What is the Meaning of Different Types of Fault Codes?

Diagnostic trouble codes (DTCs), also called engine fault codes, are essential for identifying and diagnosing malfunctions in vehicles. Want to understand these codes and keep your car running smoothly? CARDIAGTECH.NET provides high-quality diagnostic tools that help you quickly identify and resolve issues. Let’s explore the meaning behind different types of fault codes, ensuring your vehicle stays in top condition with our advanced diagnostic equipment.

1. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes used to identify and diagnose malfunctions in a vehicle. What exactly are these codes and why are they important for car maintenance?

DTCs are codes generated by a vehicle’s on-board diagnostics (OBD) system when it detects a problem. According to SAE International, these codes help technicians diagnose and resolve issues efficiently. Think of DTCs as your car’s way of telling you something is wrong, like a check-engine light that requires a specific diagnostic tool to interpret the engine fault code. Ignoring these codes can lead to more severe damage and costly repairs.

1.1 The Role of On-Board Diagnostics (OBD)

The On-Board Diagnostics (OBD) system monitors various functions of the engine, transmission, and emissions control systems. How does this system work to detect issues in your vehicle?

The OBD system continuously monitors vehicle operations and alerts the driver via the “check engine” light when a problem is detected. According to the Environmental Protection Agency (EPA), OBD-II systems, standardized since 1996, provide a uniform set of DTCs across different manufacturers. This standardization allows technicians to quickly identify issues using a diagnostic tool, saving time and ensuring accurate repairs.

1.2 Critical vs. Non-Critical DTCs

DTCs can be categorized as either critical or non-critical. What’s the difference between these two types of codes and how should you respond to them?

Critical DTCs require immediate attention as they can cause severe damage, such as a high engine temperature. Non-critical DTCs are less urgent but still important to diagnose correctly. As explained by automotive expert John Law, “Ignoring any DTC can lead to more significant problems down the road, so timely diagnosis is key.” For example, a non-critical code might indicate a minor issue with the emissions system, which, if left unattended, could lead to more severe problems.

2. Explanation of OBD-II Diagnostic Trouble Codes

OBD-II diagnostic trouble codes consist of a five-character string. How can you decipher these codes to understand the underlying problem?

Each character in the DTC provides specific information about the fault. For instance, a code like P0575 can be broken down as follows:

- First Letter: Indicates the main part at fault (P = Powertrain, B = Body, C = Chassis, U = Network).

- Second Character: Denotes whether it’s a generic (0) or manufacturer-specific code (1).

- Third Character: Specifies the system at fault (e.g., 1 = Fuel and Air Metering, 3 = Ignition System or Misfire).

- Last Two Characters: Pinpoint the specific fault.

2.1 Breakdown of the Five Characters

Let’s dive deeper into the meaning of each character in an OBD-II DTC. How does this breakdown help in diagnosing vehicle problems?

The five characters provide a structured way to understand the nature and location of the problem. According to the Society of Automotive Engineers (SAE), the first letter categorizes the area of the vehicle affected. The second character distinguishes between generic and manufacturer-specific codes, while the third character narrows down the system at fault. The last two characters give the precise fault, allowing technicians to pinpoint the issue quickly.

2.2 Examples of Common OBD-II Codes

Understanding some common OBD-II codes can help you recognize potential issues early. What are some examples of these codes and their meanings?

Here are a few common OBD-II codes:

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0171: System Too Lean (Bank 1)

- P0300: Random/Multiple Cylinder Misfire Detected

According to automotive diagnostics expert Mike Thornton, P0420 often indicates a faulty catalytic converter, while P0171 suggests a vacuum leak or a dirty mass airflow sensor. Knowing these common codes can help you understand your vehicle’s health.

2.3 Manufacturer-Specific Codes

Besides generic codes, there are manufacturer-specific codes. How do these codes differ and why are they important?

Manufacturer-specific codes are used when a manufacturer feels a generic code doesn’t cover a specific fault adequately. These codes allow for more detailed diagnostics tailored to the specific make and model of the vehicle. As stated by a Bosch Automotive Handbook, manufacturer-specific codes can provide crucial information for diagnosing unique issues that are not covered by the standard OBD-II codes.

