P13C271 Mercedes Fault Code: Diagnosis and Solutions

The P13C271 Mercedes fault code indicates a malfunction within the exhaust gas flap system. This comprehensive guide, brought to you by CARDIAGTECH.NET, explores the causes, symptoms, and effective repair strategies for this issue, ensuring your Mercedes performs optimally with tools that you can purchase immediately. Addressing this promptly prevents potential engine damage and restores your vehicle’s efficiency. Explore our selection of diagnostic tools and repair equipment at CARDIAGTECH.NET to resolve this issue efficiently.

Table of Contents

- Understanding the P13C271 Mercedes Fault Code

- Common Symptoms of a P13C271 Fault

- Causes of the P13C271 Error Code

- Diagnosing the P13C271 Fault Code: A Step-by-Step Guide

- Tools Needed for Diagnosing and Repairing P13C271

- Repairing the P13C271 Fault: Detailed Steps

- Clearing the P13C271 Code

- Preventive Measures to Avoid P13C271

- Estimated Repair Costs for P13C271

- Benefits of Using High-Quality Replacement Parts

- Advanced Diagnostic Techniques for P13C271

- Troubleshooting Common Issues During Repair

- Case Studies: Real-World P13C271 Repairs

- Understanding Mercedes-Benz Exhaust Systems

- The Role of the Exhaust Gas Flap

- Impact of P13C271 on Vehicle Performance

- When to Consult a Professional Mechanic

- DIY vs. Professional Repair: Making the Right Choice

- Warranty Implications of Repairing P13C271

- Tips for Maintaining Your Mercedes-Benz

- Future Trends in Automotive Diagnostics

- How CARDIAGTECH.NET Can Help You

- Customer Testimonials and Success Stories

- FAQ: Frequently Asked Questions About P13C271

- Conclusion: Resolving P13C271 for Optimal Performance

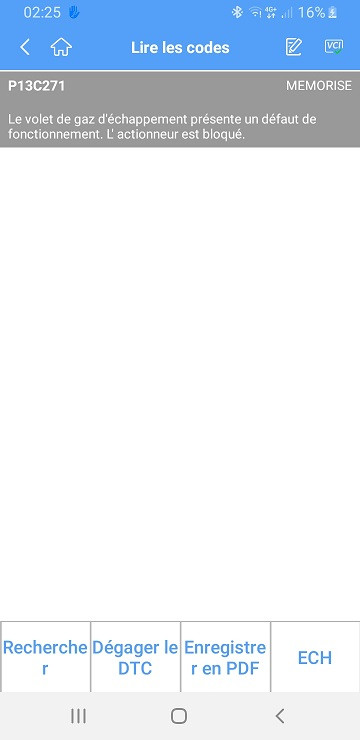

1. Understanding the P13C271 Mercedes Fault Code

The Mercedes P13C271 fault code indicates a “Exhaust gas flap actuator has a malfunction. The actuator is blocked.” This means the exhaust gas flap, crucial for managing exhaust flow and reducing emissions, is not functioning correctly. Understanding this code is the first step in diagnosing and resolving performance issues. This issue can affect fuel efficiency, engine performance, and overall vehicle emissions. For reliable diagnostic tools, visit CARDIAGTECH.NET.

- Technical Definition: The exhaust gas flap actuator is responsible for controlling the opening and closing of the exhaust flap, which regulates exhaust gas recirculation (EGR) and helps to optimize engine temperature and reduce emissions.

- Importance: Proper functioning of the exhaust gas flap ensures optimal engine performance, reduces harmful emissions, and maintains fuel efficiency.

- Common Misconceptions: Some mechanics might mistake this issue for a simple sensor problem, but the root cause often involves mechanical failure or blockage of the actuator.

Mercedes-Benz Engine Bay

Mercedes-Benz Engine Bay

2. Common Symptoms of a P13C271 Fault

Recognizing the symptoms associated with the P13C271 fault code is essential for early detection and repair. Here are some common signs that indicate a problem with the exhaust gas flap system:

- Check Engine Light: The most obvious sign is the illumination of the check engine light on your dashboard.

- Reduced Engine Performance: You may notice a decrease in power, especially during acceleration.

