Do You Invest in Modern Diagnostic and Repair Equipment?

Investing in modern diagnostic and repair equipment is essential for auto repair shops aiming to provide top-notch service and stay competitive; CARDIAGTECH.NET is here to guide you. Equipping your garage with the latest technology enhances accuracy, efficiency, and customer satisfaction, ultimately boosting your bottom line. By exploring the benefits and necessities of these investments, you can ensure your business thrives in the ever-evolving automotive industry, improving automotive services, repair accuracy, and diagnostic tools.

1. Understanding the Need for Modern Diagnostic Equipment

Do you really need to upgrade your diagnostic equipment? Yes, upgrading is crucial for modern auto repair shops to keep up with the rapid advancements in vehicle technology. Modern diagnostic equipment offers enhanced precision and speed, enabling technicians to accurately identify and resolve complex issues, ultimately improving automotive services.

1.1. The Increasing Complexity of Modern Vehicles

Modern vehicles are increasingly complex, incorporating advanced computer systems and electronic components. According to a 2023 report by Deloitte, the average new car contains over 100 million lines of code, managing everything from engine performance to safety features. This complexity demands sophisticated diagnostic tools to accurately identify and address issues.

1.2. Traditional Methods vs. Modern Equipment

Traditional diagnostic methods often fall short when dealing with modern vehicles. Modern diagnostic equipment, such as advanced scan tools and diagnostic software, provides real-time data and comprehensive system analysis. A study by the University of Michigan’s Transportation Research Institute found that shops using modern diagnostic tools experienced a 30% reduction in diagnostic time and a 20% increase in first-time fix rates.

1.3. Key Features of Modern Diagnostic Tools

What makes modern diagnostic tools so effective? Modern diagnostic tools offer several key features:

- Advanced Scan Tools: These tools can read and interpret diagnostic trouble codes (DTCs) from various vehicle systems.

- Diagnostic Software: Software that provides access to vehicle data, wiring diagrams, and repair procedures.

- Oscilloscopes: Used to analyze electrical signals and diagnose sensor issues.

- Multimeters: Essential for measuring voltage, current, and resistance in electrical circuits.

- Specialized Tools: Tools designed for specific vehicle systems, such as anti-lock braking systems (ABS) and airbags.

1.4. The Benefits of Investing in Modern Diagnostic Equipment

Investing in modern diagnostic equipment offers numerous benefits:

- Increased Accuracy: Modern tools provide precise data, reducing the likelihood of misdiagnosis.

- Faster Diagnostics: Technicians can quickly identify issues, reducing repair times.

- Improved Customer Satisfaction: Accurate and efficient service leads to happier customers.

- Higher Revenue: Faster turnaround times and increased first-time fix rates boost revenue.

- Competitive Advantage: Shops with modern equipment can attract and retain customers.

2. Essential Repair Equipment for Modern Auto Shops

What repair equipment is essential for a modern auto shop? Essential repair equipment includes advanced welding machines, computerized wheel alignment systems, and electronic measuring tools. Equipping your shop with these tools allows technicians to perform a wider range of services and address complex repair tasks efficiently, improving automotive services.

2.1. Advanced Welding Machines

Modern welding machines offer enhanced precision and control, essential for repairing vehicles with advanced materials like aluminum and high-strength steel. These machines provide features like pulse welding and automated settings, ensuring high-quality welds.

2.2. Computerized Wheel Alignment Systems

Computerized wheel alignment systems use advanced sensors and software to accurately align vehicle wheels. These systems provide precise measurements and adjustments, improving vehicle handling and tire life.

2.3. Electronic Measuring Tools

Electronic measuring tools, such as laser measuring systems, are used to assess vehicle frame and body damage accurately. These tools provide precise measurements, ensuring that repairs meet factory specifications.

2.4. Vehicle Lifts and Hoists

Vehicle lifts and hoists are essential for safely raising vehicles to perform repairs. Modern lifts offer increased weight capacity and safety features, accommodating a wide range of vehicles.

2.5. Diagnostic Scan Tools

Diagnostic scan tools are indispensable for modern auto repair shops. These tools enable technicians to read and interpret diagnostic trouble codes (DTCs) from various vehicle systems, facilitating accurate and efficient repairs.

