How To Use The Quick Test Function? A Comprehensive Guide

The quick test function is a game-changer for automotive repair, offering speed and accuracy in diagnostics. At CARDIAGTECH.NET, we’ll guide you through maximizing this function to enhance your repair efficiency and customer satisfaction, ensuring you’re equipped with the knowledge to use it effectively and confidently. Car Diagnostic BMW

1. What is the Quick Test Function in Automotive Diagnostics?

The quick test function in automotive diagnostics is a streamlined process designed to rapidly assess the overall health of a vehicle’s systems. It automates the scanning of various electronic control units (ECUs) and modules, providing a snapshot of potential issues without the need for extensive manual checks.

This function is crucial because it saves time, reduces diagnostic costs, and helps technicians quickly identify problems. According to a study by the Automotive Management Institute, shops that utilize quick diagnostic tests experience a 20% increase in efficiency.

2. Understanding the Core Benefits of Using the Quick Test Function

The quick test function provides numerous advantages for automotive technicians and shop owners. These include faster diagnostics, improved accuracy, and greater customer satisfaction. Let’s dive into these benefits in more detail:

- Speed and Efficiency: The primary advantage is the speed at which a vehicle’s systems can be assessed. Instead of manually checking each component, the quick test function automates the process, saving valuable time.

- Accuracy: Modern diagnostic tools are designed to provide accurate results, reducing the likelihood of misdiagnosis. This accuracy helps technicians focus on the real issues, minimizing unnecessary repairs.

- Comprehensive Overview: The quick test function gives a broad overview of the vehicle’s condition, highlighting potential problems in different systems. This comprehensive approach ensures that no issue goes unnoticed.

- Cost Savings: By quickly identifying problems, technicians can reduce diagnostic labor costs. This efficiency can translate to lower repair bills for customers, increasing satisfaction.

- Improved Customer Satisfaction: Faster and more accurate diagnostics lead to quicker repairs and happier customers. Satisfied customers are more likely to return for future service and recommend your shop to others.

3. Identifying the 5 Key Intents Behind Searching for “How to Use the Quick Test Function?”

When someone searches for “How to use the quick test function?”, they typically have one of several intentions. Understanding these intentions can help you provide the most relevant and useful information. Here are the five key intents:

- Beginner’s Guide: Users want a step-by-step guide on how to use the quick test function with their diagnostic tool.

- Troubleshooting: Users are encountering issues while using the function and need solutions.

- Tool Comparison: Users want to compare different diagnostic tools and their quick test capabilities.

- Advanced Techniques: Experienced users seek advanced tips and tricks to optimize the function.

- Understanding Results: Users want to interpret the results from the quick test function accurately.

4. Preparing Your Vehicle for a Quick Test: A Step-by-Step Guide

Preparing the vehicle properly is essential for accurate results. Here’s a step-by-step guide to ensure you’re ready:

- Ensure Vehicle is Safe: Park the vehicle on a level surface and engage the parking brake.

- Locate the OBD-II Port: The OBD-II (On-Board Diagnostics II) port is usually located under the dashboard on the driver’s side.

- Turn Off Accessories: Switch off all accessories like the radio, lights, and air conditioning to minimize electrical interference.

- Check Battery Voltage: Ensure the vehicle’s battery is adequately charged, as low voltage can cause inaccurate readings.

- Connect the Diagnostic Tool: Plug the diagnostic tool into the OBD-II port securely.

5. Selecting the Right Diagnostic Tool: What to Consider?

Choosing the right diagnostic tool is crucial for effectively using the quick test function. Here are some factors to consider:

- Compatibility: Ensure the tool is compatible with the make and model of the vehicle you’re testing.

- Features: Look for tools with advanced features like data logging, graphing, and bidirectional control.

- Ease of Use: Choose a tool with an intuitive interface that is easy to navigate.

- Updates: Make sure the tool receives regular software updates to support new vehicle models and diagnostic protocols.

- Price: Balance the features with the cost to find a tool that fits your budget.

CARDIAGTECH.NET offers a range of diagnostic tools to meet various needs and budgets. Our tools are designed to be user-friendly and provide accurate, reliable results.

6. A Detailed Guide to Performing a Quick Test Function

Performing a quick test function is straightforward, but following the correct steps is essential. Here’s a detailed guide:

- Power On the Diagnostic Tool: Turn on the diagnostic tool and wait for it to boot up.