- Poor Fuel Economy: A malfunctioning exhaust gas flap can lead to inefficient combustion, resulting in lower fuel mileage.

- Rough Idling: The engine may idle roughly or stall, particularly when cold.

- Unusual Noises: Strange sounds from the exhaust system, such as hissing or rattling, can indicate a problem with the exhaust gas flap.

- Increased Emissions: The vehicle may fail emissions tests due to improper exhaust gas regulation.

Table: Symptoms of P13C271 Fault

| Symptom | Description | Possible Impact |

|---|---|---|

| Check Engine Light | Dashboard light indicating a problem | Driver awareness of an issue |

| Reduced Engine Performance | Decrease in power, especially during acceleration | Difficulty in overtaking, slower response |

| Poor Fuel Economy | Inefficient combustion leading to lower fuel mileage | Increased fuel costs, more frequent refueling |

| Rough Idling | Unstable engine idle, especially when cold | Stalling, discomfort during idling |

| Unusual Noises | Hissing or rattling sounds from the exhaust system | Indicates mechanical issues within the exhaust system |

| Increased Emissions | Failure to meet emissions standards during testing | Legal repercussions, environmental impact |

3. Causes of the P13C271 Error Code

Several factors can trigger the P13C271 error code. Identifying the root cause is crucial for effective repair:

- Faulty Actuator: The actuator itself may be defective due to electrical or mechanical failure.

- Blockage: The exhaust gas flap can become blocked by carbon deposits or debris.

- Wiring Issues: Damaged or corroded wiring to the actuator can disrupt its function.

- Vacuum Leaks: Vacuum leaks in the system can affect the actuator’s ability to operate correctly.

- Software Issues: In rare cases, software glitches in the engine control unit (ECU) can cause false error codes.

Detailed Breakdown of Causes:

- Faulty Actuator:

- Electrical Failure: Internal components of the actuator may fail, preventing it from receiving or executing commands from the ECU.

- Mechanical Failure: The actuator’s gears or linkages can break or wear out, causing it to jam or move improperly.

- Blockage:

- Carbon Deposits: Over time, carbon buildup from exhaust gases can accumulate around the flap, restricting its movement.

- Debris: Foreign objects or debris can enter the exhaust system and obstruct the flap.

- Wiring Issues:

- Damaged Wiring: Physical damage to the wires, such as cuts or abrasions, can interrupt the electrical signal.

- Corrosion: Corrosion on the wiring connectors can create resistance and prevent proper communication.

- Vacuum Leaks:

- Hose Damage: Cracks or leaks in the vacuum hoses can reduce the vacuum pressure needed to operate the actuator.

- Loose Connections: Loose or disconnected vacuum lines can also lead to insufficient vacuum.

- Software Issues:

- ECU Glitches: Occasionally, software errors in the ECU can cause it to misinterpret sensor data or send incorrect commands to the actuator.

- Software Updates: An outdated or corrupted ECU software version can also contribute to the problem.

4. Diagnosing the P13C271 Fault Code: A Step-by-Step Guide

A systematic approach to diagnosing the P13C271 fault code will help pinpoint the exact cause and ensure an effective repair. Here’s a detailed step-by-step guide:

- Read the Error Code: Use an OBD-II scanner to confirm the presence of the P13C271 code. Note any other related codes that may be present.

- Inspect the Actuator: Visually inspect the exhaust gas flap actuator for any signs of damage, such as cracks, corrosion, or loose connections.

- Check Wiring and Connectors: Examine the wiring and connectors leading to the actuator. Look for frayed wires, damaged insulation, and corroded terminals.

- Test the Actuator: Use a multimeter to test the actuator’s electrical continuity and resistance. Compare your readings to the manufacturer’s specifications.

- Check for Blockages: Manually try to move the exhaust gas flap. If it’s stuck, it may be blocked by carbon deposits or debris.

- Inspect Vacuum Lines: If the actuator is vacuum-operated, check the vacuum lines for leaks or damage. Use a vacuum gauge to test the vacuum pressure.

- Perform a Functional Test: Use a diagnostic tool to activate the actuator and observe its operation. Check if it moves smoothly and responds correctly to commands.

- Review ECU Software: Check for any available software updates for the engine control unit (ECU). An outdated software version may cause the error code.