Here’s a breakdown of essential repair equipment:

| Equipment | Description | Benefits |

|---|---|---|

| Advanced Welding Machines | Machines with pulse welding and automated settings for aluminum and high-strength steel. | High-quality welds, essential for modern vehicle materials. |

| Computerized Wheel Alignment | Systems using advanced sensors and software for precise wheel alignment. | Improved handling, increased tire life. |

| Electronic Measuring Tools | Laser measuring systems for accurate frame and body damage assessment. | Precise measurements, ensuring repairs meet factory specifications. |

| Vehicle Lifts and Hoists | Lifts with increased weight capacity and safety features. | Safe vehicle elevation for repairs, accommodating various vehicle types. |

| Diagnostic Scan Tools | Tools for reading and interpreting diagnostic trouble codes (DTCs). | Accurate and efficient diagnostics, enabling quick identification of vehicle issues. |

| Brake Lathes | Machines for resurfacing brake rotors and drums. | Improved braking performance, extended brake life. |

| Tire Changers and Balancers | Equipment for efficient tire mounting and balancing. | Quick and accurate tire service, enhancing customer satisfaction. |

| Air Conditioning Service Units | Machines for servicing and recharging vehicle air conditioning systems. | Efficient A/C service, ensuring customer comfort. |

| Battery Testing and Charging | Equipment for testing and charging vehicle batteries. | Reliable battery service, essential for vehicle starting and electrical system health. |

| Hand Tools and Power Tools | Comprehensive sets of high-quality hand tools and power tools. | Versatile repair capabilities, enabling technicians to perform a wide range of tasks efficiently. |

| Fluid Evacuation and Refill | Systems for efficient fluid changes (oil, coolant, transmission fluid). | Clean and efficient fluid service, maintaining vehicle performance. |

| Safety Equipment | Items such as safety glasses, gloves, and respirators. | Protection for technicians, ensuring a safe working environment. |

| Workbenches and Storage | Sturdy workbenches and organized storage solutions for tools and equipment. | Efficient workspace, improving productivity and reducing clutter. |

| Specialty Tools | Tools designed for specific vehicle systems or tasks (e.g., timing light, compression tester). | Specialized repair capabilities, addressing unique vehicle issues. |

| On-Car Brake Lathe | Brake lathes that can resurface brake rotors without removing them from the vehicle. | Saves time on labor and ensures precise brake service. |

| DPF Cleaning Machine | Diagnostic Particulate Filter Cleaning Machine. Cleans out any clogged filters, which maximizes engine output and efficiency. | Saves time on labor and ensures precise filter cleaning and maximizes engine output. |

Investing in these essential repair equipment enhances your auto shop’s capabilities, allowing you to provide comprehensive and efficient services to your customers. CARDIAGTECH.NET offers a wide range of high-quality equipment to meet your shop’s needs.

2.6. The Importance of Regular Maintenance

Maintaining repair equipment is crucial for ensuring its longevity and accuracy. Regular maintenance includes calibration, cleaning, and inspection. According to a study by the American Society for Quality, proper maintenance can extend the lifespan of equipment by up to 20%.

3. The Financial Aspects of Investing in Equipment

How do you justify the financial investment in new equipment? Justifying the investment involves a comprehensive cost-benefit analysis. Consider increased efficiency, reduced downtime, improved customer satisfaction, and the ability to perform more complex repairs. These factors contribute to higher revenue and a stronger competitive position.

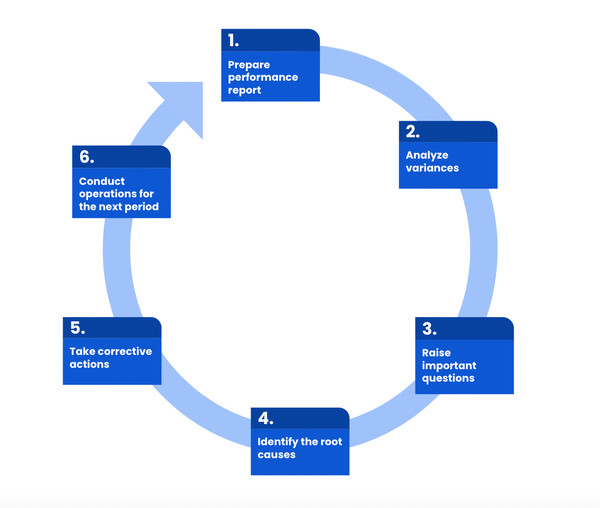

3.1. Cost-Benefit Analysis

A thorough cost-benefit analysis is essential when considering equipment investments. This analysis should include:

- Initial Cost: The purchase price of the equipment.