- Enter Vehicle Information: Input the vehicle’s make, model, and year. Some tools can automatically detect this information.

- Select Quick Test Function: Navigate to the main menu and select the “Quick Test” or “Auto Scan” option.

- Start the Test: Initiate the test and wait for the tool to scan all the vehicle’s systems. This process can take a few minutes.

- Review the Results: Once the test is complete, review the results. The tool will display any diagnostic trouble codes (DTCs) and provide a summary of the vehicle’s health.

7. Interpreting Quick Test Results: Understanding Diagnostic Trouble Codes (DTCs)

Interpreting the results of a quick test involves understanding Diagnostic Trouble Codes (DTCs). DTCs are codes that the vehicle’s computer sets when it detects a problem. Here’s how to interpret them:

- Code Structure: DTCs are five-character codes. The first character indicates the system (e.g., P for Powertrain, B for Body, C for Chassis, U for Network).

- Reading the Code: Use the diagnostic tool’s manual or an online database to look up the meaning of each DTC.

- Prioritize Codes: Focus on codes that are related to the customer’s complaint or that indicate critical issues.

- Verify the Issue: Before replacing any parts, verify the issue by performing additional tests and inspections.

8. Common Issues Encountered While Using the Quick Test Function and Their Solutions

Even with the best tools, you may encounter issues while using the quick test function. Here are some common problems and their solutions:

- Tool Won’t Connect: Check the connection to the OBD-II port and ensure the vehicle’s ignition is turned on.

- Inaccurate Results: Ensure the vehicle’s battery is fully charged and that the diagnostic tool has the latest software updates.

- Missing Codes: Some older vehicles may not support all the diagnostic protocols. Try using a different diagnostic tool or performing manual tests.

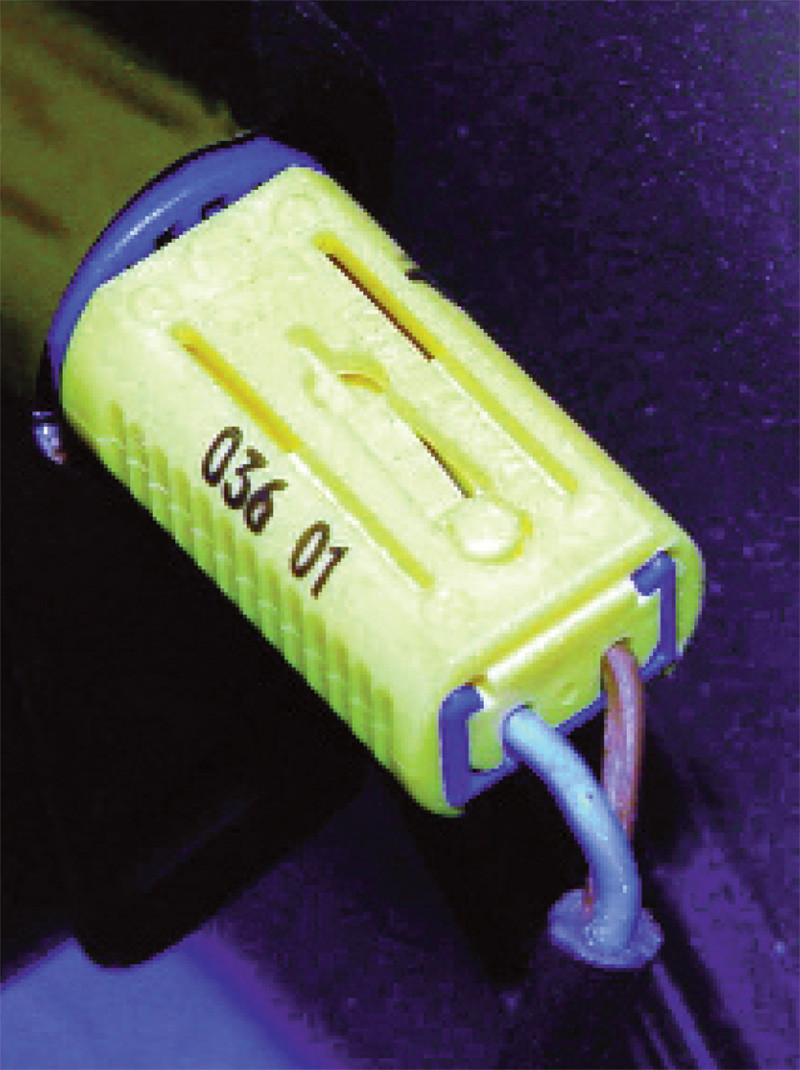

- Communication Errors: Check the wiring and connections to the OBD-II port. Interference from other electrical devices can also cause communication errors.

