Do You Have a Process for Handling Hazardous Waste According to Regulations?

Do you have a process for handling hazardous waste according to regulations? It’s a crucial question for any automotive repair business, and CARDIAGTECH.NET is here to ensure you’re not only compliant but also optimizing your operations for safety and efficiency. Proper management of hazardous waste streams minimizes environmental impact, protects your employees, and keeps you on the right side of the law. Let’s explore the ins and outs of hazardous waste management, from identifying waste streams to implementing a robust disposal plan, all while considering cost-effective solutions and best practices for waste minimization.

1. Understanding Hazardous Waste in Automotive Repair Shops

Automotive repair shops generate a variety of waste products, some of which are classified as hazardous. Understanding what constitutes hazardous waste is the first step in ensuring compliance.

1.1. What Qualifies as Hazardous Waste?

A hazardous waste is defined as a waste with properties that make it dangerous or potentially harmful to human health or the environment, according to the EPA. These wastes can be generated from various sources, including industrial processes, batteries, and even everyday items. The EPA has developed a detailed regulatory process to identify specific substances that are considered hazardous and to provide criteria for including other materials in the regulated hazardous waste universe.

- Listed Wastes: These are wastes specifically listed by the EPA as hazardous. They are categorized into four lists: F-list (non-specific source wastes), K-list (source-specific wastes), P-list, and U-list (discarded commercial chemical products).

- Characteristic Wastes: These are wastes that exhibit certain characteristics, such as ignitability, corrosivity, reactivity, or toxicity.

1.2. Common Hazardous Wastes in Automotive Repair

Several common materials used in automotive repair shops are considered hazardous waste. These include:

- Used Oil: Engine oil, transmission fluid, and other lubricants.

- Used Oil Filters: These retain oil and other contaminants.

- Antifreeze: Ethylene glycol-based coolants.

- Solvents: Parts cleaners, degreasers, and paint thinners.

- Batteries: Lead-acid batteries from vehicles.

- Brake Fluid: Hydraulic fluid used in braking systems.

- Paints and Coatings: Leftover paints, primers, and coatings.

- Shop Towels and Rags: Those contaminated with solvents, oil, or other hazardous materials.

- Aerosol Cans: Empty or partially full aerosol cans containing hazardous propellants or substances.

- Fluorescent Lamps: Containing mercury.

1.3. Regulations and Standards

The management of hazardous waste is governed by the Resource Conservation and Recovery Act (RCRA). RCRA, enacted in 1976, provides a framework for the proper management of hazardous waste from its creation to its disposal, often referred to as “cradle to grave.”

- Federal Regulations: The EPA sets national standards for hazardous waste management.

- State Regulations: States can have their own regulations that are stricter than federal regulations. It’s crucial to check your state’s policies.

- Local Regulations: Some municipalities may have additional requirements.

2. Developing a Hazardous Waste Management Plan

A comprehensive hazardous waste management plan is essential for any automotive repair shop. This plan should outline procedures for identifying, handling, storing, and disposing of hazardous waste.

2.1. Steps to Creating a Plan

- Identify Waste Streams: Conduct an audit of your shop to identify all potential hazardous waste streams.

- Designate a Hazardous Waste Coordinator: Assign an employee to oversee the hazardous waste management program.

- Training: Provide comprehensive training to all employees on hazardous waste handling and disposal procedures.

- Proper Labeling: Ensure all hazardous waste containers are clearly labeled with the contents, hazards, and accumulation start date.

- Storage Requirements: Store hazardous waste in appropriate containers that are in good condition, compatible with the waste, and kept closed.

- Record Keeping: Maintain detailed records of hazardous waste generation, storage, treatment, and disposal.

- Emergency Procedures: Develop and implement emergency procedures for spills and releases.

- Disposal Methods: Establish relationships with reputable hazardous waste disposal companies.

2.2. Key Components of a Hazardous Waste Management Plan

- Waste Identification Procedures:

- Regular audits to identify all hazardous waste streams.

- Use of EPA waste codes to classify hazardous waste.

- Documentation of waste characteristics and quantities.