- Clear the Code and Retest: After performing the above checks, clear the error code and retest the system. If the code reappears, the issue has not been resolved.

Table: Diagnostic Steps for P13C271 Fault

| Step | Action | Expected Outcome |

|---|---|---|

| 1. Read the Error Code | Use an OBD-II scanner to confirm the P13C271 code | Confirmation of the fault code and any related codes |

| 2. Inspect the Actuator | Visually inspect the actuator for damage | Identification of cracks, corrosion, or loose connections |

| 3. Check Wiring | Examine wiring and connectors for damage or corrosion | Detection of frayed wires, damaged insulation, or corroded terminals |

| 4. Test the Actuator | Use a multimeter to test electrical continuity and resistance | Confirmation of electrical functionality within manufacturer specifications |

| 5. Check for Blockages | Manually move the exhaust gas flap to check for obstructions | Determination if the flap is stuck due to carbon deposits or debris |

| 6. Inspect Vacuum Lines | Check vacuum lines for leaks or damage (if applicable) | Identification of vacuum leaks or damaged hoses |

| 7. Functional Test | Use a diagnostic tool to activate the actuator and observe its operation | Observation of actuator movement and response to commands |

| 8. Review ECU Software | Check for available software updates for the ECU | Identification of outdated software versions |

| 9. Clear and Retest | Clear the error code and retest the system | Confirmation if the issue is resolved or if the code reappears |

5. Tools Needed for Diagnosing and Repairing P13C271

Having the right tools is essential for accurately diagnosing and effectively repairing the P13C271 fault. Here’s a list of tools you’ll need:

- OBD-II Scanner: To read and clear diagnostic trouble codes.

- Multimeter: To test electrical circuits and components.

- Socket Set: For removing and installing bolts and fasteners.

- Wrench Set: For various mechanical tasks.

- Screwdriver Set: Both Phillips and flat-head screwdrivers.

- Vacuum Gauge: To test vacuum pressure in vacuum-operated systems.

- Inspection Mirror: To inspect hard-to-reach areas.

- Penetrating Oil: To loosen corroded bolts and fasteners.

- Cleaning Supplies: To remove carbon deposits and debris.

- Diagnostic Software: Mercedes-specific diagnostic software for advanced testing.

Table: Essential Tools for P13C271 Diagnosis and Repair

| Tool | Purpose | Benefit |

|---|---|---|

| OBD-II Scanner | Reads and clears diagnostic trouble codes | Accurate identification of fault codes, clearing codes after repair |

| Multimeter | Tests electrical circuits and components | Ensures proper electrical functionality, identifies faulty components |

| Socket Set | Removes and installs bolts and fasteners | Efficient disassembly and reassembly of parts |

| Wrench Set | Provides leverage for various mechanical tasks | Versatile tool for different repair needs |

| Screwdriver Set | Used for various screwing and unscrewing tasks | Essential for removing covers and securing components |

| Vacuum Gauge | Tests vacuum pressure in vacuum-operated systems | Identifies vacuum leaks and ensures proper vacuum pressure |

| Inspection Mirror | Inspects hard-to-reach areas | Allows visual inspection of difficult-to-see components |

| Penetrating Oil | Loosens corroded bolts and fasteners | Simplifies removal of rusted or seized parts |

| Cleaning Supplies | Removes carbon deposits and debris | Ensures clean connections and optimal performance |

| Diagnostic Software | Mercedes-specific software for advanced testing and calibration | Comprehensive diagnostics and accurate troubleshooting |

You can find high-quality diagnostic tools and repair equipment at CARDIAGTECH.NET to assist with these repairs.

6. Repairing the P13C271 Fault: Detailed Steps

Once you’ve diagnosed the cause of the P13C271 fault, follow these detailed steps to repair it:

- Remove the Actuator: Disconnect the electrical connector and remove any bolts or screws holding the actuator in place. Carefully detach the actuator from the exhaust gas flap.

- Clean the Flap: If the flap is blocked by carbon deposits, use a carbon cleaner and a wire brush to remove the buildup. Ensure the flap moves freely.

- Replace the Actuator: If the actuator is faulty, install a new one. Ensure it is properly aligned and securely fastened.