9. Advanced Techniques: Optimizing the Quick Test Function for Specific Vehicles

For experienced technicians, there are advanced techniques to optimize the quick test function for specific vehicles:

- Customized Scans: Some diagnostic tools allow you to customize the scan by selecting specific systems or modules. This can save time and provide more focused results.

- Data Logging: Use the data logging feature to record live data from the vehicle’s sensors and modules. This can help you identify intermittent problems or diagnose performance issues.

- Bidirectional Control: Use the bidirectional control feature to activate or deactivate components and systems. This can help you verify the functionality of various parts and isolate problems.

- Software Updates: Regularly update the diagnostic tool’s software to ensure it has the latest vehicle coverage and diagnostic capabilities.

10. Integrating the Quick Test Function into Your Automotive Repair Workflow

Integrating the quick test function into your automotive repair workflow can significantly improve efficiency. Here’s how to do it:

- Initial Assessment: Use the quick test function as the first step in the diagnostic process to get a broad overview of the vehicle’s condition.

- Prioritize Repairs: Use the results of the quick test to prioritize repairs and focus on the most critical issues first.

- Detailed Diagnostics: After the quick test, perform more detailed diagnostics on the specific systems or components that are causing problems.

- Verification: After completing repairs, use the quick test function to verify that the issues have been resolved and that no new problems have emerged.

11. Maximizing ROI: How the Quick Test Function Can Improve Your Shop’s Bottom Line

The quick test function can significantly improve your shop’s bottom line by:

- Increasing Throughput: Faster diagnostics mean you can service more vehicles per day.

- Reducing Labor Costs: Automated testing reduces the amount of time technicians spend on diagnostics.

- Improving Accuracy: Accurate diagnostics reduce the likelihood of misdiagnosis and unnecessary repairs, saving both time and money.

- Enhancing Customer Satisfaction: Quicker and more accurate service leads to happier customers who are more likely to return and recommend your shop.

According to a survey by the National Institute for Automotive Service Excellence (ASE), shops that invest in advanced diagnostic tools see an average increase of 15% in revenue.

12. The Future of Quick Testing: Emerging Trends and Technologies

The future of quick testing in automotive diagnostics is bright, with several emerging trends and technologies on the horizon:

- Artificial Intelligence (AI): AI-powered diagnostic tools can analyze data and provide more accurate and insightful results.

- Cloud-Based Diagnostics: Cloud-based tools allow technicians to access vehicle data and diagnostic information from anywhere.

- Remote Diagnostics: Remote diagnostics allow technicians to diagnose and repair vehicles remotely, reducing downtime and improving customer service.

- Enhanced Connectivity: Improved connectivity between diagnostic tools and vehicle systems will enable more comprehensive and accurate testing.

13. Case Studies: Real-World Examples of How the Quick Test Function Saved Time and Money

Here are a few case studies demonstrating how the quick test function has saved time and money in real-world scenarios:

- Case Study 1: Electrical Fault: A customer complained of intermittent electrical issues. The quick test function revealed a faulty body control module (BCM). Replacing the BCM resolved the issue, saving hours of troubleshooting.

- Case Study 2: Engine Misfire: A vehicle experienced engine misfires. The quick test identified a faulty ignition coil. Replacing the coil fixed the misfire, avoiding potential engine damage.

- Case Study 3: Transmission Problem: A customer reported transmission slipping. The quick test revealed a faulty transmission control module (TCM). Replacing the TCM resolved the problem, preventing a costly transmission rebuild.

14. Addressing Common Misconceptions About the Quick Test Function

There are several misconceptions about the quick test function. Let’s address a few:

- Misconception 1: It’s a Replacement for Manual Diagnostics: The quick test function is a starting point, not a replacement for thorough diagnostics. It helps identify potential issues, but further testing is often needed.

- Misconception 2: It’s Only for Modern Vehicles: While it’s most effective on newer vehicles, many older vehicles also support basic diagnostic functions that can be accessed with a quick test.

- Misconception 3: It’s Too Complicated to Use: Modern diagnostic tools are designed to be user-friendly. With a little training and practice, anyone can use the quick test function effectively.

