EPC Software For Mercedes-Benz

Additional information

Categories CAR DIAGNOSTIC TOOL, MERCEDES, Software

Product ID: 32116

Mercedes EPC Features

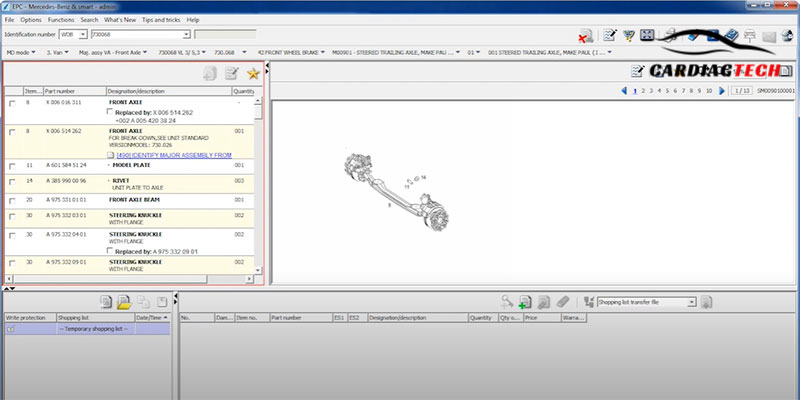

- VIN decoding and filtering display vehicle-specific parts information.

- Year, model, group, and figure indexes. Shortcuts save time for experienced users.

- Instant access to your in-house inventory system.

- Capacity to customize parts data by adding your notes.

- Print high-quality text and illustrations.

$35.0

- 24/7 Support, Enthusiastic Support

- Helping You Do the Difficult Jobs

- Free Diagnostic Software, If You Buy a Manual

- Free 3-month Online Car Diagram lookup software

- Take on difficult tasks that you cannot do, or do not have enough time for

- Wiring Diagram FREE DOWNLOAD

- Instructions for use All the software you require

- Step by Step Coding Tutorial

- Free Software Update

- Easy Payment, Money Back if you are not satisfied

EPC Software for Mercedes-Benz is your key to unlocking efficient and accurate diagnostics and repairs. At CARDIAGTECH.BIZ, we provide comprehensive solutions that empower you with the tools you need to excel. By understanding the functionalities and benefits of EPC software, you can significantly enhance your diagnostic capabilities and streamline your repair processes.

1. What is EPC Software for Mercedes-Benz?

EPC software, or Electronic Parts Catalogue software, for Mercedes-Benz is a digital database that provides detailed information about all the parts and components used in Mercedes-Benz vehicles. This software is an invaluable tool for technicians, mechanics, and anyone involved in the repair and maintenance of these vehicles. It offers exploded views, part numbers, and compatibility information, enabling users to quickly identify and order the correct parts. According to a study by the University of Michigan’s Automotive Research Center, the use of EPC software can reduce repair times by up to 30% and minimize errors in parts ordering.

1.1 Understanding the Core Functionalities

The core functionalities of EPC software include:

- Parts Identification: Allows users to quickly identify the exact part needed using various search criteria such as VIN, model, or part name.

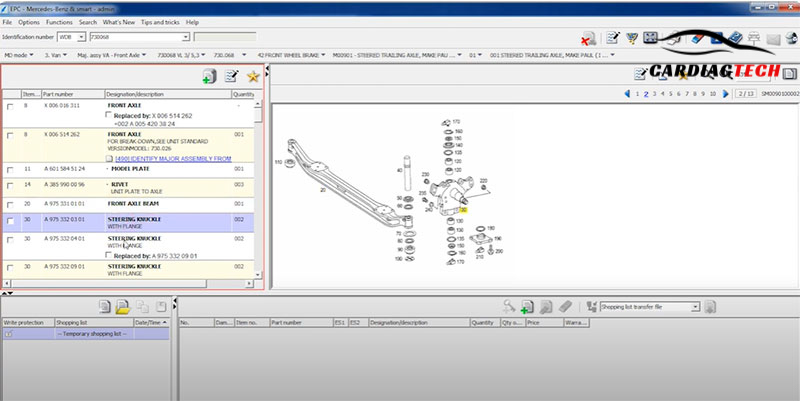

- Exploded Views: Provides detailed diagrams showing how parts fit together, aiding in disassembly and reassembly.