3. Reading J1939 DTCs

J1939 DTCs are used in heavy-duty vehicles and equipment. How do these codes differ from OBD-II codes?

J1939 DTCs, used in trucks, buses, and construction equipment, are based on four fields relaying data in a DTC fault:

- Suspect Parameter Number (SPN): A 19-bit number specifying the particular DTC.

- Failure Mode Identifier (FMI): Provides specific information relating to DTCs.

- Occurrence Counter (OC): Calculates the number of occurrences related to each SPN.

- SPN Conversion Method (CM): Defines the byte alignment of the DTC.

3.1 Understanding SPN and FMI

SPN and FMI are key components of J1939 DTCs. What do these fields represent and how do they aid in diagnostics?

The Suspect Parameter Number (SPN) identifies the specific component or system with the fault, while the Failure Mode Identifier (FMI) describes the type of fault. According to the National Institute for Automotive Service Excellence (ASE), “The combination of SPN and FMI provides a detailed description of the problem, allowing technicians to quickly identify and address the issue.”

3.2 Importance of Occurrence Counter (OC)

The Occurrence Counter (OC) tracks the number of times a fault has occurred. Why is this information important for diagnosing intermittent issues?

The Occurrence Counter helps technicians understand how frequently a fault occurs, which is especially useful for diagnosing intermittent problems. As explained in a technical paper by Cummins, the OC provides valuable insight into the reliability of the system and can help predict future failures. This information is crucial for preventative maintenance and ensuring vehicle uptime.

3.3 SPN Conversion Method (CM) Explained

The SPN Conversion Method (CM) defines the byte alignment of the DTC. How does this affect the interpretation of the code?

The SPN Conversion Method (CM) ensures that the data is correctly interpreted by defining how the bytes are aligned. This is crucial for accurate communication between different electronic control units (ECUs) in the vehicle. According to the J1939 standards, the CM ensures that the data is read correctly, preventing misdiagnosis and ensuring accurate repairs.

4. Common Diagnostic Trouble Codes and Their Meanings

Certain DTCs appear more frequently than others. What are some of the most common codes and what do they indicate about your vehicle’s health?

According to Technicians Service Training, some of the most common diagnostic trouble codes include:

- P0420 & P0430: Catalyst System Efficiency Below Threshold (Bank 1 & 2)

- P0171: System Too Lean (Bank one)

- P0300: Random/Multiple Cylinder Misfire Detected

- P0440: Evaporative Emission Control System Malfunction

- P0128: Coolant Thermostat

- P0172: System too rich (Bank one)

- P0401: Exhaust Gas Recirculation Flow Insufficient Detected

4.1 P0420 & P0430: Catalyst System Efficiency

P0420 and P0430 indicate issues with the catalytic converter. What are the potential causes and how can you address them?

These codes mean the catalytic converter isn’t efficiently breaking down harmful pollutants. Potential causes include a faulty catalytic converter, failing oxygen sensor, bad wiring, exhaust leaks, or software issues. According to the EPA, a malfunctioning catalytic converter can significantly increase emissions, making it crucial to address this issue promptly.

4.2 P0171: System Too Lean (Bank 1)

P0171 indicates that the engine is running with too much air and not enough fuel. What are the common causes of this code?

This code is triggered when the oxygen sensor detects a lean mixture. Common causes include a dirty mass airflow sensor, vacuum leak, bad oxygen sensors, low fuel pressure, or low gas. According to a study by the University of Michigan, vacuum leaks are a frequent cause of lean codes in older vehicles.

4.3 P0300: Random/Multiple Cylinder Misfire

P0300 indicates a misfire in one or more cylinders. What are the potential reasons for this misfire?

This code signals that there is no combustion in a cylinder. Reasons include worn spark plugs, damaged spark plug wires, a worn distributor cap, defective fuel injectors, ignition timing problems, low fuel pressure, or a faulty oxygen sensor. According to the National Institute for Automotive Service Excellence (ASE), misfires can lead to engine damage if not addressed quickly.

4.4 P0440: Evaporative Emission Control System

P0440 indicates a malfunction in the evaporative emission control system. What are the common causes of this code?

This code appears if the EVAP system, which stores fuel vapor, isn’t working correctly. The most common cause is an improperly seated gas cap, but it can also indicate leaks in the fuel vapor system. According to the California Air Resources Board (CARB), a properly functioning EVAP system is crucial for reducing harmful emissions.

