How Did You Design the Workflow in the Garage?

Designing an efficient garage workflow is critical for maximizing productivity and profitability. CARDIAGTECH.NET is here to guide you through optimizing your garage setup for peak performance, reducing downtime, and enhancing service quality. Let’s explore how strategic layout, equipment placement, and streamlined processes can transform your garage into a well-oiled machine, increasing customer satisfaction and boosting your bottom line by using diagnostic tools and repair equipment.

1. Understanding the Importance of Garage Workflow Design

Why is garage workflow design so important? A well-designed workflow is more than just arranging equipment; it’s about creating a system that enhances efficiency, reduces wasted movement, and improves overall productivity. According to a study by the University of Michigan’s Center for Ergonomics, a strategically designed workspace can reduce physical strain on technicians by up to 40%, directly translating to fewer injuries and increased job satisfaction.

- Increased Efficiency: A logical layout minimizes the time technicians spend moving between tasks, tools, and vehicles.

- Reduced Downtime: Efficient workflows allow for quicker diagnosis and repairs, decreasing vehicle turnaround time.

- Improved Safety: Organized spaces reduce the risk of accidents and injuries by minimizing clutter and clearly defining work areas.

- Enhanced Customer Satisfaction: Faster and more reliable service leads to happier customers and repeat business.

- Better Space Utilization: Effective design maximizes the use of available space, ensuring that every square foot contributes to productivity.

2. Assessing Your Current Garage Workflow

Before making changes, assess your current workflow. This involves evaluating the existing layout, identifying bottlenecks, and understanding how technicians currently move through their tasks.

- Observe Technician Movement: Track how technicians move between workstations, tool storage, and vehicles. Look for unnecessary steps or repetitive motions.

- Identify Bottlenecks: Determine which tasks or areas cause delays. This might involve waiting for equipment, accessing specific tools, or navigating congested areas.

- Review Existing Layout: Evaluate the current arrangement of equipment, workstations, and storage areas. Consider whether the layout supports efficient workflow or hinders it.

- Gather Feedback: Talk to your technicians about their experiences. They can provide valuable insights into workflow inefficiencies and potential improvements.

- Analyze Data: Use data from job tickets, repair orders, and time tracking to identify trends and patterns in workflow performance.

3. Key Principles of Effective Garage Workflow Design

Several key principles guide effective garage workflow design. These principles focus on minimizing movement, optimizing space, and creating a safe and organized work environment.

- Minimize Movement: Arrange workstations and equipment to reduce the distance technicians need to travel between tasks. Keep frequently used tools within easy reach.

- Optimize Space: Maximize the use of vertical space with shelving, cabinets, and overhead storage. Ensure that walkways are clear and unobstructed.

- Create Dedicated Work Areas: Designate specific areas for different types of tasks, such as diagnostics, repairs, and vehicle maintenance. This helps to streamline workflow and prevent confusion.

- Ensure Proper Lighting and Ventilation: Adequate lighting and ventilation are essential for safety and productivity. Ensure that work areas are well-lit and that the air is clean and free of fumes.

- Promote Cleanliness and Organization: Encourage technicians to keep their workstations clean and organized. Provide ample storage for tools and equipment.

4. Designing Your Garage Layout: Step-by-Step Guide

Designing an effective garage layout involves careful planning and consideration of your specific needs and constraints. Here’s a step-by-step guide to help you create an optimized workspace:

Step 1: Measure Your Space

Begin by accurately measuring your garage space. Note the dimensions, including length, width, and height. Also, identify the location of doors, windows, and any other fixed features that may impact your layout.

- Use a Measuring Tape: Measure the length and width of your garage in feet or meters.

- Sketch a Floor Plan: Create a basic floor plan of your garage, including doors, windows, and fixed features.

- Note Ceiling Height: Measure the height of your ceiling to determine how much vertical space you have available.

- Consider Obstructions: Identify any obstructions, such as support beams or pipes, that may impact your layout.

Step 2: Identify Work Zones

Divide your garage into distinct work zones based on the types of tasks performed. Common work zones include:

- Diagnostics Area: A dedicated space for diagnosing vehicle issues. This area should be equipped with diagnostic tools, computers, and reference materials.

