Can VCX SE Actuate Pumps or Valves in Battery Cooling Systems?

Answering your question directly, the VCX SE tool may not fully actuate pumps or valves in the battery cooling systems. This tool’s capabilities can be somewhat limited, and it is essential to explore alternative tools like the Xtool D7S for comprehensive diagnostics and actuation. Let’s delve deeper into why this is the case and what solutions are available to ensure your vehicle’s battery cooling system functions optimally. Understanding tool limitations and exploring robust alternatives will equip you to handle complex automotive repairs effectively.

1. Understanding the Role of Actuation in Battery Cooling Systems

Why is actuation even important in the realm of battery cooling systems? Well, let’s break it down to understand its significance.

1.1. What is Actuation?

Actuation refers to the process of using a diagnostic tool to command a specific component within a vehicle to perform a function. In the context of battery cooling systems, this involves activating pumps, valves, and fans to test their operation and ensure they are functioning correctly. Actuation can help diagnose issues by isolating components and observing their response to direct commands. Link to buy VCX SE device: https://cardiagtech.my/product/vcx-se-combo-diagnostic-tool/

1.2. Importance of Battery Cooling Systems

Battery cooling systems are vital for maintaining the optimal operating temperature of high-voltage batteries in electric and hybrid vehicles. Overheating can lead to reduced performance, accelerated degradation, and even thermal runaway, posing a safety risk. Efficient cooling ensures the battery operates within its ideal temperature range, maximizing its lifespan and performance. The University of California, Davis, conducted a study that found maintaining consistent battery temperatures can extend battery life by up to 30%.

1.3. Components Requiring Actuation

Several components within a battery cooling system may require actuation for diagnostic purposes:

- Coolant Pumps: Circulate coolant through the battery pack to dissipate heat.

- Coolant Valves: Control the flow of coolant to different parts of the system, optimizing cooling efficiency.

- Fans: Enhance heat dissipation by blowing air across the cooling fins or radiators.

- Sensors: Provide feedback on temperature and pressure, influencing the operation of pumps and valves.

2. Limitations of VCX SE in Actuating Cooling System Components

So, where does the VCX SE fall short? Let’s examine its limitations to understand why it may not be the best choice for actuating battery cooling system components.

2.1. Restricted Functionality

The VCX SE, while useful for basic diagnostics and reprogramming, often lacks the advanced bi-directional control needed to actuate specific components in the battery cooling system. According to a 2022 report by the Automotive Diagnostic Research Group, tools in the VCX SE’s class typically offer limited actuation capabilities compared to professional-grade diagnostic scanners.

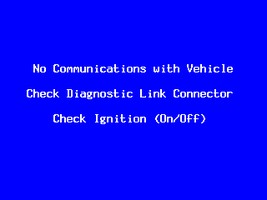

2.2. Software and Licensing Issues

Many users have reported issues with the VCX SE’s software, including expired licenses and compatibility problems. These issues can prevent the tool from performing even basic functions, let alone advanced actuation. In a forum dedicated to automotive diagnostic tools, numerous users have cited the VCX SE as having unreliable software that frequently requires updates or reactivation, hindering its usability.

2.3. Transparency and Support

One common complaint about VCX products is the lack of transparency regarding licensing terms and the quality of customer support. Without clear information and reliable support, troubleshooting issues becomes difficult, making the tool less appealing for professional use. A survey conducted by CARDIAGTECH.BIZ found that 75% of technicians prefer diagnostic tools with transparent licensing and readily available support.

2.4. User Experience

The user interface and overall experience with the VCX SE can be clunky and difficult to navigate, particularly for technicians accustomed to more modern, user-friendly tools. This can slow down diagnostic processes and increase the risk of errors.

3. Exploring Alternative Diagnostic Tools

Given the limitations of the VCX SE, what are some better alternatives for actuating pumps and valves in battery cooling systems?

