**How to Check Suspension Strut Mounts/Bearings Condition?**

Are you experiencing odd noises or steering issues with your vehicle? How to Check Suspension Strut Mounts/Bearings Condition? This article by CARDIAGTECH.NET offers a comprehensive guide on identifying, assessing, and addressing strut mount and bearing problems, ensuring your vehicle maintains optimal handling and safety. Understand the vital role of these components and learn preventative measures to extend their lifespan, ultimately improving your driving experience. Explore related terms like suspension repair, steering maintenance, and vehicle safety inspections.

1. What are Suspension Strut Mounts and Bearings?

Suspension strut mounts and bearings are vital components of a vehicle’s suspension system, especially in cars with MacPherson strut setups. According to a study by the University of Michigan Transportation Research Institute, vehicles with well-maintained suspension systems experience 20% better handling and stability. Let’s break down their roles:

- Strut Mounts: These connect the top of the strut assembly to the vehicle’s chassis. They provide a cushioning effect, reducing noise and vibration transmitted into the cabin. Mounts also allow the strut to pivot, which is crucial for steering and handling.

- Strut Bearings (or Upper Strut Mount Bearings): These bearings sit within the strut mount and allow the strut to rotate smoothly when you turn the steering wheel. They reduce friction and enable the steering system to operate efficiently.

Alt text: Suspension strut mount and bearing assembly for automotive suspension system

2. Why is Checking Strut Mounts and Bearings Important?

Regular inspection of strut mounts and bearings is essential for several reasons:

- Safety: Faulty strut mounts or bearings can compromise steering control, leading to potentially dangerous situations, especially during emergency maneuvers.

- Ride Comfort: Worn components can cause increased noise, vibration, and harshness (NVH), diminishing the overall driving experience.

- Tire Wear: Misalignment caused by bad strut mounts can lead to uneven and premature tire wear.

- Suspension Component Longevity: Addressing issues early can prevent further damage to other suspension parts, such as struts, shocks, and tires.

3. What are the Common Symptoms of Failing Strut Mounts and Bearings?

Identifying problems early can save you money and prevent further damage. Here are some telltale signs:

- Noises:

- Clunking or Knocking: Often heard when driving over bumps or turning at low speeds.

- Squeaking or Creaking: May occur when steering or going over uneven surfaces.

- Rattling: Indicates looseness or wear within the mount or bearing.

- Steering Issues:

- Stiff Steering: Difficulty turning the steering wheel.

- Binding or Erratic Steering: Steering feels jerky or inconsistent.

- Steering Wheel Play: Excessive looseness in the steering wheel.

- Vibration:

- Excessive Vibration: Felt through the steering wheel or the vehicle’s chassis.

- Alignment and Tire Wear:

- Poor Wheel Alignment: Vehicle pulls to one side.

- Uneven Tire Wear: Noticeable difference in wear patterns across the tires.

- Visual Inspection:

- Cracked or Deteriorated Rubber: Visible damage to the rubber part of the mount.

- Corrosion: Rust or corrosion around the mount or bearing area.

- Deformation: Any visible bending or warping of the mount.

4. How to Conduct a Preliminary Inspection of Strut Mounts and Bearings?

Before diving into a detailed check, perform a quick preliminary inspection:

- Listen While Driving: Pay attention to any unusual noises while driving over bumps or turning.

- Check Steering Feel: Notice if the steering feels stiffer, looser, or more erratic than usual.

- Observe Tire Wear: Look for uneven wear patterns on your tires.

- Bounce Test: Push down firmly on each corner of the vehicle and observe how it rebounds. Excessive bouncing can indicate suspension issues.

5. What Tools and Materials are Needed for a Detailed Inspection?

If the preliminary inspection raises concerns, gather the following tools for a more thorough examination:

- Jack and Jack Stands: To safely lift and support the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

- Wrench Set: Various sizes to remove and tighten bolts and nuts.

- Socket Set: Including deep sockets for strut bolts.

- Torque Wrench: To ensure proper tightening of fasteners.

- Penetrating Oil: To loosen rusted or stuck bolts.

- Flashlight: To illuminate the inspection area.

- Pry Bar: To check for play or movement in the components.