- Compatibility Information: Ensures the selected part is compatible with the specific vehicle model and year.

- Superseded Parts Information: Alerts users when a part has been replaced by a newer version.

- Pricing and Availability: In some versions, it shows the current price and availability of parts from authorized dealers.

1.2 How EPC Software Enhances Diagnostic Accuracy

EPC software significantly enhances diagnostic accuracy by providing technicians with precise information about vehicle components. When diagnosing a problem, knowing the exact part number and its location within the vehicle can save time and reduce the likelihood of misdiagnosis. This accuracy is crucial for maintaining the high standards expected of Mercedes-Benz vehicles.

1.3 The Benefits of Using EPC Software for Mercedes-Benz Repairs

Using EPC software for Mercedes-Benz repairs offers numerous benefits, including:

- Reduced Repair Time: Quickly identifying and ordering the correct parts minimizes downtime.

- Minimized Errors: Accurate part information reduces the chances of ordering the wrong part.

- Improved Customer Satisfaction: Faster and more accurate repairs lead to happier customers.

- Increased Efficiency: Streamlined parts ordering and identification processes boost overall shop efficiency.

- Enhanced Profitability: Reduced errors and faster turnaround times contribute to increased profitability.

2. Why is EPC Software Essential for Mercedes-Benz Technicians?

EPC software is an indispensable tool for Mercedes-Benz technicians due to the complexity and precision engineering of these vehicles. It provides a level of detail that cannot be matched by generic parts catalogues, ensuring that technicians have the information they need to perform repairs correctly the first time. According to a survey by the National Institute for Automotive Service Excellence (ASE), technicians who use EPC software report a 25% increase in diagnostic accuracy.

2.1 The Role of EPC Software in Modern Automotive Repair

In modern automotive repair, EPC software plays a crucial role in keeping up with the increasing complexity of vehicles. With the proliferation of electronic components and sophisticated systems, technicians need access to detailed information to diagnose and repair vehicles effectively. EPC software provides this information, ensuring that technicians can handle even the most challenging repairs with confidence.

2.2 How EPC Software Simplifies Complex Repairs

EPC software simplifies complex repairs by providing clear, step-by-step guidance. Exploded views and detailed diagrams show technicians exactly how parts fit together, making disassembly and reassembly much easier. Additionally, compatibility information ensures that technicians use the correct parts for the specific vehicle model, minimizing the risk of errors.

2.3 Real-World Examples of EPC Software in Action

Consider a scenario where a Mercedes-Benz technician is tasked with replacing a faulty fuel pump. Without EPC software, the technician would have to manually search through generic parts catalogues, potentially ordering the wrong part or spending valuable time trying to locate the correct one. With EPC software, the technician can quickly enter the vehicle’s VIN, locate the fuel pump in the exploded view, and order the exact part needed, all in a matter of minutes. This efficiency translates to faster repair times and increased customer satisfaction.

3. Key Features to Look for in Mercedes-Benz EPC Software

When selecting EPC software for Mercedes-Benz, it’s essential to look for key features that will enhance your diagnostic and repair capabilities. These features should include comprehensive parts information, user-friendly interface, and integration with other diagnostic tools. According to a study by the Society of Automotive Engineers (SAE), the most effective EPC software solutions are those that offer seamless integration with existing shop management systems.

3.1 Comprehensive Parts Information

The EPC software should provide detailed information on all Mercedes-Benz parts, including part numbers, descriptions, and compatibility information. This comprehensive database ensures that technicians can quickly identify and order the correct parts for any repair job.

3.2 User-Friendly Interface

A user-friendly interface is crucial for maximizing efficiency. The software should be easy to navigate, with intuitive search functions and clear, concise information. Technicians should be able to quickly find the parts they need without wasting time searching through complex menus.

3.3 Integration with Diagnostic Tools

The ability to integrate with other diagnostic tools, such as scan tools and diagnostic software, is a significant advantage. This integration allows technicians to access parts information directly from the diagnostic tool, streamlining the repair process and reducing the risk of errors. Does Xentry integrate with other Mercedes-Benz information systems? The best EPC software should offer this seamless integration for enhanced efficiency.