4.5 P0128: Coolant Thermostat

P0128 triggers when the coolant temperature falls below the thermostat regulating temperature. What are the possible causes?

This usually means the engine isn’t reaching its operating temperature in a specific amount of time. Typically, the coolant thermostat is stuck open or operating prematurely. Other causes include a faulty coolant temperature sensor or wiring problems. As stated by a Gates Corporation technical bulletin, a malfunctioning thermostat can affect engine efficiency and fuel economy.

4.6 P0172: System Too Rich (Bank 1)

P0172 indicates that the engine is running with too much fuel and not enough air. What are the causes of this code?

This code is triggered when the oxygen level in the exhaust is too low, indicating a fuel-heavy mixture. Causes include worn spark plugs, a fault in the coolant system, a vacuum leak, a faulty fuel regulator, a leaking fuel injector, a defective oxygen sensor, or a dirty Mass Air Flow (MAF) sensor. Automotive expert David Vizard notes that rich conditions can lead to reduced fuel economy and increased emissions.

4.7 P0401: Exhaust Gas Recirculation Flow Insufficient

P0401 indicates insufficient exhaust gas recirculation flow. What are the reasons for this issue?

This DTC is present when the computer detects an insufficient EGR flow. Reasons include a valve that can’t open properly due to low vacuum pressure, a temperature sensor that doesn’t detect the correct temperature change, or blocked EGR passages. According to a report by the U.S. Department of Energy, a properly functioning EGR system is essential for reducing nitrogen oxide emissions.

5. Understanding Permanent DTCs

Permanent Diagnostic Trouble Codes (DTCs) cannot be reset using a diagnostic scanning tool or by disconnecting the vehicle’s battery. What makes these codes permanent and how can you clear them?

Permanent DTCs can only be cleared by fixing the underlying issue and allowing the vehicle enough time to re-run the monitor that identified the initial problem. As explained by the EPA, permanent DTCs are designed to ensure that vehicle owners address the root cause of the problem before clearing the code.

5.1 Why Permanent DTCs Exist

Why were permanent DTCs introduced and what purpose do they serve?

Permanent DTCs were introduced to prevent vehicle owners from clearing codes without addressing the underlying issues, which can lead to increased emissions and potential damage. According to the EPA, these codes help ensure that vehicles comply with emissions standards and that problems are properly resolved.

5.2 How to Clear a Permanent DTC

Clearing a permanent DTC requires more than just a scanner. What steps must be taken to clear these codes?

To clear a permanent DTC, you must first fix the underlying issue that caused the code. Then, you need to drive the vehicle through the specific driving cycle required to re-run the monitor. If the monitor passes, the permanent DTC will clear automatically. As noted by automotive technician Ken Hansen, “It’s crucial to follow the manufacturer’s recommended driving cycle to ensure the monitor runs correctly.”

5.3 Importance of Addressing the Root Cause

Ignoring the root cause of a permanent DTC can lead to more severe problems. Why is it essential to address the underlying issue?

Addressing the root cause ensures that the problem is resolved, preventing further damage and potential safety issues. According to the National Highway Traffic Safety Administration (NHTSA), neglecting permanent DTCs can lead to vehicle malfunctions that compromise safety and performance.

6. How to Read Diagnostic Trouble Codes

Reading DTCs requires a scanner that plugs into the vehicle and interprets the OBD code. What are the steps to access these codes?

Here are the steps to read diagnostic trouble codes:

- Plug into the OBD port: Locate the OBD port, usually under the driver-side dashboard, and plug in the scanner.

- Turn on the ignition: Switch on the ignition to power the scanner.

- Enter necessary information: Some scanners require the vehicle identification number (VIN), model, make, or engine type.

- Navigate the OBD codes: The scanner will display active and pending codes.

- Interpreting the DTC: Use the information provided to understand the nature of the problem, consulting a website or app for detailed explanations.

