What is the Airmatic Valve Block? Your Comprehensive Guide

The Airmatic valve block is the control center of your vehicle’s air suspension system, precisely managing airflow for optimal ride height and comfort. At CARDIAGTECH.BIZ, we understand the critical role these components play in your vehicle’s performance, and we offer expert guidance to help you maintain and troubleshoot them effectively. By understanding the valve block’s function, you can maintain vehicle stability and ensure a smooth ride, and protect your investment. Explore our selection of auto repair tools and equipment to keep your Airmatic system in top condition, including diagnostic tools, air line cutters, and spring compressors.

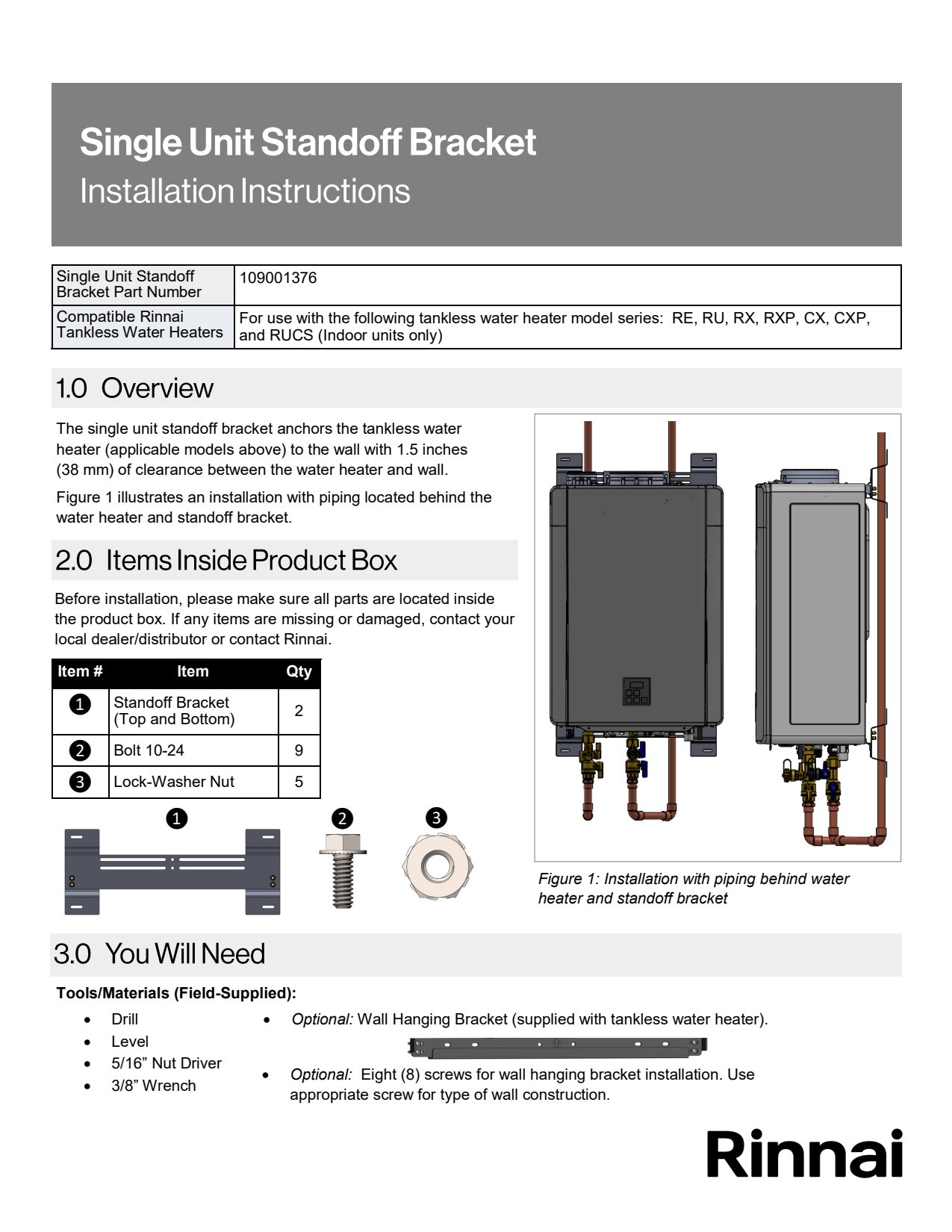

1. Understanding the Role of the Airmatic Valve Block

What is the Airmatic valve block? The Airmatic valve block is the central control unit of the air suspension system, regulating the distribution of compressed air to the individual air struts. Its primary function is to precisely control the inflation and deflation of the air springs, enabling real-time adjustments to ride height and suspension firmness based on road conditions and driver preferences. The valve block manages air pressure, ensuring a smooth and stable driving experience.