- Gloves and Safety Glasses: For personal protection.

- Camera or Phone: To document any issues found.

6. Step-by-Step Guide to Inspecting Strut Mounts and Bearings

Follow these steps for a comprehensive inspection:

- Safety First:

- Park the vehicle on a level surface.

- Engage the parking brake.

- Place wheel chocks behind the rear wheels.

- Lift the Vehicle:

- Use the jack to lift the front of the vehicle.

- Place jack stands securely under the vehicle’s frame.

- Never work under a vehicle supported only by a jack.

- Remove the Wheel:

- Use the wrench to loosen the lug nuts.

- Remove the wheel and set it aside.

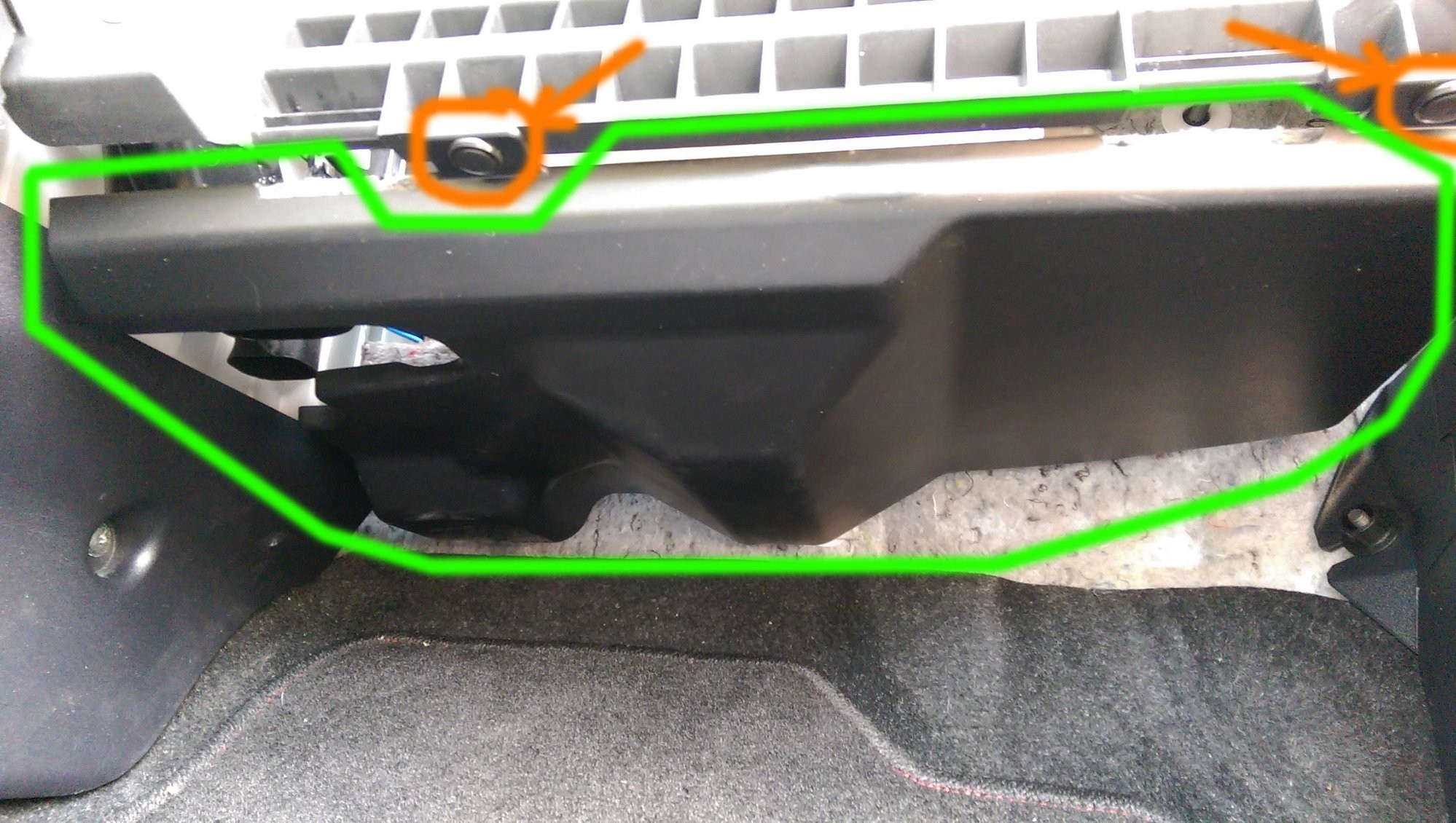

- Visual Inspection of the Strut Mount:

- Locate the strut mount at the top of the strut assembly in the wheel well.

