P0017 Code Mercedes: Causes, Symptoms, and Solutions

P0017 code Mercedes indicates a timing misalignment between the crankshaft and camshaft position sensors in engine bank 1. This diagnostic trouble code (DTC) suggests that the camshaft is not in the correct position relative to the crankshaft, which can seriously affect your Mercedes’ performance. CARDIAGTECH.NET offers the right tools and diagnostic equipment to get your Mercedes back on the road, ensuring accurate timing and optimal performance. Addressing this issue promptly can prevent further engine damage, maintain fuel efficiency, and restore your vehicle’s power. Let’s explore the symptoms, causes, and steps to resolve the P0017 error code, providing you with the knowledge and solutions for a smoother driving experience.

1. Understanding the P0017 Code

The P0017 code, defined as “Crankshaft Position – Camshaft Position Correlation (Bank 1, Sensor B),” indicates a discrepancy between the crankshaft and camshaft positions in your Mercedes-Benz engine. The crankshaft and camshaft must be synchronized for the engine to run correctly. This code appears when the Engine Control Unit (ECU) detects that the camshaft is not in the expected position relative to the crankshaft.

The ECU uses sensors to monitor the positions of both the crankshaft and camshaft. The crankshaft position sensor tracks the rotation of the crankshaft, which is connected to the pistons. The camshaft position sensor monitors the rotation of the camshaft, which controls the opening and closing of the engine’s valves. The ECU uses these signals to manage fuel injection and ignition timing.

When the signals from the crankshaft and camshaft position sensors do not align as expected, the ECU sets the P0017 code. This misalignment can result from various issues, including a worn timing chain, faulty sensors, or oil pressure problems. Addressing this code promptly is crucial to prevent further engine damage and maintain your vehicle’s performance.

1.1. What Does “Bank 1, Sensor B” Mean?

In the context of the P0017 code, “Bank 1” refers to the side of the engine that contains cylinder number one. In an inline engine, there is only one bank. In a V-shaped engine (like a V6 or V8), there are two banks. “Sensor B” typically refers to the exhaust camshaft position sensor. Each camshaft has a sensor, and the ECU needs data from both to optimize engine performance.

1.2. Common Symptoms of P0017 Code Mercedes

Identifying the symptoms associated with the P0017 code is essential for diagnosing and resolving the issue effectively. These symptoms can range from subtle changes in engine performance to more noticeable drivability problems. Here are some of the most common symptoms associated with the P0017 code in Mercedes vehicles:

- Check Engine Light: The most obvious symptom is the illumination of the check engine light on your dashboard. This light indicates that the ECU has detected a problem and stored a diagnostic trouble code (DTC).

- Rough Idle: The engine may idle roughly or unevenly. This can be due to the incorrect timing affecting the combustion process, leading to irregular engine operation.

- Reduced Engine Power: You might notice a decrease in engine power and acceleration. The timing misalignment can prevent the engine from operating at its peak efficiency, resulting in sluggish performance.

- Poor Fuel Economy: The P0017 code can lead to decreased fuel efficiency. When the engine timing is off, it can cause the engine to consume more fuel to maintain performance.

- Engine Stalling: In some cases, the engine may stall, especially at low speeds or when idling. This can occur if the timing issue is severe enough to disrupt the engine’s ability to maintain a stable idle.

- Difficulty Starting: The vehicle may be harder to start than usual. The timing misalignment can affect the engine’s ability to initiate the combustion process correctly.

- Misfires: The engine may experience misfires, which can cause rough running and further reduce engine power. Misfires occur when one or more cylinders fail to ignite the air-fuel mixture properly.

- Noises from the Engine: Unusual noises, such as ticking or rattling, may be heard from the engine. These noises can be caused by the timing chain or other components that are affected by the timing misalignment.

Alt text: Diagram showing the crankshaft and camshaft sensors in a Mercedes-Benz engine, essential for diagnosing P0017.

Recognizing these symptoms early can help you address the P0017 code quickly, preventing potential damage and ensuring your Mercedes-Benz runs smoothly. If you notice any of these signs, it’s crucial to diagnose and repair the issue as soon as possible.

1.3. Potential Causes of the P0017 Code

Several factors can trigger the P0017 code in your Mercedes-Benz. Understanding these potential causes is essential for accurate diagnosis and effective repair. Here are some of the most common causes of the P0017 code:

- Worn Timing Chain:

- A worn or stretched timing chain is one of the most common causes of the P0017 code. Over time, the timing chain can stretch due to wear and tear, leading to a misalignment between the crankshaft and camshaft.