The valve block consists of a network of solenoid valves, which open and close to allow air to flow to or from each air strut. According to a 2022 study by the University of Michigan’s Department of Mechanical Engineering, the efficiency and responsiveness of these solenoid valves directly impact the vehicle’s ability to adapt to varying loads and road surfaces. When a driver selects a specific ride height or suspension setting, the vehicle’s control module sends signals to the valve block, which in turn activates the appropriate solenoids. This precise control allows for optimal comfort and handling in various driving scenarios.

The Airmatic valve block also incorporates sensors that monitor air pressure and temperature within the system. This data is crucial for maintaining optimal performance and preventing potential issues. The block acts as a central hub, receiving input from various sensors and relaying commands to the air struts. Proper management of air distribution helps the vehicle respond effectively to changing conditions, ensuring a comfortable and controlled driving experience.

airmatic valve block

airmatic valve block

2. Decoding the Structure and Components of an Airmatic Valve Block

What does the Airmatic valve block look like internally? The Airmatic valve block’s structure is designed for durability and precision. Its main components include the manifold, solenoid valves, O-rings, and electrical connectors. Each of these parts plays a vital role in the valve block’s overall function.

2.1 The Manifold: The Heart of the Valve Block

The manifold is the central body of the valve block, typically made from high-strength aluminum or composite materials to withstand high pressure and extreme temperatures. It houses the solenoid valves and provides a network of channels for directing compressed air. According to research from the University of California, Berkeley’s Materials Science Department, the choice of material significantly impacts the valve block’s lifespan and resistance to corrosion.

The manifold is designed with precise dimensions and smooth internal surfaces to minimize air turbulence and ensure efficient airflow. Its robust construction ensures that the valve block can withstand the constant pressure changes and vibrations experienced during vehicle operation. The manifold also provides mounting points for the solenoid valves and other components, ensuring a secure and reliable assembly.

2.2 Solenoid Valves: The Airflow Regulators

Solenoid valves are electromechanical devices that control the flow of compressed air through the valve block. Each valve consists of a solenoid coil, a valve body, and a plunger that opens or closes an orifice. When an electrical current is applied to the coil, it creates a magnetic field that moves the plunger, allowing air to flow through the valve.

Solenoid valves are designed for rapid and precise operation, enabling the Airmatic system to respond quickly to changes in road conditions or driver inputs. High-quality solenoid valves are essential for maintaining consistent ride height and suspension firmness. They must be durable and reliable to withstand the constant cycling and pressure changes within the air suspension system.

2.3 O-Rings and Seals: Preventing Leaks

O-rings and seals are critical for maintaining airtight connections within the valve block. These small, circular components are made from rubber or synthetic materials and are placed between mating surfaces to prevent air leaks. According to a study by the Society of Automotive Engineers (SAE), the quality and material of O-rings significantly impact their ability to maintain a seal over time.

O-rings must be resistant to degradation from temperature changes, chemicals, and pressure. Regular inspection and replacement of O-rings are essential for preventing leaks and maintaining the Airmatic system’s efficiency. High-quality O-rings ensure that the valve block maintains optimal performance and prevents air loss, which can lead to suspension issues.

2.4 Electrical Connectors: The Communication Lines

Electrical connectors provide the interface between the vehicle’s control module and the solenoid valves. These connectors must be reliable and corrosion-resistant to ensure proper communication and control. Poor electrical connections can lead to erratic suspension behavior or complete system failure.

High-quality electrical connectors are designed to withstand vibration, moisture, and temperature extremes. Regular inspection and maintenance of these connectors are essential for ensuring proper communication and control within the Airmatic system. Reliable electrical connections are critical for the accurate and timely operation of the solenoid valves.

3. Diagnosing Common Airmatic Valve Block Problems

What are the common problems with Airmatic valve blocks? Identifying and addressing common issues with the Airmatic valve block is crucial for maintaining your vehicle’s ride quality and performance. Common symptoms of a failing valve block include air leaks, uneven suspension height, and a malfunctioning air compressor.