- Check for cracks, tears, or deterioration in the rubber part of the mount.

- Look for signs of corrosion or rust.

- Inspect the mount for any deformation or bending.

Alt text: Close-up inspection of cracked and worn strut mount rubber indicating deterioration

- Check for Movement:

- Use the pry bar to gently check for play or movement between the strut mount and the vehicle’s body.

- Excessive movement indicates a worn or damaged mount.

- Inspect the Strut Bearing:

- Have someone turn the steering wheel while you observe the strut mount.

- Listen for any squeaking, grinding, or binding noises.

- Feel for smooth rotation of the bearing. Any resistance or noise suggests a problem.

Alt text: Visual demonstration of strut bearing rotation during steering wheel movement check

- Check the Surrounding Area:

- Inspect the strut assembly for any signs of leakage from the shock absorber.

- Check the coil spring for any cracks or damage.

- Repeat on the Other Side:

- Perform the same inspection on the strut mount and bearing on the opposite side of the vehicle.

- Reassemble:

- Reinstall the wheels.

- Lower the vehicle.

- Torque the lug nuts to the manufacturer’s specification.

7. How to Differentiate Between Strut Mount and Bearing Issues?

Sometimes it can be tricky to pinpoint whether the problem lies with the strut mount or the bearing. Here’s a guide:

- Strut Mount Issues:

- Visual Damage: Cracks, tears, or deterioration in the rubber.

- Excessive Movement: Play between the mount and the vehicle body.

- Clunking Noises: Often heard when going over bumps.

- Strut Bearing Issues:

- Noises During Steering: Squeaking, grinding, or binding when turning the steering wheel.

- Stiff Steering: Difficulty turning the steering wheel.

- Uneven Rotation: Jerky or inconsistent rotation of the strut.

8. Can You Replace Strut Mounts and Bearings Yourself?

Replacing strut mounts and bearings is a complex and potentially dangerous job. It involves compressing the coil spring, which can cause serious injury if not done correctly. According to the National Highway Traffic Safety Administration (NHTSA), suspension work accounts for a significant number of DIY auto repair injuries each year.

When to Consider DIY:

- You have extensive experience with suspension systems.

- You possess the necessary tools, including a spring compressor.

- You are comfortable working with potentially dangerous components.

When to Seek Professional Help:

- You lack experience with suspension work.

- You don’t have the right tools.

- You are uncomfortable with the risks involved.

9. What is the General Cost of Replacing Strut Mounts and Bearings?

The cost of replacing strut mounts and bearings can vary depending on several factors:

- Vehicle Make and Model: Parts and labor costs differ between vehicles.

- Labor Rates: Mechanic labor rates vary by location.

- Parts Quality: Aftermarket vs. OEM (Original Equipment Manufacturer) parts.

- Additional Repairs: If other suspension components need replacement at the same time.

Here’s a general cost breakdown:

| Item | Cost (USD) |

|---|---|

| Strut Mount Part | $50 – $200 |

| Strut Bearing Part | $30 – $100 |

| Labor (per side) | $150 – $300 |

| Total (per side) | $230 – $600 |

Note: These are estimated costs and may vary.

10. What are the Benefits of Replacing Strut Mounts and Bearings?

Replacing worn strut mounts and bearings offers numerous benefits:

- Improved Steering Response: Restores smooth and precise steering.

- Enhanced Ride Comfort: Reduces noise, vibration, and harshness.

- Extended Tire Life: Prevents uneven tire wear.

- Increased Safety: Ensures optimal handling and control.

- Preservation of Other Suspension Components: Prevents further damage to struts, shocks, and other parts.

