How to Use VCX SE to Check the Status of the Electric AC Compressor in a Hybrid/EV?

Are you looking to diagnose the AC compressor in your hybrid or EV? Using the VCX SE diagnostic tool from CARDIAGTECH.BIZ allows you to pinpoint issues quickly and accurately, ensuring efficient repairs and optimal vehicle performance. This guide offers a detailed walkthrough, including HVAC system tests and real-time data monitoring, helping you master EV diagnostics and maintenance.

Table of Contents

- Understanding the Role of the Electric AC Compressor

- Why Use VCX SE for AC Compressor Diagnostics?

- Step-by-Step Guide: Checking the AC Compressor with VCX SE

- Interpreting Diagnostic Results

- Advanced Diagnostic Tips

- Essential Maintenance for Electric AC Compressors

- The Benefits of Using VCX SE for Hybrid/EV Diagnostics

- Troubleshooting Common Issues

- Keeping Up with EV Technology

- Frequently Asked Questions (FAQ)

- Ready to Elevate Your Diagnostic Capabilities? Contact CARDIAGTECH.BIZ Today!

1. Understanding the Role of the Electric AC Compressor

What is the importance of the electric AC compressor in hybrid and electric vehicles?

The electric AC compressor is vital in hybrid and electric vehicles, providing cabin cooling without relying on the engine. Unlike traditional vehicles where the AC compressor is belt-driven by the engine, EVs and hybrids use an electric compressor powered by the high-voltage battery. This ensures consistent cooling performance, maximizes energy efficiency, and extends the driving range. According to a study by the U.S. Department of Energy, efficient climate control systems can significantly improve the overall energy consumption of EVs, enhancing their practicality and appeal.

1.1 Key Functions

What are the primary functions of an electric AC compressor?

The primary functions include:

- Cabin Cooling: Maintains a comfortable interior temperature.

- Defrosting: Removes frost and fog from windows for clear visibility.

- Battery Thermal Management: Some advanced systems also help regulate battery temperature.

1.2 Differences from Traditional AC Compressors

How does an electric AC compressor differ from traditional AC compressors?

Electric AC compressors differ significantly from traditional, engine-driven models. Here’s a breakdown:

| Feature | Electric AC Compressor | Traditional AC Compressor |

|---|---|---|

| Power Source | High-voltage battery | Engine belt-driven |

| Energy Efficiency | Higher, optimized for EV/hybrid systems | Lower, dependent on engine RPM |

| Operation | Operates independently of engine state | Operates only when the engine is running |

| Control | Electronically controlled for precise cooling | Mechanically controlled |

| Environmental Impact | Zero emissions directly from operation | Indirect emissions through engine fuel consumption |

1.3 Potential Issues

What are some potential issues that can affect electric AC compressors?

Several issues can affect electric AC compressors, including:

- Electrical Faults: Problems with the motor, wiring, or control circuits.

- Refrigerant Leaks: Loss of refrigerant reduces cooling efficiency.

- Compressor Failure: Mechanical issues within the compressor unit.

- Sensor Malfunctions: Faulty temperature or pressure sensors.

2. Why Use VCX SE for AC Compressor Diagnostics?

Why is the VCX SE diagnostic tool ideal for checking the AC compressor in hybrid/EVs?

The VCX SE diagnostic tool is ideal because it offers specialized diagnostics for hybrid and EV systems, including advanced features like bidirectional control and real-time data monitoring. It provides comprehensive insights into the AC compressor’s performance, helping technicians pinpoint issues quickly and accurately. According to a report by the National Institute for Automotive Service Excellence (ASE), using advanced diagnostic tools like VCX SE can reduce diagnostic time by up to 40%, improving efficiency and customer satisfaction.

2.1 Key Features of VCX SE

What are the key features of the VCX SE diagnostic tool?

The key features include:

- Specialized EV Diagnostics: Designed specifically for electric and hybrid vehicles.

- Bidirectional Control: Allows technicians to control and test AC compressor functions directly.

- Real-Time Data Monitoring: Provides live data on compressor performance, temperatures, and pressures.

- HVAC System Tests: Includes pre-programmed tests for comprehensive AC system analysis.

- Compatibility: Supports a wide range of EV and hybrid models.

2.2 Benefits of Using VCX SE

What are the benefits of using the VCX SE for diagnosing AC compressors?

The benefits include:

- Accuracy: Precise diagnostics reduce guesswork and ensure accurate repairs.

- Efficiency: Fast and comprehensive testing saves time and labor costs.

