Explain The Term “DTC” (Diagnostic Trouble Code) in Automotive Repair

Are you puzzled by the term “DTC” and what it means for your vehicle’s health? A Diagnostic Trouble Code, or DTC, is essentially your car’s way of communicating potential problems it’s experiencing, and CARDIAGTECH.NET is here to help you understand them. We’ll break down these codes, explain how to interpret them, and show you how the right tools can make all the difference in diagnosing and resolving automotive issues. By understanding DTCs, you’ll be empowered to maintain your vehicle effectively and prevent costly repairs, optimizing your vehicle’s performance and longevity. Explore the world of automotive diagnostics with us, and unlock the power of informed vehicle maintenance and diagnostics software, OBD-II scanners, and vehicle diagnostic tools.

1. What is a DTC (Diagnostic Trouble Code)?

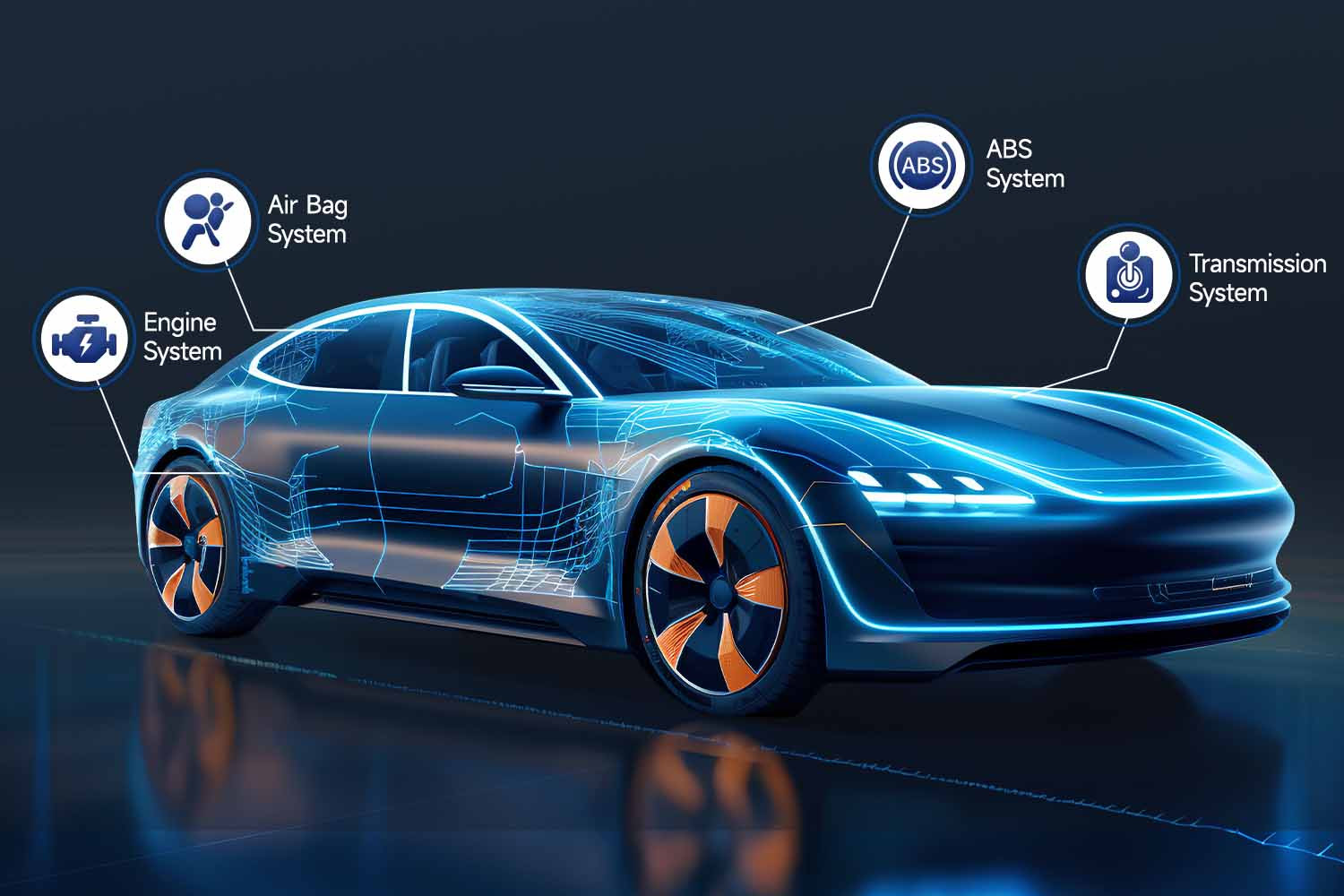

A Diagnostic Trouble Code (DTC) is a standardized code generated by a vehicle’s onboard computer system, known as the On-Board Diagnostics (OBD) system, to indicate a malfunction or issue within the vehicle. According to the Society of Automotive Engineers (SAE), these codes help technicians identify and address problems efficiently. When your vehicle’s check engine light illuminates, it’s often due to a DTC being triggered.

