**What Parameters Are Important When Diagnosing the Steering System?**

Diagnosing the steering system involves assessing various parameters to pinpoint issues, and understanding these parameters is critical for effective repairs. CARDIAGTECH.NET provides the tools and knowledge needed to address these complexities. This article explores essential diagnostic parameters, system types, and strategies for accurate troubleshooting, ensuring vehicle safety and optimal performance while providing insights into steering feedback, electric steering systems, and EPS diagnostics, enabling technicians to resolve steering problems efficiently.

1. Understanding Steering System Types

What are the different types of steering systems in modern vehicles? Modern vehicles employ various steering systems, including manual steering, hydraulic power steering (HPS), electro-hydraulic power steering (EHPS), and electric power steering (EPS). EPS systems, increasingly common since 2004, utilize an electric motor for power assist, differing significantly from hydraulic systems. According to a study by the University of Michigan Transportation Research Institute in 2022, EPS systems now account for over 60% of new vehicle production due to their efficiency and adaptability. Understanding these systems is critical for accurate diagnosis.

1.1. Manual Steering

What are the key characteristics of manual steering systems? Manual steering systems rely solely on the driver’s physical effort to turn the wheels, without any power assistance. These systems are typically found in older vehicles or those designed for simplicity and cost-effectiveness. Manual steering provides a direct feel of the road but requires more effort, especially at low speeds or when maneuvering heavy vehicles. The key components include the steering wheel, steering shaft, and a mechanical linkage that translates the rotational motion into lateral movement of the wheels.

1.2. Hydraulic Power Steering (HPS)

How does hydraulic power steering enhance vehicle maneuverability? Hydraulic power steering (HPS) uses a hydraulic pump, driven by the engine, to provide power assistance. This system reduces the effort required to turn the steering wheel, especially at low speeds. HPS systems consist of a pump, fluid reservoir, hydraulic lines, and a control valve that directs fluid pressure to assist steering. While effective, HPS systems can be less efficient due to the constant energy consumption by the pump, even when no steering input is applied.

1.3. Electro-Hydraulic Power Steering (EHPS)

What are the advantages of electro-hydraulic power steering? Electro-hydraulic power steering (EHPS) systems combine hydraulic assistance with an electric motor to drive the hydraulic pump. This setup allows the power assist to be controlled electronically, providing efficiency gains compared to traditional HPS systems. EHPS can vary the amount of assistance based on vehicle speed and steering input, optimizing fuel consumption. EHPS systems are common in vehicles needing a balance of power and efficiency.

1.4. Electric Power Steering (EPS)

How does electric power steering improve fuel efficiency and handling? Electric power steering (EPS) systems use an electric motor to directly assist steering, eliminating the need for a hydraulic pump and fluid. EPS enhances fuel efficiency by only consuming power when steering assistance is needed. Modern EPS systems can be highly sophisticated, offering variable assist levels based on vehicle speed, driving conditions, and driver preferences. EPS also supports advanced safety features like lane keep assist and parking assist. According to a 2023 report by the National Renewable Energy Laboratory, vehicles equipped with EPS can see a fuel efficiency improvement of 3-5% compared to HPS systems. CARDIAGTECH.NET offers advanced diagnostic tools to properly service and maintain EPS systems, improving vehicle performance and safety.

2. Critical Diagnostic Parameters for Steering Systems

What are the essential parameters to monitor when diagnosing steering problems? Diagnosing steering system issues requires monitoring several key parameters, including steering angle sensor data, torque sensor readings, vehicle speed input, and motor current in EPS systems. Additionally, hydraulic pressure in HPS systems and mechanical condition assessments are vital. Regularly evaluating these parameters with tools from CARDIAGTECH.NET ensures precise diagnostics and effective repairs.

2.1. Steering Angle Sensor (SAS)

Why is the steering angle sensor crucial for modern steering systems? The steering angle sensor (SAS) measures the steering wheel’s position and rate of turn. This data is critical for EPS and vehicle stability control systems. Accurate SAS readings ensure proper steering assist and prevent stability control errors. A malfunctioning SAS can cause erratic steering behavior or disable safety features.