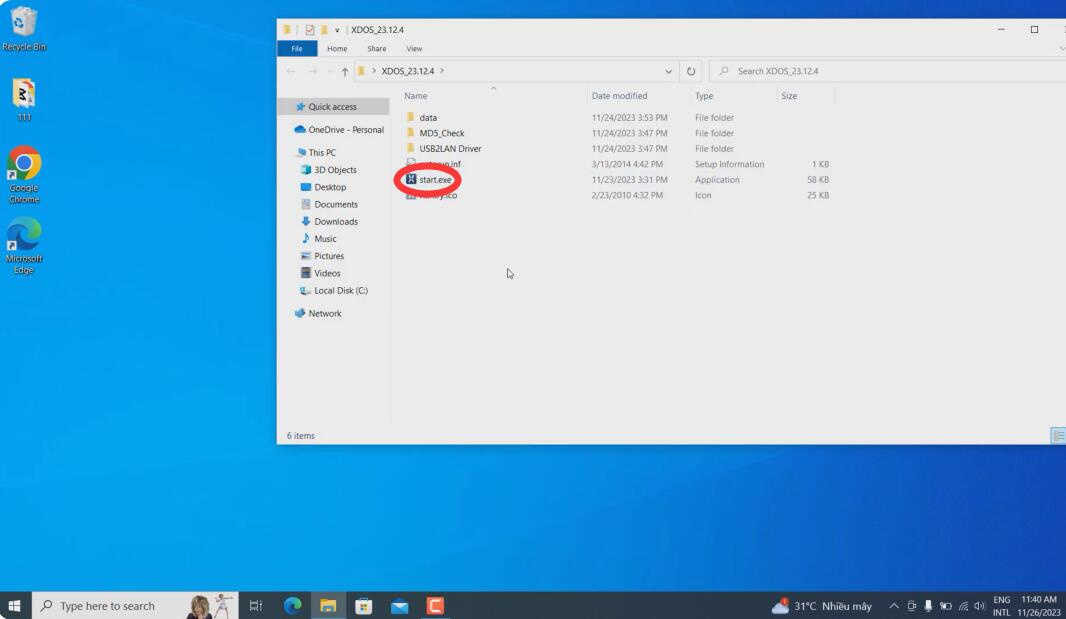

6.1 Step-by-Step Guide to Using a Scanner

Let’s break down the process of using a scanner to read DTCs. What are the key steps to follow?

Using a scanner involves several key steps. First, locate the OBD-II port, which is typically found under the driver-side dashboard. Once you’ve plugged in the scanner, turn the ignition to the “on” position without starting the engine. The scanner will then power up and prompt you to enter vehicle information such as the VIN, make, and model. After entering the necessary details, navigate through the scanner’s menu to read the DTCs.

6.2 Understanding Active and Pending Codes

Scanners often display both active and pending codes. What’s the difference between these types of codes?

Active codes indicate current malfunctions that have triggered the check engine light, while pending codes refer to intermittent faults that the system needs to see happen in consecutive warm-up cycles to be considered active. According to Bosch Automotive Handbook, pending codes can provide early warnings of potential issues, allowing for proactive maintenance.

6.3 Choosing the Right Diagnostic Tool

Selecting the right diagnostic tool is crucial for accurate readings. What factors should you consider when choosing a scanner?

When choosing a diagnostic tool, consider factors such as compatibility with your vehicle, ease of use, and features like code definitions and live data streaming. As recommended by Consumer Reports, it’s essential to choose a scanner that provides accurate and reliable information. CARDIAGTECH.NET offers a range of high-quality diagnostic tools tailored to meet your specific needs, ensuring you get the most accurate and reliable readings. Contact us at +1 (641) 206-8880 for expert advice.

7. Advanced Diagnostic Techniques

Beyond reading basic DTCs, there are advanced diagnostic techniques that can help pinpoint complex issues. What are some of these techniques?

Advanced diagnostic techniques include using an oscilloscope to analyze electrical signals, performing compression tests to evaluate engine health, and using smoke machines to detect vacuum leaks. As explained by automotive diagnostics expert Craig Van Batenburg, these techniques can provide valuable insights into complex problems that are not easily identified by DTCs alone.

7.1 Using Live Data to Diagnose Issues

Live data streaming can provide real-time information about various engine parameters. How can this data be used to diagnose issues?