1.1. The Role of DTCs in Vehicle Diagnostics

DTCs act as a critical bridge between your vehicle’s internal systems and the mechanics who work on it. They provide a specific, standardized way for the car to communicate what’s wrong, streamlining the diagnostic process.

- Efficiency: DTCs reduce the time it takes to diagnose a problem, enabling quicker repairs.

- Accuracy: By pointing to the exact issue, they minimize guesswork and prevent unnecessary repairs.

- Standardization: DTCs ensure that mechanics across different regions can understand and address the same problem in a consistent manner.

1.2. The Structure of a DTC

DTCs typically consist of a five-character alphanumeric code, each component of which provides specific information about the issue.

- First Character: Indicates the system affected (e.g., Powertrain, Chassis, Body, Network).

- Second Character: Specifies whether the code is generic (standardized across all manufacturers) or manufacturer-specific.

- Third Character: Denotes the subsystem related to the fault.

- Fourth and Fifth Characters: Provide a specific fault index, pinpointing the exact nature of the malfunction.

1.3. OBD-II vs. J1939 Standards

Vehicles use different standards for DTCs based on their class and purpose.

- OBD-II: Commonly used in light and medium-duty vehicles (6,000 to 26,000 lbs), OBD-II codes are mandated for all vehicles sold in the United States after January 1, 1996.

- J1939: Used in heavy-duty vehicles (26,001 to over 33,000 lbs), such as buses, trucks, and heavy equipment.

Knowing which standard applies to your vehicle is crucial for accurate diagnostics. If unsure, consult your vehicle’s user manual.

1.4. Decoding the Check Engine Light with DTCs

That ominous check engine light on your dashboard is more than just a warning; it’s an invitation to investigate further with the help of DTCs. Here’s how DTCs make decoding the check engine light more manageable:

- Pinpointing the Problem: By retrieving the DTC, you’re essentially getting a direct clue from your car about what’s amiss. Instead of guessing, you have a specific code that relates to a particular system or component.

- Informed Decisions: With the DTC in hand, you can research the code’s meaning and understand the severity of the issue. This knowledge empowers you to make informed decisions about whether to address the problem immediately or schedule a repair for a later date.

- Clear Communication with Mechanics: When you bring your car in for service, providing the DTC to the mechanic allows them to quickly focus on the relevant area, saving time and potentially reducing diagnostic costs.

1.5. From Code to Cure: How DTCs Streamline the Repair Process

Beyond just identifying the problem, DTCs play a vital role in streamlining the entire repair process, making it more efficient and effective for both mechanics and car owners.

- Faster Diagnostics: Armed with the DTC, mechanics can skip the initial guesswork and head straight to the system or component indicated by the code. This speeds up the diagnostic process significantly, allowing for quicker identification of the underlying issue.

- Targeted Repairs: DTCs help mechanics perform targeted repairs, focusing only on the parts or systems that are actually malfunctioning. This minimizes unnecessary work and ensures that only the required components are replaced, saving you money on labor and parts.

- Verification of Repairs: After completing the repair, mechanics can use the OBD-II scanner to clear the DTC and verify that the issue has been resolved. If the code doesn’t reappear, it confirms that the repair was successful.

Diagnostic Trouble Codes Structure

Diagnostic Trouble Codes Structure

1.6. Telematics Systems and Remote DTC Access

Modern telematics systems enhance DTC management, allowing fleet managers to receive real-time alerts whenever a vehicle generates a DTC. According to a study by the American Transportation Research Institute, proactive maintenance based on telematics data can reduce maintenance costs by up to 27%.

2. Interpreting OBD-II DTC Codes

Understanding how to interpret OBD-II DTC codes is essential for diagnosing vehicle issues effectively. Each character in the five-character code provides crucial information about the problem.

2.1. Decoding the First Character

The first character of an OBD-II DTC code indicates the system affected.

- P (Powertrain): Relates to the engine, transmission, drivetrain, and fuel system.

- C (Chassis): Involves mechanical systems outside the passenger compartment, such as steering, suspension, and braking.

- B (Body): Pertains to parts found in the passenger compartment area.