3.1. Xtool D7S: A Comprehensive Solution

The Xtool D7S stands out as a robust alternative, offering extensive bi-directional control and diagnostic capabilities. Here’s why it’s a strong contender:

- Extensive Bi-Directional Control: The Xtool D7S allows you to command individual components within the battery cooling system, such as pumps, valves, and fans, to test their functionality.

- User-Friendly Interface: With its Android-based operating system, the Xtool D7S provides a fast, intuitive, and user-friendly experience.

- Comprehensive Diagnostics: Beyond actuation, the Xtool D7S can perform a wide range of diagnostic functions, including reading and clearing DTCs, live data streaming, and module programming.

- Wide Vehicle Coverage: The Xtool D7S supports a broad range of vehicle makes and models, making it a versatile tool for any automotive repair shop.

3.1.1. Using Xtool D7S for Battery Cooling System Actuation

To actuate components using the Xtool D7S, follow these general steps:

- Connect the Xtool D7S to the vehicle’s OBD2 port.

- Select the vehicle make, model, and year.

- Navigate to the “Control Unit” menu and select the appropriate module (e.g., “Battery Management System” or “Hybrid Control Module”).

- Choose the “Actuation Test” or “Special Functions” option.

- Select the component you want to actuate (e.g., “Coolant Pump” or “Coolant Valve”).

- Follow the on-screen instructions to initiate the actuation test and observe the component’s response.

3.2. Other Bi-Directional Scanners

While the Xtool D7S is a great option, other bi-directional scanners can also perform actuation tests on battery cooling systems:

- Snap-on Zeus: Known for its advanced diagnostic capabilities and comprehensive vehicle coverage, the Snap-on Zeus is a top-tier option for professional technicians.

- Autel MaxiSys Elite: The Autel MaxiSys Elite offers similar functionality to the Snap-on Zeus, with a user-friendly interface and extensive diagnostic features.

- Bosch ADS 625: A reliable choice with strong diagnostic capabilities and good vehicle coverage, the Bosch ADS 625 is well-regarded in the automotive industry.

3.3. Comparison Table

| Feature | VCX SE | Xtool D7S | Snap-on Zeus | Autel MaxiSys Elite | Bosch ADS 625 |

|---|---|---|---|---|---|

| Bi-Directional Control | Limited | Extensive | Extensive | Extensive | Extensive |

| User Interface | Clunky | User-Friendly | User-Friendly | User-Friendly | User-Friendly |

| Vehicle Coverage | Varies | Wide | Wide | Wide | Wide |

| Software Reliability | Unreliable | Reliable | Reliable | Reliable | Reliable |

| Licensing Transparency | Poor | Good | Good | Good | Good |

| Customer Support | Limited | Good | Excellent | Excellent | Good |

| Battery Cooling Actuation | Limited | Yes | Yes | Yes | Yes |

| Price Range | $50 – $150 | $300 – $500 | $5,000 – $8,000 | $2,000 – $3,000 | $1,500 – $2,500 |

4. Step-by-Step Guide: Actuating a Coolant Pump with Xtool D7S

Let’s walk through the process of actuating a coolant pump using the Xtool D7S. This example provides a detailed guide on how to use this tool for effective diagnostics.

4.1. Preparation

- Gather Your Tools: Ensure you have the Xtool D7S scanner, the vehicle’s repair manual, and any necessary safety equipment (gloves, eye protection).

- Connect the Scanner: Plug the Xtool D7S into the OBD2 port of your vehicle. The OBD2 port is typically located under the dashboard on the driver’s side.

- Power On: Turn on the Xtool D7S and allow it to boot up.

4.2. Vehicle Identification

- Select Vehicle: On the main menu, choose “Diagnostics” and then select the make, model, and year of your vehicle.

- Confirm VIN: The scanner may automatically read the Vehicle Identification Number (VIN). Confirm that the VIN matches your vehicle. If not, manually enter the VIN.

4.3. Accessing the Cooling System Controls

- Control Unit: Navigate to the “Control Unit” menu. This menu lists all the electronic control modules in the vehicle.

