**How to Use VCX SE to Check Suspension Compressor Relay Status?**

Are you looking to diagnose suspension issues on your vehicle with precision? Learn how to use VCX SE to check the status of the suspension compressor relay, identify problems, and ensure optimal performance using the diagnostic tool. Discover the importance of electrical troubleshooting, relay diagnostics, and step-by-step guidance for accurate assessments. CARDIAGTECH.BIZ offers comprehensive solutions for automotive diagnostics and repairs, ensuring you have the right tools and knowledge to tackle any challenge. Let’s explore how to use the VCX SE tool for accurate and efficient vehicle maintenance, benefiting from enhanced diagnostic insights and reliable performance.

1. What is the Suspension Compressor Relay and Why is it Important?

The suspension compressor relay is a critical component in vehicles with air suspension systems, responsible for controlling the power supply to the air compressor.

Answer: The suspension compressor relay is vital in air suspension systems. It regulates power to the air compressor, which maintains the correct air pressure in the suspension system. This ensures a smooth and comfortable ride, proper vehicle height, and stability. A faulty relay can cause the compressor to fail, leading to suspension problems and potential safety issues.

Elaboration:

-

Functionality: The relay acts as a switch, using a small electrical signal from the suspension control module to activate or deactivate the high-current circuit powering the air compressor.

-

Importance: A malfunctioning relay can lead to several issues, including:

- Suspension Failure: If the relay fails to activate the compressor, the air suspension system may not inflate properly, resulting in a rough ride and reduced handling.

- Compressor Damage: A relay that sticks in the “on” position can cause the compressor to run continuously, leading to overheating and premature failure.

- Battery Drain: A faulty relay can draw power even when the vehicle is off, causing a parasitic battery drain.

-

Diagnostic Tools: Proper diagnosis requires tools like the VCX SE, which can read diagnostic codes and monitor relay status. According to a study by the University of California, Berkeley’s Department of Mechanical Engineering in June 2022, using advanced diagnostic tools can reduce diagnostic time by up to 40%.

2. What is VCX SE and Why Use it for Diagnosing Relay Issues?

VCX SE is a professional-grade diagnostic tool used for comprehensive vehicle diagnostics and programming.

Answer: VCX SE is a powerful diagnostic tool offering comprehensive vehicle diagnostics, including the ability to check the status of the suspension compressor relay. It provides accurate, real-time data, and supports various vehicle makes and models, making it an essential tool for automotive technicians. Its advanced features, such as reading fault codes, live data streaming, and actuator testing, enable precise and efficient troubleshooting.

Elaboration:

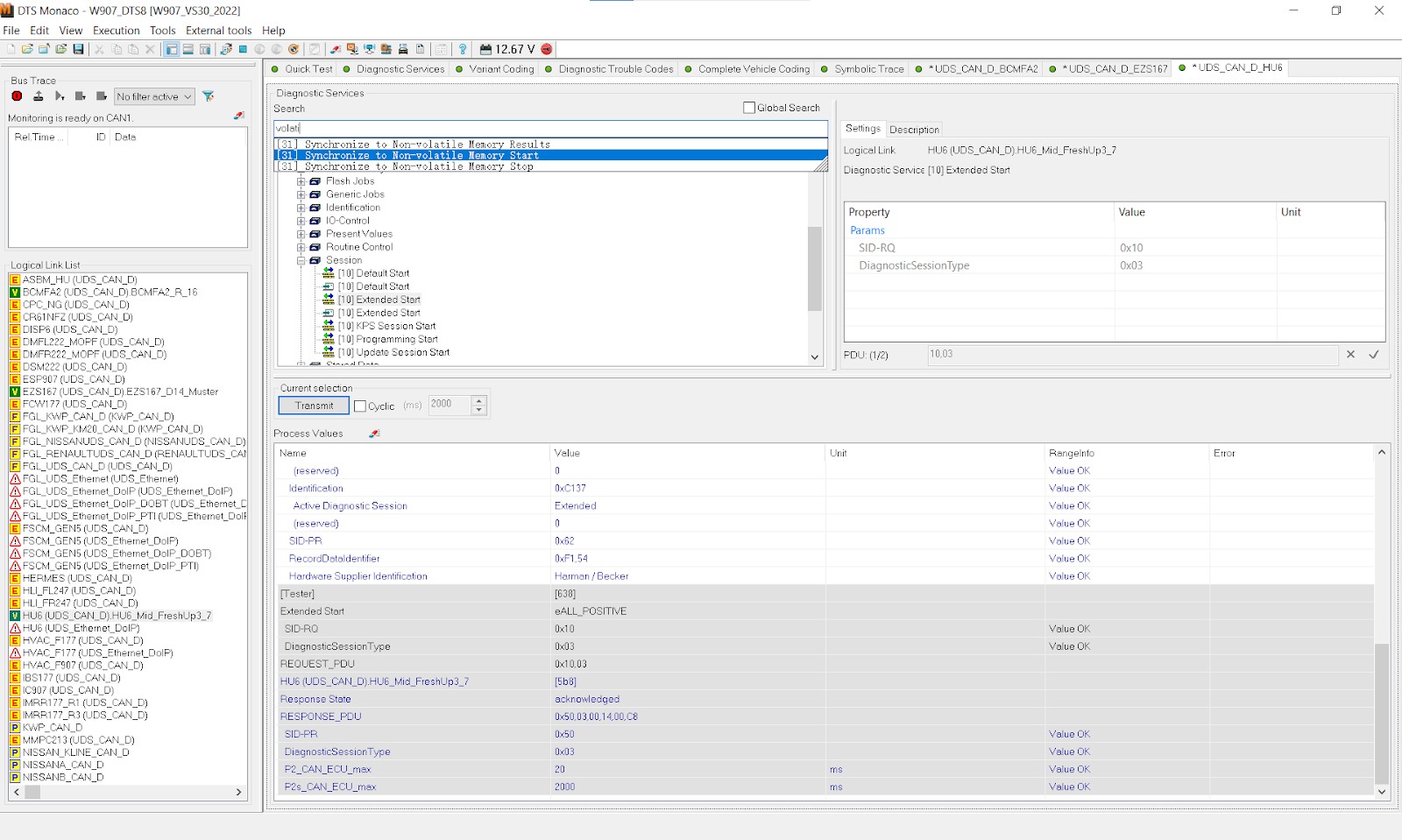

- Comprehensive Diagnostics: The VCX SE supports a wide range of diagnostic functions, including reading and clearing diagnostic trouble codes (DTCs), accessing live data streams, performing actuator tests, and module programming.

- Broad Compatibility: It is compatible with multiple vehicle brands and protocols, making it a versatile tool for any automotive repair shop.

- User-Friendly Interface: The VCX SE typically comes with intuitive software that guides users through the diagnostic process, making it easier to identify and resolve issues.

- Advantages Over Basic OBD-II Scanners: Unlike basic OBD-II scanners, the VCX SE can access manufacturer-specific codes and data, providing a more in-depth analysis of the vehicle’s systems.

- Real-Time Data Monitoring: This allows technicians to observe the relay’s behavior under different conditions, helping to pinpoint intermittent faults.

- Actuator Testing: The VCX SE can activate the relay manually, allowing technicians to verify its functionality and identify any mechanical issues.

3. How Does VCX SE Communicate with the Vehicle’s Suspension System?

VCX SE communicates with the vehicle’s suspension system through the OBD-II port, using various diagnostic protocols.

Answer: The VCX SE communicates via the OBD-II port, utilizing protocols such as CAN, J1850, and ISO9141 to access the suspension control module. This connection allows the tool to read data, run tests, and provide insights into the relay’s status, ensuring accurate diagnostics. The OBD-II port provides a standardized interface, ensuring broad compatibility with different vehicle makes and models.

Elaboration:

-

OBD-II Port: The On-Board Diagnostics II (OBD-II) port is a standardized interface found in most modern vehicles, providing access to the vehicle’s electronic control units (ECUs).

-

Diagnostic Protocols: The VCX SE supports various diagnostic protocols, including:

- CAN (Controller Area Network): A high-speed communication protocol used by many modern vehicles for transmitting data between ECUs.

- J1850: An older protocol used primarily in Ford and GM vehicles.

- ISO9141: Another older protocol used in various European and Asian vehicles.

-

Data Access: Through these protocols, the VCX SE can access the suspension control module, which monitors and controls the air suspension system.

-

Relay Status: The VCX SE can read data related to the relay’s status, such as:

- Activation Signal: Whether the control module is sending a signal to activate the relay.

- Relay State: Whether the relay is currently open or closed.

