What is The Biggest Challenge Diagnosing Modern Mercedes-Benz Vehicles?

Diagnosing modern Mercedes-Benz vehicles presents unique challenges due to their advanced technology and complex systems. CARDIAGTECH.NET offers state-of-the-art diagnostic tools and equipment to help technicians overcome these obstacles and ensure accurate and efficient repairs. Modern Mercedes-Benz diagnostics require updated training, cutting-edge tools, and a deep understanding of automotive technology, making premium diagnostic equipment essential for success.

1. Understanding the Complexity of Modern Mercedes-Benz Diagnostics

What makes diagnosing a modern Mercedes-Benz so challenging? Modern Mercedes-Benz vehicles incorporate sophisticated technology, extensive computer systems, and intricate sensor networks, making accurate diagnostics complex, requiring specialized knowledge and advanced tools.

1.1. The Evolution of Mercedes-Benz Technology

How have Mercedes-Benz vehicles evolved technologically over the years? The evolution of Mercedes-Benz vehicles showcases a transition from primarily mechanical systems to highly integrated electronic systems.

- Early Models: Early Mercedes-Benz models featured mainly mechanical components with basic electrical systems.

- Introduction of Electronics: The introduction of electronic control units (ECUs) in the 1980s marked the beginning of computer-controlled systems for engine management and basic functions.

- Advanced Systems: By the 2000s, advanced systems like electronic stability control (ESC), sophisticated anti-lock braking systems (ABS), and complex engine management systems became standard.

- Modern Era: Today’s Mercedes-Benz vehicles boast fully integrated systems with multiple interconnected ECUs, advanced driver-assistance systems (ADAS), and intricate infotainment systems.

- Digitalization: Modern vehicles use extensive sensor networks and data processing to optimize performance, safety, and comfort, creating a sophisticated diagnostic landscape.

This evolution necessitates that technicians stay updated with the latest diagnostic techniques and tools to effectively service these vehicles. According to a study by the National Automotive Service Task Force (NASTF), technicians need continuous training to keep up with the increasing complexity of modern vehicles.

1.2. Key Electronic Systems and Their Integration

What are the key electronic systems in a modern Mercedes-Benz, and how are they integrated? Modern Mercedes-Benz vehicles integrate various electronic systems, each playing a crucial role in the vehicle’s operation and performance.

- Engine Control Unit (ECU): Manages engine performance by controlling fuel injection, ignition timing, and emissions.

- Transmission Control Unit (TCU): Regulates gear shifting and transmission behavior.

- Anti-Lock Braking System (ABS): Prevents wheel lock-up during braking, enhancing safety.

- Electronic Stability Program (ESP): Enhances vehicle stability by detecting and reducing skidding.

- Airbag Control Unit (ACU): Manages the deployment of airbags in the event of a collision.

- Comfort and Convenience Systems: Includes climate control, seat adjustment, and infotainment systems.

- Advanced Driver-Assistance Systems (ADAS): Features adaptive cruise control, lane-keeping assist, and automatic emergency braking.

These systems are interconnected via communication networks like CAN (Controller Area Network) bus, allowing them to share data and coordinate functions. As stated by Bosch Automotive Handbook, the complexity of these integrated systems requires technicians to have a comprehensive understanding of automotive electronics and network communication protocols.

1.3. The Role of Sensors and Actuators

How do sensors and actuators contribute to the complexity of diagnosing modern Mercedes-Benz vehicles? Sensors and actuators are crucial components in modern Mercedes-Benz vehicles, providing data and executing commands within the electronic systems.

-

Sensors: These devices measure various parameters such as temperature, pressure, speed, and position, providing real-time data to the ECUs. Common sensors include:

- Temperature sensors (coolant, air intake)

- Pressure sensors (manifold, fuel rail)

- Speed sensors (wheel speed, engine speed)

- Position sensors (throttle position, crankshaft position)

-

Actuators: These components execute commands from the ECUs to control various vehicle functions. Common actuators include:

- Fuel injectors

- Throttle valves

- Solenoids

- Relays

- Electric motors

The increasing number and sophistication of sensors and actuators enhance vehicle performance and efficiency but also add to diagnostic complexity. Faulty sensors can provide incorrect data, leading to inaccurate diagnoses, while malfunctioning actuators can cause system failures. According to a report by the Society of Automotive Engineers (SAE), precise diagnostics require understanding the function and interaction of these components within the overall system.