- Repair Wiring: If there are wiring issues, repair or replace the damaged wires and connectors. Use heat shrink tubing to protect the connections.

- Check Vacuum Lines: If there are vacuum leaks, replace the damaged vacuum lines and ensure all connections are tight.

- Test the System: After completing the repairs, use a diagnostic tool to activate the actuator and verify that it operates correctly.

- Clear the Code: Clear the P13C271 code from the ECU using an OBD-II scanner.

- Road Test: Perform a road test to ensure the issue is resolved and the vehicle is performing as expected.

Detailed Repair Procedure:

- Removing the Actuator:

- Preparation: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Access: Locate the exhaust gas flap actuator, typically found near the exhaust manifold.

- Disconnection: Disconnect the electrical connector by pressing the release tab and gently pulling it off.

- Removal: Remove the bolts or screws securing the actuator using the appropriate socket or wrench.

- Detachment: Carefully detach the actuator from the exhaust gas flap linkage.

- Cleaning the Flap:

- Access: Ensure the exhaust gas flap is accessible for cleaning.

- Application: Apply carbon cleaner to the flap and surrounding area, allowing it to soak for several minutes.

- Scrubbing: Use a wire brush or scraper to remove the carbon deposits.

- Cleaning: Wipe away the loosened carbon with a clean cloth.

- Verification: Ensure the flap moves freely without any restrictions.

- Replacing the Actuator:

- Preparation: Ensure the new actuator is the correct part number for your vehicle.

- Installation: Align the new actuator with the exhaust gas flap linkage.

- Fastening: Secure the actuator with the bolts or screws, tightening them to the manufacturer’s specified torque.

- Connection: Reconnect the electrical connector, ensuring it clicks into place.

- Repairing Wiring:

- Inspection: Identify any damaged or corroded wires and connectors.

- Replacement: Replace damaged wires with new wires of the same gauge and insulation type.

- Connection: Use butt connectors or solder to connect the wires, ensuring a secure connection.

- Protection: Cover the connections with heat shrink tubing to protect them from moisture and corrosion.

- Checking Vacuum Lines:

- Inspection: Inspect the vacuum lines for cracks, leaks, or loose connections.

- Replacement: Replace any damaged vacuum lines with new hoses of the same diameter and material.

- Connection: Ensure all vacuum lines are securely connected to their respective fittings.

- Testing the System:

- Activation: Use a diagnostic tool to activate the actuator and observe its operation.

- Verification: Check that the actuator moves smoothly and responds correctly to commands.

- Measurement: Use a multimeter to verify the electrical signals to the actuator are within the specified range.

- Clearing the Code:

- Connection: Connect an OBD-II scanner to the vehicle’s diagnostic port.

- Selection: Select the option to clear diagnostic trouble codes.

- Confirmation: Confirm that the P13C271 code has been cleared.

- Road Test:

- Observation: Drive the vehicle under various conditions, such as city and highway driving.

- Performance: Monitor the engine performance, fuel economy, and overall drivability.

- Rechecking: Recheck for the P13C271 code to ensure it does not reappear.

Exhaust Gas Flap

Exhaust Gas Flap

7. Clearing the P13C271 Code

After repairing the underlying issue, it’s essential to clear the P13C271 code from the vehicle’s ECU. Here’s how:

- Connect OBD-II Scanner: Plug the OBD-II scanner into the diagnostic port, usually located under the dashboard.

- Turn On Ignition: Turn the ignition to the “ON” position without starting the engine.

- Access Error Codes: Navigate to the section for reading and clearing error codes.

- Clear the Code: Select the option to clear the P13C271 code.

- Verify Clearing: Confirm that the code has been successfully cleared.

- Restart Vehicle: Start the engine and check if the check engine light remains off.

Table: Steps to Clear the P13C271 Code

| Step | Action | Expected Result |

|---|---|---|

| 1. Connect OBD-II | Plug the OBD-II scanner into the diagnostic port | Scanner is successfully connected to the vehicle’s ECU |

| 2. Turn On Ignition | Turn the ignition to the “ON” position without starting the engine | Vehicle’s electrical systems are powered on |

| 3. Access Error Codes | Navigate to the section for reading and clearing error codes | Access to the list of stored diagnostic trouble codes |

| 4. Clear the Code | Select the option to clear the P13C271 code | The P13C271 code is removed from the vehicle’s ECU |

| 5. Verify Clearing | Confirm that the code has been successfully cleared | Confirmation that the P13C271 code is no longer present |

| 6. Restart Vehicle | Start the engine and check if the check engine light remains off | The check engine light should remain off if the issue is resolved |

8. Preventive Measures to Avoid P13C271

Preventing the P13C271 fault code involves regular maintenance and proactive care. Here are some measures you can take:

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule, including oil changes and filter replacements.