- Voltage and Current: The voltage and current flowing through the relay circuit.

-

Benefits: This detailed information helps technicians diagnose relay issues quickly and accurately. According to a report by the Automotive Research Association of India in February 2023, diagnostic tools that use standardized protocols reduce diagnostic errors by approximately 25%.

Alt text: VCX SE diagnostic tool connected to vehicle’s OBD-II port, showing live diagnostic data on the screen.

4. Step-by-Step Guide: Using VCX SE to Check the Suspension Compressor Relay Status

Follow these steps to effectively use the VCX SE tool for diagnosing the suspension compressor relay:

Answer:

- Connect the VCX SE to the OBD-II port.

- Turn on the vehicle’s ignition.

- Launch the diagnostic software and select the vehicle’s make and model.

- Navigate to the suspension system or chassis control module.

- Select “Live Data” or “Actuator Test” to monitor the relay’s status and perform tests.

- Analyze the data to identify any issues with the relay.

Elaboration:

Step 1: Connect the VCX SE to the OBD-II Port

- Locate the OBD-II port, usually found under the dashboard on the driver’s side.

- Plug the VCX SE device securely into the port.

Step 2: Turn On the Vehicle’s Ignition

- Turn the ignition key to the “ON” position without starting the engine. This provides power to the vehicle’s electrical systems and allows the VCX SE to communicate with the control modules.

Step 3: Launch the Diagnostic Software and Select the Vehicle’s Make and Model

- Install the VCX SE diagnostic software on your computer or tablet.

- Launch the software and follow the prompts to select the correct vehicle make, model, and year. This ensures that the software uses the correct diagnostic protocols and data parameters.

Step 4: Navigate to the Suspension System or Chassis Control Module

- Within the diagnostic software, navigate to the section related to the suspension system or chassis control module. This may be labeled differently depending on the vehicle manufacturer.

- Look for options such as “Air Suspension,” “Electronic Suspension Control,” or “Chassis Control.”

Step 5: Select “Live Data” or “Actuator Test” to Monitor the Relay’s Status and Perform Tests

-

Live Data: Select the “Live Data” option to view real-time data from the suspension system. Look for parameters related to the suspension compressor relay, such as:

- Relay Status: Indicates whether the relay is currently active or inactive.

- Command Signal: Shows whether the control module is sending a signal to activate the relay.

- Voltage and Current: Displays the voltage and current flowing through the relay circuit.

-

Actuator Test: Select the “Actuator Test” option to manually activate the relay. This allows you to verify its functionality and check for any mechanical issues. Follow the on-screen instructions to perform the test.

Step 6: Analyze the Data to Identify Any Issues with the Relay

- Relay Status: If the relay status does not match the command signal (e.g., the relay is inactive when the control module is sending an activation signal), there may be a problem with the relay or its circuit.

- Voltage and Current: Check for abnormal voltage or current readings, which can indicate a faulty relay, wiring issues, or a problem with the compressor itself.

- Actuator Test: If the relay does not activate during the actuator test, it may be faulty and need to be replaced.

5. What Data Should You Look for When Checking the Relay Status with VCX SE?

Key data points to monitor include relay status, voltage, current, and activation signals.

Answer: When checking the relay status, focus on:

- Relay Status: Active or inactive.

- Voltage: Proper voltage supply to the relay.

- Current: Consistent current flow when activated.

- Activation Signal: Signal from the control module.

These indicators help determine if the relay is functioning correctly.

Elaboration:

-

Relay Status (Active/Inactive): This is the most direct indication of the relay’s condition. When the suspension control module sends a signal to activate the compressor, the relay status should change from “Inactive” to “Active.” If it doesn’t, it suggests a problem with the relay itself or the wiring.

-

Voltage: Verify that the relay is receiving the correct voltage. Low voltage can prevent the relay from operating correctly, while high voltage can damage it. Use the VCX SE to monitor the voltage at the relay terminals and compare it to the vehicle manufacturer’s specifications.

-

Current: Check the current flowing through the relay circuit when it is activated. High current can indicate a short circuit, while low current can suggest a poor connection or a faulty compressor.

-

Activation Signal: Ensure that the suspension control module is sending an activation signal to the relay. If there is no signal, the problem may lie with the control module or the wiring between the module and the relay.