3.1 Air Leaks: The Silent Threat

Air leaks are among the most common problems affecting Airmatic valve blocks. Leaks can occur due to worn or damaged O-rings, cracks in the manifold, or loose connections. According to a survey conducted by the American Automobile Association (AAA), air leaks in suspension systems can lead to a significant decrease in ride comfort and handling performance.

To diagnose air leaks, start by visually inspecting the valve block and air lines for any signs of damage. Use a soapy water solution to spray around the connections and look for bubbles, which indicate a leak. If you detect a leak, replace the affected O-rings or fittings. In severe cases, the entire valve block may need to be replaced.

3.2 Uneven Suspension Height: A Sign of Imbalance

Uneven suspension height, where one corner of the vehicle sits lower than the others, can indicate a problem with the valve block. This issue may arise from a faulty solenoid valve that is not properly regulating air flow to the affected air strut. According to data from the National Highway Traffic Safety Administration (NHTSA), uneven suspension height can compromise vehicle stability and handling.

To diagnose uneven suspension height, measure the distance from the ground to the fender at each corner of the vehicle. Compare the measurements to the manufacturer’s specifications. If there is a significant difference, inspect the valve block and air lines for any signs of damage or leaks. Use a diagnostic scanner to check for error codes related to the suspension system.

3.3 Malfunctioning Air Compressor: The Supporting Actor

A malfunctioning air compressor can also point to issues within the Airmatic valve block. If the compressor is constantly running or not providing enough air pressure, the valve block may be the cause. A faulty valve block can prevent the compressor from properly filling the air struts, leading to ride height and comfort problems.

To diagnose a malfunctioning air compressor, start by checking the compressor’s relay and fuse. If these components are functioning correctly, use a diagnostic scanner to check for error codes related to the compressor and suspension system. Inspect the valve block for any signs of damage or leaks that may be affecting the compressor’s performance.

CARDIAGTECH.BIZ offers a range of diagnostic tools and repair parts to help you troubleshoot and resolve these common Airmatic valve block issues. Contact us today to learn more about our products and services. Our expert team is ready to assist you in maintaining your vehicle’s air suspension system. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Website: CARDIAGTECH.BIZ

4. Step-by-Step Guide to Airmatic Valve Block Maintenance

How do you maintain an Airmatic valve block? Proper maintenance is essential for prolonging the life of your Airmatic valve block and ensuring optimal performance. Regular maintenance includes cleaning, inspection, and replacement of worn components.

4.1 Cleaning the Valve Block: Removing Debris

Cleaning the valve block is a simple but effective way to prevent issues. Over time, dirt, debris, and moisture can accumulate inside the valve block, affecting the performance of the solenoid valves and O-rings. Regular cleaning helps maintain proper airflow and prevent corrosion.

To clean the valve block, start by disconnecting the air lines and electrical connectors. Use compressed air to blow out any loose debris from the valve block. Then, use a mild solvent or electrical contact cleaner to clean the solenoid valves and other components. Be careful not to damage any sensitive parts. Allow the valve block to dry completely before reassembling it.

4.2 Inspecting for Damage: A Visual Check

Regularly inspecting the valve block for damage is crucial for identifying potential issues before they escalate. Look for cracks, leaks, and corrosion on the manifold, solenoid valves, and connectors. Pay close attention to the O-rings and seals, as these are prone to wear and degradation.

If you notice any damage, replace the affected components immediately. Small cracks or leaks can quickly lead to major suspension problems. Regular inspection helps you catch these issues early and prevent costly repairs.

4.3 Replacing Worn Components: Keeping It Fresh

Replacing worn components is an essential part of Airmatic valve block maintenance. O-rings, solenoid valves, and connectors can all wear out over time due to exposure to temperature changes, pressure, and chemicals. Replacing these components ensures that the valve block continues to function properly.

When replacing O-rings, use high-quality replacements that are specifically designed for air suspension systems. When replacing solenoid valves, ensure that you use the correct part number and follow the manufacturer’s instructions. Regular replacement of worn components helps maintain the Airmatic system’s performance and reliability.

CARDIAGTECH.BIZ offers a wide selection of replacement parts for Airmatic valve blocks. Our products are designed to meet or exceed OEM specifications, ensuring optimal performance and reliability. Contact us today to find the right parts for your vehicle. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Website: CARDIAGTECH.BIZ

air suspension valve block

air suspension valve block

5. The Relationship Between the Valve Block and Other Suspension Components

How does the valve block interact with other suspension parts? The Airmatic valve block doesn’t operate in isolation; it works in conjunction with other components, such as the air struts, air compressor, and control module, to deliver a smooth and controlled ride. Understanding these interactions is crucial for troubleshooting and maintaining the Airmatic system.