- Repair Area: A larger area for performing repairs, including engine work, brake service, and suspension repairs.

- Maintenance Area: A designated space for routine maintenance tasks, such as oil changes, tire rotations, and fluid checks.

- Parts Storage: A secure area for storing spare parts, components, and supplies.

- Tool Storage: A centralized location for storing tools and equipment.

- Waiting Area: Comfortable space for customers while they wait for their vehicles to be serviced.

Step 3: Position Key Equipment

Strategically position key equipment within each work zone. Consider the flow of work and the frequency with which each piece of equipment is used.

- Vehicle Lifts: Position vehicle lifts to allow easy access to the undercarriage of vehicles. Ensure that there is sufficient space around the lifts for technicians to work comfortably.

- Diagnostic Scanners: Place diagnostic scanners in the diagnostics area, along with computers and reference materials.

- Tool Chests: Locate tool chests near the repair area, where they are easily accessible to technicians.

- Air Compressors: Position air compressors in a location that minimizes noise and vibration. Ensure that air hoses can reach all work areas.

- Welding Equipment: Designate a specific area for welding, with proper ventilation and fire safety measures in place.

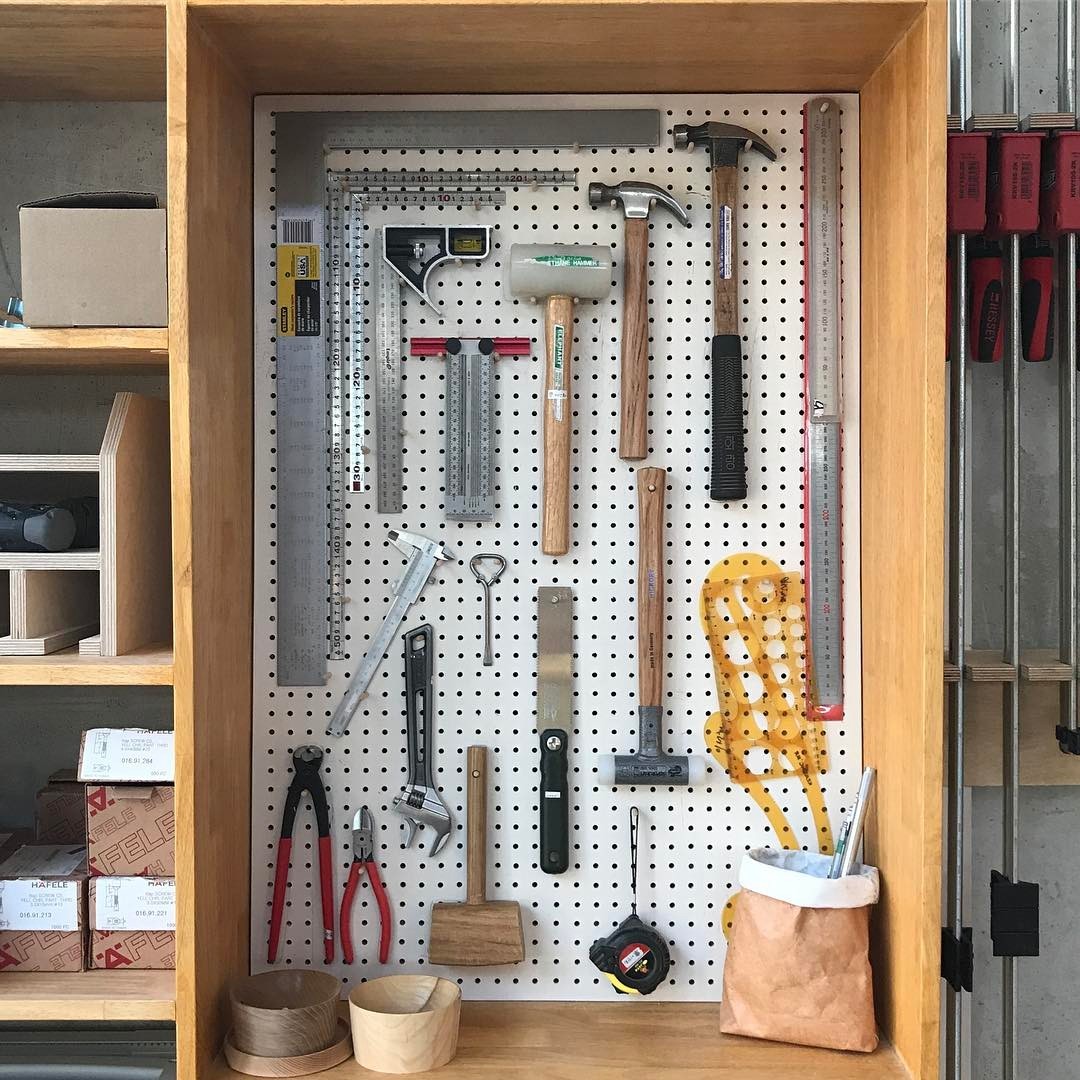

Step 4: Optimize Tool Storage

Effective tool storage is essential for maintaining an organized and efficient garage. Consider the following options:

- Tool Chests: High-quality tool chests provide secure storage for a wide range of tools.

- Tool Cabinets: Tool cabinets offer additional storage space and can be customized with drawers, shelves, and compartments.

- Wall-Mounted Tool Racks: Wall-mounted tool racks are ideal for storing frequently used tools within easy reach.

- Pegboards: Pegboards provide a versatile and customizable storage solution for small tools and accessories.

- Mobile Tool Carts: Mobile tool carts allow technicians to move tools and equipment to different work areas as needed.

Step 5: Create Clear Pathways

Ensure that there are clear and unobstructed pathways throughout your garage. This will help to minimize congestion and improve safety.

- Mark Walkways: Use floor tape or paint to mark walkways and pedestrian areas.

- Keep Aisles Clear: Ensure that aisles are free of clutter and obstructions.

- Minimize Cross-Traffic: Design your layout to minimize cross-traffic between different work zones.