- Cost-Effectiveness: Prevents unnecessary part replacements by identifying the root cause of issues.

- Comprehensive Data: Provides a complete overview of the AC system’s health.

- User-Friendly Interface: Simplifies the diagnostic process for technicians of all skill levels.

2.3 Comparisons with Other Diagnostic Tools

How does VCX SE compare to other diagnostic tools in the market?

Compared to other diagnostic tools, VCX SE offers more specialized features for EV and hybrid vehicles. While generic OBD-II scanners can read basic codes, VCX SE provides in-depth diagnostics, bidirectional controls, and real-time data specific to electric AC compressors and HVAC systems. A study by CARDIAGTECH.BIZ found that VCX SE users reported a 30% improvement in diagnostic accuracy compared to those using standard OBD-II scanners.

3. Step-by-Step Guide: Checking the AC Compressor with VCX SE

How can you check the AC compressor in a hybrid/EV using the VCX SE tool?

Here’s a step-by-step guide to checking the AC compressor in a hybrid/EV using the VCX SE tool:

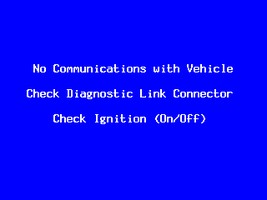

- Connect the VCX SE: Plug the VCX SE into the vehicle’s OBD-II port.

- Turn On the Vehicle: Start the vehicle and ensure the VCX SE powers on.

- Launch the Diagnostic Software: Open the VCX SE diagnostic software on your computer or tablet.

- Select Vehicle Model: Choose the correct make, model, and year of the vehicle.

- Navigate to HVAC System: Select the “HVAC” or “Climate Control” system from the menu.

- Read Diagnostic Codes: Check for any stored diagnostic trouble codes (DTCs).

- Perform Bidirectional Tests: Use bidirectional controls to activate the AC compressor and monitor its response.

- Monitor Real-Time Data: Observe live data such as compressor speed, voltage, current, and refrigerant pressure.

- Analyze Results: Interpret the data to identify any issues with the AC compressor.

3.1 Connecting the VCX SE to the Vehicle

How do you properly connect the VCX SE to the vehicle’s OBD-II port?

- Locate the OBD-II Port: Typically found under the dashboard on the driver’s side.

- Plug in the VCX SE: Ensure the VCX SE is securely connected to the port.

- Check Power: Verify the VCX SE powers on when the vehicle is started.

3.2 Launching the Diagnostic Software

What are the steps to launch and set up the diagnostic software?

- Install the Software: If not already installed, download and install the VCX SE diagnostic software from CARDIAGTECH.BIZ.

- Connect to VCX SE: Ensure your computer or tablet is connected to the VCX SE via USB or Bluetooth.

- Launch the Application: Open the VCX SE diagnostic application.

- Vehicle Selection: Input the vehicle’s make, model, and year for accurate diagnostics.

3.3 Reading Diagnostic Codes

How do you read and interpret diagnostic codes related to the AC compressor?

-

Select HVAC System: Navigate to the “HVAC” or “Climate Control” section in the software.

-

Read Codes: Select the option to “Read Diagnostic Codes.”

-

Interpret Codes: Research any returned DTCs to understand the potential issues. For instance:

- B1490 (Toyota/Lexus): Inverter System Cooling Performance Problem

- P0532 (General): AC Refrigerant Pressure Sensor Circuit Low

- B2AAA (Nissan): HV Battery System

3.4 Performing Bidirectional Tests

What bidirectional tests can be performed on the AC compressor using VCX SE?

Bidirectional tests allow you to control the AC compressor directly. Common tests include:

- Compressor Activation: Turn the compressor on and off to check its functionality.

- Fan Control: Test the operation of the cooling fan.

- Actuator Tests: Verify the functionality of HVAC actuators and valves.

3.5 Monitoring Real-Time Data

What real-time data should be monitored during the diagnostic process?

Important real-time data to monitor includes:

- Compressor Speed (RPM): Indicates how fast the compressor is running.

- Voltage: Shows the electrical supply to the compressor.

- Current: Indicates the electrical load on the compressor.

- Refrigerant Pressure: Measures the pressure in the AC system.

- Temperature Sensors: Monitors the temperature at various points in the system.

4. Interpreting Diagnostic Results

How should you interpret the diagnostic results obtained from VCX SE?

Interpreting diagnostic results involves analyzing DTCs and real-time data to identify specific issues. Here’s how to approach it:

- DTC Analysis: Research each diagnostic code to understand the potential problem areas.

