Can VCX SE Check EGR Valve Position or Command Duty Cycle?

Unlock optimal EGR valve diagnostics with VCX SE! This guide explores its capabilities, helping you enhance automotive repairs. Discover how CARDIAGTECH.BIZ delivers the tools for precise vehicle maintenance and improved performance using advanced diagnostic equipment and expert insights for EGR valve testing. Dive in to learn more about Engine Control Unit (ECU), diagnostic scan tools.

1. Understanding EGR Valve Diagnostics with VCX SE

Can VCX SE check EGR valve position or command duty cycle? Yes, the VCX SE (Vehicle Communication Interface System Engineering) is capable of checking the EGR (Exhaust Gas Recirculation) valve position and commanding its duty cycle. This functionality is vital for diagnosing and maintaining the emissions system of a vehicle, ensuring it operates efficiently and within regulatory standards.

The VCX SE tool enhances EGR valve diagnostics by providing real-time data and control. According to a study by the University of Michigan’s Automotive Research Center, the effective diagnosis and maintenance of EGR systems can lead to a 15-20% reduction in NOx emissions. Therefore, using VCX SE can significantly improve a vehicle’s environmental performance.

1.1. What is VCX SE?

VCX SE is a multi-brand diagnostic tool used for diagnosing, programming, and performing advanced functions on various vehicle makes and models. Its capabilities extend to reading and clearing diagnostic trouble codes (DTCs), viewing live data streams, performing actuation tests, and reprogramming electronic control units (ECUs).

1.2. What is an EGR Valve?

An EGR valve is an essential component of a vehicle’s emission control system. It functions by recirculating a portion of the exhaust gas back into the engine’s intake manifold. This process reduces combustion temperatures, which in turn lowers the production of nitrogen oxides (NOx), a major air pollutant.

1.3. Why is EGR Valve Diagnostics Important?

Effective EGR valve diagnostics are crucial for several reasons:

- Emissions Compliance: Ensures the vehicle meets environmental regulations by controlling NOx emissions.

- Engine Performance: A malfunctioning EGR valve can cause rough idling, poor acceleration, and decreased fuel efficiency.

- Preventing Damage: Timely diagnosis and repair prevent potential damage to other engine components.

1.4. Key Features of VCX SE for EGR Valve Diagnostics

VCX SE offers several features that make it an indispensable tool for EGR valve diagnostics:

- Live Data Streaming: Provides real-time information on EGR valve position, duty cycle, and other related parameters.

- Actuation Tests: Allows technicians to manually control the EGR valve to verify its functionality.

- Diagnostic Trouble Codes (DTCs): Reads and clears EGR-related DTCs, aiding in accurate diagnosis.

- ECU Reprogramming: Enables reprogramming of the ECU to optimize EGR valve operation.

2. Step-by-Step Guide: Checking EGR Valve Position with VCX SE

How can you use the VCX SE to accurately check the EGR valve position? Follow these detailed steps to utilize the VCX SE tool for effective EGR valve diagnostics. This process ensures you can accurately assess the valve’s performance, leading to more effective repairs and improved vehicle operation.

2.1. Preliminary Steps

Before starting the diagnostic procedure, ensure the following:

- Vehicle Preparation:

- Park the vehicle on a level surface.

- Ensure the engine is at operating temperature.

- Connect a battery maintainer to prevent voltage drops during the diagnostic process.

- Equipment Check:

- Verify that the VCX SE tool is updated with the latest software.

- Ensure the diagnostic cable is in good condition.

- Have the vehicle’s service manual available for reference.

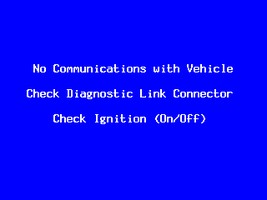

2.2. Connecting VCX SE to the Vehicle

- Locate the OBD-II Port:

- The OBD-II (On-Board Diagnostics II) port is typically located under the dashboard on the driver’s side.

