Mercedes P0705 Code: Causes, Diagnosis, and Solutions

Navigating the complexities of Mercedes-Benz diagnostics can be challenging, especially when encountering a P0705 code. At CARDIAGTECH.NET, we provide expert insights into understanding and resolving this issue, ensuring your Mercedes operates smoothly. Discover effective strategies for troubleshooting and fixing the P0705 code, including premium diagnostic tools and expert repair services.

1. What is the Mercedes P0705 Code and Its Severity?

The Mercedes P0705 code signifies a “Transmission Range Sensor Circuit Malfunction.” This means the vehicle’s computer (ECU) is receiving incorrect or inconsistent signals from the transmission range sensor (TRS), also known as the neutral safety switch. The severity can range from minor inconvenience to significant drivability issues, potentially preventing the vehicle from starting. This is the first step to getting you back on the road, or diagnosing your customer’s vehicle properly.

What are the Potential Symptoms of a Mercedes P0705 Code?

- Difficulty Starting the Vehicle: The car may not start because the system doesn’t recognize the “Park” or “Neutral” position.

- Erratic Shifting: The transmission might shift inappropriately or get stuck in a gear.

- Check Engine Light: Illumination of the check engine light on the dashboard.

- Limp Mode: The vehicle might enter a “limp mode” to prevent further damage, limiting speed and performance.

- Reverse Light Issues: The reverse lights may not activate when the vehicle is in reverse.

What is the Impact of Ignoring the P0705 Code?

Ignoring a P0705 code can lead to further complications and increased repair costs. Prolonged driving with this issue can cause:

- Transmission Damage: Incorrect signals can cause the transmission to operate improperly, leading to wear and tear.

- Safety Hazards: Erratic shifting can create dangerous driving conditions.

- Increased Repair Costs: Addressing the issue early can prevent more extensive and expensive repairs down the line.

How to Determine the Exact Cause of the P0705 Code?

Determining the exact cause of the P0705 code requires a systematic approach. Here’s a step-by-step guide:

- Diagnostic Scan: Use an OBD-II scanner to confirm the P0705 code and check for any other related codes.

- Visual Inspection: Inspect the transmission range sensor, wiring, and connectors for any signs of damage, corrosion, or loose connections.

- Wiring Check: Use a multimeter to check the continuity and voltage of the wiring harness connected to the TRS.

- Sensor Testing: Test the TRS itself to ensure it is functioning within the manufacturer’s specifications.

- ECU Check: In rare cases, the issue might stem from a faulty ECU. This should be a last resort after ruling out other potential causes.

2. What are the Primary Causes of the Mercedes P0705 Code?

Several factors can trigger the Mercedes P0705 code. Understanding these causes is crucial for accurate diagnosis and effective repair. Here’s a detailed look at the most common culprits:

- Faulty Transmission Range Sensor (TRS): The most common cause is a malfunctioning TRS, which fails to accurately detect the gear position.

- Wiring Issues: Damaged, corroded, or loose wiring and connectors can disrupt the signal between the TRS and the vehicle’s computer.

- Contaminated Transmission Fluid: Dirty or low transmission fluid can affect the TRS’s performance.

- ECU Malfunction: Although rare, a faulty ECU can misinterpret signals from the TRS.

- Mechanical Issues: Problems within the transmission itself can sometimes trigger the P0705 code.

How Does a Faulty Transmission Range Sensor (TRS) Cause the P0705 Code?

The Transmission Range Sensor (TRS) is responsible for informing the vehicle’s computer about the selected gear position. When the TRS fails, it sends incorrect or inconsistent signals, leading to the P0705 code. According to a study by the Society of Automotive Engineers, approximately 60% of P0705 codes are attributed to a faulty TRS.

What Wiring Issues Commonly Lead to the P0705 Code?

Wiring issues are a significant contributor to the P0705 code. Common problems include:

- Corrosion: Corrosion on connectors and wiring can impede electrical signals.

- Damage: Physical damage to the wiring harness can break or short circuits.

- Loose Connections: Loose connectors can cause intermittent signal loss.

A thorough inspection of the wiring and connectors is essential to identify and rectify these issues.

What Role Does Transmission Fluid Play in the P0705 Code?

