9123 Mercedes Fault Code: Expert Solutions & Repair Guide

Navigating Mercedes-Benz diagnostic trouble codes can be complex, especially when dealing with SRS (Supplemental Restraint System) issues. The 9123 Mercedes fault code indicates a resistance problem in the ignition circuit. This article provides a detailed guide to diagnosing and resolving the 9123 fault code, ensuring your Mercedes’ safety systems function correctly. For specialized tools and equipment to tackle these repairs effectively, visit CARDIAGTECH.NET, your trusted partner in automotive diagnostics and repair solutions, call us at Whatsapp: +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States. We’ll explore the root causes, diagnostic steps, and repair procedures and offer expert advice on maintaining your vehicle’s safety systems.

1. Understanding the 9123 Mercedes Fault Code

What Does the 9123 Code Signify?

The 9123 Mercedes fault code indicates that the resistance value in the ignition circuit containing component R12/14 is too high. This high resistance can disrupt the electrical signals needed for the proper operation of the Supplemental Restraint System (SRS), potentially affecting the deployment of airbags in the event of a collision.

- High Resistance: Prevents proper signal transmission.

- SRS Impact: Affects airbag deployment.

- Safety Hazard: Compromises vehicle safety.

What are the Common Symptoms Associated With the 9123 Fault Code?

Several symptoms may indicate the presence of the 9123 fault code, each pointing to potential issues within the SRS. Here’s what to watch out for:

- SRS Warning Light: The most common symptom is an illuminated SRS warning light on the dashboard.

- Diagnostic Trouble Codes (DTCs): The diagnostic system will log the 9123 fault code, which can be read using a diagnostic scanner.

- Potential Airbag Malfunction: The SRS may not function correctly, meaning airbags might not deploy in an accident.

- System Inactivity: The entire SRS system may become inactive as a safety measure.

Why is Addressing the 9123 Fault Code Important?

Addressing the 9123 fault code is paramount for ensuring the safety and proper functioning of your Mercedes-Benz. Ignoring this issue can lead to severe consequences.

- Safety: Ensuring airbags deploy correctly in a collision.

- System Integrity: Maintaining the overall functionality of the SRS.

- Legal Compliance: Addressing safety-related issues to comply with regulations.

2. Diagnosing the 9123 Mercedes Fault Code

Step-by-Step Diagnostic Procedure

Diagnosing the 9123 fault code requires a systematic approach to identify the root cause of the high resistance in the ignition circuit.

