**How to Create a Diagnostic Report in Xentry: A Comprehensive Guide**

Creating a diagnostic report in Xentry is essential for automotive technicians. CARDIAGTECH.NET provides you a guide on how to do just that along with diagnostic tools that will keep your customers happy and your shop running efficiently. By understanding the nuances of Xentry, you can streamline your diagnostic process, improve accuracy, and enhance customer satisfaction.

1. What is Xentry and Why is it Important?

Xentry is the official diagnostic software used for Mercedes-Benz vehicles. It allows technicians to perform in-depth diagnostics, programming, and maintenance on these vehicles. Xentry is crucial due to its comprehensive access to vehicle systems, enabling precise fault identification and effective repairs.

1.1 The Role of Xentry in Modern Automotive Diagnostics

Xentry stands as the cornerstone of modern automotive diagnostics for Mercedes-Benz vehicles. Its importance stems from several key factors:

- Comprehensive System Access: Xentry provides unparalleled access to all electronic control units (ECUs) within a Mercedes-Benz vehicle.

- Accurate Fault Identification: The software’s advanced diagnostic capabilities enable technicians to pinpoint faults with remarkable accuracy.

- Efficient Repair Processes: By quickly identifying the root cause of issues, Xentry streamlines the repair process, saving time and resources.

- Software Updates and Programming: Xentry facilitates the updating and programming of ECUs, ensuring vehicles operate with the latest software versions and configurations.

- Adaptations and Calibrations: The tool allows for necessary adaptations and calibrations after component replacements, maintaining optimal vehicle performance.

- Data Logging and Analysis: Xentry can log and analyze real-time data, helping technicians diagnose intermittent issues and performance anomalies.

- Integration with Workshop Systems: Its seamless integration with other workshop systems enhances overall efficiency and data management.

1.2 Benefits of Using Xentry for Diagnostics

Utilizing Xentry for diagnostics provides a multitude of benefits for automotive technicians and repair shops:

- Enhanced Diagnostic Accuracy: Xentry’s detailed diagnostic capabilities minimize guesswork and reduce the chances of misdiagnosis.

- Increased Efficiency: The software’s intuitive interface and comprehensive access to vehicle systems speed up the diagnostic process.

- Cost Savings: By accurately identifying faults and streamlining repairs, Xentry helps reduce unnecessary part replacements and labor costs.

- Improved Customer Satisfaction: Faster and more accurate diagnostics lead to quicker turnaround times and higher customer satisfaction.

- Access to Latest Vehicle Data: Xentry ensures technicians have access to the most up-to-date vehicle data and diagnostic protocols.

- Comprehensive Vehicle Coverage: The software covers a wide range of Mercedes-Benz models, making it a versatile tool for any repair shop.

- Support for Advanced Functions: Xentry supports advanced functions such as ECU programming, SCN coding, and variant coding.

2. Understanding the Key Components of Xentry

To effectively use Xentry, it’s important to understand its key components:

- Xentry Diagnosis: The core module for diagnosing vehicle faults.

- DAS (Diagnostic Assistance System): An older system that Xentry has largely replaced, but understanding its legacy can be helpful.

- WIS (Workshop Information System): Provides repair instructions, wiring diagrams, and other technical information.

- ASRA (Arbeitstexte, Standardtexte, Richtzeiten, und Ausrüstung): A database of repair times, standard texts, and equipment information.

- Vediamo: Engineering software used for advanced programming and modifications (use with caution).