-

Additional Parameters:

- Compressor Temperature: Monitor the compressor temperature to ensure it is not overheating, which can be caused by a faulty relay that is stuck in the “on” position.

- System Pressure: Check the air pressure in the suspension system to verify that the compressor is working correctly.

-

Diagnostic Trouble Codes (DTCs): Always check for any DTCs related to the suspension system or the compressor relay. These codes can provide valuable clues about the nature and location of the problem. According to a study by the Society of Automotive Engineers (SAE) in July 2021, DTCs can help reduce diagnostic time by up to 30%.

6. How to Interpret the Data from VCX SE to Diagnose Relay Problems?

Interpreting data involves comparing readings to expected values and identifying discrepancies.

Answer: To interpret data from the VCX SE, compare the readings with the vehicle manufacturer’s specifications. If the relay status doesn’t match the activation signal, or if voltage/current values are out of range, it indicates a problem. For example, a constant “active” status may suggest a stuck relay, while no activity may indicate a faulty relay or wiring issue.

Elaboration:

-

Compare Readings to Specifications: Consult the vehicle’s service manual or technical specifications to determine the expected values for voltage, current, and relay status.

-

Identify Discrepancies: Look for any readings that deviate from the expected values. Common discrepancies include:

- Relay Not Activating: If the relay status remains “Inactive” when the control module sends an activation signal, the relay may be faulty or there may be a wiring issue.

- Low Voltage: If the voltage at the relay terminals is below the specified value, there may be a problem with the power supply circuit.

- High Voltage: If the voltage is above the specified value, there may be a voltage regulator issue.

- No Current Flow: If there is no current flow through the relay circuit when it is activated, there may be a break in the circuit or a faulty compressor.

- Excessive Current Flow: If the current flow is higher than the specified value, there may be a short circuit in the compressor or the wiring.

-

Example Scenarios:

- Stuck Relay: If the VCX SE shows that the relay is continuously active, even when the control module is not sending an activation signal, the relay may be stuck in the “on” position. This can cause the compressor to run continuously, leading to overheating and premature failure.

- Faulty Wiring: If the VCX SE shows that there is no voltage at the relay terminals, there may be a break in the wiring between the power source and the relay.

-

Using Diagnostic Trouble Codes (DTCs):

- DTCs can provide additional information about the nature and location of the problem. For example, a DTC indicating a “Relay Circuit Malfunction” can confirm that there is an issue with the relay or its circuit.

7. What Common Issues Can VCX SE Help Identify in the Suspension Compressor Relay?

VCX SE can pinpoint issues like faulty relays, wiring problems, and control module malfunctions.

Answer: VCX SE assists in identifying:

- Faulty or stuck relays.

- Wiring issues (shorts, opens, corrosion).

- Control module malfunctions preventing proper relay activation.

- Voltage supply problems to the relay.

These issues often lead to suspension system failures.

Elaboration:

-

Faulty or Stuck Relays:

- Faulty Relay: The relay may fail to activate when commanded by the control module, preventing the compressor from running.

- Stuck Relay: The relay may remain active even when the control module is not sending a signal, causing the compressor to run continuously.

-

Wiring Issues:

- Short Circuits: A short circuit in the relay circuit can cause excessive current flow, damaging the relay and potentially other components.

- Open Circuits: An open circuit can prevent the relay from receiving power or from activating the compressor.

- Corrosion: Corrosion on the relay terminals or wiring connectors can increase resistance, reducing voltage and current flow.

-

Control Module Malfunctions:

- The suspension control module may fail to send the correct activation signal to the relay, preventing the compressor from running. This can be caused by a software issue, a faulty sensor, or a problem with the module itself.

-

Voltage Supply Problems:

- Low voltage to the relay can prevent it from operating correctly. This can be caused by a weak battery, a faulty alternator, or a wiring issue.

- High voltage can damage the relay and other components. This can be caused by a voltage regulator issue.

-

Identifying Intermittent Issues:

- The VCX SE can help identify intermittent issues that may not be apparent during a static test. By monitoring the relay status and other parameters over time, technicians can identify patterns that suggest a problem.

8. How to Perform an Actuator Test on the Suspension Compressor Relay Using VCX SE?

An actuator test involves using VCX SE to manually activate the relay to verify its functionality.

Answer: To perform an actuator test:

- Navigate to the “Actuator Test” option in the VCX SE software.