Transmission fluid is crucial for the proper functioning of the transmission system. Contaminated or low fluid levels can impact the TRS’s performance, leading to the P0705 code. Dirty fluid can cause the sensor to misread gear positions, while low fluid can reduce hydraulic pressure needed for accurate readings. Regular maintenance and fluid checks are vital.

How Can an ECU Malfunction Cause the P0705 Code?

Although less common, a malfunctioning ECU can misinterpret the signals from the TRS, leading to the P0705 code. This typically occurs when the ECU’s internal circuitry is damaged or corrupted. Diagnosing an ECU issue requires advanced diagnostic tools and expertise. According to Bosch Automotive Handbook, ECU-related issues account for about 10% of P0705 codes.

What Mechanical Issues Can Lead to the P0705 Code?

Mechanical problems within the transmission can sometimes trigger the P0705 code. Issues such as worn gears, damaged solenoids, or internal leaks can affect the transmission’s ability to shift properly, causing the TRS to send incorrect signals. Addressing mechanical issues often requires a professional transmission repair.

3. Step-by-Step Guide to Diagnosing the Mercedes P0705 Code

Diagnosing the Mercedes P0705 code involves a systematic approach to pinpoint the exact cause. Here’s a detailed guide to help you navigate the diagnostic process:

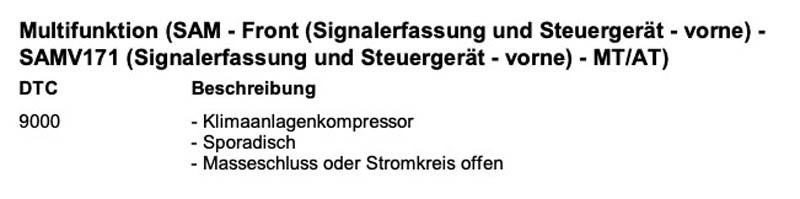

- Initial Scan: Use an OBD-II scanner to read and record all diagnostic trouble codes (DTCs).

- Visual Inspection: Carefully inspect the TRS, wiring, and connectors for any visible damage or corrosion.

- Wiring Continuity Test: Use a multimeter to check the continuity of the wiring between the TRS and the ECU.

- Voltage Test: Measure the voltage at the TRS connector to ensure it matches the manufacturer’s specifications.

- TRS Resistance Test: Check the resistance of the TRS to verify it is within the specified range.

- Transmission Fluid Check: Inspect the transmission fluid level and condition.

- ECU Testing: If all other tests pass, consider testing the ECU for proper function.

Why is an Initial Scan Important for Diagnosing the P0705 Code?

An initial scan is crucial because it provides a starting point for the diagnostic process. The OBD-II scanner can reveal the P0705 code and any other related codes that might offer additional insights into the problem. It also helps differentiate between a genuine TRS issue and other potential causes.

How to Perform a Visual Inspection of the TRS, Wiring, and Connectors?

A thorough visual inspection is essential for identifying obvious issues. Follow these steps:

- Locate the TRS: Find the transmission range sensor, usually located on the side of the transmission.

- Check for Damage: Look for any signs of physical damage to the sensor housing.

- Inspect Wiring: Examine the wiring harness for cuts, abrasions, or melted insulation.

- Check Connectors: Ensure the connectors are securely attached and free from corrosion.

- Clean if Necessary: Clean any corrosion or debris from the connectors using a wire brush and electrical cleaner.

How to Conduct a Wiring Continuity Test for the P0705 Code?

A wiring continuity test verifies the integrity of the wiring between the TRS and the ECU. Here’s how to perform it:

- Disconnect Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Locate Wiring Diagram: Obtain a wiring diagram for your specific Mercedes model.

- Set Multimeter: Set your multimeter to the continuity testing mode.

- Test Wires: Place one probe on the TRS connector and the other on the corresponding pin at the ECU.

- Check for Continuity: The multimeter should indicate continuity (usually a beep or a reading close to zero ohms).

What Voltage Levels Should You Expect When Testing the TRS?