2.2. Torque Sensor

How does the torque sensor contribute to steering feel and assist? The torque sensor measures the amount of force applied to the steering wheel by the driver. This information is used by the EPS module to determine the level of power assist needed. Correct torque sensor readings are crucial for maintaining proper steering feel and responsiveness.

2.3. Vehicle Speed Input

Why is vehicle speed input necessary for proper steering system operation? Vehicle speed input allows the EPS module to adjust steering assist based on the vehicle’s speed. Higher assist is provided at low speeds for easy maneuvering, while lower assist is provided at high speeds for stability. Inaccurate speed input can lead to inconsistent or inappropriate steering assist.

2.4. Motor Current

How does monitoring motor current help diagnose EPS issues? Monitoring the motor current in EPS systems can help diagnose issues with the electric motor or the EPS module. Abnormal current draw can indicate a failing motor, wiring problems, or a faulty EPS module. Regular monitoring can prevent unexpected failures and ensure reliable steering performance.

2.5. Hydraulic Pressure (HPS/EHPS)

What does hydraulic pressure indicate in hydraulic power steering systems? In HPS and EHPS systems, hydraulic pressure is a key indicator of the system’s health. Low pressure can indicate a failing pump, leaks, or a blocked filter. Monitoring hydraulic pressure helps diagnose issues with the power steering pump, hydraulic lines, and control valves. According to research from Texas A&M University’s Vehicle Systems & Control Laboratory in 2021, maintaining proper hydraulic pressure is crucial for optimal steering performance and responsiveness.

2.6. Mechanical Condition

Why is assessing the mechanical condition important in steering system diagnostics? Assessing the mechanical condition of steering components, such as tie rods, ball joints, and steering rack, is crucial for identifying wear, damage, or excessive play. Mechanical issues can cause vague steering, vibrations, and uneven tire wear. Regular inspections and timely replacements of worn components ensure safe and predictable steering.

3. Diagnosing Electric Power Steering (EPS) Systems

What are the key steps in diagnosing electric power steering (EPS) systems? Diagnosing EPS systems involves several steps, including scanning for diagnostic trouble codes, checking sensor inputs, and evaluating motor performance. Proper diagnosis requires specialized tools and a thorough understanding of EPS components. CARDIAGTECH.NET provides state-of-the-art diagnostic equipment to accurately identify and resolve EPS issues, restoring optimal steering performance.

3.1. Scanning for Diagnostic Trouble Codes (DTCs)

How do diagnostic trouble codes assist in EPS troubleshooting? Scanning for diagnostic trouble codes (DTCs) is the first step in diagnosing EPS issues. DTCs provide valuable information about the nature and location of the problem. A “C-series” code typically indicates issues within the EPS system, while a “U-series” code suggests communication problems between modules.

3.2. Analyzing Sensor Data

Why is analyzing sensor data important for EPS diagnostics? Analyzing sensor data from the torque sensor, steering angle sensor, and vehicle speed sensor is crucial for EPS diagnostics. Comparing live data with expected values can reveal sensor malfunctions or inconsistencies. Correlating sensor inputs helps identify the root cause of steering problems.

3.3. Evaluating Motor Performance

How do you assess motor performance in an EPS system? Evaluating the motor performance in an EPS system involves monitoring motor current, voltage, and temperature. Abnormal readings can indicate a failing motor, wiring issues, or a faulty EPS module. Motor performance tests help determine if the motor is providing the correct amount of assist.

3.4. Performing Actuator Tests

What are actuator tests and how do they aid in EPS diagnosis? Actuator tests allow technicians to command the EPS motor to operate at different levels, verifying its functionality. These tests help identify issues with the motor, wiring, or EPS module. Actuator tests are an essential part of a comprehensive EPS diagnosis.