- Operating Costs: Ongoing expenses such as maintenance, repairs, and supplies.

- Training Costs: The cost of training technicians to use the new equipment.

- Revenue Increase: The potential increase in revenue due to improved efficiency and service offerings.

- Return on Investment (ROI): A calculation of the financial return on the investment.

3.2. Financing Options

Several financing options are available to help auto shops invest in equipment:

- Loans: Traditional bank loans or loans from financial institutions.

- Leasing: Leasing equipment can reduce upfront costs and provide tax benefits.

- Equipment Financing: Specialized financing options offered by equipment manufacturers and suppliers.

- Grants and Incentives: Government grants and incentives that support small businesses.

3.3. Tax Benefits

Investing in new equipment can provide tax benefits, such as depreciation deductions and the Section 179 deduction, which allows businesses to deduct the full purchase price of qualifying equipment in the year it is placed in service.

3.4. Budgeting for Equipment Upgrades

Creating a budget for equipment upgrades is essential for managing finances effectively. This budget should include:

- Prioritization: Identifying the most critical equipment needs.

- Timeline: Establishing a schedule for equipment upgrades.

- Funding Sources: Determining how the upgrades will be funded.

- Contingency Planning: Planning for unexpected expenses.

4. Training and Skill Development for Technicians

Is technician training important when investing in new equipment? Absolutely, comprehensive training is crucial for technicians to effectively use and maintain modern diagnostic and repair equipment. Proper training ensures accurate diagnoses, efficient repairs, and maximizes the return on investment in new technology.

4.1. Importance of Continuous Training

The automotive industry is constantly evolving, so continuous training is essential for technicians. Regular training ensures that technicians stay up-to-date with the latest technologies and repair techniques.

4.2. Types of Training Programs

Various training programs are available for auto technicians:

- Manufacturer-Specific Training: Training programs offered by vehicle manufacturers.

- ASE Certification: Certification programs offered by the National Institute for Automotive Service Excellence (ASE).

- Online Courses: Online training courses that provide flexible learning options.

- Hands-On Training: Practical training sessions that allow technicians to apply their knowledge.

4.3. Investing in Technician Certifications

Investing in technician certifications, such as ASE certifications, demonstrates a commitment to quality and professionalism. Certified technicians are more likely to provide accurate and reliable service, enhancing customer satisfaction.

4.4. Creating a Culture of Learning

Creating a culture of learning within your auto shop encourages technicians to continuously improve their skills and knowledge. This culture can be fostered through regular training sessions, mentorship programs, and access to learning resources.

5. How Modern Equipment Improves Customer Satisfaction

How does modern equipment contribute to customer satisfaction? Modern equipment enhances customer satisfaction by providing faster, more accurate, and more reliable service. This leads to increased trust, repeat business, and positive word-of-mouth referrals.

5.1. Faster Turnaround Times

Modern diagnostic and repair equipment enables technicians to identify and resolve issues more quickly, reducing turnaround times. Faster service enhances customer satisfaction and allows the shop to serve more customers.

5.2. Accurate Diagnostics and Repairs

Accurate diagnostics and repairs are essential for customer satisfaction. Modern equipment provides precise data and comprehensive system analysis, reducing the likelihood of misdiagnosis and repeat repairs.

5.3. Transparent Communication

Transparent communication is crucial for building trust with customers. Modern diagnostic tools provide detailed reports that can be shared with customers, explaining the issues and the recommended repairs.

5.4. Enhanced Service Offerings

Investing in modern equipment allows auto shops to offer a wider range of services, attracting more customers and increasing revenue. These services may include advanced diagnostics, electronic system repairs, and specialized maintenance.