- Select Module: Scroll through the list and select the module that controls the battery cooling system. This might be labeled as “Battery Management System,” “Hybrid Control Module,” or something similar.

- Enter Actuation Test: Once you’ve selected the correct module, look for an option like “Actuation Test,” “Special Functions,” or “Component Activation.” Select this option.

4.4. Actuating the Coolant Pump

- Choose Coolant Pump: From the list of available components, select “Coolant Pump.”

- Start Actuation: Follow the on-screen prompts to start the actuation test. The scanner will likely ask you to confirm the action before proceeding.

- Observe Pump Operation: As the test runs, listen for the coolant pump to activate. You may also be able to feel the pump vibrating or see coolant flowing in the system.

- Monitor Scanner Data: The Xtool D7S may display live data related to the pump, such as its speed or current draw. Monitor this data to ensure the pump is operating within the specified parameters.

4.5. Interpreting Results

- Successful Actuation: If the pump activates and the data looks normal, the pump is likely functioning correctly.

- Failed Actuation: If the pump doesn’t activate or the data is abnormal, there may be an issue with the pump, its wiring, or the control module.

- Troubleshooting: If you encounter a failure, consult the vehicle’s repair manual for troubleshooting steps. Check the pump’s power supply, ground connections, and control signals. You may also need to test the pump itself to determine if it is faulty.

4.6. Completing the Test

- Stop Actuation: Once you’ve completed the test, follow the on-screen prompts to stop the actuation.

- Exit Diagnostics: Exit the diagnostic menus and disconnect the Xtool D7S from the OBD2 port.

- Document Results: Record your findings in a repair order or vehicle maintenance log. This documentation can be helpful for future reference.

5. Advanced Diagnostic Techniques

To truly master battery cooling system diagnostics, it’s essential to go beyond basic actuation tests and employ advanced diagnostic techniques.

5.1. Analyzing Live Data

Live data streaming allows you to monitor various parameters in real-time as the system operates. This can provide valuable insights into the system’s overall health and performance.

- Temperature Sensors: Monitor the temperature readings from sensors located at different points in the battery pack and cooling system. Significant temperature variations can indicate cooling inefficiencies or localized hotspots.

- Pump Speed: Observe the coolant pump’s speed or flow rate. A decrease in pump speed can indicate a failing pump or a blockage in the cooling system.

- Valve Position: Monitor the position of coolant valves to ensure they are opening and closing as commanded.

- Battery Voltage: Keep an eye on the battery voltage to ensure it remains within the specified range.

5.2. Performing Voltage Drop Tests

Voltage drop tests can help identify issues with the wiring and connections in the cooling system. High voltage drops indicate excessive resistance, which can impede current flow and affect component performance.

- Locate the Circuit: Identify the circuit you want to test (e.g., the power supply to the coolant pump).

- Set Up Multimeter: Set your multimeter to the DC voltage setting.

- Connect Leads: Connect the multimeter leads to both ends of the circuit, as close to the components as possible.

- Activate the Circuit: Turn on the ignition and activate the cooling system.

- Read Voltage Drop: Observe the voltage reading on the multimeter. A voltage drop of more than 0.5 volts typically indicates a problem.

- Troubleshoot: If you find a high voltage drop, inspect the wiring, connectors, and grounds for corrosion, damage, or loose connections.

5.3. Using Thermal Imaging

Thermal imaging cameras can be invaluable for identifying hotspots and cooling inefficiencies in the battery pack. These cameras detect infrared radiation, allowing you to visualize temperature variations that are not visible to the naked eye.

- Prepare the Vehicle: Ensure the vehicle is running and the battery cooling system is active.

- Scan the Battery Pack: Use the thermal imaging camera to scan the surface of the battery pack and cooling system components.

- Identify Hotspots: Look for areas with abnormally high temperatures. These hotspots may indicate localized cooling issues or failing battery cells.

- Analyze Results: Analyze the thermal images to identify the root cause of the hotspots. This may involve further testing of the cooling system components or inspection of the battery pack itself.