- Statistics: Timing chains typically last between 80,000 and 120,000 miles. However, this can vary based on driving conditions and maintenance practices.

- Faulty Camshaft Position Sensor:

- A malfunctioning camshaft position sensor can provide inaccurate data to the ECU, leading to the P0017 code. The sensor may fail due to electrical issues, damage, or contamination.

- Expert Opinion: According to Bosch, a leading manufacturer of automotive sensors, faulty sensors can cause a range of drivability issues and trigger diagnostic trouble codes.

- Faulty Crankshaft Position Sensor:

- Similar to the camshaft position sensor, a faulty crankshaft position sensor can also cause the P0017 code. The crankshaft sensor provides critical data about the crankshaft’s position, and if it fails, the ECU may detect a timing misalignment.

- Timing Chain Tensioner Issues:

- The timing chain tensioner maintains the correct tension on the timing chain. If the tensioner fails or becomes weak, it can cause the timing chain to slacken, leading to a timing misalignment and the P0017 code.

- Oil Pressure Problems:

- Low oil pressure can affect the performance of the timing chain tensioner and the variable valve timing (VVT) system, which relies on oil pressure to function correctly. Insufficient oil pressure can lead to timing misalignment and the P0017 code.

- Damaged Wiring or Connectors:

- Damaged, corroded, or loose wiring and connectors can disrupt the signals from the camshaft and crankshaft position sensors to the ECU. This can result in inaccurate data and the triggering of the P0017 code.

- Variable Valve Timing (VVT) System Problems:

- The VVT system adjusts the timing of the intake and exhaust valves to optimize engine performance and efficiency. If the VVT system malfunctions, it can cause the camshaft to be out of sync with the crankshaft, triggering the P0017 code.

- Balance Shaft Issues:

- In some Mercedes-Benz models, particularly those with the M272 engine, balance shaft sprocket failure can cause timing issues and trigger the P0017 code. This issue is more common in older models but should be considered.

Understanding these potential causes will help you diagnose the problem accurately and choose the right repair strategy. Regular maintenance and timely repairs can prevent many of these issues, ensuring your Mercedes-Benz runs smoothly and efficiently.

2. Diagnosing the P0017 Code

Proper diagnosis is critical to accurately identify the root cause of the P0017 code in your Mercedes-Benz. A systematic approach ensures that you address the actual problem and avoid unnecessary repairs. Here’s a step-by-step guide to diagnosing the P0017 code:

2.1. Step-by-Step Diagnostic Process

-

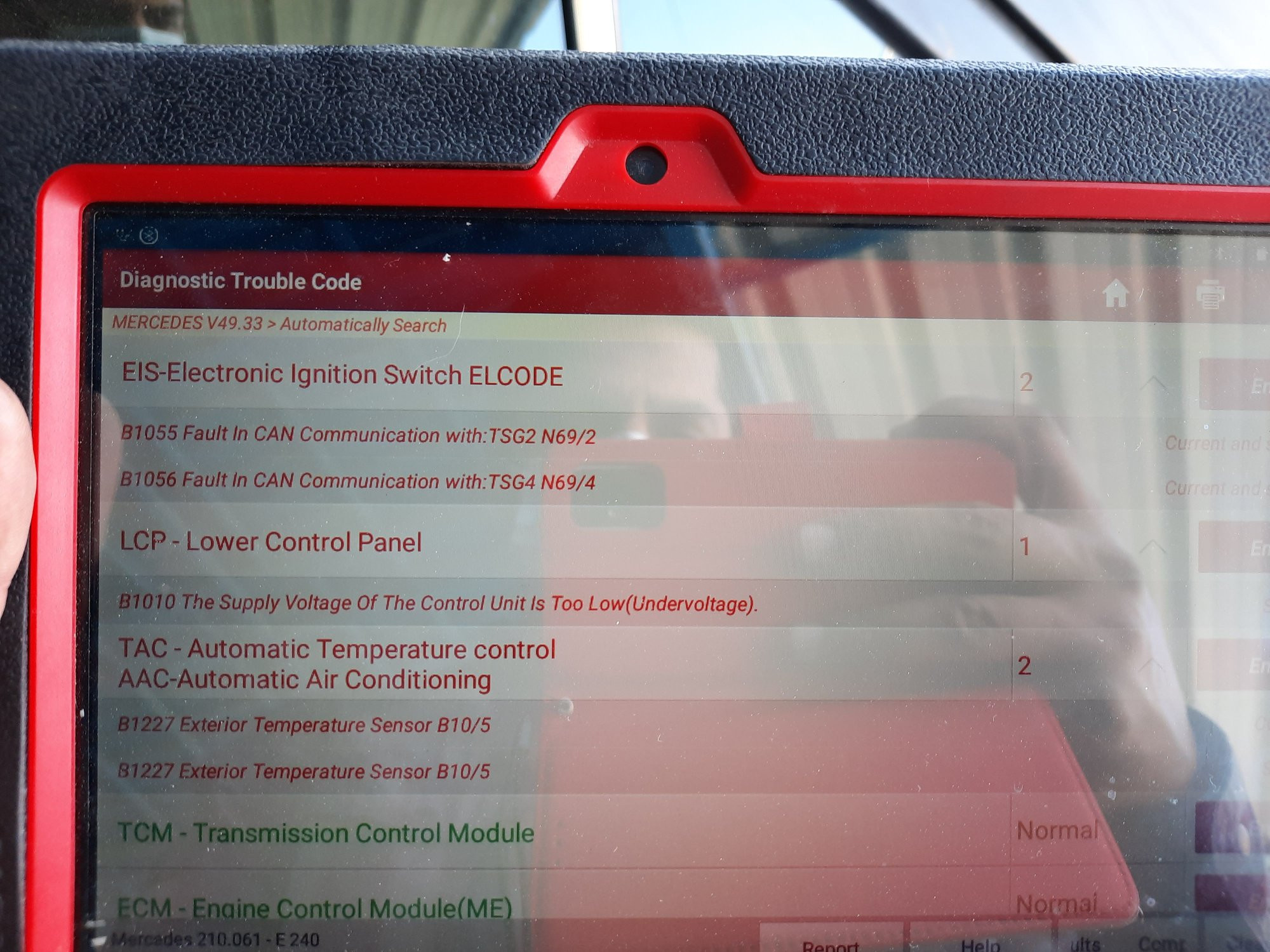

Read the Diagnostic Trouble Codes (DTCs):

- Use an OBD-II scanner to read all the diagnostic trouble codes stored in the ECU. This will help you understand if there are any other related codes that might provide additional information.

- Tool Recommendation: CARDIAGTECH.NET offers a range of OBD-II scanners suitable for diagnosing Mercedes-Benz vehicles. These tools provide accurate and reliable diagnostic information.

-

Record the Freeze Frame Data:

- Record the freeze frame data associated with the P0017 code. This data captures the engine conditions when the code was triggered, such as engine speed (RPM), engine load, and coolant temperature.

- Why it’s important: Freeze frame data can give you clues about what might have caused the code to appear.

-

Clear the Codes and Test Drive:

- Clear the DTCs and take the vehicle for a test drive. Monitor the engine performance and see if the P0017 code reappears.

- Tip: Drive the vehicle under similar conditions as when the code initially appeared to see if you can replicate the issue.

-

Inspect the Camshaft and Crankshaft Position Sensors:

- Visually inspect the camshaft and crankshaft position sensors for any signs of damage, such as cracks, corrosion, or loose connections.

- Sensor Testing: Use a multimeter to test the resistance and voltage of the sensors. Refer to the vehicle’s service manual for the correct specifications.

-

Check the Wiring and Connectors:

- Examine the wiring and connectors associated with the camshaft and crankshaft position sensors. Look for any signs of damage, such as frayed wires, corrosion, or loose connections.

- Repairing Wiring: Repair or replace any damaged wiring or connectors to ensure a good electrical connection.

-

Evaluate the Timing Chain:

- Inspect the timing chain for signs of wear or stretching. This can be done by checking the timing marks on the crankshaft and camshaft pulleys to see if they align correctly.

- Professional Inspection: If you are not comfortable inspecting the timing chain yourself, take the vehicle to a qualified mechanic for a thorough inspection.

-

Check the Timing Chain Tensioner:

- Inspect the timing chain tensioner to ensure it is functioning correctly. A faulty tensioner can cause the timing chain to slacken, leading to a timing misalignment.