Testing the voltage at the TRS connector can help determine if the sensor is receiving the correct power supply. Consult your vehicle’s repair manual for the specific voltage levels, but here are some general guidelines:

- Reference Voltage: Typically, the TRS receives a 5-volt reference signal from the ECU.

- Ground: Ensure there is a good ground connection.

- Signal Voltage: The signal voltage will vary depending on the gear position.

Use a multimeter to measure the voltage at each pin of the TRS connector with the ignition on.

How to Perform a Resistance Test on the TRS?

A resistance test checks the internal condition of the TRS. Follow these steps:

- Disconnect TRS: Disconnect the TRS from the wiring harness.

- Set Multimeter: Set your multimeter to measure resistance (ohms).

- Measure Resistance: Place the probes on the appropriate terminals of the TRS.

- Compare Readings: Compare your readings to the manufacturer’s specifications.

If the resistance is outside the specified range, the TRS is likely faulty.

What Should You Look for When Checking the Transmission Fluid?

Checking the transmission fluid involves assessing both the level and condition of the fluid. Here’s what to look for:

- Fluid Level: Ensure the fluid level is within the recommended range on the dipstick.

- Fluid Condition: The fluid should be bright red and transparent. If it is dark, smells burnt, or contains debris, it needs to be replaced.

- Leaks: Inspect for any signs of transmission fluid leaks around the transmission housing.

When Should You Suspect an ECU Issue as the Cause of the P0705 Code?

Suspect an ECU issue only after ruling out all other potential causes. If the TRS, wiring, and transmission fluid are all in good condition, the problem might lie with the ECU. Testing the ECU requires specialized equipment and should be performed by a qualified technician.

4. How to Fix the Mercedes P0705 Code: A Comprehensive Guide

Once you’ve diagnosed the cause of the Mercedes P0705 code, the next step is to implement the appropriate fix. Here’s a comprehensive guide to addressing the common issues associated with this code:

- Replacing the Transmission Range Sensor (TRS): This is the most common fix when the sensor is faulty.

- Repairing or Replacing Damaged Wiring: Addressing wiring issues is crucial for restoring proper signal transmission.

- Cleaning or Replacing Corroded Connectors: Corrosion can impede electrical signals, so cleaning or replacing affected connectors is essential.

- Flushing or Replacing Transmission Fluid: Maintaining clean transmission fluid is vital for the proper functioning of the TRS.

- ECU Repair or Replacement: In rare cases, the ECU may need to be repaired or replaced.

What are the Steps to Replace a Faulty Transmission Range Sensor (TRS)?

Replacing a faulty TRS involves several steps. Here’s a detailed guide:

- Gather Tools and Parts: You’ll need a new TRS, socket set, wrench set, screwdriver, and possibly a torque wrench.

- Disconnect Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Locate the TRS: The TRS is typically located on the side of the transmission.

- Disconnect Connectors: Disconnect the electrical connectors from the TRS.

- Remove the Old TRS: Remove the bolts or screws securing the TRS to the transmission.

- Install the New TRS: Install the new TRS, ensuring it is properly aligned and torqued to the manufacturer’s specifications.

- Reconnect Connectors: Reconnect the electrical connectors to the TRS.

- Reconnect Battery: Reconnect the negative terminal of the battery.

- Test the System: Start the vehicle and check for proper shifting and the absence of the P0705 code.

How to Repair or Replace Damaged Wiring Associated with the P0705 Code?

Repairing or replacing damaged wiring is essential for ensuring a reliable connection between the TRS and the ECU. Follow these steps:

- Identify Damaged Wiring: Locate the damaged section of wiring.

- Cut and Strip Wires: Cut out the damaged section and strip the ends of the wires.

- Splice Wires: Use butt connectors or solder to splice the wires together.

- Insulate Connections: Cover the connections with heat shrink tubing or electrical tape.

- Secure Wiring: Secure the wiring harness to prevent future damage.

- Test the System: Test the system to ensure the P0705 code is resolved.

How to Clean or Replace Corroded Connectors to Resolve the P0705 Code?

Corroded connectors can impede electrical signals and cause the P0705 code. Here’s how to address this issue:

- Disconnect Connectors: Disconnect the corroded connectors.

- Clean Connectors: Use a wire brush or electrical cleaner to remove corrosion from the terminals.