1.4. Diagnostic Trouble Codes (DTCs) and Their Limitations

What are Diagnostic Trouble Codes (DTCs), and why are they not always sufficient for accurate diagnostics? Diagnostic Trouble Codes (DTCs) are codes stored in the vehicle’s computer system when a fault is detected. While DTCs provide a starting point for diagnostics, they have limitations.

- Indirect Indication: DTCs often indicate a symptom rather than the root cause of the problem.

- Multiple Codes: Multiple DTCs can be triggered by a single underlying issue, complicating the diagnostic process.

- False Positives: Faulty sensors or wiring can trigger DTCs even when the actual component is functioning correctly.

- Lack of Detail: DTCs may not provide enough specific information to pinpoint the exact location or cause of the fault.

Technicians need to go beyond reading DTCs and perform thorough system testing and analysis to accurately diagnose the issue. A study by the Automotive Research Association of India (ARAI) emphasizes the importance of comprehensive diagnostic procedures to overcome the limitations of relying solely on DTCs.

2. The Biggest Challenges in Diagnosing Modern Mercedes-Benz Vehicles

What are the most significant challenges technicians face when diagnosing modern Mercedes-Benz vehicles? Technicians encounter several key challenges, including accessing accurate information, using the right diagnostic tools, and keeping up with continuous technological advancements.

2.1. Access to Accurate and Up-to-Date Information

Why is access to accurate and up-to-date information crucial for diagnosing Mercedes-Benz vehicles? Accurate and up-to-date information is vital because modern Mercedes-Benz vehicles are complex, and technicians need reliable data to diagnose issues effectively.

- Technical Service Bulletins (TSBs): TSBs provide information on known issues and updated repair procedures.

- Wiring Diagrams: Accurate wiring diagrams are essential for tracing electrical faults.

- Repair Manuals: Detailed repair manuals offer step-by-step instructions for various procedures.

- Diagnostic Databases: Access to comprehensive diagnostic databases helps technicians interpret DTCs and system behavior.

However, accessing this information can be challenging. Independent repair shops may find it difficult to obtain the same level of information as authorized dealerships. CARDIAGTECH.NET aims to bridge this gap by providing access to comprehensive diagnostic resources and tools, ensuring technicians have the information they need. According to research by the National Institute for Automotive Service Excellence (ASE), access to accurate information significantly reduces diagnostic time and improves repair accuracy.

2.2. The Need for Advanced Diagnostic Tools and Equipment

What types of advanced diagnostic tools are necessary for working on modern Mercedes-Benz vehicles? Diagnosing modern Mercedes-Benz vehicles requires specialized tools that can communicate with the vehicle’s complex electronic systems.