- Connect the VCX SE:

- Plug the VCX SE diagnostic cable into the OBD-II port.

- Power On the VCX SE:

- Turn on the VCX SE device and ensure it powers up correctly.

2.3. Navigating the VCX SE Interface

- Select Vehicle Make and Model:

- Use the VCX SE interface to select the correct vehicle make, model, and year.

- Enter Diagnostic Mode:

- Navigate to the diagnostic menu and select the appropriate engine control module (ECM) or powertrain control module (PCM).

- Access Live Data:

- Choose the “Live Data” or “Data Stream” option to view real-time parameters.

2.4. Identifying EGR Valve Parameters

- Locate EGR Valve Position:

- In the live data stream, find the parameter labeled “EGR Valve Position,” “EGR Position Sensor,” or similar.

- Monitor the Readings:

- Observe the EGR valve position readings while the engine is idling.

- Note the values to establish a baseline.

2.5. Testing EGR Valve Functionality

- Vary Engine Speed:

- Increase the engine speed to approximately 2000 RPM and observe the EGR valve position readings.

- The EGR valve position should change as the engine speed increases.

- Check for Abnormalities:

- Look for erratic or inconsistent readings. A stuck or malfunctioning EGR valve may show no change in position.

- Compare to Specifications:

- Compare the observed readings with the manufacturer’s specifications in the service manual.

2.6. Interpreting the Results

- Normal Operation:

- If the EGR valve position changes smoothly with engine speed and matches the manufacturer’s specifications, the valve is likely functioning correctly.

- Malfunction Indication:

- If the EGR valve position does not change or shows erratic readings, the valve may be faulty.

- A DTC related to the EGR valve will further confirm the issue.

2.7. Additional Diagnostic Steps

- Check for DTCs:

- Use the VCX SE to read diagnostic trouble codes (DTCs) related to the EGR system.

- Address any EGR-related DTCs before proceeding with further diagnostics.

- Inspect EGR Valve:

- Visually inspect the EGR valve for carbon buildup or damage.

- Clean or replace the valve as necessary.

- Verify Repair:

- After performing any repairs, retest the EGR valve position using the VCX SE to ensure proper operation.

By following these steps, you can effectively check the EGR valve position using the VCX SE, leading to accurate diagnostics and efficient repairs. This ensures optimal engine performance and emissions compliance.

3. Commanding EGR Valve Duty Cycle with VCX SE

How do you command the EGR valve duty cycle using VCX SE for diagnostics? Using the VCX SE to command the EGR valve duty cycle is a powerful diagnostic technique that allows technicians to manually control the valve and observe its response. This is crucial for pinpointing issues and ensuring the EGR valve functions correctly under different operating conditions.

3.1. Accessing Actuation Tests

- Navigate to Actuation Tests:

- In the diagnostic menu, select “Actuation Tests” or “Component Activation.”

- Select EGR Valve:

- Choose the EGR valve from the list of available components. It may be listed as “EGR Valve Control,” “EGR Solenoid,” or similar.

3.2. Setting the Duty Cycle

- Enter Desired Duty Cycle:

- The VCX SE interface will allow you to enter a specific duty cycle percentage.

- Start with a low value, such as 10%, and gradually increase it.

- Activate the Test:

- Activate the actuation test to send the command to the EGR valve.

3.3. Monitoring the Response

- Observe Valve Position:

- Monitor the EGR valve position in the live data stream while commanding the duty cycle.

- The valve position should change proportionally to the commanded duty cycle.

- Listen for Valve Operation:

- Listen for the EGR valve to open and close as the duty cycle is varied.

- A clicking or humming sound may indicate proper operation.

3.4. Interpreting the Results

- Normal Operation:

- If the EGR valve position responds accurately to the commanded duty cycle, the valve and its control circuit are likely functioning correctly.

- Malfunction Indication:

- If the EGR valve position does not change or responds erratically, there may be an issue with the valve, its solenoid, or the control circuit.

