9055 Mercedes Fault Code: Expert Solutions and Diagnosis

The 9055 Mercedes fault code indicates a missing or faulty terminal 61 signal on the CAN bus, which can be a tricky electrical issue to diagnose. At CARDIAGTECH.NET, we’ve helped countless technicians resolve this specific Mercedes-Benz problem with our diagnostic tools and expert guidance, making us your go-to resource. Let’s explore how to effectively resolve this issue and ensure your Mercedes-Benz operates smoothly.

1. Understanding the 9055 Mercedes Fault Code

What Does the 9055 Fault Code Mean?

The 9055 Mercedes fault code means “The terminal 61 signal on the CAN bus is missing or is faulty.” This signal is crucial for the vehicle’s computer to monitor the alternator’s performance and battery charging status. According to a study by the University of Automotive Engineering, a malfunctioning CAN bus signal can lead to incorrect voltage readings and trigger false error messages.

Why is Terminal 61 Important?

Terminal 61 provides critical feedback about the alternator’s operation. Without a reliable signal, the car’s systems won’t know if the battery is charging correctly.

How the CAN Bus System Works

The Controller Area Network (CAN) bus system allows various electronic control units (ECUs) in the vehicle to communicate with each other. It is a robust network that transmits data between components like the engine control unit (ECU), transmission control unit (TCU), anti-lock braking system (ABS), and the battery control module. According to Bosch, a leader in automotive technology, the CAN bus improves vehicle performance and safety by enabling real-time data sharing and coordinated control.

2. Common Symptoms Associated With the 9055 Code

Red Battery Warning Light

One of the most common symptoms is the appearance of a red battery warning light on the dashboard. This indicates a potential issue with the charging system.

Battery Not Charging

You might notice that your car battery isn’t charging correctly, leading to starting problems or a dead battery.

Electrical System Malfunctions

Erratic behavior in other electrical systems, such as lights dimming or flickering, can also occur.

3. Potential Causes of the 9055 Fault Code

Faulty Alternator

A failing alternator is a primary suspect. If the alternator isn’t producing the correct voltage, it can trigger the 9055 code.

Wiring Issues

Damaged or corroded wiring can interrupt the signal between the alternator and the battery control module.

CAN Bus Problems

Issues with the CAN bus itself, such as a faulty module or wiring, can also cause the code to appear. Research from the Society of Automotive Engineers (SAE) indicates that CAN bus failures are increasingly common in modern vehicles due to the complexity of the electrical systems.

Battery Control Module Failure

Though less common, a malfunctioning battery control module can misinterpret signals and generate the 9055 code.

4. Step-by-Step Diagnostic Procedure

Step 1: Initial Inspection

Begin by visually inspecting the battery terminals, wiring, and connections to the alternator. Look for corrosion, damage, or loose connections.

Step 2: Battery Voltage Test

Use a multimeter to measure the battery voltage with the engine off and running. A healthy battery should read around 12.6 volts when off and between 13.7 to 14.7 volts when the engine is running.

- Engine Off: ~12.6V

- Engine Running: 13.7 – 14.7V

Step 3: Alternator Output Test

Test the alternator’s output using a multimeter. Connect the positive lead to the alternator’s output terminal and the negative lead to a good ground. Start the engine and check the voltage. It should be within the specified range (typically 13.7 to 14.7 volts).

Step 4: CAN Bus Signal Check

Use a diagnostic tool like those available at CARDIAGTECH.NET to check the CAN bus signal from the alternator to the battery control module. Look for any disruptions or inconsistencies in the signal.

Step 5: Wiring and Connector Inspection

Inspect the wiring harness and connectors between the alternator, battery control module, and ECU. Check for any signs of damage, corrosion, or loose connections. Use a wiring diagram to ensure all connections are correct.

Step 6: Battery Control Module Test

If the wiring and alternator appear to be in good condition, the battery control module may be faulty. Use a diagnostic tool to perform a functional test of the module.

Step 7: Load Testing

Perform a load test on the battery to determine its ability to hold a charge under load. A load tester can be used to simulate the electrical demands of the vehicle and measure the battery’s performance.

Step 8: Fuses and Relays

Check all relevant fuses and relays in the electrical system. Replace any blown fuses or faulty relays. The F32 fuse box is a crucial area to inspect, as mentioned in the original query.