- U (Network): Signifies issues with the vehicle’s onboard computers and integration functions managed by the OBD.

2.2. Understanding the Second Character

The second character indicates whether the code is generic or manufacturer-specific.

- 0: A standard SAE international code, applicable to all OBD-II compliant vehicles.

- 1: A code specific to the car’s make or model, requiring manufacturer-specific information for interpretation.

2.3. Interpreting the Third Character

If the second character is “0,” the third character identifies the specific subsystem malfunctioning.

- 0: Fuel and air metering and auxiliary emission controls.

- 1: Fuel and air metering injection system.

- 2: Fuel and air metering (injection system).

- 3: Ignition systems or misfires.

- 4: Auxiliary emission controls.

- 5: Vehicle speed control, idle control systems, and auxiliary inputs.

- 6: Computer output circuit.

- 7-8: Transmission.

2.4. Identifying the Specific Fault Index

The fourth and fifth characters, ranging from 0 to 99, represent the “Specific Fault Index,” which identifies the exact malfunction. For example, in the code P0420:

- P: Powertrain issue.

- 0: Standard OBD-II code.

- 4: Auxiliary emission controls malfunction.

- 20: Problem with the vehicle’s catalytic converter.

2.5. Practical Example: Decoding P0420

Let’s break down the common DTC code P0420 to illustrate how these components work together:

- P – Powertrain: This indicates that the issue lies within the powertrain system, which includes the engine, transmission, and related components.

- 0 – Generic Code: The “0” signifies that this is a generic code, meaning it applies to all OBD-II compliant vehicles.

- 4 – Emission Control System: The “4” points to a problem within the emission control system, responsible for reducing harmful pollutants released into the atmosphere.

- 20 – Catalytic Converter Efficiency: The “20” narrows down the issue to the catalytic converter, specifically its efficiency. In this case, it suggests that the catalytic converter is not functioning optimally.

When you encounter a P0420 code, it’s likely that your vehicle’s catalytic converter is not efficiently converting pollutants as it should. This could be due to a variety of factors, such as a faulty oxygen sensor, exhaust leaks, or a degraded catalytic converter.

2.6. Common OBD-II DTCs and Their Meanings

| DTC | Description | Potential Causes |

|---|---|---|

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty MAF sensor, fuel pump issue, clogged fuel filter |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, low compression |

| P0401 | Exhaust Gas Recirculation (EGR) Flow Insufficient Detected | Clogged EGR valve or tube, faulty EGR valve, faulty differential pressure sensor |

| P0420 | Catalytic Converter System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, faulty oxygen sensors, engine misfires |

| P0442 | Evaporative Emission Control System Leak Detected (Small Leak) | Loose or damaged fuel cap, cracked or damaged fuel tank, faulty purge valve, damaged or disconnected vapor lines |

| P0455 | Evaporative Emission Control System Leak Detected (Gross Leak) | Missing or loose fuel cap, damaged fuel filler neck, cracked or punctured fuel tank, faulty vent valve, damaged vapor lines |

| P0505 | Idle Air Control System Malfunction | Faulty idle air control valve, vacuum leaks, carbon buildup in the throttle body |

2.7. Advanced Diagnostics: Beyond the Basics of DTC Interpretation

While understanding the individual components of a DTC is crucial, mastering advanced diagnostic techniques can take your troubleshooting skills to the next level. Here’s what advanced diagnostics entails:

- Data Logging and Analysis: Modern OBD-II scanners and software offer data logging capabilities, allowing you to record real-time data from various sensors and systems. By analyzing this data, you can identify patterns, trends, and anomalies that may not be apparent from a static DTC.

- Oscilloscope Testing: An oscilloscope is a powerful tool that allows you to visualize electrical signals from sensors and actuators. By interpreting these waveforms, you can diagnose issues with components like oxygen sensors, fuel injectors, and ignition coils.

- Advanced Scan Tool Functions: Many advanced scan tools offer features like bidirectional controls, which allow you to activate or deactivate specific components to test their functionality. This can be invaluable for diagnosing issues with systems like ABS, traction control, and electronic throttle control.

2.8. The Importance of Continuous Learning in Automotive Diagnostics

The automotive industry is constantly evolving, with new technologies and systems being introduced regularly. To stay ahead of the curve, it’s essential to commit to continuous learning and professional development.

- Stay Updated with Industry Trends: Subscribe to automotive publications, attend industry conferences, and follow reputable online resources to stay informed about the latest technologies and diagnostic techniques.

- Invest in Training and Certification: Consider pursuing advanced training programs and certifications, such as those offered by the National Institute for Automotive Service Excellence (ASE). These credentials demonstrate your expertise and commitment to excellence.