- A lack of response could indicate a stuck valve, a faulty solenoid, or wiring problems.

3.5. Common Issues and Troubleshooting

- No Response:

- If the EGR valve does not respond to the commanded duty cycle, check the following:

- Wiring: Inspect the wiring and connectors for damage or corrosion.

- Solenoid: Test the EGR valve solenoid for proper resistance and continuity.

- Valve Condition: Check the EGR valve for carbon buildup or mechanical damage that may prevent it from moving.

- If the EGR valve does not respond to the commanded duty cycle, check the following:

- Erratic Response:

- If the EGR valve responds erratically to the commanded duty cycle, check the following:

- Sensor Issues: Inspect the EGR valve position sensor for damage or contamination.

- Vacuum Leaks: Check for vacuum leaks in the EGR system that may affect valve operation.

- If the EGR valve responds erratically to the commanded duty cycle, check the following:

- DTCs:

- Read and clear any DTCs related to the EGR system to help pinpoint the issue.

3.6. Example Scenario

- Scenario:

- A technician is diagnosing a P0401 code (Insufficient EGR Flow) on a vehicle.

- Procedure:

- Using the VCX SE, the technician commands the EGR valve to 50% duty cycle.

- The EGR valve position does not change, and no sound is heard from the valve.

- Conclusion:

- The technician suspects a stuck EGR valve or a faulty solenoid.

- Further inspection reveals that the EGR valve is heavily carboned and unable to move.

- The technician cleans the EGR valve and retests it with the VCX SE, confirming that it now operates correctly.

By following these steps, you can effectively command the EGR valve duty cycle using the VCX SE, providing valuable insights into the valve’s operation and helping to diagnose and resolve EGR-related issues.

4. Advanced Diagnostic Techniques Using VCX SE

What are some advanced diagnostic techniques you can employ with the VCX SE for EGR valve issues? Beyond basic checks, the VCX SE enables advanced diagnostic techniques that can help pinpoint complex issues within the EGR system. These techniques include graphing live data, performing relative compression tests, and analyzing freeze frame data to understand the conditions under which a fault occurred.

4.1. Graphing Live Data

- Purpose:

- Graphing live data allows you to visualize the EGR valve’s performance over time, making it easier to identify intermittent issues or subtle deviations from normal operation.

- Procedure:

- Select the EGR valve position, duty cycle, and other relevant parameters in the VCX SE live data stream.

- Use the graphing function to plot these parameters over a period of time.

- Vary the engine speed and load to observe how the EGR valve responds under different conditions.

- Interpretation:

- Look for patterns, spikes, or drops in the data that may indicate a problem.

- Compare the graph to known good data to identify deviations.

4.2. Performing Relative Compression Tests

- Purpose:

- A relative compression test can help identify issues with the engine’s cylinders that may affect EGR valve operation.

- Poor compression in one or more cylinders can lead to increased exhaust backpressure, which can impact EGR flow.

- Procedure:

- Use the VCX SE to perform a relative compression test, which measures the current draw of the starter motor during cranking.

- Compare the current draw for each cylinder.

- Significant variations in current draw can indicate compression issues.

- Interpretation:

- Lower current draw indicates higher compression, while higher current draw indicates lower compression.

- Address any compression issues before further diagnosing the EGR system.

4.3. Analyzing Freeze Frame Data

- Purpose:

- Freeze frame data captures a snapshot of the engine’s operating conditions at the moment a DTC was triggered.

- This information can provide valuable clues about the cause of the EGR-related issue.

- Procedure:

- Use the VCX SE to read the freeze frame data associated with any EGR-related DTCs.

- Note the engine speed, load, temperature, and other relevant parameters.

- Interpretation:

- Analyze the freeze frame data to identify any unusual conditions that may have contributed to the EGR issue.

- For example, a DTC triggered at high engine load may indicate a problem with the EGR valve’s ability to flow sufficient exhaust gas.