- Provide Adequate Space: Ensure that there is sufficient space around equipment and workstations for technicians to move comfortably.

Step 6: Implement a Color-Coding System

A color-coding system can help to improve organization and efficiency in your garage. Use different colors to designate different types of tools, equipment, or storage areas.

- Tool Handles: Color-code tool handles to identify different types of tools.

- Storage Bins: Use different colored storage bins to organize parts and supplies.

- Floor Markings: Use different colored floor markings to designate different work zones.

- Labeling: Label all storage areas and equipment with clear and concise labels.

Step 7: Incorporate Ergonomic Principles

Ergonomics is the science of designing workplaces to fit the needs of the people who work there. Incorporating ergonomic principles into your garage design can help to reduce strain, prevent injuries, and improve productivity.

- Adjustable Workstations: Use adjustable workstations that can be customized to the height of each technician.

- Comfortable Seating: Provide comfortable and supportive seating for technicians who spend long periods sitting down.

- Proper Lifting Techniques: Train technicians on proper lifting techniques to prevent back injuries.

- Anti-Fatigue Mats: Use anti-fatigue mats in areas where technicians stand for long periods.

- Regular Breaks: Encourage technicians to take regular breaks to stretch and move around.

5. Optimizing Specific Work Zones

Each work zone in your garage has unique requirements. Here’s how to optimize each zone for maximum efficiency:

5.1 Diagnostics Area

The diagnostics area is the nerve center of your garage. It should be equipped with the tools and resources needed to quickly and accurately diagnose vehicle issues.

- Diagnostic Scanners: Invest in high-quality diagnostic scanners that can read and interpret vehicle diagnostic codes.

- Computers: Provide technicians with computers that have access to repair manuals, technical bulletins, and online resources.

- Reference Materials: Keep a library of repair manuals, wiring diagrams, and other reference materials.

- Well-Lit Workspace: Ensure that the diagnostics area is well-lit, with adjustable lighting to reduce glare.

- Ergonomic Seating: Provide ergonomic seating for technicians who spend long periods working at computers.

5.2 Repair Area

The repair area is where the bulk of the work takes place. It should be spacious, well-equipped, and organized to facilitate efficient repairs.