- Handling and Storage Procedures:

- Proper containers and storage areas for different types of hazardous waste.

- Regular inspections of containers for leaks or damage.

- Segregation of incompatible wastes.

- Disposal Procedures:

- Selection of licensed and reputable hazardous waste disposal companies.

- Proper packaging and labeling of waste for transport.

- Tracking waste from cradle to grave using manifests.

- Emergency Response Plan:

- Procedures for responding to spills, leaks, and other emergencies.

- Availability of spill kits and personal protective equipment (PPE).

- Notification procedures for regulatory agencies.

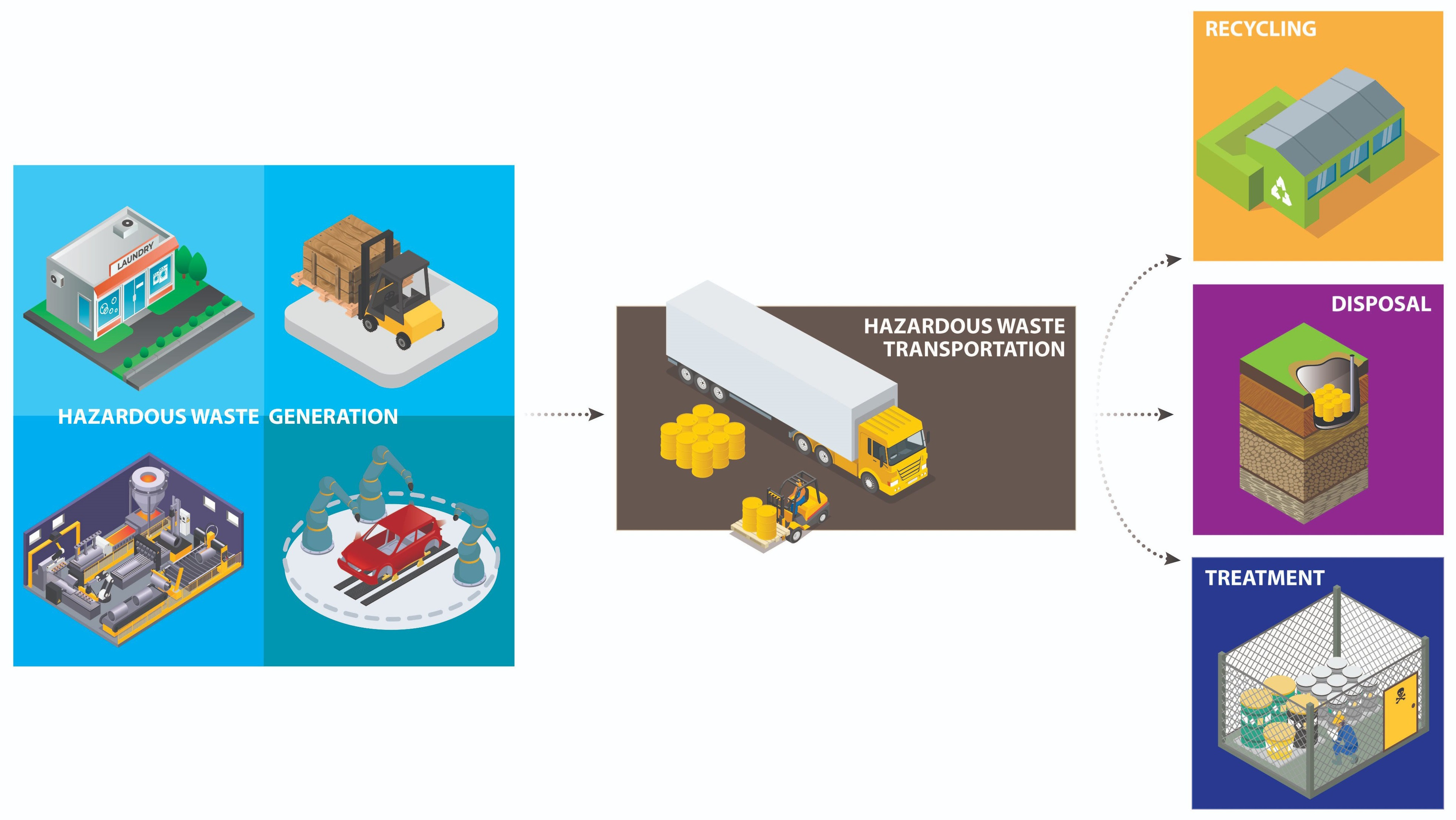

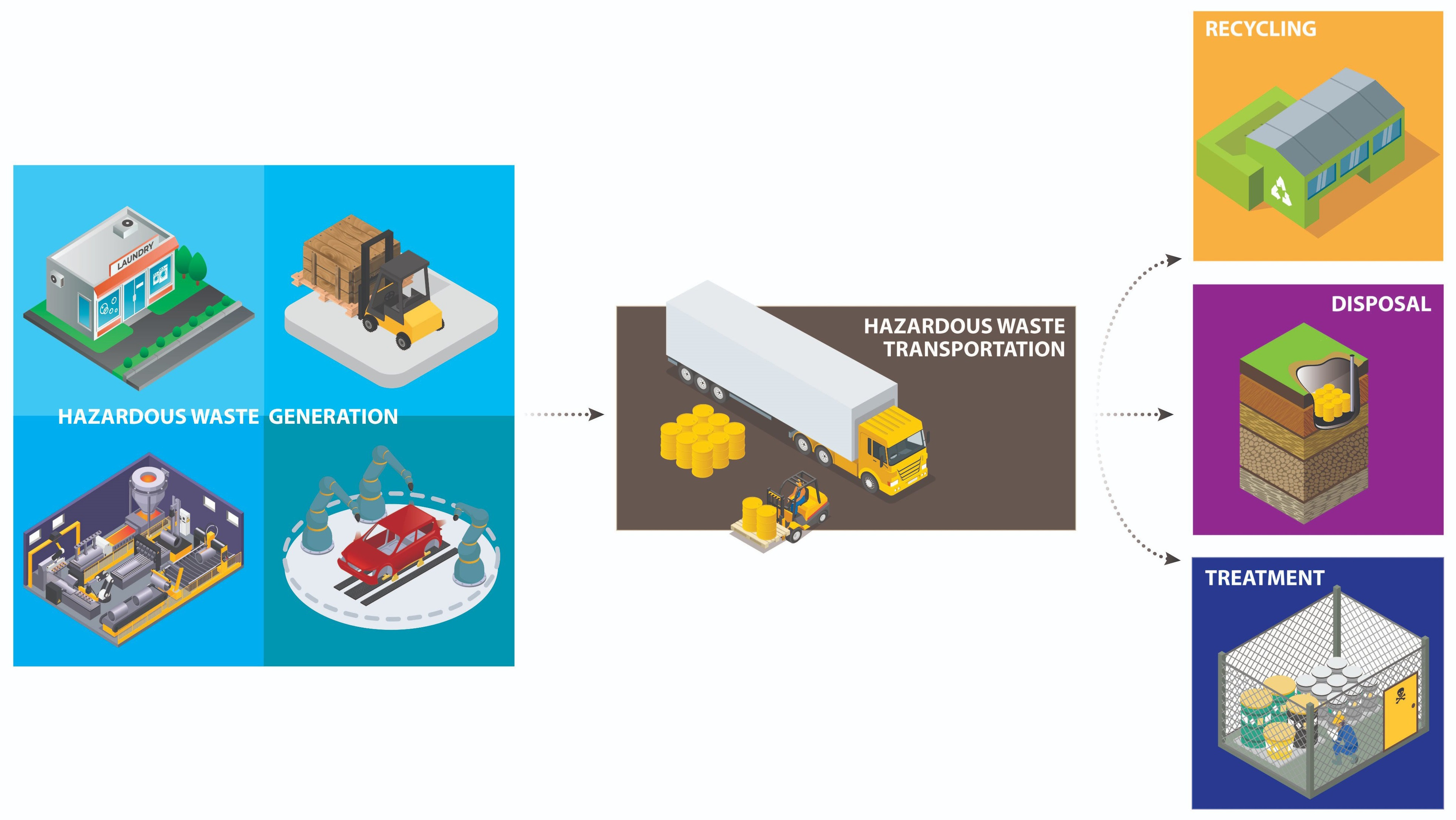

2.3. Navigating EPA’s Cradle-to-Grave Hazardous Waste Management Program

EPA’s Cradle-to-Grave Hazardous Waste Management Program, established under RCRA, ensures that hazardous waste is managed safely from its creation to its final disposal. This comprehensive approach includes strict regulations for generators, transporters, and Treatment, Storage, and Disposal Facilities (TSDFs).

- Generators: Hazardous waste generators are the first link in the management system. They must determine if their waste is hazardous, ensure proper identification and management, and document all processes. Regulations vary based on the amount of waste generated.

- Transporters: Transporters move hazardous waste to recycling, treatment, storage, or disposal facilities. They must comply with EPA’s hazardous waste regulations and the United States Department of Transportation hazardous materials regulations.