3.5. Checking Wiring and Connections

Why is inspecting wiring and connections critical for EPS system reliability? Inspecting wiring and connections for corrosion, damage, or loose connections is crucial for EPS system reliability. Wiring problems can cause intermittent issues or complete system failure. Thorough inspections ensure that all components are properly connected and functioning.

4. Diagnosing Hydraulic Power Steering (HPS) Systems

What are the key procedures for diagnosing hydraulic power steering (HPS) systems? Diagnosing HPS systems requires checking fluid levels, inspecting for leaks, and evaluating pump performance. Understanding the hydraulic components and their functions is essential for accurate diagnostics. CARDIAGTECH.NET provides the necessary tools and resources to effectively troubleshoot and repair HPS systems.

4.1. Checking Fluid Levels and Condition

Why is maintaining proper fluid levels important for HPS systems? Checking the fluid level and condition is the first step in diagnosing HPS problems. Low fluid levels can cause pump cavitation and reduced steering assist. Contaminated fluid can damage the pump and other components. Regular checks and timely fluid changes ensure optimal performance.

4.2. Inspecting for Leaks

How do you identify and address leaks in hydraulic power steering systems? Inspecting for leaks in the hydraulic lines, pump, and steering gear is crucial for HPS system maintenance. Leaks can cause fluid loss, reduced steering assist, and environmental concerns. Addressing leaks promptly prevents further damage and ensures safe operation.

4.3. Evaluating Pump Performance

What are the indicators of a failing power steering pump? Evaluating the pump performance involves checking the hydraulic pressure and flow rate. Low pressure or flow can indicate a failing pump. Testing the pump under load helps determine its ability to provide adequate steering assist.

4.4. Checking Belt Tension and Condition

Why is belt maintenance important for HPS systems? Checking the belt tension and condition is important for HPS systems driven by an engine-mounted pump. A loose or worn belt can cause reduced pump performance and steering assist. Regular belt inspections and replacements ensure reliable operation.

4.5. Bleeding the System

How do you properly bleed an HPS system after repairs? Bleeding the HPS system is necessary after repairs to remove air from the hydraulic lines. Air in the system can cause noisy operation and reduced steering assist. Following the manufacturer’s recommended bleeding procedure ensures optimal performance.

5. Steering Feedback and Its Importance

Why is steering feedback essential for driver confidence and control? Steering feedback provides the driver with a sense of connection to the road, enhancing confidence and control. Steering feedback is influenced by the design of the steering gear and the calibration of electronic systems. Restoring proper steering feedback is crucial for driver satisfaction and safety.

5.1. Mechanical Steering Feedback

How do mechanical components contribute to steering feedback in manual systems? In manual steering systems, mechanical components like the worm gear and sector shaft provide steering feedback. The preload between these components creates a center point feel, giving the driver a sense of steering wheel position. Wear in these components can lead to a loss of feedback and steering wander.

5.2. Electronic Steering Feedback

How is steering feedback simulated in electric power steering systems? In electric power steering systems, electronic steering feedback is simulated by the EPS module. The module uses data from the torque sensor, steering angle sensor, and vehicle speed sensor to provide appropriate feedback. Software calibration plays a crucial role in fine-tuning steering feel.

5.3. Diagnosing Loss of Feedback

What are the common causes of lost steering feedback in modern vehicles? Diagnosing a loss of steering feedback involves checking mechanical components, sensor data, and EPS module calibration. Mechanical wear, sensor malfunctions, or software issues can all contribute to a lack of feedback. Addressing these issues restores proper steering feel.

5.4. Recalibration and Reprogramming

Why is recalibration sometimes necessary for EPS systems? Recalibration and reprogramming of the EPS module may be necessary to restore proper steering feedback. Software updates can improve steering feel and address intermittent issues. Following manufacturer’s recommendations ensures optimal performance.

5.5. The Role of Alignment

How does wheel alignment affect steering feedback? Wheel alignment plays a crucial role in steering feedback. Incorrect alignment can cause vague steering, pulling, and uneven tire wear. Aligning the wheels to the vehicle’s thrust centerline ensures proper steering feel and handling.