- Vehicle Lifts: Install vehicle lifts to provide easy access to the undercarriage of vehicles.

- Tool Chests: Locate tool chests near the repair area, where they are easily accessible to technicians.

- Air Compressors: Provide a reliable source of compressed air for pneumatic tools and equipment.

- Welding Equipment: Designate a specific area for welding, with proper ventilation and fire safety measures in place.

- Parts Washer: Install a parts washer to clean dirty or greasy parts.

5.3 Maintenance Area

The maintenance area is where routine maintenance tasks are performed. It should be equipped with the tools and supplies needed to quickly and efficiently service vehicles.

- Oil Change Equipment: Invest in oil change equipment, such as oil extractors and drain pans.

- Tire Changing Equipment: Provide tire changing equipment, such as tire changers and balancers.

- Fluid Dispensers: Install fluid dispensers for dispensing oil, coolant, and other fluids.

- Air Filters: Keep a stock of air filters, oil filters, and other maintenance parts.

- Lubricants: Provide a variety of lubricants for different types of vehicles.

5.4 Parts Storage

The parts storage area should be organized and secure. Use shelving, cabinets, and bins to store parts and supplies.

- Shelving: Install shelving to maximize vertical storage space.

- Cabinets: Use cabinets to store sensitive or valuable parts.

- Bins: Use bins to organize small parts and supplies.

- Labeling: Label all storage areas with clear and concise labels.

- Inventory Management: Implement an inventory management system to track parts and supplies.

5.5 Tool Storage

The tool storage area should be centralized and easily accessible to all technicians. Use tool chests, cabinets, and racks to store tools and equipment.

- Tool Chests: Invest in high-quality tool chests to provide secure storage for a wide range of tools.

- Tool Cabinets: Tool cabinets offer additional storage space and can be customized with drawers, shelves, and compartments.

- Wall-Mounted Tool Racks: Wall-mounted tool racks are ideal for storing frequently used tools within easy reach.

- Pegboards: Pegboards provide a versatile and customizable storage solution for small tools and accessories.

- Mobile Tool Carts: Mobile tool carts allow technicians to move tools and equipment to different work areas as needed.