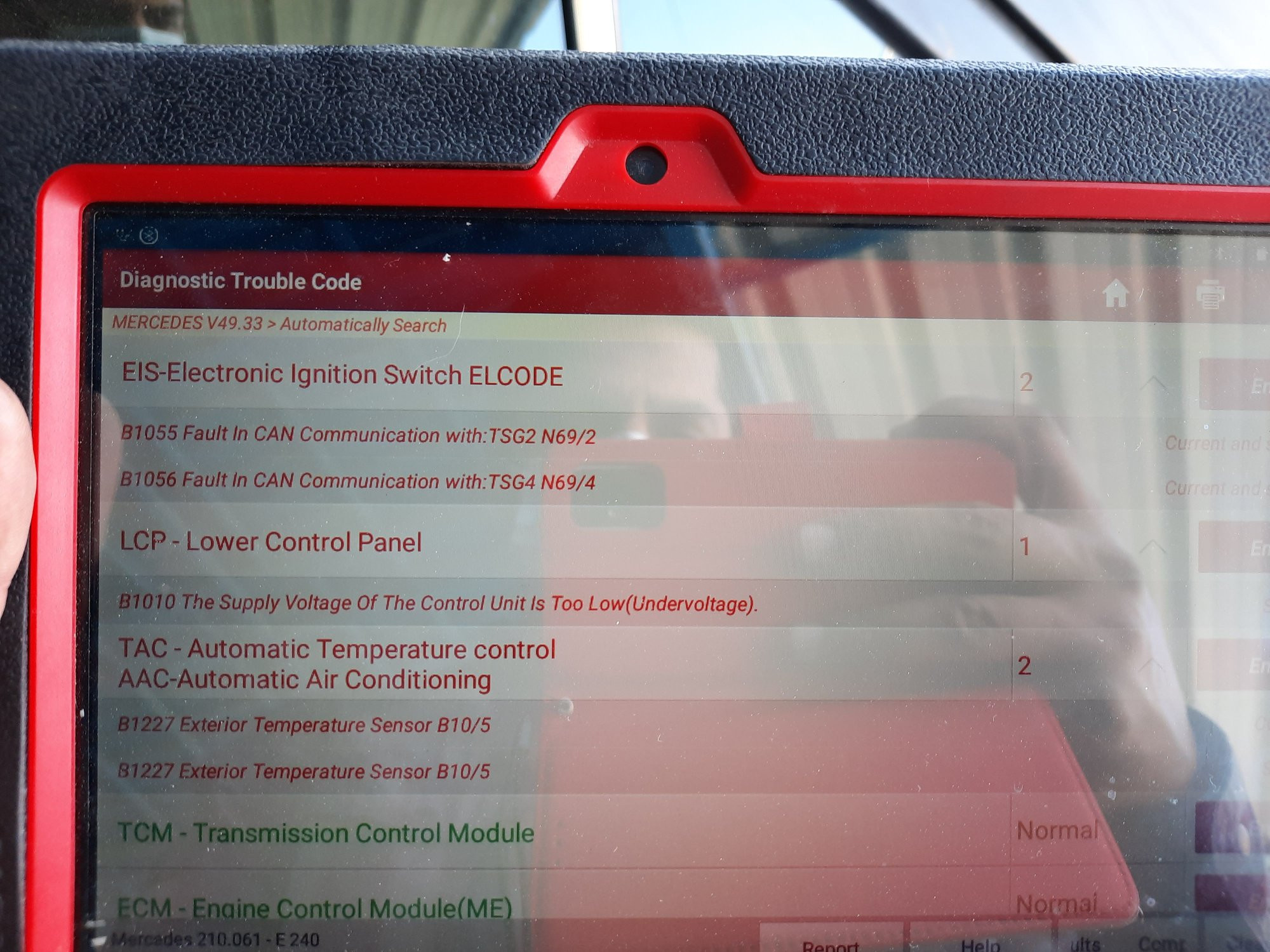

- Initial Scan: Use a diagnostic scanner to confirm the presence of the 9123 fault code.

- Visual Inspection: Check the wiring and connectors related to the SRS system for any signs of damage or corrosion.

- Resistance Measurement: Use a multimeter to measure the resistance in the ignition circuit containing component R12/14.

- Component Testing: Test the individual components within the circuit to identify any faulty parts.

- Wiring Continuity: Check the continuity of the wiring to ensure there are no breaks or shorts.

- Ground Connections: Inspect ground connections to ensure they are clean and secure.

Tools Required for Diagnosis

Having the right tools is crucial for accurately diagnosing the 9123 fault code. Here’s a list of essential equipment:

- Diagnostic Scanner: To read and clear fault codes.

- Multimeter: To measure voltage, resistance, and current.

- Wiring Diagrams: To understand the SRS circuit layout.

- Basic Hand Tools: Such as screwdrivers, pliers, and wire strippers.

- Connector Cleaning Kit: To clean corroded connectors.

Investing in high-quality diagnostic tools from CARDIAGTECH.NET can significantly enhance your diagnostic capabilities and ensure accurate results. Contact us at Whatsapp: +1 (641) 206-8880.

Common Mistakes to Avoid During Diagnosis

Several common mistakes can hinder the diagnostic process, leading to inaccurate conclusions and wasted time.

- Skipping Initial Scan: Always start with a diagnostic scan to confirm the fault code.

- Ignoring Visual Inspection: Don’t overlook the importance of a thorough visual inspection of wiring and connectors.

- Inaccurate Resistance Measurement: Ensure the multimeter is properly calibrated for accurate readings.

- Neglecting Ground Connections: Poor ground connections can cause a variety of electrical issues.

- Rushing the Process: Take your time and follow a systematic approach to avoid overlooking critical details.

3. Repairing the 9123 Mercedes Fault Code

Step-by-Step Repair Procedure

Once you’ve diagnosed the 9123 fault code, the next step is to perform the necessary repairs. Here’s a detailed procedure to guide you through the process:

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical accidents.