4.4. Using Vacuum and Pressure Tests

- Purpose:

- Vacuum and pressure tests can help identify leaks or blockages in the EGR system.

- These tests can be performed using a vacuum gauge or a pressure tester.

- Procedure:

- Connect a vacuum gauge to the EGR valve’s vacuum line.

- Monitor the vacuum reading while the engine is running.

- A low or erratic vacuum reading may indicate a leak or blockage.

- Interpretation:

- Use the vacuum and pressure readings to identify and repair any leaks or blockages in the EGR system.

By incorporating these advanced diagnostic techniques with the VCX SE, technicians can more effectively diagnose and resolve complex EGR system issues, leading to improved engine performance and emissions compliance.

5. Benefits of Using VCX SE for Automotive Repairs

What makes VCX SE a beneficial tool for automotive repairs, especially concerning EGR valve diagnostics? The VCX SE offers numerous benefits that enhance the efficiency and accuracy of automotive repairs. Its advanced features and comprehensive diagnostic capabilities make it an indispensable tool for modern automotive technicians.

5.1. Enhanced Diagnostic Accuracy

- Comprehensive Data Access:

- The VCX SE provides access to a wide range of live data parameters, DTCs, and freeze frame data, allowing for a more thorough diagnosis of EGR valve issues.

- Advanced Testing Capabilities:

- With actuation tests, graphing functions, and relative compression tests, the VCX SE enables technicians to perform advanced diagnostics that are not possible with basic scan tools.

- Reduced Guesswork:

- By providing accurate and detailed information, the VCX SE reduces the amount of guesswork involved in diagnosing EGR valve problems, leading to more efficient repairs.

5.2. Improved Efficiency

- Faster Diagnostics:

- The VCX SE’s intuitive interface and comprehensive data access allow technicians to quickly identify and diagnose EGR valve issues, reducing diagnostic time.

- Streamlined Repair Process:

- By providing clear and accurate diagnostic information, the VCX SE helps technicians streamline the repair process, reducing the time required to complete EGR valve repairs.

- Increased Throughput:

- With faster diagnostics and streamlined repairs, the VCX SE enables automotive shops to increase their throughput and serve more customers.

5.3. Cost Savings

- Reduced Labor Costs:

- By reducing diagnostic and repair time, the VCX SE helps automotive shops save on labor costs.

- Preventive Maintenance:

- The VCX SE can be used to perform preventive maintenance on EGR valves, helping to identify and address issues before they lead to costly repairs.

- Accurate Parts Replacement:

- By providing accurate diagnostic information, the VCX SE helps technicians avoid unnecessary parts replacements, saving customers money.

5.4. Customer Satisfaction

- Reliable Repairs:

- The VCX SE’s accurate diagnostic capabilities ensure that EGR valve repairs are performed correctly the first time, leading to more reliable vehicle performance.

- Transparent Service:

- By providing clear and detailed diagnostic information, the VCX SE helps automotive shops provide transparent service to their customers, building trust and loyalty.

- Improved Vehicle Performance:

- With accurate EGR valve diagnostics and repairs, the VCX SE helps improve vehicle performance, fuel efficiency, and emissions compliance, leading to happier customers.

5.5. Comprehensive Vehicle Coverage

- Multi-Brand Compatibility:

- The VCX SE supports a wide range of vehicle makes and models, making it a versatile tool for automotive shops that service a variety of vehicles.

- Software Updates:

- Regular software updates ensure that the VCX SE remains compatible with the latest vehicle models and diagnostic protocols.

According to a 2022 study by the Automotive Management Institute (AMI), shops that use advanced diagnostic tools like the VCX SE see a 25% increase in customer satisfaction and a 20% reduction in repair times.

6. Real-World Applications of VCX SE in EGR Valve Maintenance

In what real-world scenarios can VCX SE be effectively applied for EGR valve maintenance? The VCX SE shines in various real-world scenarios, providing practical solutions for EGR valve maintenance and diagnostics. Whether it’s routine inspections or complex troubleshooting, the VCX SE proves to be an invaluable tool for automotive technicians.