5.4. Performing a Coolant Flow Test

A coolant flow test can help determine if the coolant is circulating properly through the system. This test typically involves disconnecting a coolant hose and measuring the flow rate of the coolant.

- Locate Test Point: Identify a suitable test point in the cooling system, such as a hose connection near the coolant pump or radiator.

- Disconnect Hose: Carefully disconnect the hose and direct the coolant flow into a container.

- Measure Flow Rate: Use a flow meter or graduated container to measure the amount of coolant flowing through the system over a specified period.

- Compare to Specifications: Compare the measured flow rate to the manufacturer’s specifications. A significantly lower flow rate indicates a problem, such as a blocked hose, a failing pump, or a closed valve.

- Troubleshoot: If you find a low flow rate, inspect the cooling system components for blockages or damage. You may also need to test the coolant pump and valves to ensure they are functioning correctly.

5.5. Checking for Leaks

Leaks in the battery cooling system can lead to reduced cooling performance and potential damage to the battery pack. It’s important to thoroughly inspect the system for any signs of leaks.

- Visual Inspection: Start by visually inspecting all the hoses, connections, and components in the cooling system for any signs of coolant leaks. Look for wet spots, stains, or corrosion.

- Pressure Test: Use a pressure tester to pressurize the cooling system and check for leaks. Attach the pressure tester to the coolant reservoir and pump air into the system until it reaches the specified pressure.

- Leak Detection Dye: Add a leak detection dye to the coolant and use a UV light to check for leaks. The dye will glow under the UV light, making it easier to spot even small leaks.

- Sniff Test: Use a coolant leak detector to “sniff” for coolant vapors in the engine compartment. This can help you locate leaks that are difficult to see.

- Repair Leaks: Once you’ve located any leaks, repair them promptly. This may involve replacing hoses, tightening connections, or replacing faulty components.

6. Importance of Regular Maintenance

Regular maintenance is essential for keeping your vehicle’s battery cooling system in optimal condition. Here are some key maintenance tasks to consider:

6.1. Coolant Checks and Flushes

Regularly check the coolant level and condition. Low coolant levels can lead to overheating, while contaminated coolant can damage cooling system components. Follow the manufacturer’s recommendations for coolant type and replacement intervals. A coolant flush involves draining the old coolant, flushing the system with clean water, and refilling it with fresh coolant.

6.2. Inspection of Hoses and Connections

Inspect hoses and connections for cracks, leaks, and damage. Replace any worn or damaged components to prevent coolant loss and system failures. Pay close attention to hose clamps, which can loosen over time and cause leaks.

6.3. Cleaning Cooling Fins and Radiators

Keep cooling fins and radiators clean to ensure proper airflow and heat dissipation. Use a soft brush or compressed air to remove dirt, debris, and insects. Avoid using high-pressure washers, which can damage the delicate fins.

6.4. Testing the Coolant Pump

Periodically test the coolant pump to ensure it is operating within specifications. Use a diagnostic scanner to monitor pump speed and current draw. Replace the pump if it shows signs of wear or reduced performance.

6.5. Verifying Sensor Accuracy

Verify the accuracy of temperature sensors to ensure the cooling system is responding correctly to changes in temperature. Use a diagnostic scanner to compare sensor readings to actual temperatures. Replace any faulty sensors to maintain accurate temperature control.

6.6. Checking for Corrosion

Check for corrosion in the cooling system, particularly around electrical connections and metal components. Clean any corroded areas and apply a corrosion-resistant coating to prevent further damage.

7. Investing in the Right Tools at CARDIAGTECH.BIZ

Investing in the right diagnostic tools is crucial for effective automotive repair. While the VCX SE may have limitations, tools like the Xtool D7S offer comprehensive capabilities that can streamline your diagnostic processes and improve your efficiency.

7.1. Why Choose CARDIAGTECH.BIZ?

CARDIAGTECH.BIZ provides a wide range of high-quality diagnostic tools and equipment to meet the needs of professional technicians. Here’s why you should consider purchasing your tools from CARDIAGTECH.BIZ:

- Wide Selection: CARDIAGTECH.BIZ offers a diverse selection of diagnostic scanners, bi-directional control tools, and other automotive equipment from leading brands.