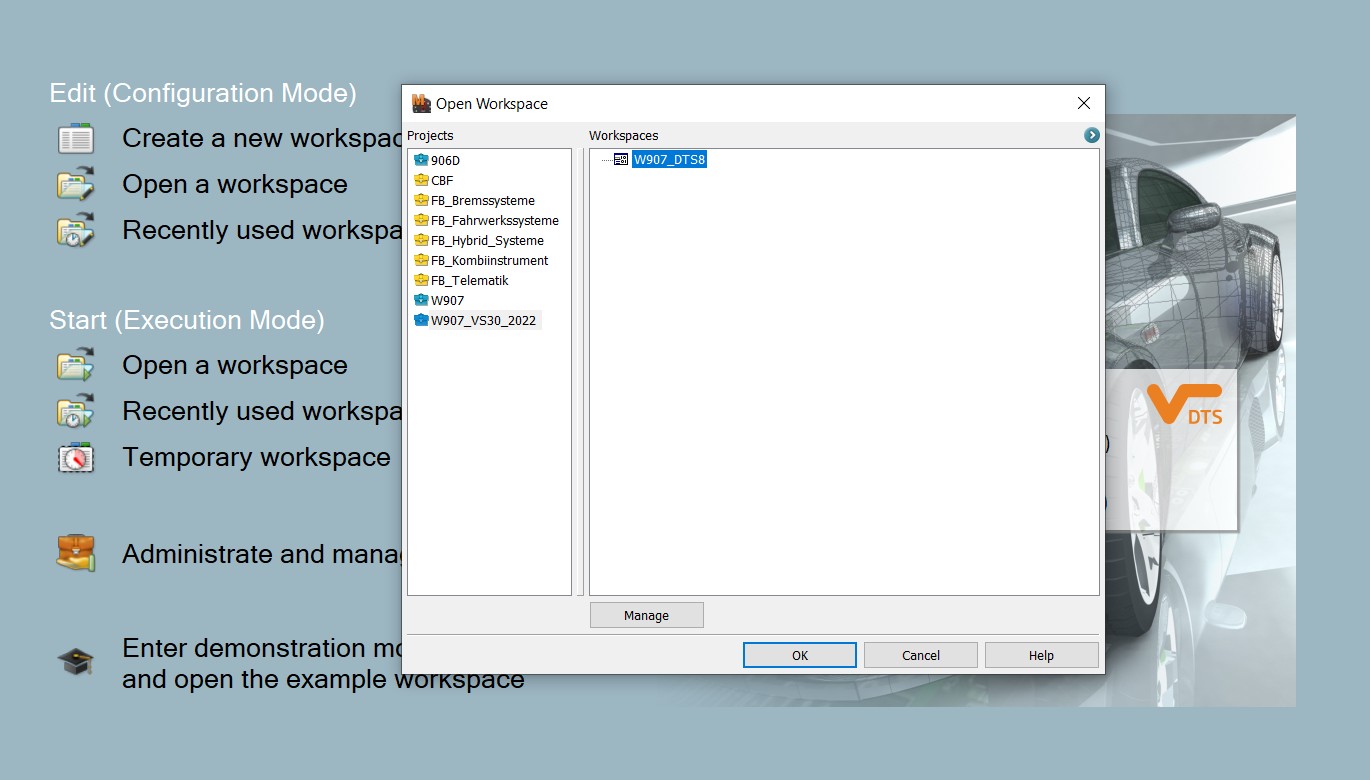

- DTS Monaco: Another engineering tool, similar to Vediamo, used for advanced diagnostics and modifications.

2.1 Navigating the Xentry Interface

Navigating the Xentry interface efficiently is crucial for maximizing its diagnostic capabilities.

- Main Menu: The starting point for all diagnostic operations.

- Vehicle Selection: Allows technicians to accurately identify the vehicle being diagnosed.

- Quick Tests: Provides a rapid overview of the vehicle’s system status.

- Control Unit Diagnostics: Enables in-depth examination of individual ECUs.

- Fault Memory: Displays stored fault codes and related information.

- Guided Tests: Offers step-by-step instructions for diagnosing specific issues.

- Variant Coding: Allows customization of vehicle settings and parameters.

- Flash Programming: Facilitates software updates and ECU programming.

- Data Logging: Records real-time data for detailed analysis.

- Actuations: Activates components for testing purposes.