- TSDFs: These facilities provide temporary storage and final treatment or disposal for hazardous wastes. TSDFs must adhere to stringent regulations covering facility management, hazardous waste management units, and measures to protect soil, groundwater, and air resources.

Cradle to Grave Hazardous Waste Management System

Cradle to Grave Hazardous Waste Management System

3. Best Practices for Handling Hazardous Waste

Implementing best practices can help your automotive repair shop manage hazardous waste efficiently and safely.

3.1. Proper Labeling and Storage

- Labeling: All hazardous waste containers must be clearly labeled with the following information:

- The words “Hazardous Waste.”

- The specific contents of the container.

- The date accumulation began.

- The relevant hazard warnings.

- Storage:

- Store hazardous waste in containers that are in good condition and compatible with the waste.

- Keep containers closed except when adding or removing waste.

- Store containers in a secure area protected from the elements.

- Separate incompatible wastes to prevent dangerous reactions.

- Conduct regular inspections of storage areas to check for leaks or damage.

3.2. Waste Minimization Techniques

- Inventory Management:

- Purchase chemicals and materials in quantities that match your needs to avoid excess waste.

- Implement a first-in, first-out (FIFO) system to use older materials before they expire.

- Keep an accurate inventory of all chemicals and materials.

- Source Reduction:

- Use less hazardous materials whenever possible.

- Optimize processes to reduce waste generation.

- Implement better cleaning and maintenance practices to extend the life of equipment and reduce waste.

- Recycling and Reuse:

- Recycle used oil, antifreeze, and batteries.

- Reuse solvents and cleaning agents whenever possible.