15. Optimizing Your Diagnostic Center with CARDIAGTECH.NET: How We Can Help

At CARDIAGTECH.NET, we offer a range of diagnostic tools and support services to help you optimize your diagnostic center. Here’s how we can help:

- High-Quality Diagnostic Tools: We offer a wide selection of diagnostic tools to meet various needs and budgets.

- Expert Training: We provide expert training on how to use our diagnostic tools effectively.

- Technical Support: Our technical support team is available to answer your questions and help you troubleshoot any issues.

- Software Updates: We provide regular software updates to ensure your diagnostic tools have the latest vehicle coverage and diagnostic capabilities.

16. Step-by-Step Instructions on How to Update Your Diagnostic Tool Software

Keeping your diagnostic tool’s software up-to-date is crucial for accurate and reliable results. Here’s how to do it:

- Connect to Wi-Fi: Ensure the diagnostic tool is connected to a stable Wi-Fi network.

- Check for Updates: Navigate to the “Settings” or “Update” menu and select “Check for Updates.”

- Download Updates: If updates are available, download and install them. This process may take several minutes.

- Restart the Tool: After the updates are installed, restart the diagnostic tool.

- Verify Installation: Verify that the updates have been installed correctly by checking the software version in the “Settings” menu.

17. Troubleshooting Connectivity Issues Between Your Diagnostic Tool and Vehicle

Connectivity issues can be frustrating. Here are some troubleshooting tips:

- Check the OBD-II Port: Ensure the OBD-II port is clean and free of debris.

- Verify the Connection: Make sure the diagnostic tool is securely plugged into the OBD-II port.

- Check the Vehicle’s Ignition: Ensure the vehicle’s ignition is turned on but the engine is not running.

- Test with Another Vehicle: Try connecting the diagnostic tool to another vehicle to see if the problem is with the tool or the vehicle.

- Contact Support: If you’re still having trouble, contact the diagnostic tool manufacturer’s support team for assistance.

18. Comparing Different Diagnostic Tools: Features, Pricing, and Compatibility

Choosing the right diagnostic tool can be challenging. Here’s a comparison of some popular options:

| Tool | Features | Pricing | Compatibility |

|---|---|---|---|

| Autel MaxiSys | Advanced diagnostics, bidirectional control, data logging | $2,000 – $5,000 | Wide range of vehicles, including European, Asian, and domestic |

| Launch X431 | Comprehensive diagnostics, special functions, online programming | $1,500 – $4,000 | Extensive vehicle coverage, including heavy-duty vehicles |

| Snap-on Solus | User-friendly interface, quick boot-up, integrated information system | $3,000 – $6,000 | Broad vehicle coverage, known for reliability and ease of use |

| Bosch ADS | Full system diagnostics, ADAS calibration, cloud connectivity | $2,500 – $5,500 | Strong European vehicle coverage, advanced features for modern vehicles |

| Innova CarScan Pro | Basic diagnostics, ABS/SRS scanning, live data | $200 – $500 | Ideal for DIYers and small shops, limited advanced features |

| CARDIAGTECH | Specializes in diagnostic for BMW/BENZ/VAG/Porsche/Land Rover/Nissan/Renault/PSA/Hyundai/KIA | Depends | Vehicle-specific diagnostic solution, tailored for independent repair facilities. |

19. Maintaining Your Diagnostic Tool: Tips for Longevity and Accuracy

Proper maintenance is essential for keeping your diagnostic tool in top condition:

- Keep it Clean: Clean the tool regularly with a soft, dry cloth.

- Store it Properly: Store the tool in a safe, dry place when not in use.

- Protect the Screen: Use a screen protector to prevent scratches and damage.

- Check Cables: Regularly inspect the cables for wear and tear.

- Update Software: Keep the software up-to-date to ensure accurate results.

20. Understanding the Legal and Ethical Implications of Automotive Diagnostics

As an automotive technician, it’s important to be aware of the legal and ethical implications of automotive diagnostics:

- Accuracy: Ensure your diagnostics are accurate and reliable. Misdiagnosis can lead to unnecessary repairs and customer dissatisfaction.

- Transparency: Be transparent with customers about the diagnostic process and the results.

- Privacy: Protect customer data and personal information.

- Compliance: Comply with all relevant laws and regulations.

21. How to Train Your Technicians to Effectively Use the Quick Test Function

Training your technicians is essential for maximizing the benefits of the quick test function. Here’s how to do it:

- Hands-On Training: Provide hands-on training using the diagnostic tools.