- Use High-Quality Fuel: Using high-quality fuel can reduce carbon deposits in the exhaust system.

- Regular Inspections: Periodically inspect the exhaust gas flap actuator and associated components for signs of wear or damage.

- Clean the Exhaust System: Consider using an exhaust system cleaner to remove carbon buildup.

- Address Issues Promptly: If you notice any symptoms of a malfunctioning exhaust gas flap, address them promptly to prevent further damage.

Table: Preventive Measures for P13C271 Fault

| Measure | Description | Benefit |

|---|---|---|

| Regular Maintenance | Follow manufacturer’s maintenance schedule | Ensures optimal engine performance and longevity |

| Use High-Quality Fuel | Use fuel with detergents to reduce carbon buildup | Minimizes carbon deposits in the exhaust system |

| Regular Inspections | Periodically inspect exhaust gas flap actuator | Early detection of wear or damage |

| Clean the Exhaust System | Use exhaust system cleaner to remove carbon buildup | Prevents blockage and ensures smooth operation of the exhaust gas flap |

| Address Issues Promptly | Promptly address any symptoms of a malfunctioning exhaust gas flap | Prevents further damage and potential costly repairs |

9. Estimated Repair Costs for P13C271

The cost to repair the P13C271 fault can vary depending on the cause and the extent of the damage. Here are some estimated costs:

- Actuator Replacement: $200 – $500 (including parts and labor).

- Wiring Repair: $100 – $300 (including parts and labor).

- Vacuum Line Replacement: $50 – $150 (including parts and labor).

- Carbon Cleaning: $50 – $200 (including labor).

- Diagnostic Fee: $50 – $150.

Table: Estimated Repair Costs for P13C271

| Repair Type | Estimated Cost (USD) | Description |

|---|---|---|

| Actuator Replacement | $200 – $500 | Includes the cost of a new actuator and the labor to install it |

| Wiring Repair | $100 – $300 | Includes the cost of wiring and connectors, plus labor for repair or replacement |

| Vacuum Line Replacement | $50 – $150 | Includes the cost of new vacuum lines and the labor to replace them |

| Carbon Cleaning | $50 – $200 | Includes the labor cost to clean carbon deposits from the exhaust gas flap |

| Diagnostic Fee | $50 – $150 | Cost for a mechanic to diagnose the issue |

10. Benefits of Using High-Quality Replacement Parts

When repairing the P13C271 fault, using high-quality replacement parts is crucial for ensuring long-term reliability and performance. Here are some benefits:

- Durability: High-quality parts are made from better materials and are designed to last longer.

- Reliability: They are less likely to fail prematurely, reducing the risk of future breakdowns.

- Performance: High-quality parts ensure optimal performance and efficiency.

- Warranty: Many high-quality parts come with a warranty, providing added peace of mind.

- Compatibility: They are designed to fit perfectly and function seamlessly with your vehicle’s systems.

Table: Benefits of High-Quality Replacement Parts

| Benefit | Description | Impact |

|---|---|---|

| Durability | Made from superior materials and designed for longevity | Longer lifespan of the replaced component, reducing the need for frequent repairs |

| Reliability | Less prone to premature failure, ensuring consistent performance | Minimizes the risk of breakdowns and unexpected issues |

| Performance | Ensures optimal functionality and efficiency of the vehicle | Improved engine performance, fuel economy, and overall driving experience |

| Warranty | Often comes with a warranty, offering protection against defects | Provides peace of mind and financial protection in case of component failure |

| Compatibility | Designed to fit perfectly and integrate seamlessly with the vehicle’s systems | Ensures proper function and avoids potential issues caused by ill-fitting or incompatible parts |

11. Advanced Diagnostic Techniques for P13C271

For complex cases of the P13C271 fault, advanced diagnostic techniques may be necessary. These techniques require specialized tools and expertise:

- Oscilloscope Testing: Using an oscilloscope to analyze the electrical signals to the actuator can reveal subtle issues that a multimeter may miss.