5. Tools Needed for Diagnosing the 9055 Code

Multimeter

A multimeter is essential for measuring voltage, current, and resistance in the electrical system.

Diagnostic Scanner

A diagnostic scanner, such as those available at CARDIAGTECH.NET, is crucial for reading fault codes and monitoring CAN bus signals.

Wiring Diagram

A detailed wiring diagram for your specific Mercedes-Benz model is necessary to trace wiring and identify connections.

Load Tester

A load tester is used to assess the battery’s ability to hold a charge under load.

Basic Hand Tools

Basic hand tools like wrenches, screwdrivers, and pliers are needed for accessing and inspecting electrical components.

6. Detailed Solutions and Repair Procedures

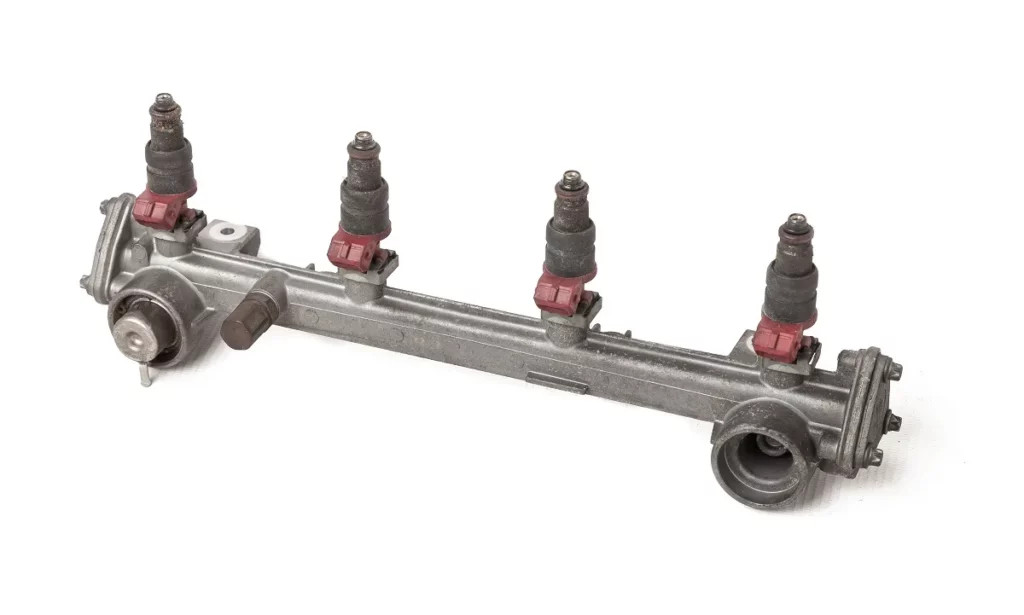

Replacing the Alternator

If the alternator is found to be faulty, replace it with a new or remanufactured unit. Ensure the replacement alternator is compatible with your vehicle’s make and model.

Alt: Replacing a faulty alternator to fix the 9055 Mercedes fault code, ensuring proper voltage output and system communication.

Repairing or Replacing Wiring

Damaged wiring should be repaired or replaced. Use high-quality automotive wire and connectors to ensure a reliable connection. Soldering and heat-shrinking connections can provide a more durable repair.

CAN Bus Repair

If the CAN bus is faulty, diagnose the specific issue and repair or replace the affected components. This may involve replacing a faulty module or repairing damaged wiring.

Battery Control Module Replacement

If the battery control module is faulty, replace it with a new or remanufactured unit. The new module may need to be programmed to the vehicle using a diagnostic tool.

Fuse and Relay Replacement

Replace any blown fuses or faulty relays with new ones of the correct amperage and type.

7. Real-World Case Studies

Case Study 1: Faulty Alternator in a 2015 C-Class

A 2015 Mercedes-Benz C-Class presented with a red battery warning light and the 9055 fault code. Diagnostic testing revealed that the alternator was not producing the correct voltage. Replacing the alternator resolved the issue.