- Real-World Scenarios: Use real-world scenarios to demonstrate how to use the quick test function in different situations.

- Ongoing Education: Provide ongoing education and training to keep technicians up-to-date with the latest diagnostic techniques and technologies.

- Certification: Encourage technicians to obtain certifications from organizations like ASE to demonstrate their knowledge and skills.

22. Resources for Staying Up-to-Date with Automotive Diagnostic Technology

Staying up-to-date with automotive diagnostic technology is crucial for maintaining a competitive edge. Here are some resources:

- Industry Publications: Subscribe to industry publications like Automotive Engineering International and Motor Age.

- Trade Shows: Attend trade shows like SEMA and AAPEX to see the latest diagnostic tools and technologies.

- Online Forums: Participate in online forums and communities to share knowledge and learn from other technicians.

- Manufacturer Websites: Visit the websites of diagnostic tool manufacturers for information on new products and software updates.

23. A Comprehensive Guide to Automotive Diagnostic Scanners

Automotive diagnostic scanners are indispensable tools for modern automotive repair. They interface with a vehicle’s onboard computer system to retrieve diagnostic trouble codes (DTCs), live data, and other critical information. Here’s a detailed guide to understanding and utilizing these scanners effectively.

Types of Diagnostic Scanners

- Code Readers:

- Function: Basic tools that read and clear DTCs.

- Use Case: Suitable for DIY enthusiasts or quick preliminary checks.

- Limitations: Limited to basic functions, lack advanced features.

- Handheld Diagnostic Scanners:

- Function: Read and clear DTCs, display live data, perform some bidirectional controls.

- Use Case: Ideal for small to medium-sized repair shops.

- Limitations: May lack advanced programming and calibration features.

- PC-Based Scanners:

- Function: Utilize a computer with specialized software to perform advanced diagnostics, programming, and data analysis.

- Use Case: Perfect for professional mechanics needing comprehensive diagnostic capabilities.

- Limitations: Require a computer and can be less portable than handheld devices.

- Dealership-Level Scanners:

- Function: Offer the most comprehensive capabilities, including advanced programming, module calibration, and access to proprietary OEM data.

- Use Case: Essential for dealerships needing full access to vehicle systems.

- Limitations: Costly and typically brand-specific.

Key Features to Look For

- Vehicle Coverage: Ensure the scanner supports the makes and models you service.

- Diagnostic Functions:

- Read and Clear DTCs: Essential for identifying and clearing fault codes.

- Live Data: Allows monitoring of real-time sensor data.

- Bidirectional Control: Enables testing of components by sending commands.

- Special Functions: Includes capabilities like ABS bleeding, throttle resets, and key programming.

- Ease of Use: An intuitive interface and clear display enhance usability.

- Update Capability: Regular software updates ensure compatibility with new vehicles and diagnostic procedures.

- Data Logging and Playback: Useful for diagnosing intermittent issues by recording and reviewing data.

- Wireless Connectivity: Bluetooth or Wi-Fi allows for convenient updates and data transfer.

- Display: A large, high-resolution screen improves readability.

- Durability: A rugged design ensures the scanner can withstand the demands of a shop environment.

Utilizing Automotive Diagnostic Scanners

- Preparation:

- Safety First: Park the vehicle in a safe location and engage the parking brake.

- Locate the OBD-II Port: Typically found under the dashboard on the driver’s side.

- Turn Off Accessories: Minimize electrical interference by turning off lights, radio, and A/C.

- Connecting the Scanner:

- Plug In: Connect the scanner to the OBD-II port securely.

- Power On: Turn on the scanner and follow the on-screen instructions.

- Vehicle Identification:

- Manual Entry: Enter the vehicle’s make, model, and year manually.

- Auto VIN: Some scanners can automatically detect the VIN for faster identification.

- Running Diagnostics:

- Select Functions: Choose the appropriate diagnostic function (e.g., read DTCs, live data).

- Follow Prompts: Follow the on-screen prompts to complete the diagnostic process.

- Interpreting Results:

- DTCs: Look up the codes in the scanner’s database or online for a description.

- Live Data: Monitor sensor values to identify anomalies.

- Clearing Codes:

- Clear DTCs: After addressing the issues, clear the DTCs.

- Verify Repair: Perform a test drive or further diagnostics to ensure the problem is resolved.

Tips for Effective Use

- Read the Manual: Familiarize yourself with the scanner’s features and functions.