- Use reusable shop towels instead of disposable ones.

- Employee Training:

- Train employees on waste minimization techniques.

- Encourage employees to identify and implement waste reduction opportunities.

- Provide ongoing training to keep employees up-to-date on best practices.

3.3. Personal Protective Equipment (PPE)

- Gloves: Wear chemical-resistant gloves when handling hazardous waste.

- Eye Protection: Use safety glasses or goggles to protect your eyes from splashes and fumes.

- Protective Clothing: Wear aprons or coveralls to protect your skin and clothing from contamination.

- Respirators: Use respirators when working with volatile chemicals or in poorly ventilated areas.

- Foot Protection: Wear steel-toed boots to protect your feet from falling objects and chemical spills.

4. Choosing a Hazardous Waste Disposal Company

Selecting the right hazardous waste disposal company is crucial for ensuring proper management and compliance.

4.1. Factors to Consider

- Licensing and Permits:

- Verify that the company is licensed and permitted to handle the types of waste you generate.

- Check for any violations or enforcement actions against the company.

- Reputation and Experience:

- Research the company’s reputation and experience in the industry.

- Read reviews and testimonials from other customers.

- Ask for references and contact them to learn about their experience with the company.

- Services Offered:

- Ensure the company offers a full range of services, including waste collection, transportation, treatment, and disposal.

- Check if they provide on-site waste management assistance and training.

- Compliance and Safety Record:

- Inquire about the company’s compliance and safety record.