11. How Often Should You Inspect and Replace Strut Mounts and Bearings?

There’s no one-size-fits-all answer, but here are some general guidelines:

- Inspection:

- Every 20,000 to 30,000 miles or during routine maintenance checks.

- Whenever you notice symptoms of a problem.

- Replacement:

- Every 60,000 to 80,000 miles, or when significant wear or damage is evident.

- When replacing struts or shocks, it’s often recommended to replace the mounts and bearings as well.

12. What are Some Tips for Extending the Life of Strut Mounts and Bearings?

Proper maintenance and driving habits can prolong the lifespan of these components:

- Avoid Potholes and Rough Roads: Reduce the impact on the suspension system.

- Maintain Proper Tire Inflation: Ensures even distribution of weight.

- Regular Wheel Alignments: Prevents uneven tire wear and strain on suspension parts.

- Minimize Heavy Loads: Avoid overloading the vehicle, which can stress the suspension.

- Address Issues Promptly: Fix any suspension problems as soon as they arise to prevent further damage.

13. What are the Different Types of Strut Mounts and Bearings?

Strut mounts and bearings come in various designs, each suited for different vehicle types and suspension systems. Here are some common types:

- Rubber Mounts:

- Most common type, offering good vibration damping.

- Made of rubber or polyurethane.

- Hydraulic Mounts:

- Provide superior damping by using hydraulic fluid.

- More expensive but offer better performance.

- Ball Bearing Mounts:

- Use ball bearings for smooth rotation.

- Common in high-performance vehicles.

- Roller Bearing Mounts:

- Employ roller bearings for increased load capacity.

- Suitable for heavier vehicles.

14. How Do Weather Conditions Affect Strut Mounts and Bearings?

Extreme weather conditions can accelerate the wear and tear of strut mounts and bearings:

- Heat: Can cause rubber components to dry out and crack.

- Cold: Can make rubber brittle and prone to breaking.

- Salt and Corrosion: Road salt used in winter can corrode metal parts.

- Moisture: Can lead to rust and degradation of bearings.

To mitigate these effects, consider:

- Regular Washing: To remove salt and debris.

- Undercoating: To protect against corrosion.

- Garage Parking: To shield the vehicle from extreme temperatures.

15. What is the Role of Strut Mounts and Bearings in Vehicle Handling?

Strut mounts and bearings play a critical role in vehicle handling and stability. Here’s how:

- Steering Precision: By allowing smooth rotation, they ensure accurate and responsive steering.

- Cornering Stability: They help maintain proper wheel alignment during turns, enhancing stability.

- Ride Comfort: They absorb vibrations and impacts, providing a smoother ride.

- NVH Reduction: They minimize noise, vibration, and harshness transmitted into the cabin.

16. What are Some Advanced Diagnostic Techniques for Strut Mounts and Bearings?

For more complex issues, advanced diagnostic techniques can help pinpoint the problem:

- Vibration Analysis: Using specialized equipment to measure and analyze vibrations in the suspension system.

- Acoustic Testing: Employing microphones to detect and isolate unusual noises.

- Computerized Alignment: Using advanced alignment machines to assess and correct wheel alignment issues.

- Ride Simulation: Simulating various driving conditions to identify suspension problems.

17. What are the Legal and Safety Considerations for Strut Mount and Bearing Maintenance?

Maintaining your vehicle’s suspension system is not just about comfort; it’s also about safety and legal compliance. According to a study by the National Safety Council, faulty suspension components contribute to approximately 5% of all vehicle accidents.

- Safety Standards: Ensure that any replacement parts meet or exceed OEM specifications.

- Inspection Requirements: Some states require regular vehicle safety inspections, which include suspension components.

- Liability: Neglecting suspension maintenance can lead to legal liabilities in the event of an accident.

18. Case Studies: Real-World Examples of Strut Mount and Bearing Issues

- Case 1: The Clunking Commuter

- Vehicle: 2015 Honda Civic

- Symptoms: Clunking noise when driving over bumps.

- Diagnosis: Worn strut mounts.

- Solution: Replaced both front strut mounts.

- Outcome: Noise eliminated, improved ride comfort.

- Case 2: The Squeaky Steerer

- Vehicle: 2012 Toyota Camry

- Symptoms: Squeaking noise when turning the steering wheel.