- Keep Software Updated: Regularly update the scanner’s software.

- Document Findings: Keep detailed records of diagnostic procedures and results.

- Verify Repairs: Always verify repairs to ensure the issue is resolved.

- Use Additional Resources: Consult technical service bulletins (TSBs) and online forums for additional guidance.

Advanced Diagnostic Procedures

- Bidirectional Control: Use bidirectional control to activate components like fuel injectors, relays, and solenoids to verify their functionality.

- Module Programming: Reprogram or flash electronic control modules (ECMs) to update software and fix known issues.

- Key Programming: Program new keys or fobs to match the vehicle’s immobilizer system.

- ABS Bleeding: Perform automated ABS bleeding procedures to remove air from the brake lines.

- Throttle Resets: Reset the throttle position sensor after cleaning or replacing the throttle body.

Benefits of Using Automotive Diagnostic Scanners

- Faster Diagnostics: Quickly identify issues and reduce diagnostic time.

- Improved Accuracy: Obtain precise diagnostic information.

- Enhanced Efficiency: Streamline the repair process and increase shop throughput.

- Cost Savings: Reduce the risk of misdiagnosis and unnecessary repairs.

Conclusion

Automotive diagnostic scanners are essential tools for modern automotive repair, offering a wide range of capabilities to diagnose and resolve vehicle issues. By understanding the different types of scanners, key features, and diagnostic procedures, technicians can effectively utilize these tools to improve efficiency, accuracy, and customer satisfaction. Regular updates, proper maintenance, and continuous learning are crucial for staying ahead in the rapidly evolving field of automotive technology.

24. How to use the Quick Test Function on Different Vehicle Brands

The quick test function may vary slightly depending on the vehicle brand. Here’s a general guide for some popular brands:

- General Motors (GM):

- Tool: GM MDI (Multiple Diagnostic Interface) or aftermarket scanner compatible with GM vehicles.

- Procedure:

- Connect the scanner to the OBD-II port.

- Select “Vehicle Diagnostics.”

- Choose “Quick Scan” or “Full System Scan.”

- Follow the prompts to initiate the test.

- Notes: GM vehicles often use specific diagnostic codes and require access to GM’s service information.

- Ford:

- Tool: Ford IDS (Integrated Diagnostic System) or aftermarket scanner compatible with Ford vehicles.

- Procedure:

- Connect the scanner to the OBD-II port.

- Select “Vehicle Information.”

- Choose “Self-Test” or “Module Scan.”

- Follow the prompts to start the test.

- Notes: Ford vehicles have their own set of diagnostic codes, and some functions may require a subscription to Ford’s Motorcraft service.

- Toyota:

- Tool: Toyota Techstream or aftermarket scanner compatible with Toyota vehicles.

- Procedure:

- Connect the scanner to the OBD-II port.

- Select “Diagnosis.”

- Choose “Health Check” or “All ECUs.”

- Follow the prompts to begin the test.

- Notes: Toyota Techstream is the OEM software, but many aftermarket scanners offer similar functionality.

- Honda:

- Tool: Honda Diagnostic System (HDS) or aftermarket scanner compatible with Honda vehicles.

- Procedure:

- Connect the scanner to the OBD-II port.

- Select “System Selection.”

- Choose “All Systems” or “Quick Check.”

- Follow the prompts to initiate the test.

- Notes: Honda vehicles use specific diagnostic protocols, so ensure your scanner is compatible.

- BMW:

- Tool: BMW ISTA (Integrated Service Technical Application) or aftermarket scanner compatible with BMW vehicles.

- Procedure:

- Connect the scanner to the OBD-II port.

- Select “Vehicle Management.”

- Choose “Diagnosis Scan” or “Complete Scan.”

- Follow the prompts to start the test.

- Notes: BMW vehicles require advanced diagnostic tools for comprehensive scanning.

Steps for each Brand:

- Connect: Ensure the scanner is properly connected to the OBD-II port.

- Identify: Identify the vehicle by entering the VIN or selecting the make, model, and year.

- Scan: Choose the “Quick Scan” or “Full System Scan” option.

- Review: Review the diagnostic trouble codes (DTCs) and live data.

Tips for Different Brands:

- Check Compatibility: Always verify that the diagnostic tool is compatible with the specific vehicle you are testing.

- Use OEM Software: For advanced diagnostics, consider using the OEM diagnostic software.