6. Common Steering System Problems and Solutions

What are the typical issues encountered in steering systems, and how can they be resolved? Common steering system problems include vague steering, noise, pulling, and uneven tire wear. Solutions range from replacing worn components to recalibrating electronic systems. With the right tools and knowledge, technicians can effectively address these issues and restore optimal steering performance.

6.1. Vague Steering

What causes vague steering and how can it be corrected? Vague steering can be caused by worn tie rod ends, ball joints, or steering rack bushings. Replacing these components and performing a wheel alignment can restore precise steering. Checking and adjusting the EPS system’s calibration can also improve steering feel.

6.2. Steering Noise

What are the potential sources of noise in the steering system? Steering noise can be caused by low power steering fluid, a failing power steering pump, or air in the hydraulic lines. Identifying the source of the noise and addressing the underlying issue resolves the problem. Flushing and refilling the power steering system can also help.

6.3. Pulling to One Side

Why does a vehicle sometimes pull to one side, and how can it be fixed? Pulling to one side is often caused by incorrect wheel alignment, uneven tire wear, or brake issues. Performing a wheel alignment, replacing worn tires, and inspecting the brakes can correct this problem. Checking the suspension components for damage is also essential.

6.4. Uneven Tire Wear

What factors contribute to uneven tire wear in steering systems? Uneven tire wear can be caused by incorrect wheel alignment, worn suspension components, or improper tire inflation. Addressing these issues and performing regular tire rotations can extend tire life. Inspecting the steering system for worn components is also crucial.

6.5. Intermittent Steering Assist

What causes intermittent steering assist in EPS systems? Intermittent steering assist in EPS systems can be caused by sensor malfunctions, wiring issues, or a failing EPS module. Scanning for diagnostic trouble codes and analyzing sensor data helps identify the root cause. Replacing faulty components and recalibrating the EPS module resolves the problem.

7. Advanced Diagnostic Tools for Steering Systems

What advanced tools are available for diagnosing and repairing steering systems? Advanced diagnostic tools for steering systems include scan tools, hydraulic pressure gauges, and alignment machines. These tools provide valuable data for accurate troubleshooting and repairs. CARDIAGTECH.NET offers a comprehensive selection of advanced tools to meet the needs of modern automotive technicians.