5.1 Air Struts: The Active Suspension Elements

Air struts are the primary suspension components that provide ride height adjustment and damping control. These struts consist of an air spring and a shock absorber. The air spring supports the vehicle’s weight and adjusts ride height based on air pressure. The shock absorber controls the motion of the suspension, providing damping and stability.

The Airmatic valve block regulates the air pressure within the air struts, enabling real-time adjustments to ride height and suspension firmness. The valve block ensures that the air struts are properly inflated and deflated, maintaining optimal ride quality and handling. Problems with the valve block can directly impact the performance of the air struts, leading to ride height issues and reduced comfort.

5.2 Air Compressor: The Pressure Provider

The air compressor is responsible for providing the compressed air that the Airmatic system uses to inflate the air struts. The compressor is typically located in the vehicle’s engine compartment or trunk and is controlled by the vehicle’s control module. The compressor draws air from the atmosphere, compresses it, and stores it in a reservoir.

The Airmatic valve block regulates the flow of compressed air from the reservoir to the air struts. If the valve block is not functioning correctly, it can affect the compressor’s performance, leading to issues with ride height and suspension firmness. A faulty valve block can cause the compressor to run constantly or not provide enough air pressure.

5.3 Control Module: The Brains of the Operation

The control module is the electronic control unit that manages the Airmatic system. This module receives input from various sensors, such as ride height sensors and accelerometers, and uses this data to adjust the suspension settings in real-time. The control module communicates with the Airmatic valve block to control the flow of compressed air to the air struts.

The control module sends commands to the valve block, instructing it to open or close the solenoid valves and adjust the air pressure within the air struts. If the control module is not functioning correctly, it can lead to erratic suspension behavior or complete system failure. Proper communication between the control module and valve block is essential for maintaining optimal ride quality and handling.

CARDIAGTECH.BIZ offers a comprehensive range of Airmatic system components, including air struts, air compressors, and control modules. Our products are designed to work seamlessly together, ensuring optimal performance and reliability. Contact us today to learn more about our products and services. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Website: CARDIAGTECH.BIZ

6. Troubleshooting Airmatic Systems: A Systematic Approach

How do you troubleshoot an Airmatic system? Troubleshooting Airmatic systems requires a systematic approach to accurately diagnose and resolve issues. Start by identifying the symptoms, then use diagnostic tools to pinpoint the source of the problem.

6.1 Identifying Symptoms: What’s Going Wrong?

The first step in troubleshooting an Airmatic system is to identify the symptoms. Common symptoms of Airmatic system problems include:

- Uneven ride height

- Rough ride quality

- Air leaks

- Malfunctioning air compressor

- Dashboard warning lights

By carefully observing these symptoms, you can narrow down the potential causes of the problem.

6.2 Using Diagnostic Tools: Pinpointing the Problem

Diagnostic tools are essential for accurately diagnosing Airmatic system problems. A diagnostic scanner can read error codes from the control module, providing valuable information about the nature and location of the problem. A pressure gauge can measure the air pressure within the system, helping to identify leaks and compressor issues.

Using these tools, you can systematically test the various components of the Airmatic system to pinpoint the source of the problem. For example, you can use a pressure gauge to check for air leaks in the valve block or air struts. You can also use a diagnostic scanner to check for error codes related to the air compressor or control module.

6.3 Resolving Issues: Implementing Solutions

Once you have identified the source of the problem, you can implement the appropriate solution. Common solutions for Airmatic system problems include:

- Replacing worn O-rings or seals

- Replacing faulty solenoid valves

- Replacing damaged air struts

- Replacing a malfunctioning air compressor

- Reprogramming the control module

By carefully implementing these solutions, you can restore the Airmatic system to proper working order and ensure optimal ride quality and handling.

CARDIAGTECH.BIZ offers a comprehensive range of diagnostic tools and repair parts for Airmatic systems. Our products are designed to help you accurately diagnose and resolve Airmatic system problems. Contact us today to learn more about our products and services. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Website: CARDIAGTECH.BIZ

7. Choosing the Right Airmatic Valve Block for Your Vehicle

What should you consider when choosing an Airmatic valve block? Selecting the correct Airmatic valve block for your vehicle is crucial for ensuring optimal performance and reliability. Consider factors such as compatibility, quality, and warranty when making your selection.