Live data allows technicians to monitor sensor readings, engine parameters, and other critical information in real-time. By analyzing this data, technicians can identify anomalies and pinpoint the root cause of the problem. According to the Society of Automotive Engineers (SAE), live data streaming is a powerful tool for diagnosing intermittent issues and complex system failures.

7.2 Performing Component Tests

Component tests involve testing individual components to ensure they are functioning correctly. What are some common component tests and how are they performed?

Component tests include checking the resistance of sensors, testing the output of actuators, and verifying the integrity of wiring harnesses. These tests can help isolate faulty components and ensure they are replaced correctly. As noted by automotive technician Mike Massel, component testing is essential for accurate diagnostics and preventing unnecessary repairs.

7.3 Analyzing Freeze Frame Data

Freeze frame data captures the engine parameters at the moment a DTC is triggered. How can this data be used to diagnose problems?

Freeze frame data provides a snapshot of the vehicle’s operating conditions when a DTC was set, including engine speed, load, and temperature. By analyzing this data, technicians can gain valuable insights into the conditions that led to the fault. According to Bosch Automotive Handbook, freeze frame data can help identify patterns and diagnose intermittent issues.

8. Maintaining Your Vehicle to Prevent Fault Codes

Regular maintenance can help prevent many common fault codes. What are some essential maintenance tasks?

Regular maintenance tasks include changing the oil, replacing air filters, inspecting hoses and belts, and checking fluid levels. By keeping your vehicle in good condition, you can prevent many common issues that trigger DTCs. As recommended by Consumer Reports, following the manufacturer’s recommended maintenance schedule is essential for long-term reliability.

8.1 Importance of Regular Oil Changes

Regular oil changes are crucial for engine health. How often should you change your oil and why is it important?

Oil changes should be performed according to the manufacturer’s recommendations, typically every 3,000 to 7,500 miles, depending on the vehicle and driving conditions. According to the American Petroleum Institute (API), regular oil changes help remove contaminants and maintain proper lubrication, preventing engine wear and potential fault codes.

8.2 Checking and Replacing Air Filters

Air filters prevent dirt and debris from entering the engine. How often should you check and replace your air filters?

Air filters should be checked regularly and replaced every 12,000 to 15,000 miles, or more frequently in dusty conditions. According to the U.S. Department of Energy, clean air filters improve engine efficiency and fuel economy, preventing issues that can trigger DTCs.

8.3 Inspecting Hoses and Belts

Hoses and belts can deteriorate over time. How often should you inspect them and what should you look for?

Hoses and belts should be inspected regularly for cracks, wear, and leaks. Replace them as needed to prevent failures that can lead to engine damage and DTCs. As noted by Gates Corporation, inspecting hoses and belts regularly can prevent costly breakdowns and ensure reliable vehicle operation.

9. The Future of Diagnostic Trouble Codes

Diagnostic technology is constantly evolving. What does the future hold for diagnostic trouble codes and vehicle diagnostics?

The future of diagnostic trouble codes includes more advanced algorithms, integration with cloud-based data analytics, and enhanced remote diagnostics capabilities. According to a report by McKinsey & Company, the automotive industry is moving towards predictive maintenance, using data analytics to anticipate and prevent failures before they occur.

9.1 Integration with Telematics Systems

Telematics systems can provide real-time data on vehicle performance. How will this integration impact diagnostic trouble codes?

Integration with telematics systems allows for continuous monitoring of vehicle health, enabling early detection of potential issues. According to a study by Berg Insight, telematics systems can significantly reduce downtime and maintenance costs by providing real-time alerts and diagnostic information.

9.2 Cloud-Based Data Analytics

Cloud-based data analytics can help identify trends and patterns in vehicle performance. How will this technology enhance diagnostics?

Cloud-based data analytics can aggregate data from multiple vehicles to identify common issues and predict failures. This technology allows for more accurate diagnostics and proactive maintenance. As explained by Bosch, cloud-based analytics can transform the way vehicles are maintained, leading to increased efficiency and reduced costs.

9.3 Remote Diagnostics and Over-the-Air Updates

Remote diagnostics and over-the-air updates can streamline the diagnostic process. How will these technologies improve vehicle maintenance?

Remote diagnostics allow technicians to access vehicle data remotely, enabling faster and more efficient troubleshooting. Over-the-air updates can fix software issues and improve vehicle performance without requiring a visit to the repair shop. According to a report by IHS Markit, these technologies are revolutionizing the automotive industry, making vehicle maintenance more convenient and cost-effective.