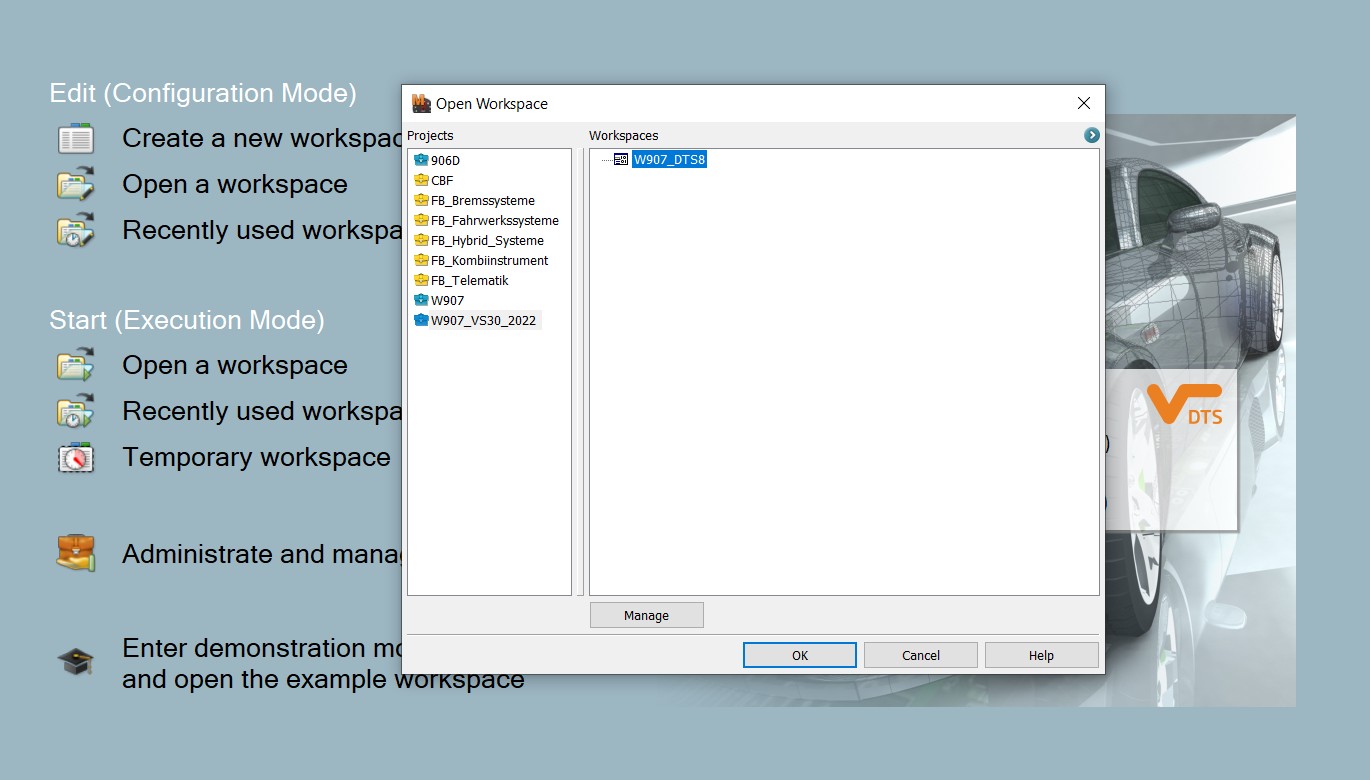

7.1. Scan Tools

How do scan tools enhance steering system diagnostics? Scan tools allow technicians to access diagnostic trouble codes, sensor data, and perform actuator tests. These tools are essential for diagnosing electronic steering systems and identifying the root cause of problems. Modern scan tools can also perform module programming and recalibration.

7.2. Hydraulic Pressure Gauges

Why are hydraulic pressure gauges necessary for diagnosing HPS systems? Hydraulic pressure gauges are used to measure the pressure in hydraulic power steering systems. These gauges help diagnose issues with the power steering pump, hydraulic lines, and control valves. Accurate pressure readings are essential for effective troubleshooting.

7.3. Alignment Machines

How do alignment machines contribute to steering system accuracy? Alignment machines are used to measure and adjust the wheel alignment angles. Proper wheel alignment ensures optimal steering feel, handling, and tire wear. Modern alignment machines provide precise measurements and step-by-step instructions for adjustments.

7.4. Multimeters

Why are multimeters essential for electrical diagnostics in steering systems? Multimeters are used to measure voltage, current, and resistance in electrical circuits. These tools are essential for diagnosing wiring issues, sensor malfunctions, and other electrical problems in steering systems. Accurate measurements are crucial for effective troubleshooting.

7.5. Oscilloscopes

How do oscilloscopes aid in diagnosing complex steering system issues? Oscilloscopes are used to visualize electrical signals and waveforms. These tools are helpful for diagnosing intermittent issues and analyzing sensor data. Oscilloscopes provide a detailed view of electrical activity, allowing technicians to identify subtle problems.

8. Preventative Maintenance for Steering Systems

Why is preventative maintenance important for ensuring long-term steering system reliability? Preventative maintenance, including regular inspections and timely fluid changes, is crucial for ensuring long-term steering system reliability. Proactive maintenance prevents unexpected failures and extends the life of steering components. CARDIAGTECH.NET supports technicians with high-quality tools and components for effective preventative maintenance.

8.1. Regular Inspections

What should be included in a regular steering system inspection? Regular inspections should include checking fluid levels, inspecting for leaks, and assessing the condition of steering components. Identifying and addressing issues early prevents further damage and ensures safe operation. Inspections should be performed at every oil change or service interval.

