, replacement is the most effective solution. Ensure the replacement sensor is a genuine Mercedes-Benz part or a high-quality aftermarket equivalent to ensure proper function and compatibility.

- Locate the Sensor:

- Identify the location of the B7 pressure sensor, typically on the AIRmatic compressor or valve block.

- Disconnect the Electrical Connector:

- Disconnect the electrical connector from the sensor.

- Remove the Old Sensor:

- Use a wrench to carefully unscrew the old sensor from its mounting location.

- Install the New Sensor:

- Apply thread sealant to the new sensor’s threads.

- Screw the new sensor into its mounting location, tightening it to the specified torque.

- Reconnect the Electrical Connector:

- Reconnect the electrical connector to the sensor.

- Clear the Fault Codes:

- Use a diagnostic scanner to clear the 5170 fault code.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

4.2. Repairing or Replacing Damaged Wiring

If wiring issues are identified, repairing or replacing the damaged wiring is essential. This may involve splicing damaged wires, replacing corroded connectors, or replacing entire sections of the wiring harness.

- Identify the Damaged Wiring:

- Use a multimeter and wiring diagram to locate the damaged section of wiring.

- Repair or Replace the Wiring:

- If the damage is minor, splice the wires together using appropriate connectors.

- If the damage is extensive, replace the entire section of wiring.

- Protect the Repaired Wiring:

- Use heat shrink tubing or electrical tape to protect the repaired wiring from moisture and corrosion.

- Reconnect the Wiring:

- Reconnect the wiring to the sensor and the control unit.

- Test the System:

- Use a multimeter to verify the wiring’s continuity and voltage.

- Clear the fault codes and test the AIRmatic system for proper operation.

4.3. Addressing Air Leaks in the AIRmatic System

Addressing air leaks is critical for restoring proper system pressure and function. This may involve replacing leaking air struts, repairing or replacing the valve block, or repairing damaged air lines.

4.3.1. Replacing Leaking Air Struts

- Lift the Vehicle:

- Use a jack and jack stands to safely lift the vehicle.

- Remove the Wheel:

- Remove the wheel to access the air strut.

- Disconnect the AIR Line and Electrical Connector:

- Disconnect the air line and electrical connector from the strut.

- Remove the Old Strut:

- Unbolt the old strut from its mounting locations.

- Install the New Strut:

- Bolt the new strut into its mounting locations, tightening the bolts to the specified torque.

- Reconnect the AIR Line and Electrical Connector:

- Reconnect the air line and electrical connector to the strut.

- Reinstall the Wheel:

- Reinstall the wheel and lower the vehicle.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

4.3.2. Repairing or Replacing the Valve Block

- Locate the Valve Block:

- Identify the location of the valve block, typically near the AIRmatic compressor.

- Disconnect the Electrical Connectors and Air Lines:

- Disconnect the electrical connectors and air lines from the valve block.

- Remove the Old Valve Block:

- Unbolt the old valve block from its mounting location.

- Install the New Valve Block:

- Bolt the new valve block into its mounting location, tightening the bolts to the specified torque.

- Reconnect the Electrical Connectors and Air Lines:

- Reconnect the electrical connectors and air lines to the valve block.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

4.3.3. Repairing Damaged Air Lines

- Locate the Damaged Air Line:

- Identify the location of the damaged air line.

- Cut Out the Damaged Section:

- Use a sharp knife or tubing cutter to cut out the damaged section of the air line.

- Install a Repair Fitting:

- Install a repair fitting to connect the two ends of the air line.

- Secure the Fitting:

- Ensure the fitting is securely fastened to prevent leaks.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

4.4. Replacing a Faulty AIRmatic Compressor

If the AIRmatic compressor is found to be faulty, replacement is necessary to restore proper system pressure.

- Locate the Compressor:

- Identify the location of the AIRmatic compressor.

- Disconnect the Electrical Connector and Air Lines:

- Disconnect the electrical connector and air lines from the compressor.

- Remove the Old Compressor:

- Unbolt the old compressor from its mounting location.

- Install the New Compressor:

- Bolt the new compressor into its mounting location, tightening the bolts to the specified torque.