- Access the SCM: Remove the Steering Wheel Module (SCM) following the WIS document AR54.25-P-2802PQ.

- Inspect the Wiring Harness: Check the SCM harness for any signs of damage, such as cuts, breaks, or corrosion.

- Repair or Replace Wiring: Repair any damaged wiring by splicing in new sections or replace the entire harness if necessary.

- Clean Connectors: Clean all connectors with a connector cleaning kit to ensure good electrical contact.

- Reassemble the SCM: Reinstall the SCM and ensure all connections are secure.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear Fault Codes: Use a diagnostic scanner to clear the 9123 fault code.

- Test the System: Perform a system test to ensure the SRS is functioning correctly.

Required Parts and Materials

Having the right parts and materials on hand is essential for a successful repair. Here’s a list of items you may need:

- Wiring Harness: Replacement SCM wiring harness.

- Connectors: New connectors to replace damaged ones.

- Solder Connectors: For splicing wires.

- Fabric Tape: To insulate wiring.

- Cable Ties: To secure the harness.

- Connector Cleaning Kit: To clean corroded connectors.

- Repair Wires: A001 540 94 05 repair wires

CARDIAGTECH.NET offers a wide range of high-quality parts and materials to ensure your repairs are durable and reliable. Visit our website or contact us at Whatsapp: +1 (641) 206-8880 for assistance.

Detailed Splicing and Soldering Techniques

Proper splicing and soldering are critical for ensuring a reliable electrical connection. Follow these steps for best results:

- Strip the Wires: Strip approximately 15 mm of insulation from the ends of the wires to be spliced.

- Braid the Wires: Braid the stripped ends of the wires together to create a strong mechanical connection.

- Apply Solder: Heat the braided wires with a soldering iron and apply solder to create a secure electrical connection.

- Insulate the Connection: Use fabric tape to insulate the soldered connection and protect it from moisture and corrosion.

For detailed guidance, refer to WIS document AR54.18-P-0100-06A for the specified repair method.

Post-Repair Testing and Verification

After completing the repairs, it’s essential to perform thorough testing and verification to ensure the SRS is functioning correctly.

- Clear Fault Codes: Use a diagnostic scanner to clear the 9123 fault code and any other related codes.

- System Test: Perform a system test using the diagnostic scanner to verify the SRS is functioning within specifications.

- Visual Inspection: Conduct a final visual inspection to ensure all connections are secure and wiring is properly routed.

- Road Test: Perform a road test to verify the SRS functions correctly under normal driving conditions.

4. Preventing Future Occurrences of the 9123 Fault Code

Best Practices for Maintaining the SRS

Preventing future occurrences of the 9123 fault code involves adopting best practices for maintaining the SRS.

- Regular Inspections: Conduct regular inspections of the SRS wiring and connectors.

- Clean Connections: Keep all electrical connections clean and free from corrosion.

- Proper Wiring Routing: Ensure wiring is properly routed and secured to prevent damage.

- Avoid Moisture Exposure: Protect the SRS components from moisture exposure.

- Professional Service: Seek professional service for any SRS-related issues.

Tips for Ensuring Longevity of Electrical Components

Ensuring the longevity of electrical components within the SRS can help prevent future issues.

- Use Quality Parts: Always use high-quality replacement parts.

- Proper Installation: Ensure all components are properly installed according to manufacturer specifications.

- Avoid Overloading Circuits: Avoid overloading circuits with excessive electrical devices.

- Regular Battery Maintenance: Maintain a healthy battery to ensure stable voltage supply.

- Protect from Extreme Temperatures: Protect electrical components from extreme temperatures.

Recommended Maintenance Schedule

Following a recommended maintenance schedule can help identify and address potential issues before they escalate.

- Every 12 Months: Inspect SRS wiring and connectors.

- Every 24 Months: Clean electrical connections.

- Every 36 Months: Test SRS functionality with a diagnostic scanner.

- Every 48 Months: Replace any worn or damaged components.

The Role of Professional Maintenance

While some maintenance tasks can be performed DIY, the SRS involves complex electrical systems that benefit from professional attention.