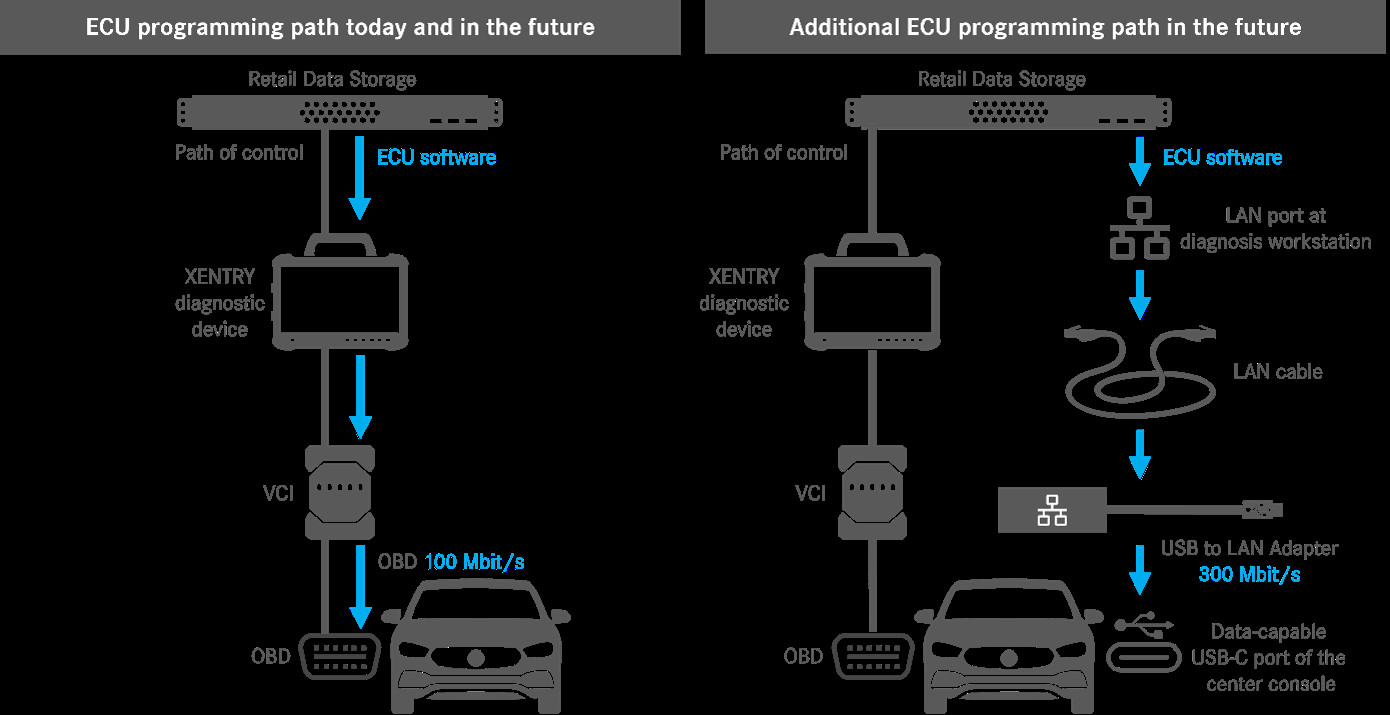

- OEM Diagnostic Scanners: These scanners provide the most comprehensive diagnostic capabilities, including access to all vehicle systems and functions.

- Multimeters and Oscilloscopes: Essential for testing electrical circuits and sensor signals.

- Specialized Software: Required for programming and coding ECUs.

- CAN Bus Analyzers: Used to diagnose communication issues within the vehicle’s network.

Investing in these tools can be expensive, posing a challenge for smaller repair shops. CARDIAGTECH.NET offers a range of diagnostic tools and equipment at competitive prices, enabling technicians to equip their workshops without breaking the bank. A study by Frost & Sullivan indicates that the adoption of advanced diagnostic tools is increasing among independent repair shops to meet the demands of modern vehicle technology.

2.3. Keeping Up with Continuous Technological Advancements

How can technicians stay current with the rapidly evolving technology in Mercedes-Benz vehicles? The automotive industry is constantly evolving, with new technologies and systems being introduced regularly.

- Continuous Training: Regular training courses and certifications are essential for staying updated.

- Industry Publications: Subscribing to industry publications and online forums provides valuable insights into new technologies.

- Vendor Support: Partnering with diagnostic tool vendors who offer ongoing support and updates is crucial.

- Online Resources: Utilizing online resources such as webinars, tutorials, and technical articles helps technicians expand their knowledge.

The fast pace of technological change can be overwhelming for technicians. CARDIAGTECH.NET supports technicians by providing access to training resources and ongoing support for our diagnostic tools, ensuring they can keep up with the latest advancements. Research from the U.S. Bureau of Labor Statistics highlights the importance of continuous education for automotive technicians to remain competitive in the industry.

2.4. Diagnosing Intermittent Problems

Why are intermittent problems particularly challenging to diagnose in modern Mercedes-Benz vehicles? Intermittent problems, which occur sporadically, can be extremely difficult to diagnose because the fault is not always present when the technician is investigating.

- Data Logging: Using diagnostic tools to log data over time can help capture the fault when it occurs.

- Thorough Inspection: A detailed inspection of wiring, connectors, and components can reveal potential sources of the problem.

- Simulation: Simulating driving conditions and system loads can help trigger the fault.

- Component Testing: Testing individual components to rule out potential causes.