- Testing the Tensioner: Some tensioners can be tested by manually checking their ability to maintain tension on the timing chain.

-

Assess Oil Pressure:

- Check the engine oil level and pressure. Low oil pressure can affect the performance of the timing chain tensioner and the VVT system.

- Oil Pressure Gauge: Use an oil pressure gauge to verify that the engine is producing the correct oil pressure.

-

Inspect the Variable Valve Timing (VVT) System:

- If your Mercedes-Benz has a VVT system, inspect it for any signs of malfunction. This may involve checking the VVT solenoid and the VVT actuator.

- VVT Solenoid Testing: Use a multimeter to test the VVT solenoid for proper operation.

-

Consult the Vehicle’s Service Manual:

- Refer to the vehicle’s service manual for specific diagnostic procedures and troubleshooting tips related to the P0017 code.

- Mercedes-Benz Resources: Mercedes-Benz provides detailed service manuals and technical documentation that can be invaluable during the diagnostic process.

2.2. Tools Needed for Diagnosis

Having the right tools can make the diagnostic process more efficient and accurate. Here are some essential tools you’ll need to diagnose the P0017 code:

- OBD-II Scanner: To read and clear diagnostic trouble codes.

- Multimeter: To test the electrical components, such as sensors and solenoids.

- Socket Set and Wrenches: To remove and install sensors and other components.

- Timing Light: To check the timing marks on the crankshaft and camshaft pulleys.

- Oil Pressure Gauge: To measure the engine oil pressure.

- Vehicle Service Manual: To provide specific diagnostic procedures and specifications for your Mercedes-Benz model.

2.3. Common Mistakes to Avoid During Diagnosis

Avoiding common mistakes during diagnosis can save you time and prevent misdiagnosis. Here are some common pitfalls to watch out for:

- Not Checking Other DTCs: Always check for other DTCs that may be related to the P0017 code. Other codes can provide valuable clues about the root cause of the problem.

- Ignoring Basic Checks: Don’t skip basic checks, such as inspecting the wiring and connectors. Simple issues like a loose connection can often be the cause of the problem.

- Replacing Parts Without Proper Testing: Avoid replacing parts without thoroughly testing them first. This can lead to unnecessary expenses and may not resolve the issue.

- Not Consulting the Service Manual: Always refer to the vehicle’s service manual for specific diagnostic procedures and specifications.

- Neglecting Freeze Frame Data: Pay attention to the freeze frame data associated with the P0017 code. This data can provide valuable information about the conditions when the code was triggered.

By following a systematic diagnostic process and avoiding common mistakes, you can accurately identify the cause of the P0017 code and implement the appropriate repair.

3. Repairing the P0017 Code

Once you have accurately diagnosed the cause of the P0017 code in your Mercedes-Benz, the next step is to perform the necessary repairs. The specific repair will depend on the underlying issue, which could range from replacing a faulty sensor to addressing a worn timing chain. Here’s a detailed guide to repairing the P0017 code:

3.1. Step-by-Step Repair Procedures

-

Replacing the Camshaft or Crankshaft Position Sensor:

- Procedure:

- Disconnect the negative battery terminal.

- Locate the faulty sensor. The camshaft position sensor is typically located on the cylinder head, while the crankshaft position sensor is usually near the crankshaft pulley.

- Disconnect the electrical connector from the sensor.

- Remove the sensor mounting bolt or screws.

- Carefully remove the old sensor.

- Install the new sensor, ensuring it is properly seated.

- Tighten the mounting bolt or screws to the specified torque.

- Reconnect the electrical connector.

- Reconnect the negative battery terminal.

- Tool Recommendation: Use a torque wrench from CARDIAGTECH.NET to ensure the sensor is tightened to the correct specification.

- Procedure:

-

Replacing the Timing Chain:

- Procedure:

- Disconnect the negative battery terminal.

- Remove the engine covers and any components that obstruct access to the timing chain.

- Align the engine to the timing marks on the crankshaft and camshaft pulleys.

- Remove the timing chain tensioner.

- Carefully remove the old timing chain.

- Install the new timing chain, ensuring it is properly aligned with the timing marks.

- Install the new timing chain tensioner.

- Verify that the timing marks are still aligned.

- Reinstall the engine covers and any removed components.

- Reconnect the negative battery terminal.