2.2 Essential Hardware and Software Requirements

To run Xentry effectively, specific hardware and software requirements must be met:

- Operating System: Windows 10 or Windows 11 (64-bit) is recommended.

- Processor: Intel Core i5 or higher.

- RAM: 8 GB or more.

- Hard Drive: 256 GB SSD or larger.

- Diagnostic Interface: Xentry Connect or a compatible interface.

- Software Subscription: Valid Xentry software license and updates.

- Internet Connection: Required for software updates, online functions, and accessing WIS/ASRA.

- Security Software: Anti-virus and firewall to protect the diagnostic system.

3. Step-by-Step Guide to Creating a Diagnostic Report

Creating a comprehensive diagnostic report in Xentry involves several key steps:

- Vehicle Identification: Accurately identify the vehicle using VIN or manual selection.

- Quick Test: Perform a quick test to get an overview of the vehicle’s system status.

- Fault Code Reading: Read and record all stored fault codes.

- Fault Code Analysis: Analyze the fault codes to understand the underlying issues.

- Guided Tests: Use guided tests for specific fault codes to pinpoint the root cause.

- Data Logging: Log relevant data to analyze intermittent issues or performance anomalies.

- Component Testing: Perform component testing using actuations to verify functionality.

- Repair and Verification: Carry out necessary repairs and verify their effectiveness.

- Variant Coding/Programming: Perform variant coding or programming if required.

- Final Test: Conduct a final quick test to ensure all issues are resolved.

- Report Generation: Generate a detailed diagnostic report.

3.1 Connecting to the Vehicle with Xentry

Establishing a reliable connection to the vehicle is the first critical step in the diagnostic process. Here’s how to do it:

- Physical Connection: Connect the Xentry diagnostic interface to the vehicle’s OBD-II port.

- Interface Setup: Ensure the diagnostic interface is properly configured and recognized by the Xentry software.

- Vehicle Selection: In Xentry, manually enter the Vehicle Identification Number (VIN) or allow the system to automatically detect it. Verify the vehicle details to ensure accuracy.

- Ignition Check: Confirm that the vehicle’s ignition is switched on.

- Communication Test: Initiate a communication test within Xentry to verify data exchange between the software and the vehicle’s ECUs.

A stable connection is crucial for accurate diagnostics. Errors in this step can lead to misinterpretations and incorrect fault identification.

3.2 Performing a Quick Test and Reading Fault Codes

Once connected, performing a Quick Test is essential to get a snapshot of the vehicle’s health. Here’s how:

- Initiate Quick Test: In Xentry, select the “Quick Test” option from the main menu.

- System Scan: Allow Xentry to scan all accessible electronic control units (ECUs) in the vehicle.

- Review Results: Examine the Quick Test results, noting any fault codes and their descriptions.

- Fault Code Details: For each fault code, record the code number, description, and status (e.g., current, stored).

- Print or Save: Save or print the Quick Test results for further analysis and documentation.

This step provides a comprehensive overview of potential issues. Analyzing the fault codes will guide subsequent diagnostic steps.

3.3 Analyzing Fault Codes and Using Guided Tests

After reading the fault codes, thorough analysis and the use of Guided Tests are vital for accurate diagnosis:

- Fault Code Research: Use Xentry’s built-in information or WIS (Workshop Information System) to research each fault code, understanding potential causes and related symptoms.

- Prioritization: Prioritize fault codes based on severity and relevance to the vehicle’s symptoms.

- Guided Test Selection: For each fault code, use Xentry to access the Guided Test function. These tests provide step-by-step instructions for diagnosing the issue.

- Follow Instructions: Carefully follow the instructions provided in the Guided Test, performing each step accurately.

- Record Results: Document the results of each test, including measured values, component responses, and any deviations from expected values.

- Interpret Results: Use the test results to narrow down the potential causes of the fault.

- Component Testing: Conduct further component testing as directed by the Guided Test or based on your analysis.