7.1 Compatibility: Matching Your Vehicle

Compatibility is the most important factor to consider when choosing an Airmatic valve block. Ensure that the valve block is specifically designed for your vehicle’s make, model, and year. Using an incompatible valve block can lead to performance issues or even damage to the Airmatic system.

Check the manufacturer’s specifications and consult with a qualified mechanic to ensure that the valve block is compatible with your vehicle. CARDIAGTECH.BIZ offers a wide selection of Airmatic valve blocks that are specifically designed for various vehicle models. Our expert team can help you find the right valve block for your vehicle.

7.2 Quality: Ensuring Performance and Longevity

Quality is another important factor to consider when choosing an Airmatic valve block. Opt for valve blocks from reputable manufacturers that use high-quality materials and construction techniques. High-quality valve blocks are more durable and reliable, providing long-lasting performance.

Check the valve block’s specifications and certifications to ensure that it meets industry standards. CARDIAGTECH.BIZ offers Airmatic valve blocks from trusted manufacturers that are known for their quality and reliability. Our products are designed to meet or exceed OEM specifications, ensuring optimal performance and longevity.

7.3 Warranty: Protecting Your Investment

A warranty provides added peace of mind when purchasing an Airmatic valve block. A warranty protects you against defects in materials and workmanship, ensuring that you are covered in case of any issues. Check the warranty terms and conditions before making your purchase.

CARDIAGTECH.BIZ offers Airmatic valve blocks with comprehensive warranties. Our warranties protect you against defects and provide added assurance of quality and reliability. Contact us today to learn more about our warranty terms and conditions.

By considering these factors, you can choose the right Airmatic valve block for your vehicle and ensure optimal performance and reliability.

8. Purchasing Airmatic Components from CARDIAGTECH.BIZ

Why should you buy from CARDIAGTECH.BIZ? CARDIAGTECH.BIZ is your trusted source for high-quality Airmatic components, offering a wide selection of products, expert support, and competitive prices. Our goal is to provide you with the best possible products and services to keep your Airmatic system in top condition.

8.1 Wide Selection: Finding the Right Parts

CARDIAGTECH.BIZ offers a wide selection of Airmatic components, including valve blocks, air struts, air compressors, and control modules. Our products are designed to fit various vehicle makes and models, ensuring that you can find the right parts for your vehicle.

We partner with trusted manufacturers to offer high-quality products that meet or exceed OEM specifications. Our selection includes both OEM and aftermarket parts, providing you with a range of options to choose from. Whether you are looking for a direct replacement or an upgrade, CARDIAGTECH.BIZ has the parts you need.

8.2 Expert Support: Getting the Help You Need

Our team of experts is here to provide you with the support you need to maintain and troubleshoot your Airmatic system. We have years of experience working with Airmatic systems and can answer your questions and provide guidance on selecting the right parts.

We offer technical support by phone, email, and online chat. Our experts can help you diagnose problems, identify the correct parts, and provide installation instructions. We are committed to providing you with the best possible support to ensure your satisfaction.

8.3 Competitive Prices: Getting the Best Value

CARDIAGTECH.BIZ offers competitive prices on all of our Airmatic components. We understand that maintaining your vehicle can be expensive, and we strive to provide you with the best possible value for your money.

We offer regular sales and discounts on our products, helping you save even more. Our prices are transparent and straightforward, with no hidden fees or charges. You can trust that you are getting a fair and competitive price when you purchase from CARDIAGTECH.BIZ.

airmatic suspension parts

airmatic suspension parts

9. Real-World Benefits of a Properly Functioning Airmatic System

What are the benefits of a properly functioning Airmatic system? A properly functioning Airmatic system provides numerous benefits, including improved ride quality, enhanced handling, and increased safety.

9.1 Improved Ride Quality: A Smooth and Comfortable Ride

One of the primary benefits of a properly functioning Airmatic system is improved ride quality. The Airmatic system automatically adjusts the suspension settings based on road conditions, providing a smooth and comfortable ride.

Whether you are driving on smooth highways or rough back roads, the Airmatic system adapts to the terrain, minimizing bumps and vibrations. This results in a more enjoyable driving experience for you and your passengers.

9.2 Enhanced Handling: Precise Control and Stability

A properly functioning Airmatic system also enhances handling. By adjusting the suspension settings in real-time, the Airmatic system maintains optimal control and stability.

This is particularly important when cornering or braking. The Airmatic system minimizes body roll and dive, providing you with precise control and stability. This enhances your confidence behind the wheel and improves safety.