- Note: Replacing the timing chain is a complex procedure that may require specialized tools and expertise. If you are not comfortable performing this repair yourself, it is best to take the vehicle to a qualified mechanic.

- Procedure:

-

Replacing the Timing Chain Tensioner:

- Procedure:

- Disconnect the negative battery terminal.

- Remove the engine covers and any components that obstruct access to the timing chain tensioner.

- Remove the old timing chain tensioner.

- Install the new timing chain tensioner.

- Ensure the tensioner is properly seated and functioning correctly.

- Reinstall the engine covers and any removed components.

- Reconnect the negative battery terminal.

- Tip: Always use a new timing chain tensioner when replacing the timing chain.

- Procedure:

-

Repairing Damaged Wiring or Connectors:

- Procedure:

- Disconnect the negative battery terminal.

- Locate the damaged wiring or connectors.

- Repair the wiring by splicing in new wires or replacing damaged sections.

- Replace any damaged connectors.

- Ensure all connections are secure and properly insulated.

- Reconnect the negative battery terminal.

- Tool Recommendation: Use a wire crimper and heat shrink tubing from CARDIAGTECH.NET to ensure a secure and durable repair.

- Procedure:

-

Addressing Oil Pressure Problems:

- Procedure:

- Check the engine oil level and add oil if necessary.

- Inspect the oil pump for any signs of damage or wear.

- Replace the oil pump if necessary.

- Check the oil pressure sensor and replace it if it is faulty.

- Use an oil pressure gauge to verify that the engine is producing the correct oil pressure.

- Note: Addressing oil pressure problems may require specialized tools and expertise. If you are not comfortable performing this repair yourself, it is best to take the vehicle to a qualified mechanic.

- Procedure:

-

Servicing the Variable Valve Timing (VVT) System:

- Procedure:

- Disconnect the negative battery terminal.

- Locate the VVT solenoid and actuator.

- Remove the VVT solenoid and inspect it for any signs of damage or contamination.

- Clean or replace the VVT solenoid if necessary.

- Inspect the VVT actuator for proper operation.

- Replace the VVT actuator if necessary.

- Reinstall the VVT solenoid and actuator.

- Reconnect the negative battery terminal.

- Tool Recommendation: Use a VVT solenoid tester from CARDIAGTECH.NET to verify that the solenoid is functioning correctly.

- Procedure:

3.2. Tools and Parts Required

Having the right tools and parts is essential for performing the repairs correctly. Here’s a list of the tools and parts you may need:

- New Camshaft or Crankshaft Position Sensor: Ensure it is compatible with your Mercedes-Benz model.

- New Timing Chain: If the old timing chain is worn or stretched.

- New Timing Chain Tensioner: To maintain the correct tension on the timing chain.

- Wiring and Connectors: To repair any damaged wiring.

- New Oil Pump: If the old oil pump is faulty.

- New Oil Pressure Sensor: If the old oil pressure sensor is faulty.

- New VVT Solenoid and Actuator: If the VVT system is malfunctioning.

- Socket Set and Wrenches: To remove and install components.

- Torque Wrench: To tighten bolts and screws to the specified torque.

- Wire Crimper and Heat Shrink Tubing: To repair wiring.

- VVT Solenoid Tester: To test the VVT solenoid.

- OBD-II Scanner: To clear the DTCs after the repair.

3.3. Post-Repair Checks

After completing the repairs, it’s essential to perform the following post-repair checks to ensure that the P0017 code is resolved:

- Clear the DTCs: Use an OBD-II scanner to clear the P0017 code and any other stored DTCs.

- Test Drive the Vehicle: Take the vehicle for a test drive to see if the P0017 code reappears.

- Monitor Engine Performance: Pay attention to the engine performance and listen for any unusual noises.

- Check for Any Remaining Symptoms: Ensure that all the symptoms associated with the P0017 code, such as rough idle or reduced engine power, have been resolved.

- Verify Timing Alignment: Use a timing light to verify that the timing marks on the crankshaft and camshaft pulleys are correctly aligned.

- Scan for New Codes: After the test drive, scan the ECU for any new DTCs.

By following these repair procedures and performing the post-repair checks, you can effectively resolve the P0017 code and ensure that your Mercedes-Benz runs smoothly and efficiently.

4. Preventing the P0017 Code

Preventing the P0017 code involves regular maintenance and proactive care to ensure the engine’s timing components remain in good condition. By following these preventative measures, you can minimize the risk of encountering the P0017 code and maintain your Mercedes-Benz’s performance.