- Expertise: Professional technicians have the expertise to diagnose and repair SRS issues accurately.

- Specialized Tools: Professionals have access to specialized tools and equipment for SRS maintenance.

- Warranty: Professional service often comes with a warranty on parts and labor.

- Safety: Entrusting SRS maintenance to professionals ensures safety and reliability.

5. Choosing the Right Tools and Equipment for SRS Repairs

Essential Diagnostic Tools from CARDIAGTECH.NET

Selecting the right diagnostic tools is crucial for effectively addressing SRS issues. CARDIAGTECH.NET offers a range of essential tools designed to meet the needs of automotive professionals and DIY enthusiasts.

- Diagnostic Scanners: Advanced diagnostic scanners for reading and clearing SRS fault codes.

- Multimeters: High-precision multimeters for measuring voltage, resistance, and current.

- Wiring Test Kits: Comprehensive wiring test kits for diagnosing electrical issues.

- Connector Tools: Specialized connector tools for removing and installing electrical connectors.

- Soldering Equipment: Professional-grade soldering equipment for reliable wire repairs.

CARDIAGTECH.NET is committed to providing high-quality tools that enhance your diagnostic and repair capabilities. Contact us at Whatsapp: +1 (641) 206-8880 for expert advice and support.

Top Diagnostic Scanners for Mercedes-Benz Vehicles

Choosing the right diagnostic scanner can significantly improve your ability to diagnose and repair Mercedes-Benz vehicles. Here are some top options:

- Autel MaxiSYS MS908S Pro: An advanced scanner with comprehensive diagnostic capabilities.

- Launch X431 V+: A versatile scanner with extensive vehicle coverage.

- iCarsoft MB II: A cost-effective scanner designed specifically for Mercedes-Benz vehicles.

- Mercedes-Benz Star Diagnosis C4: The official diagnostic system used by Mercedes-Benz dealerships.

- Foxwell NT530: A reliable scanner with a user-friendly interface.

Importance of High-Quality Multimeters and Testing Equipment

High-quality multimeters and testing equipment are essential for accurate diagnosis and repair. Investing in reliable equipment ensures precise measurements and dependable results.

- Accuracy: High-quality multimeters provide accurate readings, reducing the risk of misdiagnosis.

- Durability: Durable equipment withstands the rigors of daily use in a shop environment.

- Safety: Reliable testing equipment ensures safe operation and prevents electrical accidents.

- Efficiency: Accurate measurements save time and improve diagnostic efficiency.

- Versatility: High-quality equipment can be used for a wide range of diagnostic tasks.

How CARDIAGTECH.NET Supports Your Repair Needs

CARDIAGTECH.NET is dedicated to supporting your automotive repair needs by providing high-quality tools, equipment, and expert advice.

- Wide Selection: A wide selection of diagnostic tools, equipment, and replacement parts.

- Expert Advice: Expert advice and support to help you choose the right tools and equipment.

- Competitive Prices: Competitive prices on all products.

- Fast Shipping: Fast shipping to get you the tools you need quickly.

- Customer Support: Dedicated customer support to assist with any questions or concerns.

6. The Role of Wiring and Connections in the 9123 Fault Code

Understanding the Electrical System of the SRS

The electrical system of the SRS is a complex network of wiring, connectors, and electronic components that work together to ensure the proper deployment of airbags.

- Wiring Harness: Provides the electrical pathways for signals to travel between components.

- Connectors: Allow for easy connection and disconnection of components.

- Control Module: Monitors the system and triggers airbag deployment.

- Sensors: Detect impact and send signals to the control module.

- Airbags: Deploy in response to signals from the control module.

Common Wiring and Connection Problems

Several common wiring and connection problems can lead to the 9123 fault code.

- Corrosion: Corrosion on connectors and wiring can increase resistance and disrupt signals.

- Loose Connections: Loose connections can cause intermittent electrical problems.

- Damaged Wiring: Damaged wiring, such as cuts or breaks, can interrupt the flow of electricity.

- Short Circuits: Short circuits can cause excessive current flow and damage components.

- Grounding Issues: Poor ground connections can cause a variety of electrical problems.

How to Inspect and Repair Wiring and Connections

Inspecting and repairing wiring and connections is crucial for resolving the 9123 fault code.