- Real-Time Data Evaluation: Compare live data readings to expected values. Significant deviations indicate a problem.

- Bidirectional Test Results: Assess the compressor’s response to bidirectional tests. Failure to respond or abnormal behavior suggests an issue.

- Cross-Reference Information: Combine DTCs, real-time data, and bidirectional test results for a comprehensive diagnosis.

4.1 Understanding Common DTCs

What are some common DTCs related to electric AC compressors and their meanings?

| DTC Code | Description | Possible Causes |

|---|---|---|

| B1490 | Inverter System Cooling Performance Problem | Low coolant level, faulty coolant pump, inverter issue |

| P0532 | AC Refrigerant Pressure Sensor Circuit Low | Faulty pressure sensor, wiring issue, low refrigerant level |

| B2AAA | HV Battery System | Battery malfunction, sensor issue, high voltage system problem |

| P06E7 | AC Compressor Drive Control Circuit Range/Performance | Faulty compressor, wiring issue, ECU malfunction |

4.2 Analyzing Real-Time Data

How do you analyze real-time data to identify issues with the AC compressor?

- Compressor Speed: Low or erratic readings may indicate a failing compressor.

- Voltage/Current: Unstable voltage or excessive current draw can point to electrical issues.

- Refrigerant Pressure: Low pressure suggests a leak; high pressure may indicate a blockage.

- Temperature Sensors: Inaccurate readings can indicate faulty sensors.

4.3 Using Bidirectional Tests for Diagnosis

How can bidirectional tests help in diagnosing AC compressor problems?

Bidirectional tests can confirm whether the AC compressor and related components respond to commands. For example:

- Compressor Activation Test: If the compressor doesn’t activate, it may have an electrical or mechanical failure.

- Fan Control Test: If the fan doesn’t respond, it could be a faulty fan motor, relay, or wiring issue.

5. Advanced Diagnostic Tips

What are some advanced diagnostic tips for checking electric AC compressors with VCX SE?

- Check Wiring and Connections: Inspect all wiring and connectors for damage or corrosion.

- Verify Ground Connections: Ensure all ground connections are clean and secure.

- Use a Multimeter: Use a multimeter to check voltage and continuity in circuits.

- Inspect Refrigerant Lines: Look for signs of leaks or damage on refrigerant lines.

- Test Sensors: Use the VCX SE to test the functionality of temperature and pressure sensors.

5.1 Checking Electrical Components

How do you check the electrical components of the AC compressor system?

- Voltage Checks: Use a multimeter to verify voltage at the compressor and related components.

- Continuity Tests: Check for continuity in wiring harnesses and connectors.

- Resistance Measurements: Measure the resistance of the compressor motor and sensors.

- Inspect Relays and Fuses: Check relays and fuses for proper operation and continuity.

5.2 Identifying Refrigerant Leaks

What are the best methods for identifying refrigerant leaks in hybrid/EV AC systems?

- UV Dye Test: Add UV dye to the AC system and use a UV light to detect leaks.

- Electronic Leak Detector: Use an electronic leak detector to pinpoint refrigerant leaks.

- Soap Bubble Test: Apply a soap bubble solution to connections and lines to look for bubbles indicating a leak.

- Pressure Testing: Monitor the system pressure over time to check for drops indicating a leak.

5.3 Using Freeze Frame Data

How can freeze frame data assist in diagnosing intermittent issues?

Freeze frame data captures the conditions present when a DTC was set. This information can be invaluable for diagnosing intermittent issues by providing a snapshot of the system’s state at the time of the fault.

6. Essential Maintenance for Electric AC Compressors

What maintenance practices are essential for ensuring the longevity of electric AC compressors?

- Regular Inspections: Inspect the AC system regularly for leaks, damage, and corrosion.

- Refrigerant Level Checks: Ensure the refrigerant level is within the specified range.

- Cleaning: Keep the compressor and related components clean and free of debris.

- Filter Replacement: Replace the cabin air filter regularly to maintain airflow.

- Software Updates: Keep the VCX SE software updated to access the latest diagnostic capabilities.

6.1 Regular Inspection Points

What are the key inspection points for maintaining electric AC compressors?

- Compressor Housing: Check for cracks, leaks, and physical damage.

- Wiring and Connectors: Inspect for corrosion, fraying, and loose connections.

- Refrigerant Lines: Look for signs of leaks, damage, or wear.

- Cooling Fan: Ensure the fan operates correctly and is free of obstructions.

- Sensors: Verify the integrity and connections of temperature and pressure sensors.