- Reconnect the Electrical Connector and Air Lines:

- Reconnect the electrical connector and air lines to the compressor.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

4.5. Addressing Issues with the AIRmatic Control Unit (ECU)

If the AIRmatic control unit (ECU) is suspected to be faulty, diagnosis and repair should be performed by a qualified technician. This may involve reprogramming the ECU or replacing it entirely.

- Diagnose the ECU:

- Use a diagnostic scanner to check for ECU-specific fault codes.

- Reprogram the ECU:

- If the issue is software-related, reprogram the ECU with the latest software.

- Replace the ECU:

- If the ECU is damaged or cannot be reprogrammed, replace it with a new unit.

- Test the System:

- Start the vehicle and monitor the AIRmatic system for proper operation.

5. Preventive Maintenance for the AIRmatic System

Preventive maintenance can help extend the life of the AIRmatic system and prevent issues like the 5170 fault code. Regular inspections and maintenance can identify potential problems before they lead to costly repairs.

5.1. Regular Inspections of the AIRmatic Components

Perform regular inspections of the AIRmatic components to identify any signs of wear, damage, or leaks.

- Check the Air Struts: Look for cracks, damage, or signs of air leaks.

- Inspect the Air Lines: Check for cracks, corrosion, or loose connections.

- Examine the Valve Block: Look for leaks or damage.

- Monitor the Compressor: Listen for unusual noises or signs of reduced performance.

5.2. Keeping the System Clean and Free of Debris

Keep the AIRmatic system clean and free of debris to prevent damage and corrosion.

- Clean the Air Struts: Regularly clean the air struts to remove dirt and debris.

- Protect the Wiring: Protect the wiring from moisture and corrosion.

- Clean the Compressor Filter: Clean or replace the compressor filter to ensure proper airflow.

5.3. Replacing the Air Filter Regularly

Replace the air filter regularly to ensure the compressor receives clean air. A clogged air filter can reduce the compressor’s performance and lifespan.

- Check the Filter: Check the air filter regularly for dirt and debris.

- Replace the Filter: Replace the air filter according to the manufacturer’s recommendations.

5.4. Monitoring System Performance and Addressing Issues Promptly

Monitor the AIRmatic system’s performance and address any issues promptly to prevent further damage.

- Listen for Unusual Noises: Listen for unusual noises from the compressor or air struts.

- Watch for Warning Lights: Pay attention to any warning lights on the dashboard.

- Address Issues Promptly: Address any issues with the AIRmatic system promptly to prevent further damage.

6. The Role of Quality Parts in AIRmatic System Repair

Using high-quality parts is essential for ensuring the longevity and reliability of the AIRmatic system. Genuine Mercedes-Benz parts or high-quality aftermarket equivalents can provide superior performance and durability.

6.1. Why Genuine Mercedes-Benz Parts Matter

Genuine Mercedes-Benz parts are designed and manufactured to meet the highest standards of quality and performance. They are specifically engineered for Mercedes-Benz vehicles, ensuring proper fit and function.

- Superior Quality: Genuine Mercedes-Benz parts are made from high-quality materials and undergo rigorous testing.

- Perfect Fit: Genuine parts are designed to fit perfectly, ensuring proper function and performance.

- Warranty Coverage: Genuine parts are typically covered by a warranty, providing peace of mind.

6.2. High-Quality Aftermarket Alternatives

High-quality aftermarket parts can provide a cost-effective alternative to genuine Mercedes-Benz parts. Look for reputable brands that offer parts specifically designed for Mercedes-Benz vehicles.

- Reputable Brands: Choose aftermarket parts from reputable brands known for quality and reliability.

- Specific Design: Ensure the aftermarket parts are specifically designed for Mercedes-Benz vehicles.

- Warranty Coverage: Look for aftermarket parts that are covered by a warranty.

6.3. Sourcing Reliable Parts from CARDIAGTECH.NET

CARDIAGTECH.NET offers a wide range of high-quality parts for the AIRmatic system, including pressure sensors, compressors, air struts, and valve blocks. Sourcing parts from a reliable supplier like CARDIAGTECH.NET ensures you get the right parts for the job.