These issues often require extensive testing and patience to resolve. CARDIAGTECH.NET offers diagnostic tools with advanced data logging capabilities, enabling technicians to capture and analyze intermittent faults more effectively. According to a survey by the Automotive Management Institute (AMI), intermittent problems are one of the most common and frustrating challenges faced by automotive technicians.

2.5. Cybersecurity Concerns and Diagnostic Access

How do cybersecurity concerns affect the ability to diagnose and repair modern Mercedes-Benz vehicles? Modern vehicles are increasingly vulnerable to cyber threats, leading manufacturers to implement security measures to protect vehicle systems.

- Secure Gateways: Many Mercedes-Benz vehicles are equipped with secure gateways that restrict access to certain diagnostic functions.

- Authentication: Technicians may need to authenticate themselves using manufacturer-approved credentials to access protected systems.

- Data Encryption: Diagnostic data may be encrypted to prevent unauthorized access.

These security measures can complicate the diagnostic process for independent repair shops. CARDIAGTECH.NET provides diagnostic solutions that comply with manufacturer security protocols, ensuring technicians can securely access and diagnose vehicle systems. A report by McKinsey & Company emphasizes the growing importance of cybersecurity in the automotive industry and the need for secure diagnostic solutions.

3. Common Diagnostic Challenges by System

What are some of the most common diagnostic challenges associated with specific systems in Mercedes-Benz vehicles? Different systems present unique challenges due to their design and function.

3.1. Engine Management Systems

What are the common diagnostic challenges when working with Mercedes-Benz engine management systems? Engine management systems are complex, and diagnosing issues requires a systematic approach.

- Sensor Failures: Faulty sensors can provide incorrect data, leading to inaccurate diagnoses.

- Fuel System Problems: Issues with fuel injectors, fuel pumps, or fuel pressure regulators can cause performance problems.

- Ignition System Issues: Worn spark plugs, faulty ignition coils, or wiring problems can result in misfires.

- Emissions Control Problems: Issues with oxygen sensors, catalytic converters, or EGR valves can trigger warning lights.

Accurate diagnostics require a thorough understanding of engine management principles and the ability to interpret sensor data. CARDIAGTECH.NET offers diagnostic tools with advanced data analysis capabilities, helping technicians identify and resolve engine management issues efficiently. According to a study by the German Association of the Automotive Industry (VDA), engine management systems are among the most frequently diagnosed systems in modern vehicles.

3.2. Transmission Systems

What are the common challenges in diagnosing automatic transmission problems in Mercedes-Benz vehicles? Automatic transmissions are complex mechanical and electronic systems, making diagnostics challenging.

- Fluid Level and Condition: Low or contaminated transmission fluid can cause shifting problems.

- Solenoid Failures: Faulty solenoids can disrupt the transmission’s ability to shift gears.

- Valve Body Issues: Problems with the valve body can cause erratic shifting behavior.

- Software Glitches: Software issues in the transmission control unit (TCU) can lead to shifting problems.

Proper diagnostics require checking the transmission fluid, testing solenoids, and using diagnostic scanners to read TCU data. CARDIAGTECH.NET provides diagnostic tools that can communicate with Mercedes-Benz transmission systems, allowing technicians to diagnose and resolve transmission issues effectively. Research by the Automotive Transmission Rebuilders Association (ATRA) highlights the importance of proper diagnostic procedures for automatic transmission repairs.

3.3. Brake and ABS Systems

What specific diagnostic challenges do technicians face when diagnosing Mercedes-Benz brake and ABS systems? Brake and ABS systems are critical for safety, and accurate diagnostics are essential.

- Sensor Problems: Faulty wheel speed sensors can cause ABS malfunctions.

- Hydraulic Issues: Problems with the ABS pump, modulator, or brake lines can affect braking performance.

- Electronic Control Unit (ECU) Failures: Issues with the ABS ECU can disable the ABS system.

- Brake Pad Wear: Uneven brake pad wear can indicate underlying problems with the braking system.

Diagnosing these systems requires checking sensor signals, inspecting hydraulic components, and using diagnostic scanners to read ABS ECU data. CARDIAGTECH.NET offers diagnostic tools that support Mercedes-Benz ABS systems, enabling technicians to diagnose and repair brake issues accurately. According to a report by the National Highway Traffic Safety Administration (NHTSA), proper maintenance and diagnostics of brake systems are crucial for preventing accidents.