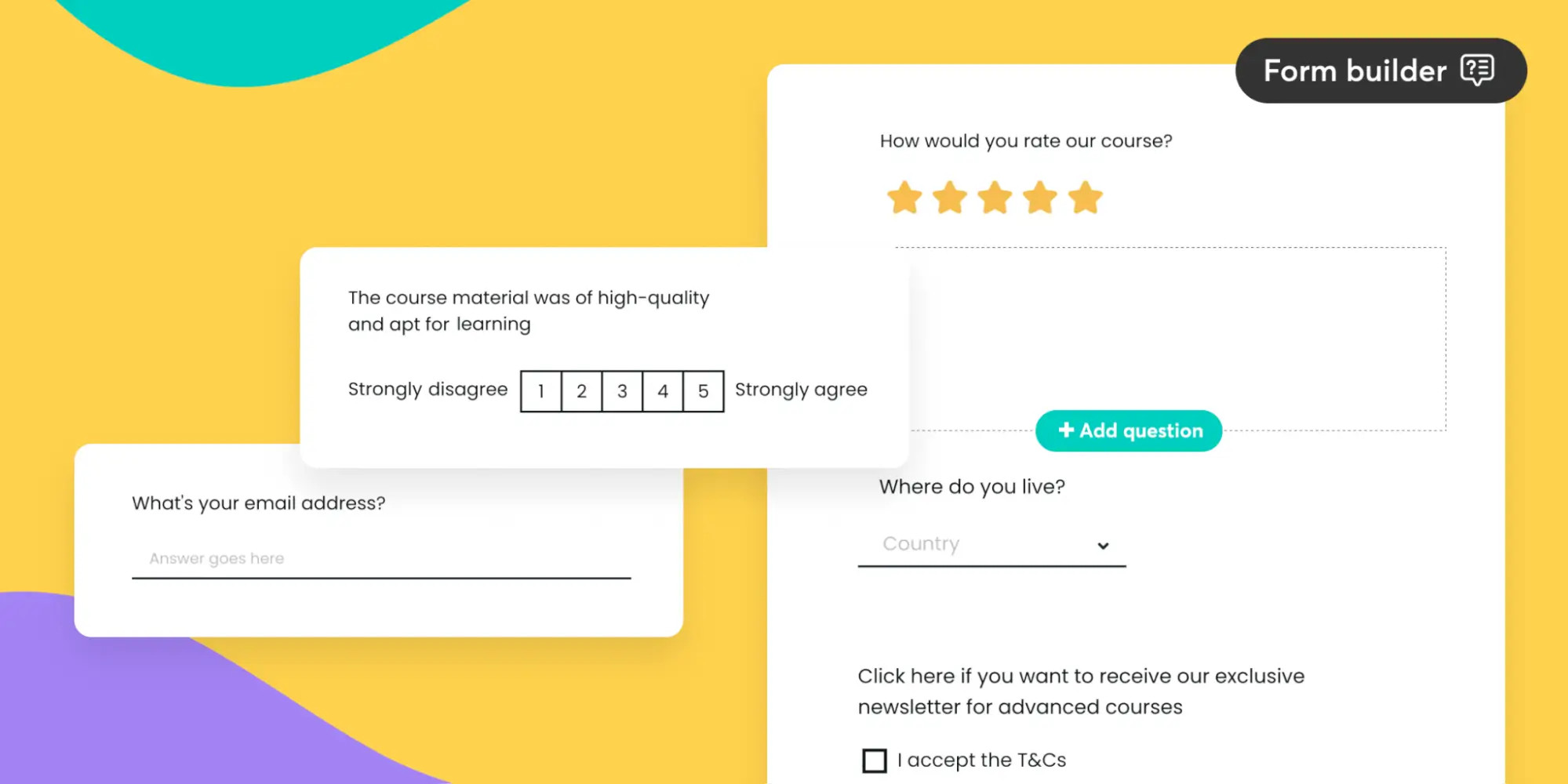

6. Implementing Technology to Enhance Workflow

Technology can play a significant role in enhancing garage workflow. Consider implementing the following technologies to streamline your operations:

- Garage Management Software: Garage management software can help you to manage appointments, track inventory, and generate reports.

- Digital Inspection Tools: Digital inspection tools allow technicians to perform inspections quickly and accurately, and to share results with customers in real-time.

- Mobile Devices: Equip technicians with mobile devices, such as tablets or smartphones, to access repair manuals, technical bulletins, and online resources.

- Wireless Communication: Implement a wireless communication system to allow technicians to communicate with each other and with the service desk.

- Cloud-Based Storage: Use cloud-based storage to store repair manuals, wiring diagrams, and other reference materials.

7. Training and Communication

Implementing a new workflow requires training and communication. Ensure that all technicians understand the new procedures and their role in the process.

- Provide Training: Provide training on the new workflow, including the location of tools and equipment, the use of technology, and the proper procedures for each task.

- Communicate Changes: Communicate changes to the workflow clearly and concisely. Explain the reasons for the changes and the benefits they will bring.

- Encourage Feedback: Encourage technicians to provide feedback on the new workflow. Use their feedback to make adjustments and improvements.

- Regular Meetings: Hold regular meetings to discuss workflow issues and to identify areas for improvement.

- Visual Aids: Use visual aids, such as flowcharts and diagrams, to illustrate the new workflow.

8. Maintaining and Improving Your Workflow

Workflow design is not a one-time event. It’s an ongoing process of monitoring, evaluating, and improving your operations.

- Monitor Performance: Track key performance indicators (KPIs), such as vehicle turnaround time, labor hours per repair, and customer satisfaction.

- Evaluate Efficiency: Regularly evaluate the efficiency of your workflow. Look for bottlenecks and areas where improvements can be made.

- Seek Feedback: Continue to seek feedback from technicians and customers. Use their feedback to identify areas for improvement.

- Stay Up-to-Date: Stay up-to-date on the latest industry trends and best practices. Attend conferences, read trade publications, and network with other garage owners.

- Continuous Improvement: Embrace a culture of continuous improvement. Always look for ways to make your workflow more efficient, safer, and more productive.