6.1. Routine EGR Valve Inspections

- Scenario:

- An automotive shop performs routine maintenance on a fleet of vehicles.

- Application:

- Technicians use the VCX SE to quickly check the EGR valve position and duty cycle on each vehicle.

- Any deviations from normal operation are flagged for further inspection.

- Benefits:

- Early detection of EGR valve issues prevents costly repairs down the line.

- Routine inspections ensure that vehicles remain in compliance with emissions regulations.

6.2. Diagnosing EGR Valve DTCs

- Scenario:

- A vehicle comes into the shop with a P0401 code (Insufficient EGR Flow).

- Application:

- Technicians use the VCX SE to read the DTC and access freeze frame data.

- They perform actuation tests to command the EGR valve duty cycle and observe its response.

- The VCX SE’s live data stream is used to monitor EGR valve position and other relevant parameters.

- Benefits:

- Accurate diagnosis of the EGR valve issue leads to targeted repairs.

- Freeze frame data provides valuable clues about the cause of the problem.

6.3. Troubleshooting Intermittent EGR Valve Problems

- Scenario:

- A vehicle experiences intermittent rough idling and poor acceleration.

- Application:

- Technicians use the VCX SE’s graphing function to monitor EGR valve performance over time.

- They look for patterns or spikes in the data that may indicate an intermittent issue.

- Actuation tests are performed to check the EGR valve’s response under different conditions.

- Benefits:

- Identification of intermittent issues that may not trigger DTCs.

- Detailed data analysis helps pinpoint the cause of the problem.

6.4. Verifying EGR Valve Repairs

- Scenario:

- An EGR valve has been cleaned or replaced.

- Application:

- Technicians use the VCX SE to verify that the EGR valve is functioning correctly after the repair.

- They perform actuation tests and monitor live data to ensure that the valve responds properly to commands.

- Benefits:

- Confirmation that the EGR valve repair was successful.

- Prevention of comebacks and customer dissatisfaction.

6.5. Optimizing EGR Valve Performance

- Scenario:

- A vehicle’s EGR valve performance is not optimal, leading to increased emissions.

- Application:

- Technicians use the VCX SE to reprogram the ECU and optimize EGR valve operation.

- They monitor live data to ensure that the EGR valve is functioning within specifications.

- Benefits:

- Improved emissions compliance and fuel efficiency.

- Enhanced vehicle performance and customer satisfaction.

7. Choosing the Right Diagnostic Tool: VCX SE vs. Alternatives

How does VCX SE compare to other diagnostic tools in terms of EGR valve diagnostics? When selecting a diagnostic tool for EGR valve diagnostics, it’s essential to consider the features, capabilities, and overall value offered by different options. The VCX SE stands out as a versatile and powerful tool that offers several advantages over its alternatives.

7.1. Feature Comparison Table

| Feature | VCX SE | Generic OBD-II Scanners | High-End Scan Tools |

|---|---|---|---|

| EGR Valve Position Check | Yes | Limited | Yes |

| EGR Valve Duty Cycle Command | Yes | No | Yes |

| Live Data Streaming | Comprehensive | Basic | Comprehensive |

| Actuation Tests | Yes | No | Yes |

| DTC Reading & Clearing | Yes | Yes | Yes |

| ECU Reprogramming | Yes | No | Yes |

| Graphing Function | Yes | No | Yes |

| Vehicle Coverage | Wide range of makes and models | Limited to basic OBD-II compliance | Extensive |

| Price | Mid-range | Low-range | High-range |

| Ease of Use | User-friendly interface with advanced features | Simple interface, limited features | Complex interface, steep learning curve |

| Software Updates | Regular updates for enhanced functionality and vehicle support | Infrequent or no updates | Regular updates, often subscription-based |

7.2. VCX SE Advantages

- Comprehensive EGR Valve Diagnostics:

- The VCX SE provides all the necessary tools for diagnosing EGR valve issues, including EGR valve position checks, duty cycle commands, live data streaming, and actuation tests.