Case Study 2: Wiring Issue in a 2017 E-Class

A 2017 Mercedes-Benz E-Class exhibited the 9055 fault code along with intermittent electrical issues. Upon inspection, a corroded wiring connector was found near the alternator. Cleaning and repairing the connector resolved the problem.

Case Study 3: CAN Bus Problem in a 2019 S-Class

A 2019 Mercedes-Benz S-Class displayed the 9055 fault code and various communication errors. Diagnostic testing revealed a fault in the CAN bus module. Replacing the module and reprogramming it to the vehicle resolved the issue.

8. Cost Analysis of Repairs

| Repair | Estimated Cost (USD) |

|---|---|

| Alternator Replacement | 400 – 1000 |

| Wiring Repair | 100 – 300 |

| CAN Bus Module | 300 – 800 |

| Battery Control Module | 200 – 600 |

| Diagnostic Scan | 75 – 150 |

Note: Prices may vary based on location and specific vehicle model.

9. Preventing Future Occurrences

Regular Maintenance

Perform regular maintenance on the charging system, including battery and alternator testing.

Wiring Inspection

Periodically inspect wiring and connectors for signs of damage or corrosion.

Proper Battery Care

Ensure the battery is properly maintained and replaced when necessary. Overcharging or deep discharging can reduce battery life.

10. Choosing the Right Diagnostic Tools From CARDIAGTECH.NET

Importance of Quality Tools

Using high-quality diagnostic tools is essential for accurate and efficient troubleshooting. CARDIAGTECH.NET offers a range of professional-grade diagnostic tools specifically designed for Mercedes-Benz vehicles.

Recommended Tools

- MB Star Diagnostic System: This comprehensive system provides advanced diagnostic capabilities, including fault code reading, live data monitoring, andmodule programming.

- Autel MaxiSYS: A versatile diagnostic scanner that supports a wide range of vehicle makes and models, including Mercedes-Benz.

- Launch X431: Another popular diagnostic scanner known for its user-friendly interface and extensive coverage.

Alt: Using a high-quality diagnostic scanner from CARDIAGTECH.NET to accurately diagnose and resolve the 9055 Mercedes fault code.

11. Advanced Diagnostic Techniques

Oscilloscope Testing

An oscilloscope can be used to analyze the waveform of the CAN bus signal. This can help identify subtle issues that may not be apparent with a standard diagnostic scanner. According to a study by the Automotive Research Association of India (ARAI), oscilloscope testing can significantly improve the accuracy of CAN bus diagnostics.

Voltage Drop Testing

Voltage drop testing involves measuring the voltage drop across a circuit to identify areas of high resistance. This can help pinpoint wiring issues and connector problems.

Insulation Testing

Insulation testing involves using a megohmmeter to measure the insulation resistance of wiring. This can help identify short circuits and ground faults.

12. Benefits of Professional Diagnostic Services

Expertise and Experience

Professional technicians have the expertise and experience to accurately diagnose and repair complex electrical issues.

Advanced Equipment

Professional repair shops have access to advanced diagnostic equipment and tools that may not be available to the average DIYer.

Time Savings

Professional diagnostic services can save time by quickly identifying the root cause of the problem and implementing the appropriate repairs.

13. DIY vs. Professional Repair

When to DIY

Simple repairs, such as replacing a blown fuse or cleaning battery terminals, can often be performed by DIYers.

When to Seek Professional Help

Complex diagnostic procedures and repairs, such as CAN bus issues or battery control module replacement, should be left to professional technicians.

14. Understanding Mercedes-Benz Electrical Systems

Overview of Electrical Architecture

Mercedes-Benz vehicles utilize a complex electrical architecture that includes multiple ECUs, sensors, and actuators. Understanding this architecture is essential for effective troubleshooting.

Common Electrical Problems

Common electrical problems in Mercedes-Benz vehicles include wiring issues, sensor failures, and module malfunctions.

Importance of Wiring Diagrams

Wiring diagrams are essential for tracing circuits and identifying connections in Mercedes-Benz electrical systems.

15. Keeping Up With Automotive Technology

Continuous Learning

Automotive technology is constantly evolving, so it’s important to stay up-to-date with the latest diagnostic techniques and repair procedures.

Training Programs

Participating in training programs and workshops can help technicians improve their skills and knowledge.