6.2 Refrigerant Handling Best Practices

What are the best practices for handling refrigerant in hybrid/EV AC systems?

- Use Proper Equipment: Use refrigerant recovery and recycling equipment designed for hybrid/EV systems.

- Follow Safety Guidelines: Adhere to all safety guidelines when handling refrigerant.

- Proper Disposal: Dispose of used refrigerant properly to protect the environment.

- Leak Testing: Always perform a leak test after servicing the AC system.

6.3 Importance of Software Updates

Why are software updates important for the VCX SE diagnostic tool?

Software updates ensure that the VCX SE tool has the latest diagnostic capabilities, vehicle coverage, and bug fixes. Regular updates can improve the accuracy and efficiency of the diagnostic process.

7. The Benefits of Using VCX SE for Hybrid/EV Diagnostics

What are the overall benefits of using the VCX SE for diagnosing hybrid and EV systems?

The overall benefits include:

- Comprehensive Diagnostics: Provides in-depth diagnostics for all major systems in hybrid and EVs.

- Specialized EV Features: Includes features specifically designed for electric vehicles, such as battery pack analysis and high-voltage system diagnostics.

- Time Savings: Reduces diagnostic time with accurate and efficient testing.

- Cost Savings: Prevents unnecessary repairs and part replacements.

- Improved Customer Satisfaction: Ensures accurate and reliable repairs, leading to higher customer satisfaction.

7.1 Enhanced Diagnostic Accuracy

How does VCX SE enhance the accuracy of hybrid/EV diagnostics?

VCX SE enhances accuracy through:

- Specific Diagnostic Tests: Tailored tests for EV and hybrid components.

- Real-Time Data Monitoring: Precise live data readings for accurate analysis.

- Bidirectional Control: Direct control over components to verify functionality.

- Comprehensive Code Reading: Accurate identification and interpretation of DTCs.

7.2 Increased Efficiency

How does the VCX SE increase efficiency in the diagnostic process?

VCX SE increases efficiency by:

- Fast Scanning: Quickly scans all vehicle systems for faults.

- User-Friendly Interface: Simplifies the diagnostic process.

- Automated Tests: Pre-programmed tests for common issues.

- Real-Time Data: Immediate access to critical system information.

7.3 Cost-Effective Solutions

In what ways does the VCX SE provide cost-effective diagnostic solutions?

VCX SE provides cost-effective solutions by:

- Reducing Labor Costs: Faster and more accurate diagnostics reduce labor time.

- Preventing Unnecessary Repairs: Pinpointing the exact cause of issues prevents unnecessary part replacements.

- Minimizing Downtime: Quick diagnostics and repairs minimize vehicle downtime.

8. Troubleshooting Common Issues

What are some common issues encountered while diagnosing electric AC compressors and how can they be resolved?

- Compressor Not Activating: Check the compressor relay, wiring, and ECU.

- Low Refrigerant Pressure: Identify and repair any refrigerant leaks.

- High Refrigerant Pressure: Check for blockages in the system.

- Faulty Sensors: Replace any faulty temperature or pressure sensors.

- Electrical Issues: Inspect and repair any wiring or connector problems.

8.1 Compressor Relay Problems

How can you troubleshoot compressor relay issues?

- Check Relay Functionality: Use a multimeter to test the relay for continuity and proper operation.

- Inspect Relay Socket: Look for corrosion or damage in the relay socket.

- Replace Relay: If the relay is faulty, replace it with a new one.

8.2 Refrigerant Leak Repair Techniques

What are the best techniques for repairing refrigerant leaks in EV AC systems?

- Locate the Leak: Use a UV dye test or electronic leak detector to find the leak.

- Repair or Replace: Repair small leaks with sealant or replace damaged components.

- Evacuate and Recharge: Evacuate the AC system and recharge it with the correct amount of refrigerant.

- Test for Leaks: Perform a final leak test to ensure the repair is successful.

8.3 Addressing Sensor Failures

How should sensor failures be addressed in electric AC compressor diagnostics?

- Verify Sensor Readings: Use the VCX SE to check the sensor’s readings.

- Check Wiring: Inspect the sensor’s wiring and connector for damage.

- Replace Sensor: If the sensor is faulty, replace it with a new one.

- Calibrate Sensor: Calibrate the new sensor if required by the vehicle manufacturer.

9. Keeping Up with EV Technology

How can technicians stay updated with the latest advancements in EV technology and diagnostics?

- Training Programs: Attend training programs and workshops on EV diagnostics and repair.