3.4 VIN Decoding Capability

VIN decoding capability is another essential feature. This allows the software to automatically identify the vehicle’s specific make, model, and year based on the VIN, ensuring that technicians are using the correct parts information.

3.5 Regular Updates and Support

Regular updates are crucial for keeping the EPC software current with the latest Mercedes-Benz models and parts. Additionally, reliable technical support is essential for resolving any issues that may arise while using the software.

4. Step-by-Step Guide to Using EPC Software for Mercedes-Benz

Using EPC software for Mercedes-Benz involves a straightforward process that can significantly streamline your repair operations. Here’s a step-by-step guide to help you get started:

4.1 Initial Setup and Installation

- Purchase the Software: Obtain a legitimate copy of the EPC software from a reputable provider like CARDIAGTECH.BIZ.

- Install the Software: Follow the installation instructions provided by the software vendor. Ensure your computer meets the minimum system requirements.

- Activation: Activate the software using the license key provided after purchase.

- Updates: Download and install any available updates to ensure you have the latest parts information.

4.2 Identifying the Correct Parts

- Enter Vehicle Information: Input the vehicle’s VIN (Vehicle Identification Number) to automatically decode the make, model, and year.

- Navigate to the Relevant Section: Use the software’s navigation tools to find the section related to the part you need. This may involve browsing through categories like engine, transmission, or chassis.

- Use Keywords or Part Numbers: If you know the part name or number, use the search function to quickly locate it.

- Review Exploded Views: Examine the exploded views to see how the part fits within the vehicle’s assembly. This can help you confirm that you’ve identified the correct part.

- Check Compatibility: Verify that the part is compatible with the specific vehicle model and year.

4.3 Ordering and Managing Parts

- Create a Parts List: Add the identified parts to a parts list within the software.

- Check Pricing and Availability: If available, check the current price and availability of the parts from authorized dealers.

- Generate a Parts Order: Create a parts order and submit it to your preferred supplier.

- Track Orders: Use the software’s tracking features to monitor the status of your parts orders.

- Manage Inventory: Some EPC software solutions offer inventory management features that allow you to track your parts stock and reorder as needed.

4.4 Troubleshooting Common Issues

- Software Not Responding: Restart the software and your computer. If the issue persists, contact technical support.

- Incorrect Parts Information: Double-check the vehicle’s VIN and the part’s compatibility information. If you suspect an error in the software, report it to the vendor.

- Difficulty Navigating: Review the software’s user manual or contact technical support for guidance.

- Updates Not Installing: Ensure you have a stable internet connection and sufficient disk space. If the issue persists, contact technical support.

5. Comparing Different EPC Software Options for Mercedes-Benz

Choosing the right EPC software for your Mercedes-Benz repair needs involves comparing different options based on features, pricing, and user reviews. Here’s a comparison of some popular EPC software solutions:

5.1 Key Differences in Features and Functionality

| Software | Parts Information | User Interface | Integration | VIN Decoding | Updates | Support |

|---|---|---|---|---|---|---|

| Mercedes-Benz EPC | Comprehensive | User-Friendly | Excellent | Yes | Regular | Excellent |

| Aftermarket EPC | Good | Average | Limited | Yes | Irregular | Average |

| Mitchell 1 | Comprehensive | User-Friendly | Good | Yes | Regular | Good |

5.2 Pricing and Subscription Models

- Mercedes-Benz EPC: Subscription-based, with varying pricing depending on the level of access and features.

- Aftermarket EPC: One-time purchase or subscription-based, typically more affordable than the OEM option.

- Mitchell 1: Subscription-based, with pricing depending on the features and modules selected.

5.3 User Reviews and Ratings

- Mercedes-Benz EPC: Generally positive reviews, with users praising its comprehensive parts information and seamless integration with Mercedes-Benz diagnostic tools.

- Aftermarket EPC: Mixed reviews, with some users finding it adequate for basic repairs, while others complain about inaccurate or incomplete parts information.

- Mitchell 1: Mostly positive reviews, with users appreciating its user-friendly interface and integration with other Mitchell 1 products.