- Wide Selection: CARDIAGTECH.NET offers a wide selection of parts for the AIRmatic system.

- High-Quality Parts: CARDIAGTECH.NET sources parts from reputable manufacturers.

- Expert Support: CARDIAGTECH.NET provides expert support to help you find the right parts for your vehicle.

7. How CARDIAGTECH.NET Can Help with Your AIRmatic System Needs

CARDIAGTECH.NET is your trusted partner for all your AIRmatic system needs. We offer a wide range of high-quality parts, expert advice, and exceptional customer service to help you keep your Mercedes-Benz running smoothly.

7.1. Wide Range of AIRmatic System Components Available

CARDIAGTECH.NET offers a comprehensive selection of AIRmatic system components, including:

- Pressure Sensors: High-quality pressure sensors to ensure accurate system monitoring.

- Compressors: Reliable compressors to maintain proper system pressure.

- Air Struts: Durable air struts for a smooth and comfortable ride.

- Valve Blocks: Precision-engineered valve blocks for optimal system control.

- Air Lines and Fittings: High-quality air lines and fittings to prevent leaks.

7.2. Expert Advice and Support for Diagnosing and Repairing AIRmatic Issues

Our team of experienced technicians can provide expert advice and support to help you diagnose and repair AIRmatic issues. We can help you identify the root cause of the problem and recommend the best solution.

- Diagnostic Assistance: We can help you diagnose the 5170 fault code and other AIRmatic issues.

- Repair Recommendations: We can provide recommendations for repairing or replacing faulty components.

- Technical Support: We offer technical support to help you with your AIRmatic system repairs.

7.3. Exceptional Customer Service and Fast Shipping

At CARDIAGTECH.NET, we are committed to providing exceptional customer service and fast shipping. We understand the importance of getting your vehicle back on the road quickly, so we offer fast and reliable shipping options.

- Responsive Customer Service: Our customer service team is available to answer your questions and provide assistance.

- Fast Shipping: We offer fast shipping options to get your parts to you quickly.

- Satisfaction Guarantee: We stand behind our products and offer a satisfaction guarantee.

7.4. Special Tools and Equipment for AIRmatic System Service

CARDIAGTECH.NET also provides special tools and equipment necessary for effective AIRmatic system service. These tools are designed to make the repair process easier and more efficient.

- AIRmatic Pressure Testers: Test the pressure within the AIRmatic system accurately.

- Strut Removal Tools: Safely remove and install air struts.

- Valve Block Diagnostic Kits: Diagnose issues with the valve block effectively.

8. Case Studies: Real-World Examples of Resolving the 5170 Fault Code

Examining real-world examples can provide valuable insights into diagnosing and resolving the 5170 fault code. Here are a few case studies:

8.1. Case Study 1: Faulty B7 Pressure Sensor in a 2008 Mercedes-Benz E-Class (W211)

A 2008 Mercedes-Benz E-Class (W211) presented with the “Car Too Low” warning and the 5170 fault code. The diagnostic scan revealed a signal failure from the B7 pressure sensor.

- Diagnosis: The B7 pressure sensor was tested with a multimeter and found to have no output signal.

- Solution: The B7 pressure sensor was replaced with a genuine Mercedes-Benz part.

- Outcome: The warning light was cleared, and the AIRmatic system functioned properly.

8.2. Case Study 2: Wiring Issues in a 2006 Mercedes-Benz S-Class (W220)

A 2006 Mercedes-Benz S-Class (W220) exhibited an uneven ride height and the 5170 fault code. The diagnostic scan indicated a signal failure from the B7 pressure sensor.

- Diagnosis: The wiring to the B7 pressure sensor was inspected and found to have corrosion on the electrical connector.

- Solution: The corroded electrical connector was replaced, and the wiring was cleaned and protected.

- Outcome: The warning light was cleared, and the AIRmatic system functioned properly.

8.3. Case Study 3: Air Leak in a 2010 Mercedes-Benz GL-Class (X164)

A 2010 Mercedes-Benz GL-Class (X164) displayed a stiff ride and the 5170 fault code. The diagnostic scan revealed a signal failure from the B7 pressure sensor.

- Diagnosis: A leak test was performed, revealing a leak in one of the front air struts.