- Apply Dielectric Grease: Apply dielectric grease to the terminals to prevent future corrosion.

- Reconnect Connectors: Reconnect the connectors, ensuring they are securely attached.

- Replace if Necessary: If the connectors are severely corroded or damaged, replace them.

Why is Flushing or Replacing Transmission Fluid Important?

Flushing or replacing transmission fluid helps maintain the proper functioning of the TRS by ensuring clean, uncontaminated fluid. Follow these steps:

- Drain Old Fluid: Drain the old transmission fluid from the transmission pan.

- Replace Filter: Replace the transmission filter.

- Refill with New Fluid: Refill the transmission with the correct type and amount of transmission fluid.

- Check Fluid Level: Check the fluid level and adjust as necessary.

- Test the System: Test the system to ensure the P0705 code is resolved.

What Does ECU Repair or Replacement Entail?

ECU repair or replacement should be considered as a last resort. Here’s what it entails:

- Diagnosis: Confirm that the ECU is indeed the source of the problem.

- Repair: If possible, the ECU can be repaired by a qualified technician.

- Replacement: If the ECU is beyond repair, it will need to be replaced.

- Programming: The new ECU will need to be programmed to match your vehicle’s specifications.

5. Tools and Equipment Needed to Fix the Mercedes P0705 Code

Having the right tools and equipment is essential for diagnosing and fixing the Mercedes P0705 code efficiently and effectively. Here’s a list of the necessary tools:

- OBD-II Scanner: For reading and clearing diagnostic trouble codes.

- Multimeter: For testing wiring continuity and voltage.

- Socket Set: For removing and installing sensors and connectors.

- Wrench Set: For tightening and loosening bolts.

- Screwdriver Set: For removing and installing screws.

- Torque Wrench: For ensuring proper torque on sensors and bolts.

- Wire Stripper/Crimper: For repairing or replacing wiring.

- Electrical Cleaner: For cleaning corroded connectors.

- Dielectric Grease: For preventing corrosion on connectors.

- Transmission Fluid Funnel: For adding transmission fluid.

What are the Key Features to Look for in an OBD-II Scanner for Mercedes Vehicles?

When selecting an OBD-II scanner for Mercedes vehicles, consider the following key features:

- Mercedes-Specific Codes: The scanner should be able to read Mercedes-specific diagnostic trouble codes.

- Live Data Streaming: The ability to stream live data from the vehicle’s sensors is crucial for accurate diagnosis.

- Bi-Directional Control: Bi-directional control allows you to activate and test various components.

- Software Updates: Ensure the scanner supports software updates to stay current with new vehicle models and diagnostic protocols.

- User-Friendly Interface: A clear and intuitive interface makes the scanner easier to use.

How to Use a Multimeter for Diagnosing Wiring Issues Related to the P0705 Code?

A multimeter is an indispensable tool for diagnosing wiring issues. Here’s how to use it effectively:

- Continuity Testing: Use the continuity setting to check for breaks in the wiring.

- Voltage Testing: Use the voltage setting to measure the voltage at various points in the circuit.

- Resistance Testing: Use the resistance setting to measure the resistance of the TRS.

- Ground Testing: Ensure there is a good ground connection by testing the voltage between the ground point and the vehicle’s chassis.

Why is a Torque Wrench Important When Replacing the Transmission Range Sensor?

A torque wrench is crucial for ensuring that the TRS is properly tightened to the manufacturer’s specifications. Overtightening can damage the sensor, while undertightening can cause it to loosen over time. Always consult the vehicle’s repair manual for the correct torque values.

How Can Electrical Cleaner and Dielectric Grease Help in Resolving the P0705 Code?

Electrical cleaner and dielectric grease are essential for addressing corrosion-related issues. Electrical cleaner removes corrosion from connectors, while dielectric grease prevents future corrosion by creating a protective barrier. Applying these products can significantly improve the reliability of electrical connections.

6. Preventative Maintenance Tips to Avoid the Mercedes P0705 Code

Preventative maintenance is key to avoiding the Mercedes P0705 code and ensuring the longevity of your vehicle’s transmission system. Here are some essential tips:

- Regular Transmission Fluid Changes: Changing the transmission fluid at the recommended intervals helps maintain its cleanliness and proper viscosity.