4.1. Regular Maintenance Tips

-

Follow the Recommended Oil Change Schedule:

- Regular oil changes are crucial for maintaining the health of your engine. Use the recommended oil type and change it according to the manufacturer’s schedule.

- Why it’s important: Clean oil ensures proper lubrication of the timing chain and tensioner, reducing wear and tear.

- Mercedes-Benz Recommendation: Mercedes-Benz typically recommends oil changes every 10,000 miles or once a year, whichever comes first.

-

Use High-Quality Oil Filters:

- Always use high-quality oil filters to ensure that the oil is properly filtered. A good oil filter will remove contaminants that can cause wear and damage to the engine components.

- Filter Recommendation: Use oil filters from reputable brands such as Bosch, Mann-Filter, or Mahle.

-

Inspect the Timing Chain and Tensioner Regularly:

- Have the timing chain and tensioner inspected regularly by a qualified mechanic. This will help you identify any signs of wear or damage early on.

- Inspection Interval: Consider inspecting the timing chain and tensioner every 50,000 miles.

-

Check and Maintain Proper Oil Pressure:

- Ensure that the engine has proper oil pressure. Low oil pressure can affect the performance of the timing chain tensioner and the VVT system.

- Monitoring Oil Pressure: Regularly check the oil pressure gauge and address any issues promptly.

-

Keep the Engine Cooling System in Good Condition:

- Maintain the engine cooling system to prevent overheating. Overheating can cause excessive wear and damage to the engine components, including the timing chain.

- Cooling System Maintenance: Flush the cooling system every two years and replace the coolant with the recommended type.

-

Address Engine Issues Promptly:

- Address any engine issues, such as misfires or rough idling, promptly. These issues can put additional stress on the timing chain and other engine components.

- Diagnostic Tools: Use an OBD-II scanner from CARDIAGTECH.NET to diagnose engine problems early on.

-

Avoid Aggressive Driving:

- Avoid aggressive driving habits, such as hard acceleration and high RPMs. These habits can put extra stress on the engine and accelerate wear and tear on the timing chain.

-

Use High-Quality Fuel:

- Use high-quality fuel to prevent the buildup of deposits in the engine. Deposits can affect the performance of the VVT system and other engine components.

- Fuel Recommendation: Use premium fuel with the octane rating recommended by Mercedes-Benz.

4.2. Identifying Potential Issues Early

Early detection of potential issues can prevent the P0017 code from occurring. Here are some signs to watch out for:

- Unusual Engine Noises: Listen for any unusual noises coming from the engine, such as ticking or rattling. These noises could indicate a problem with the timing chain or tensioner.

- Decreased Engine Performance: Pay attention to any decrease in engine performance, such as reduced power or poor fuel economy.

- Rough Idling: Watch out for rough idling or stalling, which could indicate a timing issue.

- Check Engine Light: Be vigilant about the check engine light. If it comes on, have the vehicle diagnosed promptly.

4.3. The Role of Quality Parts

Using high-quality parts is crucial for preventing the P0017 code. Low-quality parts may not meet the manufacturer’s specifications and can fail prematurely. Here’s why using quality parts is important:

- Durability: High-quality parts are more durable and can withstand the stresses of engine operation.

- Reliability: Quality parts are more reliable and less likely to fail.

- Performance: Quality parts provide better performance and help maintain the engine’s efficiency.

- Compatibility: Quality parts are designed to be compatible with your Mercedes-Benz model, ensuring proper fit and function.

By following these preventative measures and using high-quality parts, you can minimize the risk of encountering the P0017 code and keep your Mercedes-Benz running smoothly for years to come.

5. How CARDIAGTECH.NET Can Help

CARDIAGTECH.NET offers a wide range of tools and equipment to help diagnose and repair the P0017 code in your Mercedes-Benz. From OBD-II scanners to specialized tools, CARDIAGTECH.NET has everything you need to keep your vehicle running smoothly.

5.1. Recommended Tools from CARDIAGTECH.NET

-

OBD-II Scanners:

- CARDIAGTECH.NET offers a variety of OBD-II scanners that are compatible with Mercedes-Benz vehicles. These scanners allow you to read and clear diagnostic trouble codes, view freeze frame data, and monitor engine performance.