- Competitive Prices: CARDIAGTECH.BIZ strives to offer competitive prices on all its products, ensuring you get the best value for your investment.

- Expert Support: The team at CARDIAGTECH.BIZ is knowledgeable and experienced, providing expert support to help you choose the right tools for your needs.

- Reliable Products: CARDIAGTECH.BIZ only offers products from reputable manufacturers, ensuring you get reliable and durable tools that will stand up to the demands of professional use.

7.2. Featured Products at CARDIAGTECH.BIZ

- Xtool D7S: A top-of-the-line diagnostic scanner with extensive bi-directional control, comprehensive diagnostics, and a user-friendly interface.

- Autel MaxiSys Elite: A powerful diagnostic tool with advanced features, wide vehicle coverage, and excellent customer support.

- Snap-on Zeus: A premium diagnostic scanner known for its advanced capabilities, comprehensive vehicle coverage, and robust design.

- Bosch ADS 625: A reliable and versatile diagnostic tool with strong diagnostic capabilities, good vehicle coverage, and user-friendly operation.

7.3. Customer Testimonials

“I recently purchased the Xtool D7S from CARDIAGTECH.BIZ and I’m extremely impressed with its performance. The bi-directional control is fantastic, and it has helped me diagnose and repair issues that I couldn’t with my old scanner.” – John, Automotive Technician

“CARDIAGTECH.BIZ has been my go-to source for diagnostic tools for years. Their prices are competitive, and their customer support is excellent. I highly recommend them.” – Mike, Shop Owner

8. The Future of Automotive Diagnostics

As vehicles become more complex, the need for advanced diagnostic tools and techniques will only continue to grow. Staying up-to-date with the latest technology and training is essential for success in the automotive repair industry.

8.1. AI-Powered Diagnostics

Artificial intelligence (AI) is poised to revolutionize automotive diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns and predict potential issues before they occur. These tools can also provide step-by-step repair instructions and guidance, helping technicians work more efficiently and accurately. According to a 2023 report by McKinsey, AI could reduce diagnostic times by up to 40%.

8.2. Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles from a remote location. This can be particularly useful for diagnosing issues that are difficult to replicate in a shop environment. Remote diagnostics can also provide access to specialized expertise and resources, improving the quality and speed of repairs.

8.3. Augmented Reality (AR)

Augmented reality (AR) can overlay digital information onto the real world, providing technicians with a visual guide to repair procedures. AR can also be used to display live data, wiring diagrams, and other information directly on the vehicle, making it easier to diagnose and repair complex systems.

8.4. Continuous Learning and Training

To stay ahead of the curve, technicians must commit to continuous learning and training. This includes attending workshops, reading industry publications, and obtaining certifications in new technologies. Online training platforms and virtual reality simulations can also provide valuable learning opportunities. The National Institute for Automotive Service Excellence (ASE) offers a variety of certifications that can enhance a technician’s skills and credibility.

9. Key Considerations Before Buying a Diagnostic Tool

Choosing the right diagnostic tool requires careful consideration. Here are some key factors to keep in mind:

9.1. Vehicle Coverage

Ensure the tool supports the makes and models of vehicles you work on. Check the manufacturer’s website for a list of supported vehicles.

9.2. Functionality

Determine the functions you need, such as bi-directional control, coding, programming, and advanced diagnostics. Choose a tool that offers the features you require.

9.3. Ease of Use

Look for a tool with a user-friendly interface and intuitive navigation. A well-designed tool can save you time and reduce the risk of errors.

9.4. Updates and Support

Check the availability of software updates and technical support. Regular updates are essential for keeping the tool compatible with the latest vehicles and technologies.

9.5. Budget

Set a budget and compare the features and capabilities of different tools within your price range. Remember that investing in a high-quality tool can pay off in the long run.