3.4. Air Conditioning and Climate Control Systems

What are the common diagnostic challenges associated with Mercedes-Benz air conditioning and climate control systems? Air conditioning and climate control systems involve both mechanical and electrical components, leading to various potential issues.

- Refrigerant Leaks: Leaks in the system can reduce cooling performance.

- Compressor Problems: A faulty compressor can prevent the system from cooling effectively.

- Sensor Failures: Temperature and pressure sensor problems can disrupt system operation.

- Actuator Issues: Problems with blend door actuators can affect temperature control.

Diagnosing these systems requires checking refrigerant levels, testing compressor performance, and using diagnostic scanners to read sensor data. CARDIAGTECH.NET provides diagnostic tools that support Mercedes-Benz climate control systems, helping technicians diagnose and resolve AC issues efficiently. Research by the Mobile Air Conditioning Society (MACS) emphasizes the importance of proper diagnostic procedures for AC system repairs.

3.5. Body and Convenience Electronics

What are some of the unique diagnostic challenges presented by the body and convenience electronics in Mercedes-Benz vehicles? Body and convenience electronics control various functions, and diagnosing issues can be complex.

- Wiring Problems: Faulty wiring and connectors can cause various electrical problems.

- Module Failures: Issues with body control modules (BCMs) can disrupt multiple functions.

- Sensor Issues: Problems with door sensors, seat sensors, or lighting sensors can cause malfunctions.

- Software Glitches: Software issues in the BCM can lead to erratic behavior.

Diagnosing these systems requires checking wiring diagrams, testing sensors, and using diagnostic scanners to read BCM data. CARDIAGTECH.NET offers diagnostic tools that support Mercedes-Benz body electronics, enabling technicians to diagnose and repair these issues effectively. According to a survey by Automotive Engineering International, body electronics are becoming increasingly complex, requiring advanced diagnostic skills.

4. Strategies for Overcoming Diagnostic Challenges

What strategies can technicians employ to overcome the diagnostic challenges posed by modern Mercedes-Benz vehicles? Employing systematic approaches, investing in training, and leveraging support networks can significantly improve diagnostic accuracy and efficiency.

4.1. Systematic Diagnostic Approaches

Why is a systematic approach essential for diagnosing complex issues in Mercedes-Benz vehicles? A systematic approach ensures that technicians address diagnostic tasks methodically, reducing errors and improving efficiency.

- Gather Information: Collect as much information as possible about the problem, including DTCs, symptoms, and vehicle history.

- Verify the Complaint: Confirm the customer’s complaint and reproduce the issue if possible.

- Perform a Visual Inspection: Check for obvious signs of damage, such as broken wires, leaks, or worn components.

- Use Diagnostic Tools: Utilize diagnostic scanners, multimeters, and other tools to gather data and perform tests.

- Analyze Data: Interpret the data and identify potential causes of the problem.

- Verify the Repair: After making repairs, verify that the issue is resolved and that no new problems have been introduced.

Following a systematic approach helps technicians avoid guesswork and ensures that all potential causes are considered. A study by the Society of Automotive Technicians (SAT) emphasizes the importance of systematic diagnostic procedures for efficient and accurate repairs.

4.2. Investing in Training and Education

How does continuous training and education benefit technicians working on modern Mercedes-Benz vehicles? Continuous training and education are vital for keeping technicians up-to-date with the latest technologies and diagnostic techniques.

- Manufacturer-Specific Training: Courses offered by Mercedes-Benz provide in-depth knowledge of their vehicles and systems.

- Diagnostic Tool Training: Training on how to use diagnostic tools effectively can improve diagnostic accuracy.

- Industry Certifications: Certifications such as ASE demonstrate competency and commitment to professional development.

- Online Resources: Utilizing online resources such as webinars, tutorials, and technical articles helps technicians expand their knowledge.

Investing in training and education enhances technicians’ skills and confidence, enabling them to diagnose and repair complex issues more effectively. Research from the National Automotive Technicians Education Foundation (NATEF) highlights the positive impact of training and education on technician performance.