- Inspect Wiring and Connectors: Periodically inspect the wiring and connectors for any signs of damage or corrosion.

- Check TRS Function: Monitor the performance of the TRS and address any issues promptly.

- Avoid Harsh Driving Conditions: Minimize harsh driving conditions that can put excessive strain on the transmission.

- Address Leaks Promptly: Repair any transmission fluid leaks promptly to maintain proper fluid levels.

How Often Should You Change Your Mercedes-Benz Transmission Fluid?

The frequency of transmission fluid changes depends on your vehicle’s model and driving conditions. However, a general guideline is to change the fluid every 60,000 to 100,000 miles. Consult your vehicle’s owner’s manual for specific recommendations.

What are the Signs of Transmission Fluid Contamination?

Recognizing the signs of transmission fluid contamination can help you address the issue before it leads to more significant problems. Look for the following:

- Dark or Black Fluid: Clean transmission fluid is typically bright red.

- Burnt Smell: A burnt smell indicates that the fluid has been overheated and is no longer effective.

- Debris in Fluid: The presence of metal shavings or other debris indicates internal transmission wear.

- Erratic Shifting: Difficulty shifting or slipping gears can be a sign of contaminated fluid.

How to Inspect Wiring and Connectors for Potential Issues?

Regularly inspecting the wiring and connectors can help you identify and address potential issues before they cause the P0705 code. Follow these steps:

- Visual Check: Look for any signs of damage, such as cuts, abrasions, or melted insulation.

- Connector Inspection: Ensure the connectors are securely attached and free from corrosion.

- Wiring Harness Security: Make sure the wiring harness is properly secured and not rubbing against any sharp edges.

What Driving Habits Can Contribute to Transmission Problems?

Certain driving habits can put excessive strain on the transmission and increase the risk of problems like the P0705 code. Avoid the following:

- Aggressive Acceleration: Rapid acceleration can cause excessive wear on the transmission components.

- Hard Braking: Hard braking can put strain on the transmission, especially when downshifting.

- Towing Over Capacity: Towing loads that exceed your vehicle’s capacity can overwork the transmission.

- Neglecting Maintenance: Failing to perform regular maintenance, such as fluid changes, can lead to transmission problems.

Why is Addressing Transmission Fluid Leaks Important?

Addressing transmission fluid leaks promptly is crucial for maintaining proper fluid levels and preventing transmission damage. Low fluid levels can cause the transmission to overheat and wear prematurely. Regularly check for leaks around the transmission housing and repair them as soon as possible.

7. Common Mistakes to Avoid When Dealing with the Mercedes P0705 Code

When addressing the Mercedes P0705 code, it’s important to avoid common mistakes that can lead to misdiagnosis or ineffective repairs. Here are some pitfalls to watch out for:

- Not Performing a Thorough Diagnosis: Jumping to conclusions without a comprehensive diagnosis can lead to unnecessary repairs.

- Ignoring Related Codes: Failing to address other diagnostic trouble codes can mask the underlying issue.

- Using Incorrect Parts: Using parts that are not specifically designed for your Mercedes model can cause compatibility issues.

- Overlooking Wiring Issues: Wiring problems are a common cause of the P0705 code, so don’t neglect this area.

- Neglecting Transmission Fluid: Overlooking the condition and level of the transmission fluid can lead to further complications.

Why is a Thorough Diagnosis Essential Before Attempting Any Repairs?

A thorough diagnosis is crucial for accurately identifying the root cause of the P0705 code. This involves performing a comprehensive scan, visual inspection, and component testing. Skipping these steps can lead to misdiagnosis and unnecessary repairs, costing you time and money.

How Can Ignoring Related Codes Hinder the Repair Process?

Ignoring related diagnostic trouble codes can prevent you from identifying the underlying issue. These codes often provide valuable clues that can help you pinpoint the source of the problem. Always address all codes to ensure a comprehensive repair.

What are the Risks of Using Non-OEM Parts for Mercedes-Benz Vehicles?