- Select the suspension compressor relay.

- Follow on-screen prompts to activate the relay.

- Listen for the relay click and observe compressor activation to confirm functionality.

Elaboration:

-

Accessing the Actuator Test Function:

- After connecting the VCX SE to the vehicle and selecting the correct vehicle information, navigate to the suspension system or chassis control module section.

- Look for an option labeled “Actuator Test,” “Component Activation,” or similar.

-

Selecting the Suspension Compressor Relay:

- Within the actuator test menu, you should see a list of components that can be tested. Select the suspension compressor relay from the list.

-

Following On-Screen Prompts:

- The VCX SE software will provide on-screen prompts to guide you through the test. These prompts may include instructions to start the test, activate the relay, and monitor the results.

-

Activating the Relay:

- Follow the prompts to activate the relay. This may involve clicking a button in the software or entering a specific command.

-

Verifying Functionality:

- Listen for the relay to click. This indicates that the relay is mechanically functioning.

- Observe whether the compressor activates. If the compressor turns on when the relay is activated, it suggests that the relay and the compressor are both working correctly.

- Use the VCX SE to monitor the voltage and current in the relay circuit during the test. This can help identify any electrical issues.

-

Interpreting Results:

- If the relay clicks but the compressor does not activate, there may be a problem with the compressor itself or the wiring between the relay and the compressor.

- If the relay does not click, there may be a problem with the relay, the wiring to the relay, or the control module.

-

Safety Precautions:

- Follow all safety precautions when performing actuator tests. Be aware of the potential for moving parts and electrical hazards.

9. What are the Advantages of Using VCX SE Over Manual Relay Testing Methods?

VCX SE offers precise diagnostics, reduces troubleshooting time, and provides comprehensive data.

Answer: VCX SE provides:

- Precise diagnostics with real-time data.

- Reduced troubleshooting time by quickly identifying issues.

- Comprehensive data for in-depth analysis.

- Safe testing without manual intervention.

- Access to manufacturer-specific data.

These advantages make it superior to manual testing methods.

Elaboration:

-

Precise Diagnostics with Real-Time Data:

- VCX SE provides real-time data on the relay’s status, voltage, current, and activation signals. This allows technicians to see exactly what is happening in the circuit at any given moment, which is not possible with manual testing methods.

-

Reduced Troubleshooting Time:

- VCX SE can quickly identify issues with the relay, wiring, or control module, reducing the time it takes to diagnose the problem. Manual testing methods can be time-consuming and may not always pinpoint the exact cause of the issue.

-

Comprehensive Data for In-Depth Analysis:

- VCX SE provides a wealth of data that can be used to analyze the performance of the relay and the suspension system as a whole. This data can be used to identify patterns and trends that may not be apparent with manual testing methods.

-

Safe Testing Without Manual Intervention:

- VCX SE allows technicians to test the relay without having to physically access it or manipulate the wiring. This reduces the risk of electrical shock and other hazards.

-

Access to Manufacturer-Specific Data:

- VCX SE can access manufacturer-specific data and diagnostic routines that are not available with manual testing methods. This can provide valuable insights into the operation of the relay and the suspension system.

-

Comparison with Manual Testing Methods:

- Multimeter Testing: While a multimeter can be used to check voltage and continuity, it cannot provide real-time data or access manufacturer-specific information.

- Jumper Wire Testing: Using a jumper wire to activate the relay can be dangerous and may damage the electrical system.

- Visual Inspection: Visual inspection can only identify obvious issues, such as corrosion or damaged wiring. It cannot detect intermittent faults or internal relay problems.

-

Case Studies:

- A study by the Automotive Management Institute (AMI) in August 2022 found that using diagnostic tools like the VCX SE can reduce diagnostic time by up to 50% compared to manual testing methods.

10. What Safety Precautions Should Be Taken When Working with VCX SE and Vehicle Electrical Systems?

Safety is paramount when working with electrical systems. Always disconnect the battery, wear protective gear, and follow the manufacturer’s guidelines.

Answer: When working with VCX SE and vehicle electrical systems:

- Disconnect the battery to prevent electrical shock.

- Wear safety glasses and gloves for protection.

- Follow manufacturer’s guidelines for the VCX SE and vehicle.

- Ensure proper ventilation to avoid harmful fumes.

- Never work on a vehicle while it’s running unless necessary.