4.3. Leveraging Online Resources and Communities

How can online resources and communities help technicians diagnose and repair Mercedes-Benz vehicles? Online resources and communities provide valuable support and information for technicians.

- Online Forums: Forums dedicated to Mercedes-Benz diagnostics allow technicians to share information, ask questions, and learn from each other.

- Technical Databases: Online databases provide access to wiring diagrams, repair manuals, and diagnostic information.

- Video Tutorials: Video tutorials offer step-by-step instructions for various diagnostic and repair procedures.

- Vendor Support: Diagnostic tool vendors often provide online support, including FAQs, troubleshooting guides, and software updates.

Leveraging these resources can help technicians overcome diagnostic challenges and stay up-to-date with the latest information. A survey by the Automotive Service Association (ASA) indicates that online resources and communities are increasingly important for automotive technicians.

4.4. Utilizing OEM and Aftermarket Diagnostic Tools Effectively

What are the key considerations when choosing and using OEM and aftermarket diagnostic tools for Mercedes-Benz vehicles? Both OEM and aftermarket diagnostic tools offer unique advantages, and choosing the right tool depends on the technician’s needs and budget.

- OEM Tools: Provide the most comprehensive diagnostic capabilities and access to all vehicle systems.

- Aftermarket Tools: Offer a more affordable alternative, with a wide range of features and capabilities.

When using diagnostic tools, it is important to:

- Keep Software Updated: Ensure that the diagnostic tool has the latest software updates to support new vehicle models and systems.

- Follow Instructions: Follow the manufacturer’s instructions for using the diagnostic tool to avoid errors.

- Interpret Data Carefully: Analyze the data carefully and consider all potential causes of the problem.

Utilizing diagnostic tools effectively can significantly improve diagnostic accuracy and efficiency. A report by the Equipment and Tool Institute (ETI) emphasizes the importance of proper tool usage and maintenance for accurate diagnostics.

4.5. Collaborating with Other Technicians and Experts

Why is collaboration important for diagnosing complex issues in modern Mercedes-Benz vehicles? Collaborating with other technicians and experts can provide valuable insights and support for diagnosing complex issues.

- Sharing Knowledge: Sharing knowledge and experience with other technicians can help identify potential causes of the problem.

- Seeking Advice: Asking for advice from experts can provide guidance and direction.

- Teamwork: Working as a team can improve diagnostic efficiency and accuracy.

Collaboration can be particularly helpful when dealing with intermittent problems or complex systems. Research from the Automotive Career Development Center (ACDC) highlights the benefits of collaboration and teamwork in the automotive industry.

5. The Future of Mercedes-Benz Diagnostics

What trends and technologies will shape the future of Mercedes-Benz diagnostics? The future of automotive diagnostics will be influenced by advancements in technology, including artificial intelligence (AI), remote diagnostics, and enhanced data analytics.

5.1. Artificial Intelligence (AI) in Diagnostics

How will artificial intelligence (AI) transform the diagnostic process for Mercedes-Benz vehicles? AI has the potential to revolutionize automotive diagnostics by:

- Automated Diagnostics: AI algorithms can analyze diagnostic data and automatically identify potential causes of the problem.

- Predictive Maintenance: AI can predict when components are likely to fail, allowing for proactive maintenance.

- Remote Diagnostics: AI can enable remote diagnostics, allowing technicians to diagnose and repair vehicles from a distance.

- Improved Accuracy: AI can improve diagnostic accuracy by analyzing large amounts of data and identifying patterns that humans may miss.

AI-powered diagnostic tools can significantly improve diagnostic efficiency and accuracy, reducing downtime and improving customer satisfaction. A report by Deloitte predicts that AI will play an increasingly important role in the automotive industry, including diagnostics.

5.2. Remote Diagnostics and Over-the-Air (OTA) Updates

What role will remote diagnostics and over-the-air (OTA) updates play in the future of Mercedes-Benz vehicle maintenance? Remote diagnostics and OTA updates enable technicians to diagnose and repair vehicles remotely, reducing the need for physical visits.

- Remote Diagnostics: Technicians can access vehicle data remotely and perform diagnostic tests from a distance.