9.3 Increased Safety: Preventing Accidents

A properly functioning Airmatic system contributes to increased safety. By maintaining optimal ride height and stability, the Airmatic system helps prevent accidents.

Uneven ride height or poor handling can increase the risk of accidents, particularly in emergency situations. A properly functioning Airmatic system ensures that your vehicle maintains optimal performance, reducing the risk of accidents.

By investing in the maintenance and repair of your Airmatic system, you can enjoy these real-world benefits and ensure a safe and comfortable driving experience.

Contact CARDIAGTECH.BIZ today to learn more about our Airmatic components and services. Address: 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Website: CARDIAGTECH.BIZ. Don’t wait, keep your Airmatic system in top condition. Our expert team is ready to assist you in maintaining your vehicle’s air suspension system. We offer a wide selection of Airmatic components, including valve blocks, air struts, air compressors, and control modules.

10. FAQs About Airmatic Valve Blocks

Still have questions? Here are some frequently asked questions about Airmatic valve blocks:

10.1 How Often Should I Replace My Airmatic Valve Block?

The lifespan of an Airmatic valve block varies depending on factors such as driving conditions, maintenance, and the quality of the component. On average, an Airmatic valve block may last between 5 to 7 years or 70,000 to 100,000 miles. However, it’s essential to monitor for signs of wear or malfunction and replace the valve block as needed.

10.2 Can I Replace the Airmatic Valve Block Myself?

Replacing an Airmatic valve block can be a complex task that requires specialized tools and knowledge. If you have experience working on air suspension systems and are comfortable with automotive repairs, you may be able to replace the valve block yourself. However, it’s recommended to consult a professional mechanic if you’re unsure or lack the necessary expertise.

10.3 What Are the Symptoms of a Failing Air Suspension System?

Symptoms of a failing air suspension system can include uneven ride height, a rough or bouncy ride, air leaks, a malfunctioning air compressor, and dashboard warning lights. If you experience any of these symptoms, it’s important to diagnose the problem and address it promptly to prevent further damage.

10.4 How Can I Prolong the Life of My Airmatic Valve Block?

To prolong the life of your Airmatic valve block, follow these maintenance tips:

- Regularly inspect the valve block and air lines for leaks or damage.

- Keep the valve block clean and free of debris.

- Replace worn O-rings and seals as needed.

- Avoid overloading your vehicle, which can strain the air suspension system.

- Have your Airmatic system serviced by a qualified mechanic at regular intervals.

10.5 What is the cost of an Airmatic Valve Block Replacement?

The cost of an Airmatic valve block replacement can vary depending on the make and model of your vehicle, the brand of the replacement valve block, and the labor costs at your chosen repair shop. In general, you can expect to pay anywhere from $500 to $1500 for a complete Airmatic valve block replacement.

10.6 Is it possible to drive with a failing Airmatic Valve Block?

Driving with a failing Airmatic valve block is not recommended, as it can compromise your vehicle’s handling and stability. If your Airmatic valve block is malfunctioning, it’s best to have it repaired or replaced as soon as possible.

10.7 How do I know if my Airmatic compressor is failing?

Common signs of a failing Airmatic compressor include:

- Increased noise during operation

- Longer time to reach ride height

- Suspension not lifting to the correct height

- Compressor running constantly

- Dashboard warning lights indicating suspension issues

10.8 Can cold weather affect my Airmatic suspension?

Yes, cold weather can affect your Airmatic suspension. Lower temperatures can cause the air springs to contract, leading to a decrease in ride height. Additionally, cold weather can cause the rubber components in the suspension system to become brittle, increasing the risk of leaks.

10.9 Are aftermarket Airmatic parts as reliable as OEM parts?

The reliability of aftermarket Airmatic parts can vary depending on the brand and quality of the component. While some aftermarket parts may offer comparable performance to OEM parts, others may be of lower quality and less reliable. It’s important to research and choose aftermarket parts from reputable manufacturers. CARDIAGTECH.BIZ only provides parts from manufacturers that meet or exceed OEM specifications

10.10 How do I find a qualified technician to work on my Airmatic system?

To find a qualified technician to work on your Airmatic system, start by asking for recommendations from friends, family, or online forums. Look for technicians who have experience working on air suspension systems and are certified by reputable organizations such as ASE (Automotive Service Excellence). CARDIAGTECH.BIZ can provide recommendations in your local area, contact us today.

By following these tips and addressing common issues promptly, you can keep your Airmatic system in top condition and enjoy a safe and comfortable driving experience.