- Benefits: Accurate diagnostics, user-friendly interface, and real-time data monitoring.

- Example: The Autel MaxiCOM MK808 is a popular choice for Mercedes-Benz owners.

-

Multimeters:

- A multimeter is an essential tool for testing electrical components, such as sensors and solenoids. CARDIAGTECH.NET offers a range of multimeters with various features and price points.

- Benefits: Accurate readings, durable construction, and easy-to-use design.

- Example: The Fluke 115 Digital Multimeter is a reliable and accurate tool for automotive diagnostics.

-

Torque Wrenches:

- A torque wrench is necessary for tightening bolts and screws to the specified torque. This ensures that components are properly installed and prevents damage.

- Benefits: Accurate torque settings, durable construction, and easy-to-read display.

- Example: The CDI Torque Products 100-250I Digital Torque Wrench is a high-quality tool for automotive repairs.

-

Timing Lights:

- A timing light is used to check the timing marks on the crankshaft and camshaft pulleys. This ensures that the engine timing is correct.

- Benefits: Accurate timing measurements, easy-to-use design, and durable construction.

- Example: The Innova 3568 Timing Light is a popular choice for automotive enthusiasts and professionals.

-

Oil Pressure Gauges:

- An oil pressure gauge is used to measure the engine oil pressure. This helps you identify any oil pressure problems that could affect the performance of the timing chain tensioner and the VVT system.

- Benefits: Accurate pressure readings, durable construction, and easy-to-read display.

- Example: The Actron CP7838 Oil Pressure Gauge is a reliable and accurate tool for measuring oil pressure.

-

VVT Solenoid Testers:

- A VVT solenoid tester is used to verify that the VVT solenoid is functioning correctly. This helps you diagnose any VVT system problems that could be causing the P0017 code.

- Benefits: Accurate testing, easy-to-use design, and reliable performance.

- Example: The OTC 6522 VVT Solenoid Tester is a valuable tool for diagnosing VVT system issues.

-

Socket Sets and Wrenches:

- A comprehensive socket set and wrench set are essential for removing and installing components. CARDIAGTECH.NET offers a variety of socket sets and wrench sets with various sizes and configurations.

- Benefits: Durable construction, comprehensive range of sizes, and comfortable grip.

- Example: The Craftsman 450-Piece Mechanic’s Tool Set is a comprehensive set for automotive repairs.

5.2. How to Purchase Tools from CARDIAGTECH.NET

Purchasing tools from CARDIAGTECH.NET is easy and convenient. Here’s how to do it:

- Visit the Website: Go to CARDIAGTECH.NET using your web browser.

- Browse the Catalog: Browse the catalog to find the tools you need. You can search by category, brand, or keyword.

- Add to Cart: Add the tools you want to purchase to your shopping cart.

- Review Your Cart: Review your shopping cart to make sure you have everything you need.

- Checkout: Proceed to the checkout page and enter your shipping and billing information.

- Place Your Order: Place your order and wait for your tools to arrive.

5.3. Contacting CARDIAGTECH.NET for Support

If you need assistance with diagnosing or repairing the P0017 code, or if you have any questions about the tools offered by CARDIAGTECH.NET, you can contact their support team.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

CARDIAGTECH.NET is committed to providing high-quality tools and excellent customer support to help you keep your Mercedes-Benz running smoothly.

6. Understanding the M272 Engine and Balance Shaft Issues

The Mercedes-Benz M272 engine is a V6 engine that was used in a variety of models from 2004 to 2015. While the M272 is generally a reliable engine, it is known for a potential issue with the balance shaft sprocket. Understanding this issue can help you diagnose and prevent problems associated with the P0017 code.

6.1. The M272 Engine Overview

The M272 engine is a 2.5L, 3.0L, or 3.5L V6 engine that replaced the M112 engine. It features a four-valve-per-cylinder design, variable valve timing, and a magnesium intake manifold. The M272 engine was used in a wide range of Mercedes-Benz models, including the C-Class, E-Class, and S-Class.

6.2. Balance Shaft Sprocket Failure

One of the most common issues with the M272 engine is the failure of the balance shaft sprocket. The balance shaft is a rotating shaft that helps to reduce engine vibrations. The sprocket that drives the balance shaft can wear down prematurely, leading to timing issues and the P0017 code.