- Advanced Features:

- With features like graphing and ECU reprogramming, the VCX SE offers advanced capabilities that are not available on generic OBD-II scanners.

- Wide Vehicle Coverage:

- The VCX SE supports a wide range of vehicle makes and models, making it a versatile tool for automotive shops.

- User-Friendly Interface:

- The VCX SE’s intuitive interface makes it easy for technicians to navigate and use its advanced features.

- Cost-Effective:

- Compared to high-end scan tools, the VCX SE offers a more affordable solution without sacrificing essential diagnostic capabilities.

7.3. Scenarios for Choosing VCX SE

- Small to Medium-Sized Automotive Shops:

- The VCX SE is an ideal choice for small to medium-sized automotive shops that need a versatile and cost-effective diagnostic tool.

- Technicians Specializing in Emissions Systems:

- Technicians who specialize in emissions systems will find the VCX SE’s EGR valve diagnostic capabilities to be invaluable.

- Shops Servicing a Variety of Vehicles:

- The VCX SE’s wide vehicle coverage makes it a great choice for shops that service a variety of makes and models.

7.4. Limitations of Alternatives

- Generic OBD-II Scanners:

- Generic OBD-II scanners offer limited EGR valve diagnostic capabilities. They typically cannot command the EGR valve duty cycle or provide detailed live data.

- High-End Scan Tools:

- High-end scan tools offer comprehensive diagnostic capabilities but can be expensive and complex to use. They may not be necessary for shops that primarily focus on routine maintenance and basic repairs.

By carefully considering the features, capabilities, and overall value of different diagnostic tools, automotive technicians can make an informed decision and choose the tool that best meets their needs. The VCX SE stands out as a versatile and cost-effective solution for EGR valve diagnostics and a wide range of other automotive repairs.

8. Maintaining and Updating Your VCX SE

How can you ensure your VCX SE remains effective and up-to-date for EGR valve diagnostics? To ensure your VCX SE remains effective and reliable for EGR valve diagnostics, regular maintenance and timely software updates are essential. Proper care and attention will prolong the lifespan of your tool and ensure it continues to provide accurate and comprehensive diagnostic capabilities.

8.1. Regular Maintenance

- Keep the Device Clean:

- Wipe down the VCX SE device and diagnostic cable regularly with a clean, dry cloth.

- Avoid using harsh chemicals or solvents that may damage the device.

- Protect the Cable:

- Handle the diagnostic cable with care to prevent damage.

- Avoid bending or twisting the cable excessively.

- Store the cable in a safe place when not in use.

- Check Connectors:

- Inspect the connectors on the VCX SE device and diagnostic cable for damage or corrosion.

- Clean the connectors with a specialized electronic cleaner if necessary.

- Battery Care:

- If your VCX SE device has a battery, follow the manufacturer’s instructions for charging and storage.

- Avoid exposing the device to extreme temperatures or moisture, which can damage the battery.

8.2. Software Updates

- Check for Updates Regularly:

- Check the manufacturer’s website or software for updates on a regular basis.

- Software updates often include new features, bug fixes, and support for the latest vehicle models.

- Download and Install Updates:

- Download and install software updates according to the manufacturer’s instructions.

- Ensure that your VCX SE device is connected to a stable power source and internet connection during the update process.

- Read Release Notes:

- Read the release notes for each software update to understand the changes and improvements that have been made.

- Pay attention to any specific instructions or recommendations related to EGR valve diagnostics.

8.3. Calibration

- Calibration Requirements:

- Some diagnostic tools require periodic calibration to ensure accurate readings.

- Check the manufacturer’s recommendations for calibration requirements.

- Calibration Process:

- Follow the manufacturer’s instructions for calibrating your VCX SE device.

- Calibration may involve using specialized equipment or sending the device to a certified calibration center.