Using non-OEM (Original Equipment Manufacturer) parts can lead to compatibility issues and reduced performance. OEM parts are specifically designed and tested for your Mercedes model, ensuring optimal fit and function. While non-OEM parts may be cheaper, they can compromise the reliability and longevity of your vehicle.

Why is it Important to Thoroughly Inspect the Wiring When Addressing the P0705 Code?

Wiring issues are a common cause of the P0705 code, so it’s essential to thoroughly inspect the wiring harness and connectors. Look for any signs of damage, corrosion, or loose connections. Addressing wiring problems can often resolve the P0705 code and prevent future issues.

How Can Neglecting Transmission Fluid Impact the Success of Your Repair Efforts?

Neglecting the condition and level of the transmission fluid can undermine your repair efforts. Dirty or low fluid can affect the performance of the TRS and other transmission components. Always check the fluid and replace it if necessary to ensure optimal operation.

8. Understanding the Transmission Range Sensor (TRS) in Detail

The Transmission Range Sensor (TRS), also known as the Neutral Safety Switch, is a critical component in your Mercedes-Benz’s transmission system. It plays a vital role in determining the gear position and ensuring safe operation. Here’s a detailed look at the TRS:

- Function of the TRS: The TRS detects the position of the gear selector and sends this information to the vehicle’s computer (ECU).

- Location of the TRS: The TRS is typically located on the side of the transmission.

- Types of TRS: There are different types of TRS, including mechanical and electronic sensors.

- Common Failure Modes: Common failure modes include electrical malfunction, mechanical damage, and corrosion.

- Testing the TRS: The TRS can be tested using a multimeter to check for proper resistance and voltage.

What is the Primary Function of the Transmission Range Sensor (TRS)?

The primary function of the TRS is to detect the position of the gear selector (e.g., Park, Reverse, Neutral, Drive) and transmit this information to the vehicle’s computer. This allows the ECU to control various functions, such as starting the engine, engaging the reverse lights, and controlling the transmission shifting.

Where is the Transmission Range Sensor (TRS) Typically Located on a Mercedes-Benz?

The TRS is typically located on the side of the transmission, where it can directly interface with the gear selector mechanism. The exact location may vary depending on the specific Mercedes model. Consult your vehicle’s repair manual for detailed information.

What are the Different Types of Transmission Range Sensors (TRS)?

There are different types of TRS, including:

- Mechanical TRS: These sensors use mechanical contacts to detect the gear position.

- Electronic TRS: These sensors use electronic components, such as potentiometers or Hall effect sensors, to detect the gear position.

Electronic TRS sensors are more common in modern vehicles due to their increased accuracy and reliability.

What are the Common Failure Modes of a Transmission Range Sensor (TRS)?

Common failure modes of a TRS include:

- Electrical Malfunction: This can include short circuits, open circuits, or internal component failure.

- Mechanical Damage: Physical damage to the sensor housing or internal components can cause it to fail.

- Corrosion: Corrosion on the terminals or internal components can impede electrical signals.

- Wear and Tear: Over time, the sensor can wear out due to normal use.

How Can You Test a Transmission Range Sensor (TRS) Using a Multimeter?

You can test a TRS using a multimeter to check for proper resistance and voltage. Follow these steps:

- Disconnect TRS: Disconnect the TRS from the wiring harness.

- Resistance Test: Use the multimeter to measure the resistance between the terminals of the TRS. Compare your readings to the manufacturer’s specifications.

- Voltage Test: With the ignition on, use the multimeter to measure the voltage at the TRS connector. Ensure the voltage levels are within the specified range.

9. Advanced Diagnostic Techniques for Complex P0705 Code Issues

In some cases, the Mercedes P0705 code may be caused by complex issues that require advanced diagnostic techniques. Here are some advanced methods to consider:

- Using a Professional-Grade Diagnostic Scanner: A high-end scanner can provide more detailed information and perform advanced functions.

- Performing a Pinpoint Test: Pinpoint testing involves systematically testing each component in the circuit to isolate the problem.

- Checking the CAN Bus Communication: The CAN (Controller Area Network) bus is used for communication between the ECU and other modules.

- Analyzing Live Data: Live data analysis can help you identify intermittent issues and unusual sensor readings.