Guided Tests are designed to streamline the diagnostic process, providing clear, actionable steps to identify the root cause of the fault.

3.4 Performing Component Testing and Actuations

Component testing and actuations are crucial for verifying the functionality of individual components and systems:

- Access Actuations: In Xentry, navigate to the component or system you want to test and access the actuation menu.

- Select Test: Choose the appropriate test or actuation for the component.

- Follow Instructions: Follow the on-screen instructions, paying attention to any warnings or safety precautions.

- Observe Response: Observe the component’s response to the actuation, noting any unusual behavior or deviations from expected operation.

- Measure Values: Use a multimeter or oscilloscope to measure relevant electrical values, such as voltage, current, and resistance.

- Record Results: Document the results of each test, including the component’s response, measured values, and any observed issues.

- Interpret Results: Use the test results to determine whether the component is functioning correctly.

Component testing and actuations help isolate faults and confirm the proper operation of individual parts, ensuring accurate diagnoses and effective repairs.

3.5 Data Logging for Intermittent Issues

Data logging is invaluable for diagnosing intermittent issues that may not be present during a static diagnostic test:

- Select Parameters: In Xentry, choose the parameters you want to monitor, focusing on those relevant to the suspected issue.

- Start Logging: Start the data logging function and drive the vehicle under conditions that typically trigger the intermittent problem.

- Monitor Data: Continuously monitor the logged data, looking for anomalies or deviations from expected values.

- Analyze Data: After the logging session, analyze the recorded data using Xentry’s graphing and analysis tools.

- Identify Patterns: Look for patterns or correlations in the data that may indicate the cause of the intermittent issue.

- Record Findings: Document your findings, including any anomalies, patterns, or correlations.

Data logging provides a dynamic view of the vehicle’s operation, helping to uncover issues that are difficult to diagnose through static testing.

3.6 Generating the Diagnostic Report

Once the diagnostic process is complete, generating a comprehensive report is essential for documentation and communication:

- Review Data: Review all the data collected during the diagnostic process, including fault codes, Guided Test results, component test results, and data logging findings.

- Summarize Findings: Summarize the key findings of your diagnostic investigation, including the identified faults and their root causes.

- Include Recommendations: Provide clear recommendations for repairs, component replacements, or other corrective actions.

- Generate Report: Use Xentry’s report generation function to create a detailed diagnostic report.

- Review Report: Carefully review the report to ensure it is accurate and complete.

- Save and Print: Save the report electronically and print a copy for your records and for the customer.

A well-prepared diagnostic report provides a clear and concise summary of the vehicle’s issues, the diagnostic process, and the recommended solutions.

4. Advanced Xentry Functions for Complex Diagnostics

For complex diagnostic scenarios, Xentry offers advanced functions such as ECU programming, SCN coding, and variant coding.

4.1 ECU Programming and Software Updates

ECU programming and software updates are critical for ensuring optimal vehicle performance and addressing software-related issues:

- Check for Updates: Use Xentry to check for available software updates for the vehicle’s ECUs.

- Backup Data: Before programming, back up the existing ECU data to prevent data loss.

- Follow Instructions: Carefully follow the on-screen instructions provided by Xentry for the programming process.

- Maintain Power: Ensure a stable power supply to the vehicle during programming to prevent interruptions.

- Verify Success: After programming, verify that the process was successful and that the ECU is functioning correctly.

- Test Systems: Test all relevant vehicle systems to ensure they are working as expected.

ECU programming can resolve a variety of issues, including software glitches, performance problems, and compatibility issues.

4.2 SCN Coding for Component Replacement

SCN (Software Calibration Number) coding is necessary when replacing certain components to ensure they are properly integrated with the vehicle’s systems:

- Identify Requirement: Determine if SCN coding is required for the component you are replacing.

- Connect to Server: Connect to the Mercedes-Benz online server through Xentry.