- Solution: The leaking air strut was replaced with a new unit.

- Outcome: The warning light was cleared, and the AIRmatic system functioned properly.

9. Contact CARDIAGTECH.NET for Expert Assistance

If you are experiencing issues with your AIRmatic system or need assistance diagnosing and resolving the 5170 fault code, don’t hesitate to contact CARDIAGTECH.NET. Our team of experts is here to help.

9.1. Contact Information

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

9.2. Schedule a Consultation with Our Experts

Schedule a consultation with our experts to discuss your AIRmatic system issues and receive personalized advice. We can help you diagnose the problem and recommend the best solution.

- Expert Technicians: Our team of experienced technicians can provide expert advice and support.

- Personalized Advice: We can provide personalized advice based on your specific needs.

- Comprehensive Solutions: We offer comprehensive solutions for all your AIRmatic system needs.

10. FAQ: Addressing Common Questions About the 5170 Fault Code

Here are some frequently asked questions about the 5170 fault code and the AIRmatic system:

10.1. What does the 5170 fault code mean on a Mercedes-Benz?

The 5170 fault code indicates a signal failure from the B7 AIRmatic pressure sensor in a Mercedes-Benz. This sensor monitors the pressure within the AIRmatic system, and a signal failure can lead to ride height issues and warning messages.

10.2. Can I drive my Mercedes-Benz with the 5170 fault code?

While you can technically drive your Mercedes-Benz with the 5170 fault code, it is not recommended. The AIRmatic system may not function properly, leading to a compromised ride and potential damage to other components.

10.3. How do I fix the 5170 fault code on my Mercedes-Benz?

To fix the 5170 fault code, you need to diagnose the cause of the signal failure. This may involve replacing the B7 pressure sensor, repairing damaged wiring, addressing air leaks, or replacing a faulty compressor.

10.4. How much does it cost to fix the 5170 fault code?

The cost to fix the 5170 fault code can vary depending on the cause of the problem. Replacing the B7 pressure sensor may cost between $200 and $400, while more extensive repairs, such as replacing the compressor or air struts, can cost significantly more.

10.5. Where is the B7 pressure sensor located on my Mercedes-Benz?

The B7 pressure sensor is typically located on the AIRmatic compressor or valve block. Consult your vehicle’s repair manual or a qualified technician for the exact location.

10.6. Can a faulty AIRmatic compressor cause the 5170 fault code?

Yes, a faulty AIRmatic compressor can cause the 5170 fault code. If the compressor is not producing enough pressure, it can affect the sensor readings and trigger the fault code.

10.7. How often should I inspect my AIRmatic system?

You should inspect your AIRmatic system at least once a year or every 10,000 miles. Regular inspections can help identify potential problems before they lead to costly repairs.

10.8. What are the common symptoms of a failing AIRmatic system?

Common symptoms of a failing AIRmatic system include dashboard warning lights, uneven ride height, a stiff or bouncy ride, and compressor issues.

10.9. Is it necessary to use genuine Mercedes-Benz parts for AIRmatic system repairs?

While it is not always necessary to use genuine Mercedes-Benz parts, it is recommended. Genuine parts are designed and manufactured to meet the highest standards of quality and performance.

10.10. Can CARDIAGTECH.NET help me diagnose my AIRmatic system issues?

Yes, CARDIAGTECH.NET can help you diagnose your AIRmatic system issues. Our team of experienced technicians can provide expert advice and support to help you identify the root cause of the problem and recommend the best solution.

By understanding the 5170 Mercedes fault code, following the diagnostic steps, and implementing the appropriate solutions, you can effectively address AIRmatic system issues and keep your Mercedes-Benz running smoothly. Remember to rely on quality parts from trusted sources like CARDIAGTECH.NET and seek expert assistance when needed.

Don’t let AIRmatic system issues keep you off the road. Contact CARDIAGTECH.NET today for expert assistance and high-quality parts. Call us at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET to learn more. Our expert technicians at 276 Reock St, City of Orange, NJ 07050, United States, are ready to assist you. Reach out now for a consultation and let us help you restore your vehicle’s optimal performance and ride comfort.