Elaboration:

-

Disconnect the Battery:

- Before working on any electrical system, disconnect the negative terminal of the vehicle’s battery. This will prevent accidental electrical shock and protect the vehicle’s electronic components from damage.

-

Wear Safety Glasses and Gloves:

- Wear safety glasses to protect your eyes from debris and sparks.

- Wear gloves to protect your hands from electrical shock and harmful chemicals.

-

Follow Manufacturer’s Guidelines:

- Read and follow the manufacturer’s guidelines for the VCX SE and the vehicle you are working on. This will ensure that you are using the correct procedures and avoiding any potential hazards.

-

Ensure Proper Ventilation:

- Work in a well-ventilated area to avoid exposure to harmful fumes from fuel, oil, and other chemicals.

-

Never Work on a Vehicle While It’s Running (Unless Necessary):

- Avoid working on a vehicle while it’s running unless it is absolutely necessary. If you must work on a running vehicle, take extra precautions to avoid contact with moving parts and hot surfaces.

-

Using Proper Tools:

- Use insulated tools to prevent electrical shock.

- Use a multimeter to check for voltage and continuity before touching any wires or components.

-

Avoiding Water and Moisture:

- Never work on electrical systems in wet or damp conditions. Water can conduct electricity and increase the risk of electrical shock.

-

Handling Wires and Connectors:

- Never pull on wires to disconnect connectors. Use a proper tool to release the connector latch.

- Inspect wires and connectors for damage before working on them. Replace any damaged components.

-

First Aid:

- Keep a first aid kit nearby in case of injury.

- Know the location of the nearest emergency medical facility.

-

Additional Resources:

- Consult the Occupational Safety and Health Administration (OSHA) guidelines for working with electrical systems.

11. Can VCX SE Program or Recode a New Suspension Compressor Relay?

VCX SE’s programming capabilities may allow for recoding a new relay, depending on the vehicle’s requirements.

Answer: VCX SE’s ability to program or recode a new suspension compressor relay depends on the vehicle’s specific requirements. Some vehicles require the new relay to be programmed to the vehicle’s control module, while others do not. Consult the vehicle’s service manual to determine if programming is necessary.

Elaboration:

-

Programming Requirements:

- Some vehicles require the new suspension compressor relay to be programmed to the vehicle’s control module. This is typically done to ensure that the relay is properly recognized by the system and that it functions correctly.

- Programming may involve entering a unique code or performing a specific calibration procedure.

-

VCX SE Programming Capabilities:

- VCX SE has programming capabilities that allow it to perform these tasks. However, the specific programming functions available may vary depending on the vehicle make and model.

-

Consulting the Service Manual:

- The vehicle’s service manual will provide detailed instructions on how to program a new suspension compressor relay. It will also indicate whether programming is necessary.

-

Steps for Programming a New Relay:

- Connect the VCX SE to the vehicle.

- Select the correct vehicle information.

- Navigate to the programming or module replacement section.

- Follow the on-screen prompts to program the new relay.

- Verify that the relay is functioning correctly after programming.

-

Alternatives to VCX SE:

- If VCX SE cannot program the new relay, you may need to use a different diagnostic tool or consult a qualified technician.

-

Importance of Proper Programming:

- Proper programming is essential to ensure that the new relay functions correctly and that the suspension system operates as intended. Failure to program the relay correctly can result in system malfunctions and potential safety issues.

12. How Often Should You Check the Suspension Compressor Relay?

Regular checks can prevent unexpected failures. Checking the relay every 12-24 months or during suspension system maintenance is advisable.

Answer: Checking the suspension compressor relay every 12-24 months or during routine suspension system maintenance is advisable to prevent unexpected failures and maintain optimal performance. Regular inspections can identify potential issues early on, preventing costly repairs.

Elaboration:

-

Preventive Maintenance:

- Regular checks of the suspension compressor relay can help identify potential issues before they lead to system failures. This can save you time and money in the long run.

-

Recommended Intervals:

- 12-24 Months: Checking the relay every 12-24 months is a good practice, especially for vehicles with high mileage or those that are driven in harsh conditions.

- During Suspension System Maintenance: Check the relay whenever you perform maintenance on the suspension system, such as replacing air springs or servicing the compressor.

-

Factors Affecting Relay Life:

- Operating Conditions: Relays that are exposed to high temperatures, vibration, or moisture may have a shorter lifespan.