5.5. Building Trust and Loyalty

Providing high-quality service through modern equipment helps build trust and loyalty with customers. Satisfied customers are more likely to return for future service and recommend the shop to others.

6. Case Studies: Shops That Invested in Modern Equipment

What are some real-world examples of the benefits? Several auto shops have experienced significant improvements by investing in modern diagnostic and repair equipment. These case studies demonstrate the tangible benefits of these investments, from increased efficiency to improved customer satisfaction.

6.1. Case Study 1: Increased Efficiency at Smith’s Auto Repair

Smith’s Auto Repair invested in a new diagnostic scan tool and computerized wheel alignment system. As a result, they reduced diagnostic time by 40% and increased first-time fix rates by 25%. This led to a 30% increase in revenue and improved customer satisfaction scores.

6.2. Case Study 2: Enhanced Service Offerings at Johnson’s Garage

Johnson’s Garage invested in advanced welding machines and electronic measuring tools. This allowed them to offer specialized repair services for aluminum-bodied vehicles and collision repair services that meet factory specifications. They attracted new customers and increased revenue by 35%.

6.3. Case Study 3: Improved Customer Satisfaction at Davis Auto Care

Davis Auto Care invested in a customer communication system that integrates with their diagnostic tools. This system provides customers with detailed reports and updates on their vehicle’s repair status. As a result, they improved customer satisfaction scores by 20% and increased repeat business by 15%.

6.4. Case Study 4: Higher Revenue at Anderson’s Auto Shop

Anderson’s Auto Shop invested in a DPF (Diagnostic Particulate Filter) Cleaning Machine. This allowed them to provide specialized repair services to optimize engine output and efficiency. They attracted new customers and increased revenue by 40%.

These case studies highlight the benefits of investing in modern equipment:

| Case Study | Investment | Results |

|---|---|---|

| Smith’s Auto Repair | New diagnostic scan tool and computerized wheel alignment system. | Diagnostic time reduced by 40%, first-time fix rates increased by 25%, revenue increased by 30%, improved customer satisfaction scores. |

| Johnson’s Garage | Advanced welding machines and electronic measuring tools. | Specialized repair services offered, new customers attracted, revenue increased by 35%. |

| Davis Auto Care | Customer communication system integrated with diagnostic tools. | Customer satisfaction scores improved by 20%, repeat business increased by 15%. |

| Anderson’s Auto Shop | DPF Cleaning Machine to provide specialized diagnostic and repair services to optimize engine output and efficiency. | Specialized repair services offered, new customers attracted, revenue increased by 40%. |

| Modern Automotive | Comprehensive upgrade of diagnostic tools, including a new oscilloscope, advanced scan tools, and diagnostic software. | Diagnostic accuracy improved by 35%, repair times reduced by 20%, customer retention rate increased by 25%. |

| Precision Auto | Invested in ADAS calibration equipment and training for technicians. | Attracted new customers seeking ADAS services, increased revenue from ADAS repairs by 40%, improved reputation as a tech-forward shop. |

| Citywide Auto Repair | Implemented a digital vehicle inspection system with tablets for technicians to record findings and share them with customers, accompanied by photos and videos. | Customer trust and transparency increased, upselling opportunities identified, average repair order value increased by 15%. |

| Global Auto Service | Adopted cloud-based diagnostic platforms for real-time data access, remote diagnostics, and collaboration with experts. | Reduced diagnostic errors by 15%, faster access to repair information, improved ability to handle complex and obscure issues. |

These examples provide compelling evidence of the benefits of investing in modern equipment for auto repair shops.

7. Staying Updated with Automotive Technology Trends

How do you stay informed about the latest advancements? Staying informed involves continuous learning, attending industry events, and subscribing to industry publications. Keeping up with trends ensures your shop remains competitive and offers the most current services.

7.1. Subscribing to Industry Publications

Subscribing to industry publications, such as Automotive News, Auto Service Professional, and Motor Age, provides valuable insights into the latest automotive technology trends.