- Follow Instructions: Follow the on-screen instructions to perform SCN coding.

- Enter Data: Enter any required data, such as the new component’s serial number.

- Verify Success: Verify that the SCN coding process was successful and that the new component is functioning correctly.

- Test Systems: Test all relevant vehicle systems to ensure they are working as expected with the new component.

SCN coding ensures that replacement components are properly calibrated and synchronized with the vehicle’s other systems.

4.3 Variant Coding for Customization

Variant coding allows technicians to customize certain vehicle settings and parameters to meet specific customer needs or preferences:

- Access Variant Coding: In Xentry, access the variant coding menu for the relevant ECU.

- Identify Options: Identify the available coding options and their potential effects.

- Make Changes: Make the desired changes to the vehicle’s settings.

- Verify Compatibility: Verify that the changes are compatible with the vehicle’s other systems.

- Test Systems: Test all relevant vehicle systems to ensure they are working as expected with the new settings.

Variant coding can be used to customize a variety of features, such as lighting, comfort settings, and driver assistance systems.

5. Tips and Tricks for Efficient Xentry Diagnostics

To maximize your efficiency with Xentry, consider these tips and tricks:

- Keep Software Updated: Regularly update your Xentry software to ensure you have the latest features and diagnostic data.

- Use a Fast Computer: Use a computer with a fast processor and plenty of RAM to ensure smooth performance.

- Stable Internet Connection: Maintain a stable internet connection for accessing online functions and data.

- Learn Keyboard Shortcuts: Learn and use keyboard shortcuts to speed up common tasks.

- Customize Interface: Customize the Xentry interface to suit your preferences and workflow.

- Regular Training: Attend regular training courses to stay up-to-date on the latest Xentry features and diagnostic techniques.

- Utilize WIS/ASRA: Make full use of the WIS (Workshop Information System) and ASRA (Arbeitstexte, Standardtexte, Richtzeiten, und Ausrüstung) databases for repair information and labor times.

5.1 Common Mistakes to Avoid

Avoiding common mistakes is crucial for ensuring accurate and efficient diagnostics:

- Incorrect Vehicle Identification: Always double-check the vehicle identification to ensure you are working with the correct data.

- Ignoring Fault Code Descriptions: Read and understand the fault code descriptions before proceeding with diagnostics.

- Skipping Guided Tests: Use Guided Tests whenever available to streamline the diagnostic process.

- Neglecting Component Testing: Perform component testing to verify the functionality of individual parts.

- Failing to Backup Data: Always back up ECU data before performing programming or coding.

- Ignoring Power Supply: Ensure a stable power supply during programming to prevent interruptions.

- Rushing the Process: Take your time and follow each step carefully to avoid mistakes.

5.2 Troubleshooting Common Xentry Issues

Troubleshooting common Xentry issues can save time and frustration:

- Connection Problems: Check the physical connection between the diagnostic interface and the vehicle.

- Software Errors: Restart the Xentry software and your computer.

- License Issues: Verify that your Xentry license is valid and activated.

- Communication Errors: Check the vehicle’s CAN bus for any issues.

- Database Errors: Reinstall the Xentry software and database.

6. The Future of Automotive Diagnostics with Xentry

The future of automotive diagnostics with Xentry is evolving rapidly, driven by advancements in technology and the increasing complexity of modern vehicles.

6.1 Integration with AI and Machine Learning

AI and machine learning are poised to revolutionize automotive diagnostics. Xentry will likely integrate these technologies to:

- Predictive Diagnostics: Analyze vehicle data to predict potential issues before they occur.

- Automated Fault Code Analysis: Automatically analyze fault codes and suggest possible causes and solutions.

- Adaptive Guided Tests: Customize Guided Tests based on the vehicle’s specific history and data.

- Remote Diagnostics: Enable remote diagnostics and troubleshooting by analyzing data transmitted from the vehicle.