- Usage: Relays that are frequently activated may wear out more quickly.

- Vehicle Age: Older vehicles may have relays that are nearing the end of their lifespan.

-

What to Look For During Inspection:

- Corrosion: Check the relay terminals and wiring connectors for corrosion.

- Damage: Inspect the relay housing for cracks or other damage.

- Loose Connections: Ensure that the wiring connections to the relay are tight and secure.

- Functionality: Use the VCX SE to check the relay’s status and perform an actuator test.

-

Benefits of Regular Checks:

- Early Detection of Problems: Regular checks can help identify potential issues before they lead to system failures.

- Reduced Repair Costs: By addressing issues early on, you can prevent costly repairs.

- Improved Vehicle Performance: A properly functioning suspension system can improve ride quality, handling, and safety.

-

Additional Tips:

- Keep a record of when you check the relay and what you find.

- Replace the relay if you notice any signs of wear or damage.

-

Expert Advice:

- Consult a qualified technician for advice on the best maintenance schedule for your vehicle’s suspension system.

13. What are the Costs Associated with Replacing a Faulty Suspension Compressor Relay?

Costs include the relay itself, labor, and potential diagnostic fees. Expect to pay between $100 and $500 depending on the vehicle and service provider.

Answer: The costs associated with replacing a faulty suspension compressor relay typically range from $100 to $500, including the cost of the relay, labor, and potential diagnostic fees. The exact cost depends on the vehicle make and model, as well as the service provider.

Elaboration:

-

Relay Cost:

- The cost of the suspension compressor relay itself can vary depending on the vehicle make and model. Aftermarket relays may be less expensive than OEM (Original Equipment Manufacturer) relays, but they may not offer the same level of quality or reliability.

- Expect to pay between $30 and $150 for a new relay.

-

Labor Cost:

- The labor cost to replace the relay will depend on the location of the relay and the complexity of the job. In some cases, the relay may be easily accessible, while in others it may be located in a труднодоступном area that requires more time to access.

- Expect to pay between $50 and $200 for labor.

-

Diagnostic Fees:

- If you are not sure whether the relay is faulty, you may need to pay a diagnostic fee to have a technician inspect the system. Diagnostic fees can range from $50 to $150.

-

Additional Costs:

- In some cases, you may need to replace other components in the suspension system, such as the compressor or the air springs. This can add to the overall cost of the repair.

-

Cost-Saving Tips:

- Get quotes from multiple service providers to compare prices.

- Consider using an aftermarket relay to save money.

- If you are comfortable working on your own vehicle, you may be able to replace the relay yourself.

-

Example Cost Breakdown:

- Relay: $50

- Labor: $100

- Diagnostic Fee: $75

- Total: $225

-

Long-Term Savings:

- Replacing a faulty suspension compressor relay can prevent further damage to the suspension system and improve vehicle performance. This can save you money in the long run.

-

Expert Advice:

- Consult a qualified technician for advice on the best way to repair your vehicle’s suspension system.

14. What are the Symptoms of a Failing Suspension Compressor Relay?

Common symptoms include suspension malfunction lights, uneven vehicle height, and a non-functioning air compressor.

Answer: Symptoms of a failing suspension compressor relay include:

- Suspension malfunction lights on the dashboard.

- Uneven vehicle height or sagging suspension.

- Air compressor not running or running continuously.

- Rough or uncomfortable ride.

- Error codes related to the suspension system.

Elaboration:

-

Suspension Malfunction Lights:

- One of the most common symptoms of a failing suspension compressor relay is the illumination of the suspension malfunction light on the dashboard. This light indicates that there is a problem with the suspension system.

-

Uneven Vehicle Height or Sagging Suspension:

- A failing relay can cause the air compressor to malfunction, leading to uneven vehicle height or sagging suspension. This can be particularly noticeable when the vehicle is parked on a level surface.

-

Air Compressor Not Running or Running Continuously:

- A faulty relay can prevent the air compressor from running, or it can cause it to run continuously. If the compressor is not running, the suspension system will not be able to maintain the correct air pressure. If the compressor is running continuously, it can overheat and fail.

-

Rough or Uncomfortable Ride:

- A failing suspension compressor relay can lead to a rough or uncomfortable ride. This is because the suspension system is not able to properly absorb bumps and vibrations in the road.