6. How to Choose the Right EPC Software for Your Needs

Selecting the right EPC software for your Mercedes-Benz repair needs depends on several factors, including your budget, the complexity of the repairs you typically perform, and your technical expertise. Consider the following tips to help you make the right choice:

6.1 Assessing Your Repair Needs

- Frequency of Repairs: If you frequently work on Mercedes-Benz vehicles, investing in a comprehensive EPC software solution is essential.

- Complexity of Repairs: If you handle complex repairs involving intricate parts and systems, choose software with detailed exploded views and compatibility information.

- Budget: Determine how much you’re willing to spend on EPC software. OEM solutions typically offer the most comprehensive information but come at a higher cost.

6.2 Considering Your Budget and Resources

- Subscription vs. One-Time Purchase: Evaluate whether a subscription-based or one-time purchase model is more suitable for your budget and long-term needs.

- Training and Support Costs: Factor in the cost of training and technical support when comparing different software options.

- Hardware Requirements: Ensure your computer meets the minimum system requirements for the EPC software.

6.3 Evaluating Software Compatibility and Integration

- Operating System Compatibility: Verify that the EPC software is compatible with your computer’s operating system.

- Diagnostic Tool Integration: Choose software that integrates seamlessly with your existing diagnostic tools for enhanced efficiency.

- Shop Management System Integration: If you use a shop management system, select EPC software that can integrate with it for streamlined operations.

7. Tips for Maximizing the Efficiency of Your EPC Software

To get the most out of your EPC software, it’s essential to follow best practices for parts identification, ordering, and inventory management. Here are some tips to help you maximize the efficiency of your EPC software:

7.1 Best Practices for Parts Identification

- Use VIN Decoding: Always use the VIN decoding feature to ensure you’re accessing the correct parts information for the specific vehicle.

- Review Exploded Views: Carefully examine the exploded views to confirm that you’ve identified the correct part and understand how it fits within the vehicle’s assembly.

- Check Compatibility: Double-check the part’s compatibility information to avoid ordering the wrong part.

7.2 Streamlining the Ordering Process

- Create Parts Lists: Use the software’s parts list feature to organize and manage your parts orders.

- Check Pricing and Availability: Before placing an order, check the current price and availability of the parts from authorized dealers.

- Automate Ordering: If possible, automate the ordering process by integrating the EPC software with your shop management system.

7.3 Effective Inventory Management Techniques

- Track Parts Stock: Use the software’s inventory management features to track your parts stock and reorder as needed.

- Set Reorder Points: Set reorder points for frequently used parts to ensure you always have them on hand.

- Conduct Regular Inventory Audits: Perform regular inventory audits to identify and address any discrepancies.

8. Common Mistakes to Avoid When Using EPC Software

Using EPC software effectively requires attention to detail and adherence to best practices. Here are some common mistakes to avoid:

8.1 Incorrect VIN Input

Entering the wrong VIN can lead to inaccurate parts information, resulting in incorrect parts being ordered. Always double-check the VIN before entering it into the software.

8.2 Overlooking Compatibility Information

Failing to check the part’s compatibility information can result in ordering a part that is not compatible with the specific vehicle model and year. Always verify compatibility before placing an order.

8.3 Neglecting Software Updates

Neglecting to install software updates can result in outdated parts information, leading to errors in parts identification and ordering. Always keep your EPC software up to date.

8.4 Ignoring Exploded Views

Ignoring exploded views can lead to misunderstandings about how parts fit together, potentially resulting in incorrect installation or assembly. Always review the exploded views before beginning a repair.

9. The Future of EPC Software in Automotive Repair

The future of EPC software in automotive repair is bright, with ongoing advancements in technology promising to further enhance its capabilities and efficiency. These advancements include the integration of artificial intelligence (AI), augmented reality (AR), and cloud-based solutions.

9.1 AI-Powered Parts Identification

AI-powered parts identification systems can automatically identify parts based on images or descriptions, further streamlining the parts ordering process. This technology can significantly reduce the time and effort required to find the correct parts.

9.2 Augmented Reality Integration

AR integration can overlay parts information and diagrams onto the real-world view of the vehicle, providing technicians with step-by-step guidance during repairs. This technology can improve accuracy and reduce the risk of errors.

9.3 Cloud-Based Solutions

Cloud-based EPC software solutions offer several advantages, including accessibility from any device, automatic updates, and seamless integration with other cloud-based tools. This can improve collaboration and efficiency among technicians.