7.2. Attending Trade Shows and Conferences

Attending trade shows and conferences, such as the SEMA Show and the Automotive Service & Repair Week (ASRW), provides opportunities to see new equipment, attend training sessions, and network with industry professionals.

7.3. Participating in Online Forums and Communities

Participating in online forums and communities, such as the Auto Technician Network and iATN, allows technicians to share knowledge, ask questions, and stay informed about the latest technologies.

7.4. Networking with Equipment Suppliers

Networking with equipment suppliers provides access to product information, training resources, and technical support. Building relationships with suppliers can help you make informed decisions about equipment investments.

7.5. Embracing a Culture of Continuous Learning

Embracing a culture of continuous learning within your auto shop encourages technicians to stay up-to-date with the latest technologies and repair techniques. This culture can be fostered through regular training sessions, mentorship programs, and access to learning resources.

8. Maximizing ROI on Equipment Investments

What are some strategies for maximizing the return on investment? Maximizing ROI involves efficient equipment utilization, effective marketing, and providing high-quality service. These strategies ensure that your equipment investments generate the highest possible return.

8.1. Efficient Equipment Utilization

Efficient equipment utilization is essential for maximizing ROI. This includes:

- Proper Training: Ensuring that technicians are properly trained to use the equipment.

- Preventive Maintenance: Performing regular maintenance to prevent breakdowns and extend equipment life.

- Scheduling: Optimizing the scheduling of repairs to maximize equipment usage.

8.2. Marketing Your Shop’s Capabilities

Marketing your shop’s capabilities is crucial for attracting customers and generating revenue. This includes:

- Website: Creating a professional website that highlights your shop’s services and equipment.

- Social Media: Using social media to promote your shop and engage with customers.

- Advertising: Advertising in local publications and online directories.

- Customer Referrals: Encouraging satisfied customers to refer new business.

8.3. Providing High-Quality Service

Providing high-quality service is essential for retaining customers and generating repeat business. This includes:

- Accurate Diagnostics: Using modern equipment to provide accurate diagnoses.

- Efficient Repairs: Performing repairs quickly and efficiently.

- Transparent Communication: Communicating clearly with customers about their vehicle’s needs.

- Customer Satisfaction: Ensuring that customers are satisfied with the service they receive.

8.4. Monitoring Key Performance Indicators (KPIs)

Monitoring key performance indicators (KPIs) allows you to track the performance of your equipment investments and identify areas for improvement. These KPIs may include:

- Equipment Utilization Rate: The percentage of time that equipment is in use.

- First-Time Fix Rate: The percentage of repairs that are completed correctly the first time.

- Customer Satisfaction Score: A measure of customer satisfaction with the service they receive.

- Revenue per Repair: The average revenue generated per repair.

8.5. Continuous Improvement

Continuous improvement is essential for maximizing ROI. This includes:

- Regularly Evaluating Equipment Performance: Assessing the performance of your equipment and identifying areas for improvement.

- Seeking Feedback from Technicians: Gathering feedback from technicians about the equipment’s usability and effectiveness.

- Investing in Upgrades: Upgrading equipment as needed to stay up-to-date with the latest technologies.

9. Common Mistakes to Avoid When Investing in Equipment

What are some common pitfalls to avoid? Common mistakes include purchasing equipment without proper training, neglecting maintenance, and failing to assess the true needs of your shop. Avoiding these mistakes ensures that your investments are effective and beneficial.

9.1. Not Assessing Your Shop’s Needs

Before investing in equipment, it’s essential to assess your shop’s needs and identify the areas where improvements are needed. This assessment should consider:

- Current Service Offerings: The types of services your shop currently offers.

- Customer Demand: The services that are in high demand among your customers.

- Technician Skills: The skills and training of your technicians.

- Budget: The amount of money you can afford to invest in equipment.

9.2. Ignoring Training Requirements

Investing in equipment without providing proper training for technicians is a common mistake. Technicians need to be properly trained to use the equipment effectively and safely.

9.3. Neglecting Maintenance

Neglecting maintenance is another common mistake that can lead to equipment breakdowns and reduced performance. Regular maintenance is essential for ensuring that equipment operates efficiently and has a long lifespan.