- Join Online Communities and Forums: Engage with other automotive professionals in online communities and forums. Share your experiences, ask questions, and learn from the collective knowledge of the group.

2.9. How CARDIAGTECH.NET Enhances Your DTC Interpretation Skills

CARDIAGTECH.NET provides an array of tools and resources designed to enhance your ability to interpret and address DTCs effectively.

- Advanced Diagnostic Tools: We offer state-of-the-art OBD-II scanners and diagnostic software that provide detailed DTC descriptions, probable causes, and repair procedures.

- Comprehensive Training Materials: Our website features a library of articles, videos, and tutorials covering various aspects of DTC interpretation and automotive diagnostics.

- Expert Support: Our team of experienced technicians is available to provide guidance and support, helping you navigate complex diagnostic challenges.

By leveraging the resources available at CARDIAGTECH.NET, you can deepen your understanding of DTCs and become a more proficient automotive diagnostician.

3. Interpreting J1939 DTC Codes

J1939 is the standard for heavy-duty vehicles, and its DTCs have a different structure than OBD-II codes.

3.1. Understanding the J1939 Structure

A J1939 code consists of four fields:

- Suspect Parameter Number (SPN): A diagnostic fault code assigned by the SAE to a specific part or electric subsystem, helping technicians locate the problem.

- Failure Mode Identifier (FMI): Identifies the type of error, such as sensor short-circuits or calibration errors.

- Occurrence Counter (OC): Indicates how many times an error has occurred.

- SPN Conversion Method (CM): Defines the byte alignment within the DTC and indicates how SPN and FMI should be handled.

3.2. The Significance of SPN and FMI

The Suspect Parameter Number (SPN) and Failure Mode Identifier (FMI) are the core components of a J1939 DTC, providing crucial information about the nature and location of the fault.

- Suspect Parameter Number (SPN): This is a numeric code that identifies the specific component or system that is experiencing the issue. Each SPN corresponds to a particular sensor, actuator, or electronic control unit (ECU) within the vehicle.

- Failure Mode Identifier (FMI): This code describes the type of fault that has occurred with the identified component or system. It could indicate a short circuit, open circuit, out-of-range value, or other abnormal condition.

3.3. Practical Example: Decoding a J1939 Code

Let’s consider an example of a J1939 DTC with the following values:

- SPN: 108 (Engine Coolant Temperature)

- FMI: 4 (Signal Low)

In this case, the SPN indicates that the issue is related to the engine coolant temperature sensor, while the FMI suggests that the signal from the sensor is too low. This could be due to a faulty sensor, a wiring issue, or a problem with the ECU.

3.4. Real-World Applications of J1939 DTCs in Fleet Management

J1939 DTCs play a vital role in fleet management, enabling fleet managers to proactively monitor the health of their heavy-duty vehicles and prevent costly breakdowns. Here are some real-world applications of J1939 DTCs in fleet management:

- Remote Diagnostics: With telematics systems that support J1939, fleet managers can remotely access DTCs from their vehicles in real-time. This allows them to identify potential issues before they escalate into major problems.

- Predictive Maintenance: By analyzing historical J1939 DTC data, fleet managers can identify patterns and trends that may indicate the need for preventative maintenance. This helps them schedule maintenance tasks proactively, reducing the risk of unexpected downtime.

- Driver Alerts: Telematics systems can be configured to send alerts to drivers when certain J1939 DTCs are triggered. This allows drivers to take immediate action, such as pulling over to the side of the road or contacting maintenance personnel.

3.5. Tools and Technologies for J1939 DTC Interpretation

Interpreting J1939 DTCs requires specialized tools and technologies that are designed to handle the complexities of heavy-duty vehicle diagnostics. Here are some of the key tools and technologies used for J1939 DTC interpretation:

- J1939 Scan Tools: These are handheld devices that connect to the vehicle’s diagnostic port and allow technicians to read J1939 DTCs, view real-time data, and perform diagnostic tests.

- Telematics Systems: These systems use GPS tracking and cellular communication to transmit J1939 DTC data from the vehicle to a central server. Fleet managers can then access this data through a web-based interface.

- Diagnostic Software: This software provides detailed information about J1939 DTCs, including their potential causes, troubleshooting steps, and repair procedures.

3.6. The Role of Telematics in J1939 Code Management

Telematics devices connected to a vehicle’s J1939 port can transmit fuel usage and emissions data over broadband to a computer. They also provide real-time preventative maintenance alerts and engine fault information. According to a study by Frost & Sullivan, telematics solutions can reduce vehicle downtime by up to 20%.