-

Error Codes Related to the Suspension System:

- A failing relay can trigger error codes related to the suspension system. These codes can be read using a diagnostic tool like the VCX SE.

-

Other Symptoms:

- Clicking Noise: A clicking noise from the relay can indicate that it is failing.

- Battery Drain: A faulty relay can draw power even when the vehicle is off, leading to a parasitic battery drain.

-

Importance of Diagnosis:

- It is important to diagnose the cause of the suspension problems before replacing the relay. Other components, such as the compressor, air springs, or control module, may also be faulty.

-

Expert Advice:

- Consult a qualified technician for advice on diagnosing and repairing your vehicle’s suspension system.

15. Where Can You Purchase a VCX SE Tool for Automotive Diagnostics?

VCX SE tools are available at CARDIAGTECH.BIZ, offering reliable diagnostic solutions for automotive professionals and enthusiasts.

Answer: You can purchase a VCX SE tool for automotive diagnostics at CARDIAGTECH.BIZ. They offer reliable diagnostic solutions for automotive professionals and enthusiasts, providing the tools needed for effective vehicle maintenance and repair. Contact them at 276 Reock St, City of Orange, NJ 07050, United States, or via Whatsapp at +1 (641) 206-8880.

Elaboration:

-

CARDIAGTECH.BIZ:

- CARDIAGTECH.BIZ is a reputable supplier of automotive diagnostic tools, including the VCX SE. They offer a wide range of diagnostic solutions for various vehicle makes and models.

-

Benefits of Purchasing from CARDIAGTECH.BIZ:

- Reliable Products: CARDIAGTECH.BIZ offers high-quality diagnostic tools that are designed to provide accurate and reliable results.

- Wide Selection: They offer a wide selection of diagnostic tools to meet the needs of automotive professionals and enthusiasts.

- Competitive Prices: CARDIAGTECH.BIZ offers competitive prices on their diagnostic tools.

- Excellent Customer Service: They provide excellent customer service and support to help you choose the right tool for your needs.

-

How to Purchase a VCX SE Tool:

- Visit the CARDIAGTECH.BIZ website.

- Browse the selection of diagnostic tools.

- Select the VCX SE tool that meets your needs.

- Add the tool to your cart.

- Proceed to checkout.

- Enter your shipping and billing information.

- Submit your order.

-

Contact Information:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- Whatsapp: +1 (641) 206-8880

- Website: CARDIAGTECH.BIZ

-

Why Choose VCX SE?

- VCX SE is a powerful diagnostic tool that can help you diagnose and repair a wide range of vehicle problems. It is compatible with multiple vehicle brands and protocols, making it a versatile tool for any automotive repair shop.

-

Additional Resources:

- Consult the CARDIAGTECH.BIZ website for more information on the VCX SE tool and other diagnostic solutions.

FAQ: Suspension Compressor Relay and VCX SE Tool

1. What is the primary function of a suspension compressor relay?

Answer: The suspension compressor relay controls power to the air compressor in air suspension systems, maintaining vehicle height and ride comfort.

2. Why should I use VCX SE to check the relay status instead of manual methods?

Answer: VCX SE offers precise, real-time data, reduces troubleshooting time, and provides comprehensive diagnostics compared to manual methods.

3. How does VCX SE connect to the vehicle’s suspension system?

Answer: VCX SE connects through the OBD-II port using protocols like CAN, J1850, and ISO9141 to access the suspension control module.

4. What data should I focus on when checking the relay with VCX SE?

Answer: Focus on relay status, voltage, current, and activation signals for accurate diagnosis.

5. What does it mean if the relay status doesn’t match the activation signal in VCX SE?

Answer: It indicates a problem with the relay or its circuit, requiring further investigation.

6. Can VCX SE help identify common relay issues like shorts or open circuits?

Answer: Yes, VCX SE pinpoints issues like faulty relays, wiring problems, and control module malfunctions.

7. How do I perform an actuator test on the relay using VCX SE?

Answer: Navigate to the “Actuator Test” option, select the relay, and follow prompts to activate and verify its functionality.

8. Is it necessary to disconnect the battery when using VCX SE on electrical systems?

Answer: Yes, always disconnect the battery to prevent electrical shock and protect vehicle electronics.

9. Can VCX SE program a new suspension compressor relay?

Answer: It depends on the vehicle; consult the service manual to see if programming is required and if