- Diagnosis: Faulty strut bearings.

- Solution: Replaced both front strut bearings.

- Outcome: Noise eliminated, smoother steering.

- Case 3: The Uneven Wearer

- Vehicle: 2018 Ford Fusion

- Symptoms: Uneven tire wear, pulling to one side.

- Diagnosis: Damaged strut mount and poor alignment.

- Solution: Replaced strut mount, performed wheel alignment.

- Outcome: Tire wear normalized, improved handling.

19. Strut Mounts and Bearings: A Comparative Analysis of Brands

When it comes to replacement parts, choosing the right brand can impact performance and longevity. Here’s a comparison of some popular brands:

| Brand | Type | Price Range (USD) | Pros | Cons |

|---|---|---|---|---|

| Monroe | Rubber | $60 – $150 | Good balance of price and quality, widely available. | May not be as durable as premium brands. |

| KYB | Rubber/Hydraulic | $70 – $200 | Known for quality and durability, good for performance vehicles. | Higher price point. |

| Moog | Rubber/Ball | $50 – $180 | Offers a range of options, including performance-oriented mounts. | Some users report issues with long-term durability. |

| SKF | Roller Bearing | $80 – $250 | Premium brand known for high-quality bearings and mounts. | More expensive. |

| Mevotech | Rubber | $40 – $120 | Budget-friendly option, suitable for basic replacements. | May not last as long as higher-end brands. |

20. How to Document Strut Mount and Bearing Inspections?

Keeping a record of inspections and maintenance can help you track the condition of your suspension system and plan for future repairs. Here’s how to document your findings:

- Create a Log: Use a notebook or digital document to record each inspection.

- Include Key Information:

- Date of inspection.

- Vehicle make, model, and mileage.

- Description of any symptoms observed.

- Detailed notes on the condition of the strut mounts and bearings.

- Photos of any damage or wear.

- Recommendations for repair or replacement.

- Keep Records Organized: Store the log in a safe and accessible location.

21. What are the Environmental Considerations for Strut Mount and Bearing Disposal?

Disposing of old strut mounts and bearings properly is essential to protect the environment. Here are some guidelines:

- Recycle Metal Parts: Metal components can be recycled at a local recycling center.

- Dispose of Rubber Properly: Rubber parts should be disposed of at a designated waste facility.

- Avoid Landfilling: Do not dispose of these components in 일반 landfill, as they can leach harmful chemicals into the soil.

- Check Local Regulations: Follow local regulations for proper disposal of automotive parts.

22. How to Find a Reputable Mechanic for Strut Mount and Bearing Replacement?

If you decide to seek professional help, finding a trustworthy mechanic is crucial. Here’s how:

- Ask for Recommendations: Get referrals from friends, family, or online forums.

- Check Online Reviews: Look for mechanics with positive reviews and high ratings.

- Verify Certifications: Ensure the mechanic is certified by organizations like ASE (Automotive Service Excellence).

- Get Multiple Estimates: Compare quotes from several mechanics to ensure fair pricing.

- Ask About Warranty: Inquire about the warranty on parts and labor.

- Visit the Shop: Check the cleanliness and organization of the shop.

23. How to Prepare Your Vehicle for Strut Mount and Bearing Replacement?

Before taking your vehicle to the mechanic, there are a few steps you can take to prepare:

- Gather Information: Collect any relevant information about the symptoms you’ve observed.

- Document Issues: Take photos or videos of any visible damage or wear.

- Remove Personal Items: Clear out any personal belongings from the vehicle.

- Provide Clear Instructions: Communicate your concerns and expectations to the mechanic.

- Ask Questions: Don’t hesitate to ask questions about the repair process and costs.

24. Strut Mount and Bearing Replacement: A Look at the Future Trends

The automotive industry is constantly evolving, and so are suspension systems. Here are some future trends to watch for:

- Advanced Materials: Use of lighter and more durable materials like carbon fiber and composites.

- Smart Suspension Systems: Integration of sensors and electronics to adjust damping and ride height in real-time.

- Active Mounts: Mounts that actively dampen vibrations using electronic controls.

- Predictive Maintenance: Use of data analytics to predict when strut mounts and bearings will need replacement.