3.7. Expert Insights: Tips for Effective J1939 Troubleshooting

Troubleshooting J1939 DTCs can be a complex process, requiring a deep understanding of heavy-duty vehicle systems and diagnostic techniques. Here are some tips from industry experts to help you effectively troubleshoot J1939 DTCs:

- Start with the Basics: Before diving into advanced diagnostics, always start by checking the basics, such as fluid levels, wiring connections, and sensor functionality.

- Use OEM Information: Consult the vehicle manufacturer’s service information for detailed troubleshooting procedures and diagnostic tips.

- Verify the Fault: Before replacing any components, always verify that the fault is actually present by performing diagnostic tests and checking for related symptoms.

- Document Your Work: Keep a detailed record of your diagnostic process, including the DTCs you encountered, the tests you performed, and the components you replaced.

3.8. Benefits of Choosing CARDIAGTECH.NET for J1939 Solutions

CARDIAGTECH.NET is your trusted partner for all your J1939 diagnostic needs. We offer a comprehensive range of solutions designed to help you effectively interpret and troubleshoot J1939 DTCs.

- Wide Selection of J1939 Tools: We offer a wide selection of J1939 scan tools, telematics systems, and diagnostic software from leading manufacturers.

- Expert Support: Our team of experienced technicians is available to provide technical support and guidance, helping you navigate complex J1939 diagnostic challenges.

- Competitive Pricing: We offer competitive pricing on all our J1939 solutions, ensuring that you get the best value for your investment.

3.9. Future Trends in J1939 Diagnostics and Technology

The field of J1939 diagnostics and technology is constantly evolving, with new advancements emerging regularly. Here are some of the key trends that are shaping the future of J1939 diagnostics:

- Wireless Diagnostics: Wireless scan tools and telematics systems are becoming increasingly popular, allowing technicians to diagnose J1939 DTCs from anywhere in the shop or in the field.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms are enabling remote access to J1939 DTC data and diagnostic tools, facilitating collaboration between technicians and remote experts.

- Artificial Intelligence (AI): AI-powered diagnostic systems are being developed to automatically analyze J1939 DTC data and provide technicians with intelligent recommendations for troubleshooting and repair.

By staying informed about these emerging trends, you can ensure that you’re well-equipped to handle the J1939 diagnostic challenges of the future.

3.10. Connecting J1939 Diagnostics to CARDIAGTECH.NET Solutions

CARDIAGTECH.NET is at the forefront of providing advanced diagnostic solutions, including those tailored for J1939 protocols. We offer a suite of tools and services designed to streamline the diagnostic process for heavy-duty vehicles, making it easier than ever to manage and maintain your fleet.

- Real-Time J1939 Data Monitoring: Our telematics solutions allow for real-time monitoring of J1939 data, enabling fleet managers to quickly identify and address potential issues. This proactive approach helps prevent breakdowns and minimizes downtime.

- Comprehensive Diagnostic Reporting: CARDIAGTECH.NET’s diagnostic software generates detailed reports based on J1939 data, providing valuable insights into the health and performance of your vehicles. These reports can be used to optimize maintenance schedules and improve overall fleet efficiency.

- Remote Diagnostics and Support: Our remote diagnostic capabilities enable technicians to access J1939 data from anywhere, allowing for faster and more efficient troubleshooting. This reduces the need for on-site visits and minimizes repair costs.

By integrating CARDIAGTECH.NET’s J1939 solutions into your fleet management strategy, you can enhance your diagnostic capabilities, reduce maintenance costs, and improve the overall performance of your heavy-duty vehicles.

4. Clearing a DTC Code

Clearing a DTC code should only be done after addressing the underlying issue. If you clear a code without fixing the problem, the check engine light will likely reappear.

4.1. Using a Code Reader

- Connect an OBD-II scanner to the diagnostic port, usually located below the steering wheel.

- Turn on the ignition without starting the engine.

- Press the ‘Read’ or ‘Scan’ button to access the DTC code.

- After fixing the issue, use the scanner to clear the code.

4.2. Understanding Permanent DTCs

Permanent DTCs cannot be cleared using a scanner or by disconnecting the battery. These codes clear automatically once the vehicle’s onboard system no longer detects the issue after the problem has been resolved.

4.3. Why You Shouldn’t Ignore DTCs

Ignoring a DTC can lead to a cascade of problems, affecting everything from fuel efficiency to engine performance. Here’s why addressing DTCs promptly is crucial:

- Preventing Further Damage: Ignoring a DTC can allow a minor issue to snowball into a major problem, potentially causing significant damage to your vehicle’s engine or other systems.