10. CARDIAGTECH.NET: Your Partner in Vehicle Diagnostics

CARDIAGTECH.NET is committed to providing high-quality diagnostic tools and solutions. How can we help you keep your vehicle running smoothly?

At CARDIAGTECH.NET, we offer a wide range of diagnostic tools and equipment to help you accurately identify and resolve vehicle issues. Our products are designed to meet the needs of both professional technicians and DIY enthusiasts.

10.1 High-Quality Diagnostic Tools

We offer a variety of high-quality diagnostic tools to meet your needs. What types of tools do we provide?

Our selection includes OBD-II scanners, J1939 diagnostic tools, and advanced diagnostic equipment for component testing and live data analysis. All our products are rigorously tested to ensure accuracy and reliability.

10.2 Expert Support and Guidance

Our team of experts is here to provide support and guidance. How can we assist you with your diagnostic needs?

We offer expert support and guidance to help you choose the right tools and interpret diagnostic data. Our team is available to answer your questions and provide technical assistance. Contact us at +1 (641) 206-8880 for personalized support.

10.3 Contact Us Today

Ready to improve your vehicle diagnostics? Contact CARDIAGTECH.NET today.

Don’t let diagnostic trouble codes slow you down. Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States or call us at +1 (641) 206-8880. Visit our website at CARDIAGTECH.NET to explore our range of diagnostic tools and equipment. Let us help you keep your vehicle running smoothly and efficiently.

Dealing with car troubles and fault codes can be daunting, but with CARDIAGTECH.NET, you’re not alone. Our team is here to provide expert guidance on selecting the right diagnostic tools to identify and resolve those pesky issues. Whether you’re a seasoned mechanic or a DIY enthusiast, we have the perfect solutions to keep your vehicle running smoothly. Don’t hesitate to reach out and discover how our top-notch equipment can make all the difference in your automotive maintenance routine. Contact us today via Whatsapp: +1 (641) 206-8880 and let us simplify your car care journey.

FAQ: Understanding Diagnostic Trouble Codes

1. What is a diagnostic trouble code (DTC)?

A diagnostic trouble code (DTC) is a code generated by a vehicle’s on-board diagnostics (OBD) system when it detects a problem. These codes help technicians diagnose and resolve issues efficiently.

2. How do I read diagnostic trouble codes?

You can read DTCs using a scanner that plugs into the vehicle’s OBD port, typically located under the driver-side dashboard. The scanner interprets the code, providing information about the fault.

3. What is the difference between active and pending codes?

Active codes indicate current malfunctions that have triggered the check engine light, while pending codes refer to intermittent faults that the system needs to see happen in consecutive warm-up cycles to be considered active.

4. What is a permanent DTC?

A permanent DTC cannot be reset using a diagnostic scanning tool or by disconnecting the vehicle’s battery. It can only be cleared by fixing the underlying issue and allowing the vehicle enough time to re-run the monitor that identified the initial problem.

5. What does the first letter in a DTC indicate?

The first letter indicates the main part at fault: P = Powertrain, B = Body, C = Chassis, U = Network.

6. What is the most common cause of a P0440 code?

The most common cause of a P0440 code, indicating an evaporative emission control system malfunction, is an improperly seated gas cap.

7. How often should I change my oil to prevent fault codes?

Oil changes should be performed according to the manufacturer’s recommendations, typically every 3,000 to 7,500 miles, depending on the vehicle and driving conditions.

8. What are some advanced diagnostic techniques?

Advanced diagnostic techniques include using an oscilloscope to analyze electrical signals, performing compression tests to evaluate engine health, and using smoke machines to detect vacuum leaks.

9. How can telematics systems impact diagnostic trouble codes?

Integration with telematics systems allows for continuous monitoring of vehicle health, enabling early detection of potential issues and providing real-time alerts and diagnostic information.

10. How can CARDIAGTECH.NET help with vehicle diagnostics?

CARDIAGTECH.NET provides high-quality diagnostic tools and equipment, along with expert support and guidance, to help you accurately identify and resolve vehicle issues. Contact us at +1 (641) 206-8880 for personalized assistance.