- Ask for information on their environmental and safety policies and procedures.

- Cost and Contract Terms:

- Obtain quotes from multiple companies and compare costs.

- Review the contract terms carefully, including liability and insurance coverage.

4.2. Due Diligence Checklist

- Verify licenses and permits.

- Check the company’s safety record.

- Review the company’s insurance coverage.

- Ask for references and contact them.

- Inspect the company’s facilities.

- Evaluate their waste management plan.

- Compare costs and contract terms.

4.3. Manifest System

The manifest system is a critical component of hazardous waste management, ensuring that waste is tracked from “cradle to grave.”

- What is a Manifest?

- A manifest is a shipping document that accompanies hazardous waste during transportation.

- It contains information about the waste generator, transporter, and disposal facility, as well as the type and quantity of waste.

- How Does It Work?

- The generator prepares the manifest and provides it to the transporter.

- The transporter signs the manifest, acknowledging receipt of the waste.

- The transporter delivers the waste to the designated disposal facility.

- The disposal facility signs the manifest, confirming receipt of the waste.

- Copies of the manifest are sent to the generator, transporter, and regulatory agencies.

- Importance of the Manifest System:

- Ensures accountability for hazardous waste.

- Tracks the movement of waste from generation to disposal.

- Provides documentation for regulatory compliance.

- Helps prevent illegal dumping and mismanagement of waste.

5. Regulations for Specific Wastes

Understanding the specific regulations for different types of hazardous wastes is essential for compliance.

5.1. Used Oil Management

Used oil is a common waste stream in automotive repair shops. Proper management is crucial to prevent environmental contamination.

- Storage:

- Store used oil in tanks or containers that are in good condition and properly labeled.

- Keep containers closed and protected from the elements.

- Inspect tanks and containers regularly for leaks or damage.

- Recycling:

- Recycle used oil whenever possible.

- Send used oil to a licensed recycling facility.

- Keep records of used oil recycling activities.

- Disposal:

- Dispose of used oil that cannot be recycled in accordance with federal and state regulations.

- Use a licensed hazardous waste disposal company.

5.2. Battery Management

Lead-acid batteries are another common waste stream. They must be managed properly to prevent lead contamination.

- Storage:

- Store batteries in a secure area with a containment system to capture leaks.

- Keep batteries upright to prevent acid spills.

- Separate damaged batteries from undamaged ones.

- Recycling:

- Recycle lead-acid batteries whenever possible.

- Send batteries to a licensed recycling facility.

- Keep records of battery recycling activities.

5.3. Antifreeze Management

Antifreeze contains ethylene glycol, which is toxic. Proper management is essential to prevent poisoning.

- Storage:

- Store antifreeze in closed containers that are in good condition.

- Keep containers labeled and protected from the elements.

- Recycling:

- Recycle antifreeze whenever possible.

- Use a licensed recycling facility.

- Disposal:

- Dispose of antifreeze that cannot be recycled in accordance with federal and state regulations.

5.4. Solvent Management

Solvents used for cleaning and degreasing can be hazardous. Proper management is crucial to prevent air and water pollution.

- Storage:

- Store solvents in closed containers that are compatible with the material.

- Keep containers labeled and protected from the elements.

- Waste Minimization:

- Use less hazardous solvents whenever possible.

- Reuse solvents when appropriate.

- Disposal:

- Dispose of solvents in accordance with federal and state regulations.

- Use a licensed hazardous waste disposal company.

6. Training and Education

Proper training and education are essential for ensuring that employees understand how to handle hazardous waste safely and compliantly.

6.1. Training Program Requirements

- Initial Training: Provide initial training to all employees who handle hazardous waste.

- Annual Training: Conduct annual refresher training to keep employees up-to-date on regulations and best practices.

- Training Content: Cover topics such as waste identification, handling, storage, disposal, emergency procedures, and PPE.

- Documentation: Maintain records of all training activities, including dates, attendees, and topics covered.

6.2. Employee Responsibilities

- Follow Procedures: Follow all established procedures for handling hazardous waste.

- Report Problems: Report any spills, leaks, or other problems to the hazardous waste coordinator.