- Maintaining Fuel Efficiency: Many DTCs relate to issues that can negatively impact fuel efficiency, such as a faulty oxygen sensor or a vacuum leak. Addressing these issues promptly can help you save money at the pump.

- Ensuring Vehicle Safety: Some DTCs indicate problems that could compromise vehicle safety, such as a malfunctioning brake system or a faulty airbag. Addressing these issues is essential to protect yourself and your passengers.

4.4. Safe Practices for Clearing DTCs

While clearing a DTC can be a useful diagnostic step, it’s important to follow safe practices to avoid unintended consequences. Here are some guidelines to keep in mind:

- Only Clear DTCs After Repair: As mentioned earlier, only clear DTCs after you’ve addressed the underlying issue. Clearing a DTC without fixing the problem will only mask the symptom, allowing the problem to persist and potentially worsen.

- Document the DTC: Before clearing a DTC, make a note of the code and its description. This will help you track the issue and ensure that it doesn’t reappear.

- Monitor Vehicle Performance: After clearing a DTC, monitor your vehicle’s performance closely. If the check engine light comes back on or you notice any unusual symptoms, have your vehicle inspected by a qualified mechanic.

4.5. When to Seek Professional Help

While you can clear many DTCs yourself, there are certain situations where it’s best to seek professional help from a qualified mechanic. Here are some scenarios where professional assistance is recommended:

- Complex DTCs: If you encounter a DTC that you don’t understand or that requires specialized diagnostic equipment, it’s best to consult a mechanic.

- Recurring DTCs: If a DTC reappears shortly after being cleared, it indicates a persistent problem that needs professional attention.

- Safety-Related DTCs: If you encounter a DTC that relates to a safety-critical system, such as brakes, airbags, or steering, have your vehicle inspected by a mechanic immediately.

4.6. How CARDIAGTECH.NET Supports Your DTC Management

CARDIAGTECH.NET provides the tools and knowledge necessary to effectively manage and clear DTCs. We offer a range of OBD-II scanners and diagnostic software to help you identify and resolve vehicle issues.

- Diagnostic Tools: Our selection of OBD-II scanners enables you to read and clear DTCs quickly and easily.

- Educational Resources: We offer comprehensive resources to help you understand the meaning of different DTCs and how to address them effectively.

- Expert Support: Our team of experienced technicians is available to provide guidance and support, helping you navigate complex diagnostic challenges.

4.7. Navigating the World of Automotive Repairs

When it comes to automotive repairs, knowledge is power. The more you understand about your vehicle and its systems, the better equipped you’ll be to make informed decisions about maintenance and repairs.

- Research Repair Costs: Before taking your vehicle to a mechanic, research the typical cost of the repair. This will help you avoid being overcharged and ensure that you’re getting a fair price.

- Get Multiple Quotes: Get quotes from multiple mechanics before authorizing any repairs. This will allow you to compare prices and services and choose the option that best meets your needs.

- Ask Questions: Don’t be afraid to ask your mechanic questions about the repair process. A reputable mechanic will be happy to explain the issue and the steps they’re taking to fix it.

- Review the Invoice: Before paying the invoice, review it carefully to ensure that you’re only being charged for the work that was authorized. If you have any questions or concerns, discuss them with the mechanic.

4.8. Why CARDIAGTECH.NET is Your Go-To Resource for Automotive Expertise

CARDIAGTECH.NET is more than just a provider of diagnostic tools; we’re your go-to resource for all things automotive. We’re committed to empowering you with the knowledge, tools, and support you need to keep your vehicle running smoothly and safely.

- Comprehensive Product Range: We offer a wide range of diagnostic tools, scan tools, and automotive accessories from leading manufacturers.

- Expert Guidance: Our team of experienced technicians is available to provide expert guidance and support, helping you navigate complex automotive challenges.

- Commitment to Customer Satisfaction: We’re committed to providing exceptional customer service and ensuring that you’re completely satisfied with your purchase.

4.9. Connecting DTC Management to Long-Term Vehicle Health

Effective DTC management is not just about addressing immediate issues; it’s about investing in the long-term health and reliability of your vehicle. By proactively monitoring DTCs, addressing potential problems early, and following safe practices for clearing codes, you can extend the life of your vehicle and avoid costly repairs down the road.

- Preventive Maintenance: Use DTCs as a tool for preventive maintenance. By monitoring DTC trends and addressing potential problems early, you can prevent minor issues from escalating into major repairs.

- Regular Inspections: Schedule regular inspections with a qualified mechanic to identify potential problems before they trigger DTCs. This can help you catch issues early and prevent costly repairs.