- Visual Inspection: Check wiring and connectors for signs of damage or corrosion.

- Continuity Testing: Use a multimeter to check the continuity of wiring.

- Voltage Testing: Use a multimeter to check voltage levels at connectors.

- Connector Cleaning: Clean corroded connectors with a connector cleaning kit.

- Wiring Repair: Repair damaged wiring by splicing in new sections or replacing the entire harness.

- Secure Connections: Ensure all connections are secure and properly seated.

The Impact of Poor Connections on SRS Functionality

Poor electrical connections can significantly impact the functionality of the SRS, potentially compromising safety.

- Increased Resistance: Poor connections increase resistance, disrupting electrical signals.

- Intermittent Problems: Loose connections can cause intermittent electrical problems.

- System Failure: Corrosion and damage can lead to system failure.

- Compromised Safety: Airbags may not deploy correctly in an accident.

- Diagnostic Challenges: Intermittent problems can be difficult to diagnose.

7. The Role of the Steering Wheel Module (SCM) in the 9123 Fault Code

What is the Steering Wheel Module (SCM)?

The Steering Wheel Module (SCM) is a critical component of the SRS, responsible for transmitting electrical signals between the steering wheel and the vehicle’s electrical system.

- Signal Transmission: Facilitates communication between the steering wheel and other systems.

- Airbag Connection: Connects the airbag to the SRS control module.

- Control Functions: Integrates various control functions, such as audio and cruise control.

- Spiral Cable: Contains a spiral cable that allows the steering wheel to rotate while maintaining electrical connections.

Common Issues with the SCM

Several common issues can affect the SCM, leading to the 9123 fault code.

- Spiral Cable Failure: The spiral cable can break or become damaged, interrupting electrical signals.

- Connector Corrosion: Corrosion on the SCM connectors can increase resistance.

- Wiring Damage: Damage to the SCM wiring can disrupt electrical signals.

- Module Malfunction: The SCM itself can malfunction, causing a variety of electrical problems.

How to Diagnose SCM-Related Problems

Diagnosing SCM-related problems requires a systematic approach to identify the root cause.

- Visual Inspection: Check the SCM for any signs of damage or corrosion.

- Continuity Testing: Use a multimeter to check the continuity of the spiral cable.

- Voltage Testing: Use a multimeter to check voltage levels at the SCM connectors.

- Diagnostic Scan: Use a diagnostic scanner to check for SCM-related fault codes.

- Component Testing: Test the individual components within the SCM to identify any faulty parts.

Repairing or Replacing the SCM

Repairing or replacing the SCM may be necessary to resolve the 9123 fault code.

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical accidents.

- Remove the Steering Wheel: Remove the steering wheel following the manufacturer’s instructions.

- Remove the SCM: Remove the SCM from the steering column.

- Repair or Replace: Repair any damaged wiring or connectors, or replace the entire SCM if necessary.

- Reassemble: Reinstall the SCM and steering wheel.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear Fault Codes: Use a diagnostic scanner to clear any SCM-related fault codes.

- Test the System: Perform a system test to ensure the SRS is functioning correctly.

8. Advanced Diagnostic Techniques for the 9123 Fault Code

Using Oscilloscopes for Signal Analysis

Oscilloscopes are advanced diagnostic tools that allow you to visualize electrical signals over time, providing valuable insights into the performance of the SRS.

- Signal Visualization: Oscilloscopes display electrical signals as waveforms, making it easier to identify anomalies.

- Waveform Analysis: Analyze waveforms to identify signal distortion, noise, and other issues.

- Component Testing: Use oscilloscopes to test the performance of individual components within the SRS.

- Intermittent Problems: Oscilloscopes can help diagnose intermittent electrical problems that are difficult to detect with a multimeter.

Advanced Wiring and Circuit Testing

Advanced wiring and circuit testing techniques can help pinpoint the exact location of electrical problems within the SRS.

- Load Testing: Use a load tester to check the capacity of wiring to carry current under load.

- Insulation Testing: Use an insulation tester to check for insulation breakdown in wiring.

- Circuit Tracing: Use a circuit tracer to follow the path of electrical circuits and identify breaks or shorts.