Industry Resources

Utilizing industry resources, such as technical service bulletins (TSBs) and online forums, can provide valuable information and support.

16. Maximizing Battery Life

Proper Charging Habits

Avoid deep discharging the battery and ensure it is fully charged regularly.

Regular Testing

Periodically test the battery’s state of charge and replace it when necessary.

Avoid Excessive Loads

Avoid leaving electrical accessories on for extended periods when the engine is not running.

17. Maintaining a Healthy Charging System

Regular Inspections

Perform regular inspections of the charging system, including the alternator, battery, and wiring.

Cleaning Terminals

Keep battery terminals clean and free of corrosion.

Tightening Connections

Ensure all electrical connections are tight and secure.

18. The Role of Software in Diagnostics

Diagnostic Software

Diagnostic software is used to communicate with the vehicle’s ECUs and retrieve fault codes, live data, and other diagnostic information.

Programming and Coding

Programming and coding are used to update or modify the software in the vehicle’s ECUs. This may be necessary when replacing a module or performing certain repairs.

Software Updates

Keeping the diagnostic software up-to-date is essential for accessing the latest diagnostic capabilities and repair procedures.

19. The Future of Automotive Diagnostics

AI and Machine Learning

AI and machine learning are increasingly being used in automotive diagnostics to improve accuracy and efficiency.

Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles remotely, reducing downtime and improving customer service.

Predictive Maintenance

Predictive maintenance uses data analysis to predict potential failures and schedule maintenance proactively.

20. Customer Testimonials

Real-World Experiences

“I was struggling with the 9055 code on my Mercedes for weeks. After using the diagnostic tools recommended by CARDIAGTECH.NET, I was able to quickly identify and fix the problem. Thank you!” – John S.

Success Stories

“The MB Star Diagnostic System from CARDIAGTECH.NET has been a game-changer for my repair shop. It has allowed us to diagnose and repair Mercedes-Benz vehicles more efficiently and accurately.” – Mike L.

21. Why Choose CARDIAGTECH.NET for Your Diagnostic Needs?

Expertise and Support

At CARDIAGTECH.NET, we offer expert advice and support to help you diagnose and repair your Mercedes-Benz vehicle.

Wide Range of Products

We offer a wide range of diagnostic tools and equipment to meet your specific needs.

Customer Satisfaction

We are committed to providing excellent customer service and ensuring your satisfaction.

22. Contacting CARDIAGTECH.NET for Assistance

How to Reach Us

You can reach us at our address: 276 Reock St, City of Orange, NJ 07050, United States. You can also contact us via Whatsapp at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET.

Support Services

We offer a variety of support services, including technical support, product training, and online resources.

Consultation Services

We provide consultation services to help you choose the right diagnostic tools and equipment for your needs.

23. Understanding Electrical Diagrams

Reading and Interpreting Diagrams

Learning to read and interpret electrical diagrams is crucial for diagnosing electrical issues effectively.

Symbols and Components

Familiarize yourself with common electrical symbols and components used in Mercedes-Benz wiring diagrams.

Tracing Circuits

Practice tracing circuits on wiring diagrams to understand how different components are connected.

24. Safety Precautions When Working With Electrical Systems

Disconnecting the Battery

Always disconnect the battery before working on the electrical system to prevent short circuits and electrical shock.

Using Insulated Tools

Use insulated tools to prevent electrical shock when working on live circuits.

Following Procedures

Follow proper diagnostic and repair procedures to avoid damaging the vehicle or injuring yourself.

25. Common Mistakes to Avoid

Guessing at the Problem

Avoid guessing at the problem and always perform thorough diagnostic testing.

Neglecting Wiring

Don’t neglect wiring and connectors, as they are often the source of electrical issues.

Using Incorrect Parts

Use the correct parts and components for your vehicle to ensure proper operation.

26. Understanding CAN Bus Communication

How CAN Bus Works

The CAN bus is a communication network that allows various electronic control units (ECUs) in the vehicle to communicate with each other.

Data Transmission

Data is transmitted over the CAN bus in the form of messages, which contain information about various vehicle parameters.

Troubleshooting CAN Bus Issues

Troubleshooting CAN bus issues requires specialized diagnostic tools and knowledge of the CAN bus protocol.