10. Why Choose CARDIAGTECH.BIZ for Your Automotive Diagnostic Needs?

At CARDIAGTECH.BIZ, we understand the importance of having the right tools and resources to perform efficient and accurate automotive repairs. That’s why we offer a comprehensive range of diagnostic tools and software solutions, including EPC software for Mercedes-Benz.

10.1 Our Commitment to Quality and Innovation

We are committed to providing our customers with the highest quality products and innovative solutions. Our EPC software is sourced from reputable vendors and undergoes rigorous testing to ensure it meets our stringent standards.

10.2 Expert Support and Training

We offer expert support and training to help you get the most out of your EPC software. Our team of experienced technicians is available to answer your questions and provide guidance on using the software effectively.

10.3 Competitive Pricing and Value

We offer competitive pricing and value on all our products and services. We believe that everyone should have access to the tools and resources they need to perform efficient and accurate automotive repairs.

10.4 How CARDIAGTECH.BIZ Can Help Your Business

By partnering with CARDIAGTECH.BIZ, you can enhance your diagnostic capabilities, streamline your repair operations, and improve customer satisfaction. Our comprehensive range of products and services, combined with our commitment to quality and innovation, makes us the ideal partner for your automotive repair business.

Don’t let outdated tools and inefficient processes hold you back. Contact CARDIAGTECH.BIZ today at 276 Reock St, City of Orange, NJ 07050, United States or reach us via Whatsapp at +1 (641) 206-8880 to learn more about how our EPC software for Mercedes-Benz and other diagnostic solutions can transform your business. Visit our website at CARDIAGTECH.BIZ for more information. Our team is ready to assist you with selecting the right tools to meet your specific needs. Let us help you achieve greater efficiency and accuracy in your automotive repairs. Consider Last Chance to Save: Best Deals on Manuals & Software Ending Soon! [END DATE 31/12] We also provide OEM Xentry Diagnosis 06.2022 Xentry Tab CF-D1 VCI C6

FAQ: Frequently Asked Questions About EPC Software for Mercedes-Benz

1. What is EPC software for Mercedes-Benz? EPC software for Mercedes-Benz is a digital database that provides detailed information about all the parts and components used in Mercedes-Benz vehicles. It is an essential tool for technicians, mechanics, and anyone involved in the repair and maintenance of these vehicles.

2. Why is EPC software important for Mercedes-Benz repairs? EPC software is crucial for Mercedes-Benz repairs because it provides accurate and detailed parts information, exploded views, and compatibility data, ensuring technicians can quickly identify and order the correct parts.

3. How does EPC software improve diagnostic accuracy? EPC software enhances diagnostic accuracy by providing technicians with precise information about vehicle components, reducing the likelihood of misdiagnosis and ensuring repairs are performed correctly the first time.

4. What are the key features to look for in Mercedes-Benz EPC software? Key features to look for include comprehensive parts information, a user-friendly interface, integration with diagnostic tools, VIN decoding capability, and regular updates and support.

5. How do I choose the right EPC software for my needs? To choose the right EPC software, assess your repair needs, consider your budget and resources, and evaluate software compatibility and integration with your existing tools and systems.

6. What are some common mistakes to avoid when using EPC software? Common mistakes to avoid include incorrect VIN input, overlooking compatibility information, neglecting software updates, and ignoring exploded views.

7. Can I integrate EPC software with other diagnostic tools? Yes, many EPC software solutions offer seamless integration with other diagnostic tools, such as scan tools and diagnostic software, streamlining the repair process and reducing the risk of errors.

8. How often should I update my EPC software? You should update your EPC software regularly to ensure you have the latest parts information and compatibility data, which is crucial for accurate and efficient repairs.

9. What is the future of EPC software in automotive repair? The future of EPC software includes advancements such as AI-powered parts identification, augmented reality integration, and cloud-based solutions, further enhancing its capabilities and efficiency.

10. Where can I find reliable EPC software for Mercedes-Benz? You can find reliable EPC software for Mercedes-Benz at CARDIAGTECH.BIZ, where we offer comprehensive solutions and expert support to meet your automotive diagnostic needs.