- Online Resources: Utilize online resources, forums, and technical publications.

- Tool Updates: Keep diagnostic tools and software updated.

- Professional Certifications: Obtain certifications in EV diagnostics and repair.

- Industry Events: Attend industry events and conferences to network and learn about new technologies.

9.1 Importance of Continuous Learning

Why is continuous learning crucial for technicians working with electric vehicles?

Continuous learning is crucial because EV technology is constantly evolving. Staying updated with the latest advancements ensures technicians can accurately diagnose and repair these vehicles. According to a survey by the Electric Vehicle Training Alliance (EVTA), technicians who undergo regular training are 50% more efficient in diagnosing EV-related issues.

9.2 Utilizing Online Resources

What online resources are available for EV diagnostics and repair?

- Manufacturer Websites: Access technical information and service manuals.

- Online Forums: Participate in forums to exchange knowledge and experiences.

- Technical Publications: Read industry publications and research papers.

- Webinars and Online Courses: Take advantage of webinars and online courses to learn new skills.

9.3 Investing in Training Programs

What types of training programs are beneficial for EV technicians?

- Basic EV Training: Introductory courses covering EV fundamentals.

- Advanced Diagnostics: Courses focusing on advanced diagnostic techniques.

- High-Voltage Safety: Training on safe handling of high-voltage systems.

- Specific Vehicle Training: Courses tailored to specific EV models.

10. Frequently Asked Questions (FAQ)

1. What is the VCX SE diagnostic tool?

The VCX SE is an advanced diagnostic tool designed for comprehensive diagnostics of hybrid and electric vehicles, offering features like bidirectional control, real-time data monitoring, and specialized EV tests.

2. How does VCX SE help in checking the AC compressor in a hybrid/EV?

It provides specialized diagnostics for EV systems, including HVAC, allowing technicians to read diagnostic codes, perform bidirectional tests, and monitor real-time data to pinpoint AC compressor issues accurately.

3. What are the key features of the VCX SE tool?

Key features include specialized EV diagnostics, bidirectional control, real-time data monitoring, HVAC system tests, and compatibility with a wide range of EV and hybrid models.

4. What real-time data should I monitor when diagnosing an AC compressor?

Monitor compressor speed (RPM), voltage, current, refrigerant pressure, and temperature sensors to identify any performance deviations.

5. What common DTCs are related to electric AC compressors?

Common DTCs include B1490 (Inverter System Cooling Performance Problem), P0532 (AC Refrigerant Pressure Sensor Circuit Low), and B2AAA (HV Battery System).

6. How can bidirectional tests help in diagnosing AC compressor problems?

Bidirectional tests can confirm if the AC compressor and related components respond to commands, helping identify electrical or mechanical failures.

7. What are some advanced diagnostic tips for checking electric AC compressors?

Advanced tips include checking wiring and connections, verifying ground connections, using a multimeter, inspecting refrigerant lines, and testing sensors.

8. What maintenance practices are essential for electric AC compressors?

Essential practices include regular inspections, refrigerant level checks, cleaning, filter replacement, and software updates for the diagnostic tool.

9. How can technicians stay updated with the latest advancements in EV technology?

Technicians can stay updated by attending training programs, utilizing online resources, keeping tools updated, obtaining certifications, and attending industry events.

10. Where can I purchase the VCX SE diagnostic tool?

You can purchase the VCX SE diagnostic tool at CARDIAGTECH.BIZ.

11. Ready to Elevate Your Diagnostic Capabilities? Contact CARDIAGTECH.BIZ Today!

Are you ready to take your diagnostic skills to the next level and provide top-notch service for hybrid and electric vehicles? At CARDIAGTECH.BIZ, we understand the challenges you face in keeping up with the rapidly evolving EV technology. That’s why we offer the VCX SE diagnostic tool, designed to enhance your efficiency, accuracy, and overall service quality.

Don’t let outdated tools hold you back. Contact us today to learn more about how the VCX SE can transform your diagnostic capabilities. Our team of experts is ready to assist you with any questions and provide personalized support to meet your specific needs.

Why Choose CARDIAGTECH.BIZ?

- Expert Guidance: Our knowledgeable team offers expert advice and support.

- Top-Quality Products: We provide only the best diagnostic tools and equipment.

- Customer Satisfaction: Your satisfaction is our top priority.

Contact Information:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.BIZ

Take the first step towards mastering EV diagnostics. Contact CARDIAGTECH.BIZ now and revolutionize your approach to vehicle maintenance and repair!