- According to a study by McKinsey, AI in automotive could unlock $450 billion in value annually by 2030.

6.2 Enhanced Remote Diagnostic Capabilities

Remote diagnostics are becoming increasingly important, and Xentry will likely enhance its capabilities in this area:

- Real-Time Data Streaming: Enable real-time streaming of vehicle data to remote technicians.

- Remote Control: Allow remote technicians to control certain vehicle functions for testing purposes.

- Augmented Reality: Use augmented reality to guide on-site technicians through complex diagnostic procedures.

- Secure Communication: Ensure secure communication between the vehicle and remote diagnostic systems.

- According to a report by Global Market Insights, the remote diagnostics market is expected to reach $11.4 billion by 2027.

6.3 Cloud-Based Diagnostics and Data Management

Cloud-based diagnostics and data management offer numerous benefits for automotive technicians and repair shops:

- Centralized Data Storage: Store all diagnostic data in the cloud for easy access and analysis.

- Real-Time Updates: Receive real-time software updates and diagnostic information.

- Collaboration: Collaborate with other technicians and experts through cloud-based platforms.

- Scalability: Easily scale diagnostic resources as needed.

- A study by Statista forecasts that cloud spending will reach $482 billion in 2022, indicating a strong trend toward cloud-based solutions.

7. Conclusion: Mastering Xentry for Automotive Excellence

Mastering Xentry is crucial for automotive technicians aiming for excellence in Mercedes-Benz vehicle diagnostics. By understanding its key components, following step-by-step procedures, and leveraging advanced functions, you can ensure accurate and efficient diagnostics, leading to enhanced customer satisfaction and a competitive edge in the automotive industry.

Ready to take your diagnostic skills to the next level? CARDIAGTECH.NET offers a wide range of Xentry diagnostic tools and support to help you excel. Contact us today at 276 Reock St, City of Orange, NJ 07050, United States or via Whatsapp at +1 (641) 206-8880. Visit our website at CARDIAGTECH.NET to explore our offerings and elevate your automotive diagnostic capabilities. We are available for immediate consultations and look forward to answering any questions you may have.

8. FAQs About Creating Diagnostic Reports in Xentry

8.1 What is the purpose of a diagnostic report in Xentry?

A diagnostic report in Xentry documents the vehicle’s system status, fault codes, test results, and recommended repairs, providing a clear record for technicians and customers.

8.2 How do I connect Xentry to a Mercedes-Benz vehicle?

Connect the Xentry diagnostic interface to the vehicle’s OBD-II port, ensure the interface is configured correctly, and select the vehicle in the Xentry software.

8.3 What is a Quick Test in Xentry?

A Quick Test scans all accessible ECUs to provide a rapid overview of the vehicle’s system status and any stored fault codes.

8.4 How do I analyze fault codes in Xentry?

Use Xentry’s built-in information or WIS (Workshop Information System) to research each fault code, understand potential causes, and prioritize them based on severity.

8.5 What are Guided Tests in Xentry?

Guided Tests provide step-by-step instructions for diagnosing specific fault codes, helping technicians pinpoint the root cause of the issue.

8.6 How do I perform component testing in Xentry?

Access the actuation menu for the component you want to test, select the appropriate test, follow the instructions, and observe the component’s response, measuring relevant electrical values as needed.

8.7 What is data logging used for in Xentry?

Data logging is used to diagnose intermittent issues by monitoring relevant parameters while driving the vehicle under conditions that typically trigger the problem.

8.8 How do I generate a diagnostic report in Xentry?

Review all collected data, summarize findings, include recommendations, and use Xentry’s report generation function to create a detailed diagnostic report.

8.9 What is SCN coding in Xentry?

SCN (Software Calibration Number) coding is necessary when replacing certain components to ensure they are properly integrated with the vehicle’s systems.

8.10 How often should I update my Xentry software?

Regularly update your Xentry software to ensure you have the latest features, diagnostic data, and security updates.