- Smoke Testing: Smoke testing the exhaust system can help identify vacuum leaks that may be affecting the actuator.

- ECU Programming: In some cases, reprogramming the ECU may be necessary to resolve software glitches causing the error code.

- Data Logging: Recording and analyzing data from various sensors can help identify intermittent issues that are difficult to diagnose.

Table: Advanced Diagnostic Techniques for P13C271

| Technique | Description | Benefit |

|---|---|---|

| Oscilloscope Testing | Analyzing electrical signals to the actuator with an oscilloscope | Detects subtle electrical issues that a multimeter may miss |

| Smoke Testing | Using smoke to identify vacuum leaks in the exhaust system | Pinpoints vacuum leaks that may be affecting the actuator’s operation |

| ECU Programming | Reprogramming the engine control unit to resolve software glitches | Corrects software-related issues causing the error code |

| Data Logging | Recording and analyzing data from various sensors to identify intermittent issues | Helps identify elusive problems that are difficult to diagnose with standard methods |

12. Troubleshooting Common Issues During Repair

During the repair process, you may encounter some common issues. Here’s how to troubleshoot them:

- Stuck Bolts: Use penetrating oil and heat to loosen stuck bolts. If necessary, use a bolt extractor.

- Broken Connectors: Replace broken connectors with new ones. Ensure they are properly wired and secured.

- Incorrect Parts: Double-check the part number to ensure you have the correct replacement part.

- Code Won’t Clear: Ensure the underlying issue is fully resolved before attempting to clear the code.

- New Actuator Fails: Test the new actuator to ensure it is functioning correctly. Check the wiring and connections.

Table: Troubleshooting Common Repair Issues

| Issue | Solution |

|---|---|

| Stuck Bolts | Use penetrating oil and heat; if necessary, use a bolt extractor |

| Broken Connectors | Replace broken connectors, ensuring proper wiring and secure connections |

| Incorrect Parts | Double-check the part number to ensure the correct replacement part |

| Code Won’t Clear | Ensure the underlying issue is fully resolved before attempting to clear the code |

| New Actuator Fails | Test the new actuator to ensure proper function; check wiring and connections |

13. Case Studies: Real-World P13C271 Repairs

Examining real-world case studies can provide valuable insights into how to effectively repair the P13C271 fault:

- Case Study 1: A 2015 Mercedes C300 had a P13C271 code due to a blocked exhaust gas flap. The mechanic cleaned the flap, and the code was resolved.

- Case Study 2: A 2017 Mercedes E350 had a P13C271 code due to a faulty actuator. Replacing the actuator fixed the issue.

- Case Study 3: A 2019 Mercedes GLC300 had a P13C271 code due to damaged wiring. Repairing the wiring resolved the problem.

Table: Case Studies of P13C271 Repairs

| Case Study | Vehicle | Issue | Solution | Outcome |

|---|---|---|---|---|

| 1 | 2015 Mercedes C300 | Blocked exhaust gas flap | Cleaned the flap | Code resolved |

| 2 | 2017 Mercedes E350 | Faulty actuator | Replaced the actuator | Issue fixed |

| 3 | 2019 Mercedes GLC300 | Damaged wiring | Repaired the wiring | Problem resolved |

14. Understanding Mercedes-Benz Exhaust Systems

A thorough understanding of Mercedes-Benz exhaust systems is essential for diagnosing and repairing issues like the P13C271 fault. The exhaust system performs several critical functions:

- Emission Control: Reduces harmful pollutants from the engine.

- Noise Reduction: Minimizes engine noise for a quieter ride.

- Performance Enhancement: Optimizes engine performance by managing exhaust flow.

Key Components of the Exhaust System:

- Exhaust Manifold: Collects exhaust gases from the engine cylinders.

- Catalytic Converter: Reduces harmful emissions by converting pollutants into less harmful substances.

- Oxygen Sensors: Monitors the oxygen content in the exhaust gases to optimize engine performance.

- Muffler: Reduces engine noise.