-

Symptoms of Balance Shaft Sprocket Failure:

- Check engine light

- Rough idling

- Reduced engine power

- Engine misfires

- Unusual engine noises

-

Causes of Balance Shaft Sprocket Failure:

- Poor quality materials

- Inadequate lubrication

- High engine loads

-

Affected Models:

- The balance shaft sprocket issue is more common in M272 engines manufactured between 2004 and 2008. Some of the affected models include:

- C-Class (W203, W204)

- E-Class (W211, W212)

- S-Class (W221)

- CLK (W209)

- SLK (R171)

- The balance shaft sprocket issue is more common in M272 engines manufactured between 2004 and 2008. Some of the affected models include:

6.3. Diagnosing Balance Shaft Issues

Diagnosing balance shaft sprocket failure requires a thorough inspection of the engine. Here are some steps to follow:

- Check for Diagnostic Trouble Codes: Use an OBD-II scanner to check for any stored diagnostic trouble codes. The P0017 code is a common code associated with balance shaft issues.

- Inspect the Timing Chain: Remove the valve cover and inspect the timing chain for any signs of wear or stretching.

- Check the Timing Marks: Verify that the timing marks on the crankshaft and camshaft pulleys are correctly aligned.

- Inspect the Balance Shaft Sprocket: Use a borescope to inspect the balance shaft sprocket for any signs of wear or damage.

6.4. Repairing Balance Shaft Issues

Repairing balance shaft sprocket failure requires replacing the balance shaft sprocket. This is a complex procedure that involves removing the engine and disassembling it.

-

Repair Steps:

- Remove the engine from the vehicle.

- Disassemble the engine.

- Replace the balance shaft sprocket.

- Reassemble the engine.

- Reinstall the engine in the vehicle.

-

Cost of Repair:

- The cost of repairing balance shaft sprocket failure can range from $3,000 to $7,000, depending on the extent of the damage and the labor rates at your local mechanic.

6.5. Preventing Balance Shaft Issues

Preventing balance shaft issues involves regular maintenance and proactive care. Here are some tips to follow:

- Follow the Recommended Oil Change Schedule: Change the engine oil and filter regularly.

- Use High-Quality Oil: Use high-quality synthetic oil that meets Mercedes-Benz specifications.

- Avoid Aggressive Driving: Avoid aggressive driving habits that can put stress on the engine.

- Address Engine Issues Promptly: Address any engine issues, such as misfires or rough idling, promptly.

By understanding the M272 engine and the potential issues with the balance shaft sprocket, you can take steps to prevent problems and maintain your Mercedes-Benz’s performance.

7. Understanding Timing Chains and Timing Belts

In the realm of internal combustion engines, timing chains and timing belts play a crucial role in synchronizing the rotation of the crankshaft and camshaft(s). While both serve the same fundamental purpose, they differ significantly in design, materials, maintenance requirements, and lifespan.

7.1. Purpose of Timing Chains and Timing Belts

The primary function of both timing chains and timing belts is to maintain the precise timing relationship between the crankshaft and camshaft(s). The crankshaft, connected to the pistons, drives the up-and-down motion of the engine. The camshaft(s), on the other hand, control the opening and closing of the intake and exhaust valves. Proper synchronization between these two components is essential for efficient engine operation.

7.2. Timing Chain vs. Timing Belt: Key Differences

| Feature | Timing Chain | Timing Belt |

|---|---|---|

| Material | Typically made of metal, similar to a bicycle chain. Constructed from interconnected links or plates, providing robustness and resistance to wear. | Constructed from reinforced rubber or synthetic materials with teeth that mesh with gears on the crankshaft and camshaft(s). |

| Location | Usually located inside the engine, often running within the engine’s oil lubrication system. | Typically located outside the engine, although some engines may have them running internally. |

| Lifespan | Generally designed to last the life of the engine, often exceeding 100,000 miles or more. May require replacement only in cases of severe wear, neglect, or engine damage. | Has a shorter lifespan compared to timing chains. Replacement intervals typically range from 60,000 to 100,000 miles, depending on the manufacturer’s recommendations. |

| Maintenance | Requires minimal maintenance, as it is lubricated by the engine oil. Periodic inspections for wear or tension may be necessary, but replacement is rare under normal circumstances. | Requires periodic replacement at specified intervals to prevent breakage or failure. Inspection for cracks, wear, or fraying is also recommended. |

| Noise | Can produce more noise compared to timing belts due to the |