- Proper Vehicle Care: Follow the manufacturer’s recommendations for vehicle care, including regular oil changes, fluid checks, and tire rotations. This will help keep your vehicle running smoothly and prevent premature wear and tear.

By adopting a proactive approach to DTC management and vehicle care, you can ensure that your vehicle remains reliable, efficient, and safe for years to come.

5. Managing DTC Codes for an Expanding Fleet

For fleet managers, monitoring DTC codes across multiple vehicles can be challenging. A telematics system simplifies this process.

5.1. Setting Up Alerts

Set up alerts to notify you when a vehicle triggers a DTC. These alerts should include the DTC code and a description of the issue, enabling quick assessment and action.

5.2. Automating Fleet Maintenance

Use a telematics system to schedule maintenance reminders based on mileage and hours of use. This helps maintain vehicles proactively, extending their lifespan and reducing downtime.

5.3. Creating DTC Reports

Generate on-demand reports across your entire fleet to identify trends, such as parts that wear out faster. This allows for proactive repairs and prevents minor issues from escalating.

5.4. The Challenges of Fleet Maintenance

Managing a fleet of vehicles presents unique challenges, particularly when it comes to maintenance. Fleet managers face a complex set of responsibilities, including:

- Ensuring Vehicle Safety: Maintaining a safe fleet is paramount. Fleet managers must ensure that all vehicles are in good working order and meet safety standards.

- Minimizing Downtime: Downtime can be costly for fleet operators. Fleet managers must strive to minimize downtime by proactively addressing maintenance issues.

- Controlling Costs: Fleet maintenance can be a significant expense. Fleet managers must find ways to control costs without compromising safety or reliability.

- Tracking Maintenance Records: Keeping accurate maintenance records is essential for fleet management. Fleet managers must track all maintenance activities for each vehicle in the fleet.

5.5. Leveraging Telematics for Enhanced Fleet Maintenance

Telematics systems offer a powerful solution for addressing the challenges of fleet maintenance. By leveraging telematics technology, fleet managers can gain real-time visibility into the health and performance of their vehicles, enabling them to proactively address maintenance issues and optimize fleet operations.

- Remote Diagnostics: Telematics systems can remotely access DTCs and other diagnostic data from vehicles, allowing fleet managers to identify potential problems before they escalate.

- Predictive Maintenance: By analyzing historical data, telematics systems can predict when maintenance will be required, allowing fleet managers to schedule maintenance tasks proactively.

- Automated Alerts: Telematics systems can send automated alerts to fleet managers when certain DTCs are triggered or when maintenance is due, ensuring that issues are addressed promptly.

- Improved Maintenance Scheduling: Telematics systems can optimize maintenance schedules based on vehicle usage and operating conditions, ensuring that maintenance tasks are performed at the right time.

5.6. Real-World Success Stories: How Telematics Transforms Fleet Management

The benefits of telematics for fleet maintenance are not just theoretical; they’re supported by real-world success stories. Here are a few examples of how telematics has transformed fleet management for organizations around the world:

- Reduced Downtime: A major trucking company reduced downtime by 20% by using telematics to proactively identify and address maintenance issues.

- Lower Maintenance Costs: A construction company reduced maintenance costs by 15% by using telematics to optimize maintenance schedules and prevent breakdowns.

- Improved Safety: A transportation company improved safety by using telematics to monitor vehicle performance and driver behavior, identifying potential safety hazards.

5.7. Proactive Maintenance Strategies for Fleet Vehicles

In the realm of fleet management, proactive maintenance stands as a cornerstone for ensuring the longevity, safety, and operational efficiency of vehicles. Unlike reactive maintenance, which addresses issues as they arise, proactive maintenance involves implementing a strategic, forward-thinking approach to vehicle care.

- Regular Inspections: Conducting regular inspections is fundamental to proactive maintenance. These inspections should encompass a comprehensive assessment of various vehicle components and systems, including brakes, tires, lights, fluids, and safety equipment.

- Fluid Analysis: Regular fluid analysis offers valuable insights into the condition of critical engine and transmission components. By analyzing oil, coolant, and other fluids, potential issues can be detected early on, preventing costly damage and downtime.

- Tire Management: Proper tire management is essential for ensuring vehicle safety, fuel efficiency, and optimal performance. Fleet managers should implement a tire maintenance program that includes regular inspections, rotations, and pressure checks.

- Preventive Replacements: Instead of waiting for components to fail, proactive maintenance involves replacing wear items on a predetermined schedule. This approach minimizes the risk of breakdowns and ensures that vehicles remain in optimal operating condition.