- Use PPE: Use appropriate PPE when handling hazardous waste.

- Participate in Training: Attend all required training sessions.

6.3. Resources for Training

- EPA: The EPA provides a variety of resources for hazardous waste training, including online courses and publications.

- State Agencies: State environmental agencies also offer training programs and resources.

- Private Consultants: Private consultants can provide customized training for your specific needs.

7. Emergency Preparedness and Spill Response

Developing an emergency preparedness and spill response plan is essential for protecting employees and the environment.

7.1. Developing an Emergency Plan

- Identify Potential Hazards: Identify all potential hazards associated with hazardous waste handling and storage.

- Develop Response Procedures: Develop detailed procedures for responding to spills, leaks, fires, and other emergencies.

- Establish Communication Protocols: Establish clear communication protocols for notifying employees, regulatory agencies, and emergency responders.

- Designate Emergency Responders: Designate and train employees to serve as emergency responders.

- Assemble Emergency Equipment: Assemble and maintain emergency equipment, such as spill kits, fire extinguishers, and first aid supplies.

- Conduct Drills: Conduct regular drills to test the effectiveness of the emergency plan.

7.2. Spill Response Procedures

- Immediate Actions:

- Evacuate the area if necessary.

- Stop the source of the spill if possible.

- Contain the spill to prevent it from spreading.

- Cleanup:

- Use appropriate PPE to protect yourself from exposure.

- Absorb the spill with absorbent materials.

- Clean the affected area with appropriate cleaning agents.

- Reporting:

- Report the spill to the hazardous waste coordinator and regulatory agencies as required.

- Document the spill and response actions.

7.3. Spill Prevention Measures

- Proper Storage: Store hazardous waste in appropriate containers and storage areas.

- Regular Inspections: Conduct regular inspections of containers and storage areas to check for leaks or damage.

- Employee Training: Train employees on spill prevention measures.

- Spill Containment: Install spill containment systems, such as berms and drip pans, to capture spills.

8. Record Keeping and Reporting

Maintaining accurate records and submitting timely reports are essential for demonstrating compliance with hazardous waste regulations.

8.1. Required Records

- Waste Manifests: Keep copies of all waste manifests.

- Training Records: Maintain records of all training activities.

- Inspection Records: Keep records of all inspections of hazardous waste storage areas.

- Emergency Response Records: Document any spills or other emergencies and the response actions taken.

- Disposal Records: Keep records of all hazardous waste disposal activities.

8.2. Reporting Requirements

- Biennial Reporting: The EPA requires hazardous waste generators to submit a biennial report summarizing their waste management activities.

- State Reporting: Many states have additional reporting requirements.

- Emergency Reporting: Report spills and other emergencies to regulatory agencies as required.

8.3. Electronic Record Keeping

- Benefits of Electronic Record Keeping:

- Improved accuracy and efficiency.

- Easier access to information.

- Reduced paper consumption.

- Better compliance with regulations.

- Choosing an Electronic System:

- Select a system that meets your specific needs.

- Ensure the system is secure and reliable.

- Provide training to employees on how to use the system.

9. EPA Hazardous Waste Initiatives

Staying informed about EPA’s hazardous waste initiatives can help you prepare for future regulatory changes and opportunities for improvement.

9.1. Unified Agenda of Regulatory and Deregulatory Actions

- What is the Unified Agenda?

- The Unified Agenda is a report published by the EPA that provides information on upcoming regulatory and deregulatory actions.

- It includes information on the status of rulemakings, deadlines, and contact information.

- How to Use the Unified Agenda:

- Review the Unified Agenda regularly to stay informed about upcoming changes.

- Identify rulemakings that may affect your business.

- Participate in the rulemaking process by submitting comments and attending public hearings.

9.2. Sustainable Materials Management (SMM)

- What is SMM?

- Sustainable Materials Management (SMM) is an approach to managing materials that focuses on reducing their environmental impact throughout their lifecycle.

- It emphasizes waste prevention, recycling, and the use of sustainable materials.

- Benefits of SMM:

- Reduced environmental impact.