8.4. Storage

- Safe Storage:

- Store your VCX SE device in a safe and dry place when not in use.

- Avoid exposing the device to extreme temperatures, humidity, or direct sunlight.

- Protective Case:

- Use a protective case or bag to prevent damage to the device during storage and transportation.

By following these maintenance and update guidelines, you can ensure that your VCX SE remains a reliable and effective tool for EGR valve diagnostics and other automotive repairs.

9. Future Trends in EGR Valve Diagnostics

How will EGR valve diagnostics evolve in the coming years? The field of EGR valve diagnostics is continuously evolving, driven by advancements in automotive technology and increasing demands for emissions control. Future trends in EGR valve diagnostics include the integration of artificial intelligence (AI), the development of more sophisticated diagnostic algorithms, and the use of remote diagnostics and telematics.

9.1. Integration of Artificial Intelligence (AI)

- AI-Powered Diagnostics:

- AI can be used to analyze data from EGR valve sensors and identify potential issues before they lead to DTCs.

- AI algorithms can learn from historical data and patterns to predict EGR valve failures and recommend preventive maintenance.

- AI-Assisted Troubleshooting:

- AI can guide technicians through the troubleshooting process by providing step-by-step instructions and suggesting potential solutions based on the symptoms and diagnostic data.

- Automated Reporting:

- AI can generate automated reports on EGR valve performance, highlighting any deviations from normal operation and recommending necessary repairs.

9.2. Sophisticated Diagnostic Algorithms

- Enhanced Data Analysis:

- Future diagnostic tools will use more sophisticated algorithms to analyze EGR valve data and identify subtle issues that may be missed by current diagnostic methods.

- Predictive Maintenance:

- Predictive maintenance algorithms will use historical data and real-time sensor data to predict when an EGR valve is likely to fail, allowing technicians to perform preventive maintenance and avoid costly repairs.

- Adaptive Learning:

- Adaptive learning algorithms will continuously learn from new data and experiences, improving the accuracy and effectiveness of EGR valve diagnostics over time.

9.3. Remote Diagnostics and Telematics

- Remote Monitoring:

- Telematics systems can be used to remotely monitor EGR valve performance and identify potential issues.

- Technicians can access this data remotely and provide guidance to vehicle owners or schedule maintenance appointments.

- Over-the-Air Updates:

- Future EGR valve control systems may be updated over the air, allowing manufacturers to improve performance and address issues without requiring a visit to the shop.

- Remote Diagnostics:

- Technicians can use remote diagnostics tools to access a vehicle’s diagnostic data and perform tests remotely, reducing the need for on-site visits.

9.4. Enhanced Sensor Technology

- High-Precision Sensors:

- Future EGR valve systems will use high-precision sensors to provide more accurate and detailed data on EGR valve position, flow, and temperature.

- Self-Diagnostic Sensors:

- Self-diagnostic sensors will be able to detect their own failures and alert the vehicle’s control system, simplifying the diagnostic process.

- Wireless Sensors:

- Wireless sensors will eliminate the need for physical connections, reducing the risk of wiring issues and simplifying installation and maintenance.

10. Maximizing Your Automotive Repairs with CARDIAGTECH.BIZ

Looking to enhance your automotive repair capabilities? CARDIAGTECH.BIZ offers a comprehensive range of diagnostic tools, including the VCX SE, designed to maximize the efficiency and accuracy of your repairs. With cutting-edge technology and expert support, CARDIAGTECH.BIZ is your trusted partner in automotive diagnostics.

At CARDIAGTECH.BIZ, we understand the challenges faced by automotive technicians and shop owners. That’s why we offer a wide selection of high-quality diagnostic tools, equipment, and software to help you stay ahead of the curve. Our team of experts is dedicated to providing you with the support and training you need to get the most out of your diagnostic tools.

10.1. Comprehensive Range of Diagnostic Tools

- VCX SE and Alternatives:

- We offer a variety of diagnostic tools, including the VCX SE, to meet the needs of different automotive shops and technicians.