- OTA Updates: Software updates can be delivered over the air, eliminating the need for physical visits to the repair shop.

These technologies can improve diagnostic efficiency and convenience, reducing downtime and improving customer satisfaction. Research from Gartner indicates that remote diagnostics and OTA updates will become increasingly common in the automotive industry.

5.3. Enhanced Data Analytics and Predictive Maintenance

How will enhanced data analytics and predictive maintenance improve the reliability and longevity of Mercedes-Benz vehicles? Enhanced data analytics and predictive maintenance can improve vehicle reliability and longevity by:

- Monitoring Vehicle Data: Continuously monitoring vehicle data to identify potential problems early on.

- Predicting Component Failures: Using data analytics to predict when components are likely to fail.

- Proactive Maintenance: Performing maintenance before components fail, preventing breakdowns and reducing downtime.

These technologies can improve vehicle reliability, reduce maintenance costs, and improve customer satisfaction. A report by McKinsey & Company emphasizes the importance of data analytics and predictive maintenance in the automotive industry.

6. CARDIAGTECH.NET Solutions for Mercedes-Benz Diagnostics

How does CARDIAGTECH.NET support technicians in diagnosing and repairing modern Mercedes-Benz vehicles? CARDIAGTECH.NET offers a comprehensive range of diagnostic tools, equipment, and support services to help technicians overcome the challenges of diagnosing modern Mercedes-Benz vehicles.

6.1. Advanced Diagnostic Tools and Equipment

What specific diagnostic tools and equipment does CARDIAGTECH.NET offer for Mercedes-Benz vehicles? CARDIAGTECH.NET provides a wide range of diagnostic tools and equipment, including:

- OEM Diagnostic Scanners: Provide comprehensive diagnostic capabilities and access to all vehicle systems.

- Multimeters and Oscilloscopes: Essential for testing electrical circuits and sensor signals.

- Specialized Software: Required for programming and coding ECUs.

- CAN Bus Analyzers: Used to diagnose communication issues within the vehicle’s network.

These tools are designed to meet the needs of technicians working on modern Mercedes-Benz vehicles, providing accurate and reliable diagnostic data.

6.2. Comprehensive Diagnostic Software and Updates

How does CARDIAGTECH.NET ensure that technicians have access to the latest diagnostic software and updates? CARDIAGTECH.NET provides regular software updates and technical support to ensure that technicians have access to the latest diagnostic information.

- Software Updates: Regular software updates to support new vehicle models and systems.

- Technical Support: Online and telephone support from experienced technicians.

- Diagnostic Databases: Access to comprehensive diagnostic databases with wiring diagrams, repair manuals, and troubleshooting guides.

These resources help technicians stay up-to-date with the latest technologies and diagnostic techniques.

6.3. Training and Support Resources

What types of training and support resources does CARDIAGTECH.NET offer to help technicians improve their diagnostic skills? CARDIAGTECH.NET offers a variety of training and support resources, including:

- Online Training Courses: Online courses covering various diagnostic topics.

- Video Tutorials: Video tutorials offering step-by-step instructions for various diagnostic and repair procedures.

- Technical Articles: Technical articles providing insights into new technologies and diagnostic techniques.

- Online Forums: Online forums where technicians can share information, ask questions, and learn from each other.

These resources help technicians improve their diagnostic skills and stay up-to-date with the latest technologies.

6.4. Secure and Compliant Diagnostic Solutions

How does CARDIAGTECH.NET address cybersecurity concerns and ensure secure diagnostic access for Mercedes-Benz vehicles? CARDIAGTECH.NET provides diagnostic solutions that comply with manufacturer security protocols, ensuring technicians can securely access and diagnose vehicle systems.

- Secure Gateways: Diagnostic tools that support secure gateways.

- Authentication: Authentication protocols to verify technician credentials.

- Data Encryption: Data encryption to protect diagnostic data from unauthorized access.

These security measures ensure that technicians can diagnose and repair vehicles safely and securely.

6.5. Cost-Effective Solutions for Independent Repair Shops

How does CARDIAGTECH.NET provide cost-effective diagnostic solutions for independent repair shops working on Mercedes-Benz vehicles? CARDIAGTECH.NET offers a range of diagnostic tools and equipment at competitive prices, enabling independent repair shops to equip their workshops without breaking the bank.