- Cost savings.

- Improved resource efficiency.

- Enhanced reputation.

- Implementing SMM:

- Conduct a waste audit to identify opportunities for improvement.

- Implement waste prevention and recycling programs.

- Use sustainable materials whenever possible.

- Track your progress and report your results.

10. Compliance Inspections and Enforcement

Understanding what to expect during a compliance inspection and how to avoid enforcement actions is crucial for maintaining a clean compliance record.

10.1. Preparing for an Inspection

- Review Regulations: Review all applicable federal, state, and local regulations.

- Conduct Self-Audits: Conduct regular self-audits to identify and correct any compliance issues.

- Maintain Records: Keep accurate and up-to-date records of all hazardous waste management activities.

- Train Employees: Ensure that all employees are properly trained on hazardous waste regulations and procedures.

10.2. During the Inspection

- Be Cooperative: Be cooperative and respectful to the inspector.

- Provide Information: Provide accurate and complete information in a timely manner.

- Take Notes: Take notes on the inspector’s observations and findings.

- Ask Questions: Ask questions to clarify any points of confusion.

10.3. Avoiding Enforcement Actions

- Compliance is Key: The best way to avoid enforcement actions is to comply with all applicable regulations.

- Correct Violations: Promptly correct any violations identified during an inspection.

- Develop a Corrective Action Plan: Develop a corrective action plan to prevent future violations.

- Communicate with Regulators: Maintain open communication with regulatory agencies.

11. Cost-Effective Hazardous Waste Management Strategies

Managing hazardous waste doesn’t have to break the bank. Several cost-effective strategies can help you reduce expenses while maintaining compliance.

11.1. Waste Reduction Techniques

- Inventory Management: Efficient inventory management reduces the amount of unused or expired chemicals that become waste.

- Substitution: Using less hazardous alternatives can significantly reduce disposal costs.

- Process Optimization: Streamlining processes to minimize waste generation can lead to substantial savings.

11.2. Recycling and Reuse Programs

- Used Oil Recycling: Recycling used oil not only protects the environment but also reduces disposal costs.

- Antifreeze Recycling: Recycling antifreeze can be more cost-effective than disposal, especially in large quantities.

- Solvent Recovery Systems: Investing in solvent recovery systems can allow you to reuse solvents, reducing the need for new purchases and lowering disposal costs.

11.3. Negotiating with Disposal Companies

- Competitive Bidding: Get quotes from multiple disposal companies to ensure you’re getting the best price.

- Volume Discounts: Negotiate volume discounts for regular waste pickups.

- Contract Terms: Review contract terms carefully to avoid hidden fees and ensure favorable pricing.

12. Case Studies: Successful Hazardous Waste Management in Automotive Repair

Real-world examples of successful hazardous waste management can provide valuable insights and inspiration.

12.1. Case Study 1: Small Shop, Big Impact

- Challenge: A small automotive repair shop struggled with high disposal costs and limited storage space.

- Solution: Implemented a comprehensive waste reduction program, including inventory management, substitution of less hazardous materials, and recycling.

- Results: Reduced hazardous waste generation by 40%, lowered disposal costs by 30%, and freed up valuable storage space.

12.2. Case Study 2: Medium-Sized Garage, Streamlined Processes

- Challenge: A medium-sized garage faced compliance issues due to inadequate training and record keeping.

- Solution: Developed a comprehensive training program, implemented an electronic record-keeping system, and improved communication with regulatory agencies.

- Results: Achieved 100% compliance, avoided enforcement actions, and improved employee morale.

12.3. Case Study 3: Large Dealership, Sustainable Practices

- Challenge: A large dealership sought to improve its environmental performance and reduce its carbon footprint.

- Solution: Implemented a sustainable materials management program, including waste prevention, recycling, and the use of sustainable materials.

- Results: Reduced hazardous waste generation by 50%, lowered energy consumption by 20%, and enhanced its reputation as an environmentally responsible business.

13. Resources and Tools for Hazardous Waste Management

Numerous resources and tools are available to help automotive repair shops manage hazardous waste effectively.