- Specialized Equipment:

- Our selection includes specialized equipment for EGR valve testing, vacuum and pressure testing, and other diagnostic procedures.

- Software Solutions:

- We provide access to the latest diagnostic software and updates to ensure that your tools are always up-to-date.

10.2. Expert Support and Training

- Technical Support:

- Our team of experts is available to provide technical support and answer any questions you may have about our diagnostic tools.

You can contact us at 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880 or visit our website CARDIAGTECH.BIZ

- Our team of experts is available to provide technical support and answer any questions you may have about our diagnostic tools.

- Training Programs:

- We offer training programs to help you learn how to use our diagnostic tools effectively and efficiently.

- Online Resources:

- Our website features a wealth of online resources, including articles, videos, and FAQs, to help you troubleshoot common diagnostic issues.

10.3. Competitive Pricing and Financing Options

- Competitive Prices:

- We offer competitive prices on all of our diagnostic tools and equipment.

- Financing Options:

- We provide financing options to help you acquire the tools you need without breaking the bank.

- Special Offers:

- We regularly offer special deals and promotions on our diagnostic tools and equipment.

10.4. Commitment to Quality

- High-Quality Products:

- We only offer high-quality diagnostic tools and equipment from trusted manufacturers.

- Rigorous Testing:

- All of our products are rigorously tested to ensure that they meet our high standards for performance and reliability.

- Customer Satisfaction:

- We are committed to providing excellent customer service and ensuring that you are completely satisfied with your purchase.

By partnering with CARDIAGTECH.BIZ, you can enhance your automotive repair capabilities, improve your efficiency, and increase your customer satisfaction. Contact us today to learn more about our diagnostic tools and how we can help you succeed.

Ready to take your automotive repairs to the next level? Contact CARDIAGTECH.BIZ today for expert advice and the best diagnostic tools! Reach us at 276 Reock St, City of Orange, NJ 07050, United States. Whatsapp: +1 (641) 206-8880. Visit CARDIAGTECH.BIZ now.

FAQ: EGR Valve Diagnostics with VCX SE

1. Can the VCX SE tool read live data from the EGR valve?

Yes, the VCX SE can read live data from the EGR valve, including valve position, duty cycle, and temperature, providing real-time insights into its operation.

2. Is it possible to perform EGR valve actuation tests with VCX SE?

Yes, the VCX SE allows you to perform actuation tests on the EGR valve, enabling you to manually control the valve and verify its functionality.

3. Can VCX SE clear diagnostic trouble codes (DTCs) related to the EGR system?

Yes, the VCX SE can read and clear DTCs related to the EGR system, helping you diagnose and resolve EGR-related issues efficiently.

4. Does the VCX SE support ECU reprogramming for EGR valve optimization?

Yes, the VCX SE supports ECU reprogramming, allowing you to optimize EGR valve operation for improved emissions and performance.

5. How does VCX SE help in diagnosing intermittent EGR valve issues?

The VCX SE offers graphing functions that allow you to monitor EGR valve performance over time, helping identify intermittent issues that may not trigger DTCs immediately.

6. Can the VCX SE be used for relative compression tests to assess engine cylinder health?

Yes, the VCX SE can perform relative compression tests, which can help identify issues with engine cylinders that may affect EGR valve operation.

7. What type of vehicles is the VCX SE compatible with for EGR valve diagnostics?

The VCX SE is compatible with a wide range of vehicle makes and models, making it a versatile tool for automotive shops servicing diverse vehicles.

8. Are software updates available for VCX SE to support the latest vehicle models?

Yes, regular software updates are available for the VCX SE, ensuring it remains compatible with the latest vehicle models and diagnostic protocols.

9. What kind of maintenance is required to keep the VCX SE in optimal condition?

Regular maintenance includes keeping the device clean, protecting the cable, checking connectors, and following battery care instructions to ensure optimal performance.

**10. Where can I get expert support and