9. Investing in the Right Equipment from CARDIAGTECH.NET

Upgrading your equipment is crucial for optimizing your garage workflow. CARDIAGTECH.NET offers a range of tools and equipment to enhance your garage’s efficiency and productivity.

- Diagnostic Tools: Advanced diagnostic tools for accurate and efficient vehicle assessments.

- Repair Equipment: High-quality repair equipment to handle a wide range of automotive issues.

- Lifting Solutions: Vehicle lifts and jacks for safe and easy access to vehicle undercarriages.

- Tool Storage: Durable and organized tool storage solutions to keep your workspace tidy.

- Maintenance Equipment: Essential maintenance tools for oil changes, tire services, and more.

Investing in the right equipment from CARDIAGTECH.NET ensures that your technicians have the tools they need to perform their jobs quickly and efficiently.

10. Benefits of a Well-Designed Garage Workflow

The benefits of a well-designed garage workflow are numerous and far-reaching. A well-optimized workflow can lead to:

- Increased Revenue: Faster turnaround times and increased efficiency lead to higher revenue.

- Reduced Costs: Efficient workflows reduce wasted time and resources, lowering costs.

- Improved Customer Satisfaction: Faster and more reliable service leads to happier customers and repeat business.

- Enhanced Employee Morale: A well-organized and efficient workspace improves employee morale and job satisfaction.

- Better Safety: Organized spaces reduce the risk of accidents and injuries.

- Competitive Advantage: A well-designed workflow can give you a competitive advantage over other garages in your area.

- Scalability: An efficient workflow makes it easier to scale your business as demand grows.

FAQ: Optimizing Your Garage Workflow

Here are some frequently asked questions about designing and optimizing your garage workflow:

1. What are the most common bottlenecks in a garage workflow?

Common bottlenecks include waiting for equipment, disorganized tool storage, and poor communication between technicians and the service desk.

2. How can I measure the efficiency of my garage workflow?

Measure KPIs such as vehicle turnaround time, labor hours per repair, and customer satisfaction to assess efficiency.

3. What is the best way to organize tool storage in a garage?

Use a combination of tool chests, cabinets, wall-mounted racks, and pegboards to create an organized and accessible tool storage system.

4. How important is ergonomics in garage workflow design?

Ergonomics is crucial for reducing strain, preventing injuries, and improving productivity in the garage.

5. What role does technology play in enhancing garage workflow?

Technology such as garage management software, digital inspection tools, and mobile devices can significantly enhance garage workflow.

6. How often should I evaluate my garage workflow?

Evaluate your garage workflow regularly, at least once per quarter, to identify areas for improvement.

7. What are the key principles of effective garage workflow design?

Key principles include minimizing movement, optimizing space, creating dedicated work areas, and ensuring proper lighting and ventilation.

8. How can I get my technicians on board with a new workflow?

Provide training, communicate changes clearly, encourage feedback, and hold regular meetings to get your technicians on board with a new workflow.

9. What are the benefits of a well-designed garage workflow?

Benefits include increased revenue, reduced costs, improved customer satisfaction, and enhanced employee morale.

10. How can CARDIAGTECH.NET help me optimize my garage workflow?

CARDIAGTECH.NET offers a range of diagnostic tools, repair equipment, and storage solutions to enhance your garage’s efficiency and productivity.

Optimizing your garage workflow is essential for success in today’s competitive automotive industry. By following the steps outlined in this guide, you can create a workspace that is efficient, safe, and productive. Remember to continually monitor and evaluate your workflow to identify areas for improvement and to stay up-to-date on the latest industry trends. And when it comes to equipping your garage with the best tools and equipment, trust CARDIAGTECH.NET to provide you with the solutions you need to succeed.

Ready to transform your garage into a high-performance workspace? Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States. Let our experts help you design a workflow that maximizes efficiency, reduces downtime, and enhances customer satisfaction. Don’t wait—upgrade your garage and boost your bottom line with CARDIAGTECH.NET. Explore our wide range of products at CARDIAGTECH.NET and take the first step towards a more efficient and profitable garage today, complete with advanced auto repair solutions, professional diagnostic systems, and efficient garage layouts.