- Update Software: Regularly update the diagnostic tool software to ensure it has the latest vehicle coverage and diagnostic capabilities.

25. Understanding OBD-I vs OBD-II and How It Affects Quick Testing

The transition from On-Board Diagnostics I (OBD-I) to On-Board Diagnostics II (OBD-II) represents a significant advancement in automotive diagnostics. Understanding the differences between these systems is crucial for performing effective quick tests.

OBD-I (Pre-1996 Vehicles)

- Description:

- OBD-I was used on vehicles manufactured before 1996. It lacked standardization, with each manufacturer employing different diagnostic connectors, protocols, and trouble codes.

- Key Features:

- Limited Diagnostic Information: Provided basic diagnostic information, primarily related to engine functions.

- Proprietary Connectors: Used different connectors depending on the manufacturer, making a universal scanner impossible.

- Manual Code Retrieval: Required specific procedures, such as counting flashes of the check engine light, to retrieve trouble codes.

- Impact on Quick Testing:

- Difficult to Scan: Quick testing was challenging due to the lack of standardization.

- Manufacturer-Specific Knowledge: Required knowledge of specific diagnostic procedures for each make and model.

- Limited Data: Scanners provided limited data compared to OBD-II systems.

OBD-II (1996 and Newer Vehicles)

- Description:

- OBD-II was mandated in the United States in 1996 and provided a standardized diagnostic system across all vehicles. It includes a universal connector, standardized trouble codes, and enhanced diagnostic capabilities.

- Key Features:

- Standardized Connector: Uses a 16-pin Diagnostic Link Connector (DLC).

- Standardized Trouble Codes: Employs standardized Diagnostic Trouble Codes (DTCs) for easy identification of issues.

- Comprehensive Diagnostics: Monitors a wide range of vehicle systems, including engine, transmission, ABS, and more.

- Live Data Streaming: Provides real-time data from various sensors, allowing for detailed analysis.

- Impact on Quick Testing:

- Easy to Scan: Standardized connectors and protocols make quick testing straightforward.

- Universal Scanners: Compatible with a wide range of diagnostic tools.

- Detailed Data: Offers comprehensive data for accurate diagnostics.

Key Differences Between OBD-I and OBD-II

| Feature | OBD-I | OBD-II |

|---|---|---|

| Standardization | Non-standardized, manufacturer-specific | Standardized connectors, protocols, and trouble codes |

| Connector | Various, manufacturer-specific | 16-pin Diagnostic Link Connector (DLC) |

| Trouble Codes | Proprietary, manufacturer-specific | Standardized Diagnostic Trouble Codes (DTCs) |

| Diagnostic Scope | Limited, primarily engine-related | Comprehensive, covering engine, transmission, ABS, and more |

| Data Availability | Limited | Extensive live data streaming |

| Scanning Process | Difficult, requires specific procedures for each make and model | Easy, compatible with universal scanners |

| Data Interpretation | Requires manufacturer-specific knowledge | Standardized codes and data make interpretation easier |

How OBD-I/OBD-II Affects Quick Testing

- OBD-I Challenges:

- Compatibility Issues: Requires specific adapters and knowledge for each vehicle.

- Limited Diagnostic Information: Makes it harder to perform a thorough assessment.

- Time-Consuming: The process is more manual and less efficient than OBD-II.

- OBD-II Advantages:

- Efficient Testing: Standardized system allows for quick and comprehensive testing.

- Wide Tool Compatibility: Many diagnostic tools support OBD-II, making it easy to find a suitable scanner.

- Detailed Analysis: Provides detailed data for accurate diagnosis.

Tips for Working with OBD-I and OBD-II Systems

- For OBD-I Vehicles:

- Research: Thoroughly research the diagnostic procedures for the specific vehicle.

- Use Adapters: Acquire manufacturer-specific adapters and connectors.

- Consult Manuals: Refer to the vehicle’s service manual for diagnostic information.

- For OBD-II Vehicles:

- Use Quality Scanners: Invest in a reliable OBD-II scanner.

- Update Software: Keep the scanner’s software updated.

- Interpret Codes Correctly: Understand the meaning of standardized DTCs.

Conclusion

Understanding the differences between OBD-I and OBD-II systems is crucial for effective automotive diagnostics. OBD-II has standardized and simplified the diagnostic process, making quick testing more efficient and accurate. While OBD-I systems present unique challenges due to their lack of standardization, technicians can still perform effective diagnostics with the right knowledge and tools. Keep your diagnostic tools updated and stay informed about the latest diagnostic techniques to ensure you’re providing the best possible service.