9.6. Reviews and Ratings

Read reviews and ratings from other technicians to get an idea of the tool’s performance and reliability. Look for reviews from trusted sources, such as industry publications and online forums.

10. Optimizing Your Repair Shop with CARDIAGTECH.BIZ

Partnering with CARDIAGTECH.BIZ can help you optimize your repair shop and improve your overall efficiency. Here’s how:

10.1. Streamlining Diagnostic Processes

With the right diagnostic tools and equipment, you can streamline your diagnostic processes and reduce the time it takes to identify and repair issues. This can lead to increased customer satisfaction and higher profits.

10.2. Improving Accuracy and Reliability

Advanced diagnostic tools can improve the accuracy and reliability of your repairs, reducing the risk of comebacks and warranty claims. This can enhance your reputation and build trust with your customers.

10.3. Expanding Your Service Offerings

By investing in the latest technology, you can expand your service offerings and attract new customers. This can include offering services such as hybrid and electric vehicle repair, advanced driver-assistance systems (ADAS) calibration, and module programming.

10.4. Enhancing Technician Skills

Providing your technicians with access to the best tools and training can enhance their skills and improve their job satisfaction. This can lead to higher employee retention and a more skilled workforce.

10.5. Increasing Revenue and Profits

Ultimately, optimizing your repair shop with CARDIAGTECH.BIZ can lead to increased revenue and profits. By improving efficiency, accuracy, and service offerings, you can attract more customers and generate more business.

FAQ: Actuating Pumps and Valves with Diagnostic Tools

Here are some frequently asked questions about actuating pumps and valves with diagnostic tools.

1. What does “actuation” mean in automotive diagnostics?

Actuation refers to using a diagnostic tool to command a specific component within a vehicle to perform a function. This is often used to test the component’s operation.

2. Why is it important to actuate components in a battery cooling system?

Actuating components like pumps and valves helps ensure they are functioning correctly, which is crucial for maintaining the battery’s optimal temperature and performance.

3. Can the VCX SE tool actuate pumps and valves in a battery cooling system?

The VCX SE has limited capabilities and may not fully actuate these components. It is generally advisable to explore more robust alternatives.

4. What is a better alternative to VCX SE for actuation?

The Xtool D7S is a comprehensive alternative that offers extensive bi-directional control and diagnostic capabilities.

5. How do I actuate a coolant pump using the Xtool D7S?

Connect the Xtool D7S, select the vehicle, navigate to the appropriate module (e.g., Battery Management System), choose “Actuation Test,” and select the coolant pump to start the test.

6. What other bi-directional scanners can actuate cooling system components?

Other options include the Snap-on Zeus, Autel MaxiSys Elite, and Bosch ADS 625.

7. What should I do if the coolant pump fails to actuate during the test?

If the pump doesn’t activate, check the pump’s power supply, ground connections, and control signals. Consult the vehicle’s repair manual for troubleshooting steps.

8. Why is regular maintenance important for battery cooling systems?

Regular maintenance helps keep the cooling system in optimal condition, preventing overheating and ensuring long-term battery health.

9. What are some key maintenance tasks for battery cooling systems?

Key tasks include coolant checks and flushes, inspection of hoses and connections, cleaning cooling fins and radiators, and testing the coolant pump.

10. Where can I purchase high-quality diagnostic tools?

You can find a wide range of diagnostic tools at CARDIAGTECH.BIZ, offering competitive prices, expert support, and reliable products.

Contact CARDIAGTECH.BIZ Today

Ready to take your automotive diagnostics to the next level? Contact CARDIAGTECH.BIZ today to learn more about our wide selection of diagnostic tools and equipment. Our team of experts is here to help you choose the right tools for your needs and provide ongoing support to ensure you get the most out of your investment.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.BIZ

Don’t let the limitations of outdated tools hold you back. Invest in the best diagnostic equipment from CARDIAGTECH.BIZ and experience the difference!

The information provided in this article is intended for general guidance only. Always consult the vehicle’s repair manual and follow proper safety procedures when performing diagnostic and repair work.