- Exhaust Pipes: Carries exhaust gases from the manifold to the tailpipe.

- Exhaust Gas Flap: Regulates exhaust gas recirculation (EGR) to reduce emissions and optimize engine temperature.

Table: Key Components of Mercedes-Benz Exhaust Systems

| Component | Function | Importance |

|---|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders | Directs exhaust gases efficiently into the exhaust system |

| Catalytic Converter | Reduces harmful emissions by converting pollutants into less harmful substances | Essential for meeting emissions standards and reducing environmental impact |

| Oxygen Sensors | Monitors oxygen content in exhaust gases to optimize engine performance and fuel efficiency | Crucial for maintaining proper air-fuel mixture and efficient combustion |

| Muffler | Reduces engine noise | Provides a quieter and more comfortable driving experience |

| Exhaust Pipes | Carries exhaust gases from the manifold to the tailpipe | Transports exhaust gases safely away from the engine and passenger compartment |

| Exhaust Gas Flap | Regulates exhaust gas recirculation (EGR) to reduce emissions and optimize engine temperature | Helps lower emissions and improves engine efficiency by recirculating exhaust gases back into the engine |

15. The Role of the Exhaust Gas Flap

The exhaust gas flap plays a crucial role in modern Mercedes-Benz vehicles. Its primary functions include:

- Exhaust Gas Recirculation (EGR): Controls the amount of exhaust gas recirculated back into the engine to reduce emissions.

- Engine Temperature Management: Helps regulate engine temperature by controlling exhaust flow.

- Performance Optimization: Improves engine performance and fuel efficiency by optimizing exhaust gas flow.

How the Exhaust Gas Flap Works:

The exhaust gas flap is controlled by an actuator, which receives signals from the ECU. The ECU adjusts the position of the flap based on various factors, such as engine load, speed, and temperature. By modulating the flow of exhaust gases, the flap helps to reduce emissions and optimize engine performance.

Table: Role and Functions of the Exhaust Gas Flap

| Function | Description | Benefit |

|---|---|---|

| Exhaust Gas Recirculation | Controls the amount of exhaust gas recirculated back into the engine to reduce emissions | Lowers emissions, improves fuel efficiency, and reduces engine knocking |

| Engine Temperature Management | Helps regulate engine temperature by controlling exhaust flow | Prevents overheating and ensures optimal engine operating temperature |

| Performance Optimization | Improves engine performance and fuel efficiency by optimizing exhaust gas flow | Enhances overall engine performance, fuel economy, and responsiveness |

16. Impact of P13C271 on Vehicle Performance

The P13C271 fault code can have several negative impacts on vehicle performance:

- Reduced Power: The engine may experience a noticeable reduction in power, especially during acceleration.

- Poor Fuel Economy: Inefficient combustion can lead to lower fuel mileage.

- Rough Idling: The engine may idle roughly or stall, particularly when cold.

- Increased Emissions: The vehicle may fail emissions tests due to improper exhaust gas regulation.

- Check Engine Light: The check engine light will remain illuminated, causing concern for the driver.

Table: Impact of P13C271 on Vehicle Performance

| Impact | Description | Cause |

|---|---|---|

| Reduced Power | Noticeable decrease in engine power, especially during acceleration | Malfunctioning exhaust gas flap affecting engine’s ability to breathe efficiently |

| Poor Fuel Economy | Inefficient combustion leading to lower fuel mileage | Improper regulation of exhaust gases causing suboptimal air-fuel mixture |

| Rough Idling | Unstable engine idle, especially when cold | Disrupted exhaust gas recirculation affecting idle stability |

| Increased Emissions | Failure to meet emissions standards during testing | Inadequate control of exhaust gases resulting in higher pollutant output |

| Check Engine Light | The check engine light remains illuminated on the dashboard | The vehicle’s computer detects a problem in the exhaust gas flap system |

17. When to Consult a Professional Mechanic

While some repairs can be done DIY, there are situations where consulting a professional mechanic is necessary:

- Lack of Experience: If you are not comfortable working on your vehicle or lack experience with automotive repairs.

- Complex Issues: If the issue is complex and requires specialized diagnostic tools or expertise.

- Persistent Problems: If you have attempted to repair the issue yourself but the problem persists