- Affordable Tools: Diagnostic tools and equipment at competitive prices.

- Flexible Financing Options: Flexible financing options to help shops invest in the tools they need.

- Trade-In Programs: Trade-in programs to help shops upgrade their existing tools.

These solutions help independent repair shops compete with dealerships and provide high-quality diagnostic services to their customers.

Navigating the complexities of modern Mercedes-Benz diagnostics requires specialized knowledge, advanced tools, and continuous training. CARDIAGTECH.NET is committed to providing technicians with the resources they need to overcome these challenges and deliver exceptional service.

For expert assistance and to explore our range of diagnostic solutions, contact CARDIAGTECH.NET at:

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Don’t let diagnostic challenges hold you back. Contact us today and elevate your diagnostic capabilities with CARDIAGTECH.NET.

FAQ: Diagnosing Modern Mercedes-Benz Vehicles

-

What is the most common diagnostic challenge with modern Mercedes-Benz vehicles?

The integration of complex electronic systems is often cited as the biggest challenge. Technicians need to understand how various systems communicate and interact. According to a survey by the Automotive Management Institute (AMI), staying current with rapidly changing technology is a top concern for automotive technicians. -

Why are OEM diagnostic tools preferred for Mercedes-Benz vehicles?

OEM (Original Equipment Manufacturer) diagnostic tools offer the most comprehensive access to vehicle systems and functions, providing detailed diagnostic information and support for advanced features. These tools are specifically designed for Mercedes-Benz vehicles, ensuring accurate and reliable diagnostics. -

How important is training for diagnosing modern Mercedes-Benz vehicles?

Training is crucial. Modern Mercedes-Benz vehicles incorporate advanced technologies that require specialized knowledge. Continuous training helps technicians stay updated with the latest diagnostic techniques and repair procedures. The National Automotive Technicians Education Foundation (NATEF) emphasizes the importance of ongoing education for automotive technicians. -

What role do wiring diagrams play in diagnosing Mercedes-Benz vehicles?

Wiring diagrams are essential for tracing electrical faults and understanding how different components are connected. Accurate wiring diagrams help technicians identify and resolve electrical issues efficiently. -

What are the limitations of relying solely on Diagnostic Trouble Codes (DTCs)?

DTCs provide a starting point, but they often indicate a symptom rather than the root cause of the problem. Technicians need to perform thorough system testing and analysis to accurately diagnose the issue. A study by the Automotive Research Association of India (ARAI) highlights the importance of comprehensive diagnostic procedures. -

How do cybersecurity measures impact the diagnostic process?

Cybersecurity measures, such as secure gateways, can restrict access to certain diagnostic functions, complicating the diagnostic process for independent repair shops. Technicians need to use secure and compliant diagnostic solutions to access protected systems. -

Why are intermittent problems difficult to diagnose?

Intermittent problems occur sporadically, making it difficult to capture the fault during the diagnostic process. Advanced data logging capabilities and thorough inspection techniques are needed to diagnose these issues effectively. -

How can remote diagnostics improve the efficiency of Mercedes-Benz vehicle maintenance?

Remote diagnostics allow technicians to access vehicle data and perform diagnostic tests from a distance, reducing the need for physical visits and improving diagnostic efficiency. This technology can also enable over-the-air (OTA) updates, further streamlining the maintenance process. -

What is the role of artificial intelligence (AI) in future diagnostics?

AI has the potential to automate diagnostic processes, predict component failures, and improve diagnostic accuracy by analyzing large amounts of data. AI-powered diagnostic tools can significantly enhance diagnostic efficiency and reduce downtime. -

How can CARDIAGTECH.NET help technicians diagnose modern Mercedes-Benz vehicles?

CARDIAGTECH.NET offers a range of advanced diagnostic tools, comprehensive software, training resources, and secure diagnostic solutions designed to help technicians overcome the challenges of diagnosing modern Mercedes-Benz vehicles. Our cost-effective solutions are tailored to meet the needs of independent repair shops, providing access to the latest technologies and expert support. Contact us at +1 (641) 206-8880 or visit CARDIAGTECH.NET for more information.