5.8. Cost-Effective Fleet Management Techniques

Effective fleet management hinges on implementing strategies that not only optimize vehicle performance but also minimize operational costs. With rising fuel prices, maintenance expenses, and regulatory requirements, fleet managers must adopt innovative techniques to ensure cost-effectiveness.

- Fuel Efficiency Programs: Fuel costs represent a significant portion of fleet operating expenses. Implementing fuel efficiency programs can help reduce fuel consumption and lower overall costs.

- Driver Training: Investing in driver training can yield significant cost savings. Well-trained drivers are more likely to operate vehicles safely, efficiently, and responsibly.

- Route Optimization: Efficient route planning can minimize mileage, reduce fuel consumption, and lower wear and tear on vehicles. Fleet managers should leverage route optimization software to identify the most efficient routes for their drivers.

- Negotiated Vendor Contracts: Negotiating favorable contracts with vendors, such as fuel suppliers, maintenance providers, and insurance companies, can result in significant cost savings. Fleet managers should regularly review vendor contracts and explore opportunities for cost reduction.

5.9. How CARDIAGTECH.NET Streamlines Fleet Diagnostics and Maintenance

CARDIAGTECH.NET offers a comprehensive suite of tools and services designed to streamline fleet diagnostics and maintenance, empowering fleet managers to enhance efficiency, reduce costs, and improve overall fleet performance.

- Advanced Diagnostic Tools: Our advanced diagnostic tools enable fleet managers to remotely access DTCs, monitor vehicle health, and diagnose potential issues in real-time.

- Automated Maintenance Scheduling: Our telematics solutions automate maintenance scheduling based on vehicle usage, mileage, and operating conditions, ensuring that maintenance tasks are performed at the right time.

- Comprehensive Reporting: We provide comprehensive reporting on vehicle health, maintenance activities, and diagnostic data, giving fleet managers valuable insights into fleet performance.

- Expert Support: Our team of experienced technicians is available to provide expert support and guidance, helping fleet managers navigate complex diagnostic and maintenance challenges.

5.10. Partner with CARDIAGTECH.NET for Comprehensive Fleet Management

CARDIAGTECH.NET is dedicated to providing comprehensive fleet management solutions that empower businesses to optimize their operations, reduce costs, and improve overall performance. We offer a range of tools and services designed to address the unique challenges of fleet management, including remote diagnostics, automated maintenance scheduling, and comprehensive reporting.

- Customized Solutions: We work closely with our clients to develop customized solutions that meet their specific needs and requirements.

- Dedicated Support: Our dedicated support team is available to provide expert guidance and assistance, ensuring that our clients get the most out of our solutions.

- Continuous Innovation: We are committed to continuous innovation, constantly developing new and improved solutions to meet the evolving needs of the fleet management industry.

Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or call us at +1 (641) 206-8880 to learn more about how we can help you optimize your fleet management operations. Visit our website at CARDIAGTECH.NET for more information. Our innovative diagnostic tools, including OBD-II scanners and vehicle diagnostic tools, are designed to keep your fleet running smoothly and efficiently. Let us help you take your fleet management to the next level with our advanced diagnostic solutions and maintenance software.

Conclusion

Understanding DTC codes is essential for effective vehicle maintenance and diagnostics. Whether you are dealing with OBD-II codes in light-duty vehicles or J1939 codes in heavy-duty trucks, knowing how to interpret these codes can save you time and money.

CARDIAGTECH.NET offers the tools and resources you need to manage DTC codes effectively, from handheld scanners to comprehensive telematics systems. Contact us today at 276 Reock St, City of Orange, NJ 07050, United States or call us at +1 (641) 206-8880 for a free consultation, and let us help you keep your vehicle or fleet running smoothly. Visit our website at CARDIAGTECH.NET for more information on our range of automotive diagnostic tools and maintenance solutions, including advanced diagnostics software.

Ready to take control of your vehicle’s diagnostics? Contact CARDIAGTECH.NET today via WhatsApp at +1 (641) 206-8880, and let our experts guide you toward the best diagnostic tools for your needs. We are located at 276 Reock St, City of Orange, NJ 07050, United States, and our website, CARDIAGTECH.NET, offers a wide array of OBD-II scanners, vehicle diagnostic tools, and maintenance solutions designed to keep you ahead of any automotive issues. Don’t wait for the check engine light to ruin your day; connect with us now and ensure your vehicle’s peak performance and longevity.

FAQ: Diagnostic Trouble Codes (DTCs)

1. What is a Diagnostic Trouble Code (DTC)?

A Diagnostic Trouble Code (DTC)