- Consulting a Mercedes-Benz Specialist: If you’re unable to resolve the issue, consider consulting a specialist.

What Advantages Does a Professional-Grade Diagnostic Scanner Offer?

A professional-grade diagnostic scanner offers several advantages over basic OBD-II scanners:

- Advanced Functions: These scanners can perform advanced functions such as bi-directional control, component testing, and module programming.

- Detailed Data: They provide more detailed data and diagnostic information.

- Mercedes-Specific Coverage: They offer comprehensive coverage of Mercedes-Benz vehicles.

- Software Updates: They receive regular software updates to stay current with new models and diagnostic protocols.

How to Perform a Pinpoint Test to Isolate the Cause of the P0705 Code?

Pinpoint testing involves systematically testing each component in the circuit to isolate the problem. Follow these steps:

- Identify Components: Identify all components in the circuit, including the TRS, wiring, connectors, and ECU.

- Test Each Component: Test each component using a multimeter or other appropriate tools.

- Compare Readings: Compare your readings to the manufacturer’s specifications.

- Isolate the Problem: The component that fails the test is likely the source of the problem.

Why is Checking the CAN Bus Communication Important?

The CAN bus is used for communication between the ECU and other modules. If there is a problem with the CAN bus, it can disrupt the signals from the TRS and cause the P0705 code. Check the CAN bus for any communication errors or network issues.

How Can Analyzing Live Data Help Diagnose Intermittent P0705 Code Issues?

Analyzing live data can help you identify intermittent issues and unusual sensor readings. Use a diagnostic scanner to monitor the TRS signal, transmission temperature, and other relevant parameters. Look for any fluctuations or anomalies that might indicate a problem.

When Should You Consult a Mercedes-Benz Specialist for P0705 Code Issues?

If you’re unable to resolve the P0705 code using basic diagnostic and repair techniques, consider consulting a Mercedes-Benz specialist. These specialists have the expertise, experience, and specialized tools to diagnose and repair complex issues.

10. Cost Analysis of Repairing the Mercedes P0705 Code

Understanding the cost associated with repairing the Mercedes P0705 code is essential for budgeting and making informed decisions. Here’s a breakdown of the potential costs:

- Diagnostic Scan: $75 – $150

- Transmission Range Sensor (TRS) Replacement: $200 – $500

- Wiring Repair: $100 – $300

- Connector Replacement: $50 – $150

- Transmission Fluid Change: $100 – $250

- ECU Repair or Replacement: $500 – $1500+

What Factors Influence the Cost of a Diagnostic Scan for the P0705 Code?

The cost of a diagnostic scan can vary depending on the shop’s labor rates, the complexity of the diagnostic process, and the type of equipment used. Dealerships and specialized repair shops may charge more for diagnostic scans.

What is the Average Cost of Replacing a Transmission Range Sensor (TRS) on a Mercedes-Benz?

The average cost of replacing a TRS on a Mercedes-Benz ranges from $200 to $500. This includes the cost of the sensor and the labor for installation. The exact cost will depend on the specific model and the shop’s labor rates.

How Much Does Wiring Repair Typically Cost for the P0705 Code?

Wiring repair costs typically range from $100 to $300, depending on the extent of the damage and the complexity of the repair. Minor wiring repairs, such as splicing wires, may cost less than replacing an entire wiring harness.

What is the Cost of Replacing Corroded Connectors When Addressing the P0705 Code?

The cost of replacing corroded connectors typically ranges from $50 to $150. This includes the cost of the connectors and the labor for installation. Replacing connectors is a relatively simple and inexpensive repair.

Why Can ECU Repair or Replacement Be a Significant Expense When Addressing the P0705 Code?

ECU repair or replacement can be a significant expense due to the complexity of the ECU and the need for specialized programming. The cost can range from $500 to $1500 or more, depending on the specific model and the extent of the damage.

At CARDIAGTECH.NET, we understand the challenges you face in maintaining and repairing your Mercedes-Benz. That’s why we offer top-quality diagnostic tools and equipment to help you accurately diagnose and fix issues like the P0705 code. Don’t let vehicle troubles slow you down. Contact us today at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET for expert advice and the best solutions for your automotive needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you keep your Mercedes running smoothly.