25. Strut Mount and Bearing Myths Debunked

There are many misconceptions about strut mounts and bearings. Let’s debunk some common myths:

- Myth: You only need to replace one strut mount or bearing at a time.

- Reality: It’s always recommended to replace both sides simultaneously to ensure even performance and handling.

- Myth: Strut mounts and bearings last forever.

- Reality: They are wear items and need to be inspected and replaced periodically.

- Myth: All strut mounts and bearings are the same.

- Reality: They come in various designs and materials, each suited for different vehicles and driving conditions.

- Myth: Replacing strut mounts and bearings is a simple DIY job.

- Reality: It requires specialized tools and expertise and can be dangerous if not done correctly.

26. Resources and Further Reading on Strut Mounts and Bearings

To deepen your understanding, here are some resources and further reading materials:

- Automotive Repair Manuals: Haynes, Chilton, and other repair manuals provide detailed information on suspension systems.

- Online Forums: Websites like Bob Is The Oil Guy and AutoGeekOnline offer discussions and advice from experienced mechanics and enthusiasts.

- Educational Websites: Websites like Engineering Explained and Donut Media offer educational videos on automotive technology.

- Industry Associations: Organizations like ASE and AAA provide resources and certifications for automotive professionals.

27. FAQ: Addressing Common Questions About Strut Mounts and Bearings

- Q1: How do I know if my strut mounts are bad?

- Listen for clunking noises over bumps, check for cracks in the rubber, and inspect for excessive movement.

- Q2: Can I drive with a bad strut mount?

- It’s not recommended, as it can compromise steering and safety.

- Q3: How long do strut mounts typically last?

- Around 60,000 to 80,000 miles, depending on driving conditions.

- Q4: What happens if I don’t replace my strut mounts?

- It can lead to poor handling, uneven tire wear, and damage to other suspension components.

- Q5: Are aftermarket strut mounts as good as OEM?

- Some aftermarket brands offer comparable quality, but it’s essential to choose reputable brands.

- Q6: Can I replace strut mounts without a spring compressor?

- No, a spring compressor is essential for safety.

- Q7: How much does it cost to replace strut mounts?

- Between $230 and $600 per side, including parts and labor.

- Q8: Should I replace strut mounts when replacing struts?

- Yes, it’s highly recommended to replace them at the same time.

- Q9: What are the signs of a bad strut bearing?

- Squeaking or grinding noises when turning the steering wheel.

- Q10: Can bad strut mounts affect wheel alignment?

- Yes, they can cause misalignment and uneven tire wear.

28. How CARDIAGTECH.NET Can Help You with Your Strut Mount and Bearing Needs?

At CARDIAGTECH.NET, we understand the importance of a properly functioning suspension system. Worn or damaged strut mounts and bearings can significantly impact your vehicle’s handling, safety, and overall driving experience. That’s why we offer a range of high-quality tools and equipment designed to help you diagnose and address these issues effectively.

Our selection includes:

- Spring Compressors: Heavy-duty spring compressors for safe and efficient strut disassembly and assembly.

- Diagnostic Tools: Advanced diagnostic tools to accurately identify suspension problems.

- Socket Sets: Comprehensive socket sets with the right sizes for strut mount and bearing replacement.

- Torque Wrenches: Precision torque wrenches to ensure proper tightening of fasteners.

We also provide expert advice and support to help you choose the right tools for your needs. Whether you’re a professional mechanic or a DIY enthusiast, CARDIAGTECH.NET is your trusted partner for suspension maintenance.

29. Call to Action: Contact CARDIAGTECH.NET Today!

Don’t wait until your suspension problems become a safety hazard. Contact CARDIAGTECH.NET today for expert advice and high-quality tools to address your strut mount and bearing needs.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Our team is ready to assist you with any questions and provide tailored recommendations to ensure your vehicle maintains optimal handling and safety. Invest in the right tools and expertise to keep your suspension system in top condition. Contact us now and experience the CARDIAGTECH.NET difference. Prioritize your safety and enhance your driving experience with CARDIAGTECH.NET’s premium tools and expert support. Take action today and let us help you maintain a smooth and safe ride. Trust CARDIAGTECH.NET for all your automotive diagnostic and repair needs.