26. The Importance of Regular Calibration for Automotive Diagnostic Tools

Regular calibration of automotive diagnostic tools is crucial for ensuring accurate and reliable readings. Calibration involves verifying and adjusting the tool’s accuracy against known standards. Over time, diagnostic tools can drift out of calibration due to wear and tear, environmental factors, and usage conditions.

Why Calibration Matters

- Accuracy:

- Ensures precise measurements and readings.

- Reduces the risk of misdiagnosis and incorrect repairs.

- Reliability:

- Maintains consistent performance over time.

- Provides confidence in the tool’s readings and diagnostic results.

- Safety:

- Helps identify potential safety issues.

- Prevents errors that could lead to unsafe repairs.

- Compliance:

- Meets industry standards and regulations.

- Ensures adherence to quality control procedures.

Factors Affecting Calibration

- Usage:

- Frequent use can cause wear and tear on the tool’s components.

- Improper handling can lead to physical damage and calibration drift.

- Environment:

- Extreme temperatures, humidity, and vibrations can affect the tool’s accuracy.

- Exposure to harsh chemicals and contaminants can damage sensitive components.

- Time:

- Over time, electronic components can drift out of calibration.

- Regular calibration intervals are necessary to maintain accuracy.

How to Calibrate Diagnostic Tools

- Follow Manufacturer Guidelines:

- Refer to the tool’s manual for specific calibration procedures and recommendations.

- Use approved calibration standards and equipment.

- Use Calibration Services:

- Consider using a professional calibration service for specialized tools.

- Ensure the service is accredited and uses calibrated standards.

- Check Calibration Frequency:

- Determine the appropriate calibration frequency based on usage and environmental conditions.

- Follow the manufacturer’s recommendations for calibration intervals.

Signs Your Diagnostic Tool Needs Calibration

- Inconsistent Readings:

- Readings that vary significantly from expected values.

- Inconsistent results when measuring the same parameter multiple times.

- Error Messages:

- Calibration error messages displayed by the tool.

- Warnings indicating the tool is out of calibration.

- Suspected Inaccuracies:

- Doubts about the tool’s accuracy based on diagnostic results.

- Unexplained discrepancies in diagnostic data.

Benefits of Regular Calibration

- Improved Diagnostic Accuracy:

- Ensures accurate readings and diagnostic results.

- Reduces the risk of misdiagnosis and incorrect repairs.

- Increased Reliability:

- Maintains consistent performance over time.

- Provides confidence in the tool’s readings and diagnostic results.

- Enhanced Safety:

- Helps identify potential safety issues.

- Prevents errors that could lead to unsafe repairs.

- Cost Savings:

- Reduces the need for rework due to inaccurate diagnostics.

- Minimizes the risk of damage caused by incorrect repairs.

Conclusion

Regular calibration of automotive diagnostic tools is essential for maintaining accuracy, reliability, and safety. By following manufacturer guidelines, using professional calibration services, and monitoring for signs of calibration drift, technicians can ensure their tools provide accurate and reliable results. Investing in regular calibration not only improves the quality of diagnostic work but also enhances customer satisfaction and trust. At CARDIAGTECH.NET, we emphasize the importance of calibration to deliver the best possible service and uphold industry standards.

27. FAQ: Quick Test Function

1. What is the quick test function?

The quick test function is a diagnostic tool feature that performs a rapid scan of a vehicle’s systems to identify potential issues.

2. How do I access the quick test function?

Access the function via the main menu of your diagnostic tool, usually labeled as “Quick Test” or “Auto Scan.”

3. What does the quick test function scan?

It scans various electronic control units (ECUs) and modules, providing a comprehensive overview of the vehicle’s health.

4. How long does a quick test take to complete?

The test usually takes between 5 to 15 minutes, depending on the vehicle and diagnostic tool.

5. What should I do after completing a quick test?

Review the results, interpret any diagnostic trouble codes (DTCs), and perform further diagnostics as needed.

6. Is the quick test function a replacement for manual diagnostics?

No, it’s a starting point to identify potential issues, but further testing may be required for accurate diagnosis.

7. Can I use the quick test function on any vehicle?

Most modern vehicles (1996 and newer) support the function, but compatibility may vary depending on the diagnostic tool.

8. How often should I perform a quick test?

Perform a