Data Logging and Analysis

Data logging and analysis involve recording data from the SRS over time and analyzing it to identify patterns and anomalies.

- Record Data: Use a diagnostic scanner to record data from the SRS while the vehicle is in operation.

- Analyze Data: Analyze the data to identify patterns and anomalies that may indicate electrical problems.

- Intermittent Problems: Data logging can help diagnose intermittent problems that are difficult to detect with static testing.

Seeking Expert Assistance

When faced with complex diagnostic challenges, seeking expert assistance can save time and prevent misdiagnosis.

- Experienced Technicians: Consult with experienced technicians who have expertise in SRS diagnostics.

- Online Forums: Participate in online forums to share information and seek advice from other technicians.

- Technical Support: Contact the manufacturer of your diagnostic tools for technical support.

9. Case Studies: Real-World Examples of 9123 Fault Code Repairs

Case Study 1: Corrosion in SCM Connectors

- Vehicle: Mercedes-Benz C-Class

- Symptom: SRS warning light illuminated, 9123 fault code present.

- Diagnosis: Visual inspection revealed corrosion in the SCM connectors.

- Repair: Cleaned the connectors with a connector cleaning kit and applied dielectric grease to prevent future corrosion.

- Result: Fault code cleared, SRS functioning correctly.

Case Study 2: Damaged Spiral Cable

- Vehicle: Mercedes-Benz E-Class

- Symptom: SRS warning light illuminated, 9123 fault code present.

- Diagnosis: Continuity testing revealed a break in the spiral cable within the SCM.

- Repair: Replaced the SCM with a new unit.

- Result: Fault code cleared, SRS functioning correctly.

Case Study 3: Grounding Issue

- Vehicle: Mercedes-Benz S-Class

- Symptom: SRS warning light illuminated, 9123 fault code present.

- Diagnosis: Voltage testing revealed a poor ground connection.

- Repair: Cleaned and tightened the ground connection.

- Result: Fault code cleared, SRS functioning correctly.

Lessons Learned

These case studies highlight the importance of thorough diagnosis and attention to detail when addressing the 9123 fault code. Common issues such as corrosion, damaged wiring, and grounding problems can often be resolved with simple repairs.

10. FAQs About the 9123 Mercedes Fault Code

What does the 9123 Mercedes fault code mean?

The 9123 Mercedes fault code indicates that the resistance value in the ignition circuit containing component R12/14 is too high, affecting the SRS.

Can I drive my Mercedes with the 9123 fault code?

Driving with the 9123 fault code is not recommended as it indicates a problem with the SRS, potentially affecting airbag deployment.

How do I clear the 9123 fault code?

You can clear the 9123 fault code using a diagnostic scanner after repairing the underlying issue.

What tools do I need to diagnose the 9123 fault code?

You will need a diagnostic scanner, multimeter, wiring diagrams, and basic hand tools.

Is it safe to repair the SRS system myself?

Repairing the SRS system can be dangerous if not done correctly. It is recommended to seek professional assistance if you are not experienced.

How often should I inspect my Mercedes’ SRS?

You should inspect your Mercedes’ SRS at least every 12 months to ensure it is functioning correctly.

Can a bad battery cause the 9123 fault code?

Yes, a bad battery can cause voltage fluctuations that trigger the 9123 fault code.

What is the Steering Wheel Module (SCM)?

The Steering Wheel Module (SCM) is a component of the SRS that transmits electrical signals between the steering wheel and the vehicle’s electrical system.

Where can I buy reliable diagnostic tools for Mercedes-Benz vehicles?

You can buy reliable diagnostic tools for Mercedes-Benz vehicles at CARDIAGTECH.NET. Call us at Whatsapp: +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States.

What should I do if I’m unable to resolve the 9123 fault code?

If you are unable to resolve the 9123 fault code, seek assistance from a qualified Mercedes-Benz technician.

By understanding the intricacies of the 9123 Mercedes fault code and following the diagnostic and repair procedures outlined in this guide, you can ensure the safety and reliability of your vehicle’s SRS. Remember, CARDIAGTECH.NET is your trusted partner for all your automotive diagnostic and repair needs. Contact us today to explore our wide range of tools and equipment.