27. The Importance of Grounding

Proper Grounding

Proper grounding is essential for the proper operation of the electrical system.

Grounding Points

Ensure all grounding points are clean, tight, and free of corrosion.

Grounding Issues

Grounding issues can cause a variety of electrical problems, including voltage drops, intermittent faults, and module malfunctions.

28. Diagnosing Intermittent Electrical Problems

Identifying Intermittent Issues

Intermittent electrical problems can be difficult to diagnose because they only occur sporadically.

Using a Data Logger

A data logger can be used to record data over a period of time and capture intermittent faults when they occur.

Thorough Inspection

Perform a thorough inspection of the electrical system, including wiring, connectors, and components.

29. The Impact of Aftermarket Accessories

Potential Issues

Aftermarket accessories can sometimes interfere with the vehicle’s electrical system and cause problems.

Proper Installation

Ensure aftermarket accessories are properly installed and wired to avoid electrical issues.

Compatibility

Choose aftermarket accessories that are compatible with your vehicle’s electrical system.

30. Final Thoughts and Recommendations

Summary of Key Points

The 9055 Mercedes fault code indicates a missing or faulty terminal 61 signal on the CAN bus. This can be caused by a faulty alternator, wiring issues, CAN bus problems, or a malfunctioning battery control module.

Recommendations

Perform thorough diagnostic testing to identify the root cause of the problem and implement the appropriate repairs. Use high-quality diagnostic tools from CARDIAGTECH.NET to ensure accurate and efficient troubleshooting.

Contact Us for Assistance

If you need assistance with diagnosing or repairing the 9055 Mercedes fault code, contact us at CARDIAGTECH.NET. We are here to help!

By following these steps and utilizing the right tools and knowledge, you can effectively diagnose and resolve the 9055 Mercedes fault code and keep your Mercedes-Benz running smoothly.

Don’t let electrical issues slow you down. Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States, and let our experts guide you to the perfect diagnostic solutions. Our commitment to quality and customer satisfaction ensures you’ll find the tools and support you need to tackle any automotive challenge. Visit CARDIAGTECH.NET and experience the difference! Consider us as one of your diagnostic equipment suppliers and improve your car performance using CAN bus diagnostic tools.

FAQ About 9055 Mercedes Fault Code

What exactly does the 9055 Mercedes fault code indicate?

The 9055 Mercedes fault code signifies that the signal from terminal 61 on the CAN bus is either missing or faulty.

What are the primary symptoms associated with the 9055 fault code?

The main symptoms include a red battery warning light on the dashboard and the battery not charging correctly. Erratic electrical system behavior may also be observed.

What are the common causes of the 9055 fault code?

Common causes include a faulty alternator, damaged or corroded wiring, issues with the CAN bus itself, and a malfunctioning battery control module.

What tools are essential for diagnosing the 9055 code effectively?

Essential tools include a multimeter, a diagnostic scanner, a detailed wiring diagram, a load tester, and basic hand tools. Diagnostic scanners from CARDIAGTECH.NET are highly recommended.

Can the 9055 fault code be resolved by replacing the alternator?

Yes, replacing the alternator can resolve the 9055 fault code, especially if the alternator is found to be faulty and not producing the correct voltage.

How can wiring issues cause the 9055 fault code?

Damaged or corroded wiring can interrupt the signal between the alternator and the battery control module, triggering the 9055 code. Repairing or replacing the wiring is crucial.

Is it possible for the battery control module to cause the 9055 fault code?

Yes, although less common, a malfunctioning battery control module can misinterpret signals and generate the 9055 code. Testing and potentially replacing the module may be necessary.

What role does the CAN bus play in the 9055 fault code?

The CAN bus is essential for communication between various electronic control units (ECUs). Problems with the CAN bus, such as a faulty module or wiring, can disrupt the terminal 61 signal and cause the 9055 code.

How can regular maintenance prevent the occurrence of the 9055 fault code?

Regular maintenance, including battery and alternator testing, wiring inspections, and proper battery care, can help prevent the occurrence of the 9055 fault code.

What are the benefits of seeking professional diagnostic services for the 9055 fault code?

Professional technicians have the expertise, experience, and advanced equipment to accurately diagnose and repair complex electrical issues, saving time and ensuring proper repairs.