13.1. EPA Resources

- EPA Website: The EPA website provides a wealth of information on hazardous waste regulations, guidance documents, and training materials.

- RCRA Hotline: The RCRA Hotline can provide answers to your questions about hazardous waste regulations.

- Small Business Assistance Program: The EPA’s Small Business Assistance Program offers free and confidential assistance to small businesses on environmental compliance issues.

13.2. State and Local Resources

- State Environmental Agencies: State environmental agencies provide information on state-specific hazardous waste regulations and compliance assistance.

- Local Government Agencies: Local government agencies may offer additional resources and support for hazardous waste management.

13.3. Online Tools and Software

- Hazardous Waste Management Software: Several software programs can help you track and manage your hazardous waste.

- Online Training Courses: Online training courses can provide employees with the knowledge and skills they need to handle hazardous waste safely and compliantly.

- Compliance Checklists: Compliance checklists can help you ensure that you are meeting all regulatory requirements.

14. Future Trends in Hazardous Waste Management

Staying ahead of future trends in hazardous waste management can help you prepare for upcoming challenges and opportunities.

14.1. Increased Regulation

- Stricter Standards: Regulations are likely to become stricter in the future, with increased emphasis on waste reduction, recycling, and pollution prevention.

- Expanded Coverage: The scope of hazardous waste regulations may expand to include additional materials and industries.

14.2. Technological Innovations

- Advanced Treatment Technologies: New treatment technologies are being developed to more effectively remove contaminants from hazardous waste.

- Smart Waste Management Systems: Smart waste management systems use sensors and data analytics to optimize waste collection and disposal.

14.3. Focus on Sustainability

- Circular Economy: The circular economy is a model that emphasizes waste prevention, recycling, and the reuse of materials.

- Green Chemistry: Green chemistry is the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances.

15. Frequently Asked Questions (FAQs) About Hazardous Waste Management

Here are some frequently asked questions about hazardous waste management in automotive repair shops.

15.1. What is the definition of hazardous waste?

Hazardous waste is waste that is dangerous or potentially harmful to human health or the environment, as defined by the EPA.

15.2. What are the common hazardous wastes generated in automotive repair shops?

Common hazardous wastes include used oil, used oil filters, antifreeze, solvents, batteries, brake fluid, paints, and contaminated shop towels.

15.3. How do I identify if my waste is hazardous?

You can identify hazardous waste by determining if it is a listed waste or exhibits characteristics such as ignitability, corrosivity, reactivity, or toxicity.

15.4. What are the storage requirements for hazardous waste?

Hazardous waste must be stored in appropriate containers that are in good condition, compatible with the waste, and kept closed.

15.5. How often should I train my employees on hazardous waste management?

Employees should receive initial training when they start handling hazardous waste and annual refresher training thereafter.

15.6. What is a hazardous waste manifest, and why is it important?

A hazardous waste manifest is a shipping document that tracks hazardous waste from generation to disposal, ensuring accountability and compliance.

15.7. How do I choose a reputable hazardous waste disposal company?

Consider factors such as licensing, reputation, services offered, compliance record, and cost when selecting a disposal company.

15.8. What should I do in the event of a hazardous waste spill?

Evacuate the area, contain the spill, clean it up using appropriate PPE, and report the spill to regulatory agencies as required.

15.9. What are some cost-effective strategies for managing hazardous waste?

Cost-effective strategies include waste reduction, recycling, and negotiating with disposal companies for better rates.

15.10. Where can I find more information about hazardous waste regulations?

You can find more information on the EPA website, state environmental agency websites, and through private consultants.

Managing hazardous waste according to regulations is essential for the health of your business and the environment. By implementing a comprehensive hazardous waste management plan, following best practices, and staying informed about regulatory changes, you can ensure compliance and protect your employees and the environment. Need assistance with your automotive repair shop’s hazardous waste management? Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp at +1 (641) 206-8880. Let us help you find the right tools and strategies to ensure your shop is safe, compliant, and efficient. Visit CARDIAGTECH.NET today for more information and expert support. Take action now to improve your shop’s environmental performance!