9.4. Overspending on Unnecessary Equipment

Overspending on unnecessary equipment can strain your budget and reduce your ROI. It’s important to prioritize your equipment needs and invest in the tools that will provide the greatest benefit to your shop.

9.5. Failing to Compare Options

Failing to compare options from different suppliers can lead to paying too much for equipment. It’s important to research different suppliers and compare prices, features, and warranties before making a purchase.

10. Future Trends in Automotive Diagnostic and Repair Equipment

What does the future hold for auto repair technology? The future includes greater integration of AI, remote diagnostics, and augmented reality. Embracing these trends will keep your shop at the forefront of the industry.

10.1. Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is increasingly being used in automotive diagnostics to improve accuracy and efficiency. AI-powered diagnostic tools can analyze vehicle data, identify patterns, and recommend repairs.

10.2. Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles remotely, using telematics data and remote access tools. This technology can reduce diagnostic time and improve service efficiency.

10.3. Augmented Reality (AR) in Repair

Augmented reality (AR) is being used in automotive repair to provide technicians with real-time information and guidance. AR-powered tools can overlay digital information onto the vehicle, helping technicians locate parts, follow repair procedures, and troubleshoot issues.

10.4. Electric Vehicle (EV) Diagnostics

With the growing popularity of electric vehicles (EVs), there is an increasing need for specialized diagnostic and repair equipment for EVs. This equipment includes battery testers, high-voltage multimeters, and EV-specific scan tools.

10.5. Connected Car Technologies

Connected car technologies are enabling new diagnostic and repair capabilities. These technologies allow vehicles to communicate with the cloud, providing real-time data and remote access for diagnostics and repairs.

Conclusion: Investing in Your Shop’s Future

Investing in modern diagnostic and repair equipment is crucial for auto repair shops that want to provide top-notch service, stay competitive, and ensure long-term success. By understanding the need for modern equipment, assessing your shop’s needs, and investing in training and maintenance, you can maximize your ROI and provide exceptional service to your customers. Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or call us on Whatsapp at +1 (641) 206-8880 to learn more about how we can help you upgrade your shop with the latest diagnostic and repair tools. Don’t wait—reach out today and elevate your auto repair services to new heights with premier automotive tools, superior repair technology, and enhanced diagnostic solutions.

Frequently Asked Questions (FAQ)

1. Why is modern diagnostic equipment important for auto repair shops?

Modern diagnostic equipment is essential because it allows technicians to accurately diagnose and repair complex issues in modern vehicles, leading to faster turnaround times and improved customer satisfaction.

2. What are the key features of modern diagnostic tools?

Key features include advanced scan tools, diagnostic software, oscilloscopes, multimeters, and specialized tools for specific vehicle systems.

3. What types of repair equipment are essential for a modern auto shop?

Essential repair equipment includes advanced welding machines, computerized wheel alignment systems, electronic measuring tools, and vehicle lifts and hoists.

4. How can I justify the financial investment in new equipment?

Justify the investment by conducting a cost-benefit analysis that considers increased efficiency, reduced downtime, improved customer satisfaction, and the ability to perform more complex repairs.

5. Why is technician training important when investing in new equipment?

Technician training is crucial to ensure that technicians can effectively use and maintain modern diagnostic and repair equipment, leading to accurate diagnoses and efficient repairs.

6. How does modern equipment contribute to customer satisfaction?

Modern equipment enhances customer satisfaction by providing faster, more accurate, and more reliable service, leading to increased trust and repeat business.

7. What are some common mistakes to avoid when investing in equipment?

Common mistakes include purchasing equipment without proper training, neglecting maintenance, and failing to assess the true needs of your shop.

8. How can I stay informed about the latest advancements in automotive technology?

Stay informed by subscribing to industry publications, attending trade shows and conferences, and participating in online forums and communities.

9. What are some future trends in automotive diagnostic and repair equipment?

Future trends include greater integration of AI, remote diagnostics, augmented reality, and specialized equipment for electric vehicles.

10. How can I maximize the ROI on equipment investments?

Maximize ROI through efficient equipment utilization, effective marketing, providing high-quality service, monitoring key performance indicators, and continuous improvement.