8.2. Fluid Changes

How often should power steering fluid be changed? Power steering fluid should be changed according to the manufacturer’s recommendations. Regular fluid changes remove contaminants and ensure optimal performance. Using the correct type of fluid is essential for preventing damage to the power steering system.

8.3. Component Lubrication

Why is lubricating steering components important? Lubricating steering components, such as tie rod ends and ball joints, reduces friction and wear. Proper lubrication extends the life of these components and ensures smooth steering operation. Using high-quality grease is essential for effective lubrication.

8.4. Wheel Alignment

How often should wheel alignment be checked and adjusted? Wheel alignment should be checked and adjusted at least once a year, or whenever new tires are installed. Proper wheel alignment ensures optimal steering feel, handling, and tire wear. Regular alignment checks prevent uneven tire wear and improve fuel efficiency.

8.5. Belt Maintenance

Why is maintaining the drive belt important for HPS systems? Maintaining the drive belt for HPS systems is crucial for ensuring reliable pump operation. A worn or loose belt can cause reduced steering assist and pump damage. Regular belt inspections and replacements prevent unexpected failures.

9. Safety Considerations When Working on Steering Systems

What safety precautions should technicians take when servicing steering systems? Safety is paramount when working on steering systems. Technicians should disconnect the battery, use proper lifting techniques, and follow manufacturer’s guidelines. Adhering to safety protocols prevents injuries and ensures a safe working environment.

9.1. Disconnecting the Battery

Why is disconnecting the battery important when working on steering systems? Disconnecting the battery prevents accidental activation of electrical components. This is especially important when working on EPS systems to avoid injuries or damage to the system. Following proper disconnection procedures ensures safety.

9.2. Using Proper Lifting Techniques

Why is using proper lifting techniques important when working on steering systems? Using proper lifting techniques prevents injuries when raising the vehicle to access steering components. Following safety guidelines for jack placement and using jack stands ensures a stable and safe working environment.

9.3. Following Manufacturer’s Guidelines

Why should manufacturer’s guidelines be followed during steering system repairs? Following manufacturer’s guidelines ensures that repairs are performed correctly and safely. Manufacturer’s guidelines provide detailed instructions for disassembly, assembly, and testing. Adhering to these guidelines prevents damage to the system and ensures optimal performance.

9.4. Wearing Safety Gear

Why is wearing safety gear important when working on steering systems? Wearing safety gear, such as gloves and eye protection, protects technicians from injuries. Gloves prevent skin contact with fluids and chemicals, while eye protection prevents debris from entering the eyes. Using appropriate safety gear ensures a safe working environment.

9.5. Verifying System Operation

Why is verifying system operation after repairs important? Verifying system operation after repairs ensures that the steering system is functioning correctly. Performing a test drive and checking for proper steering feel, noise, and pulling confirms that the repairs were successful. Addressing any remaining issues ensures safe and reliable operation.

10. Staying Updated with Steering System Technology

How can technicians stay updated with the latest advancements in steering system technology? Staying updated with the latest advancements in steering system technology requires ongoing training and access to technical resources. Attending seminars, reading technical publications, and using online resources keeps technicians informed about new technologies and diagnostic techniques. CARDIAGTECH.NET supports technicians with access to the latest tools, information, and training materials.

10.1. Attending Training Seminars

Why is attending training seminars important for staying updated? Attending training seminars provides hands-on experience and expert instruction on new steering system technologies. Seminars cover diagnostic techniques, repair procedures, and the use of advanced tools. Participating in training seminars enhances skills and knowledge.

10.2. Reading Technical Publications

Why is reading technical publications important for staying informed? Reading technical publications keeps technicians informed about the latest advancements in steering system technology. Publications cover diagnostic tips, repair strategies, and new product information. Staying informed ensures that technicians are prepared to handle any steering system issue.

10.3. Using Online Resources

How can online resources aid in staying updated with steering system technology? Online resources, such as manufacturer websites and technical forums, provide access to valuable information. These resources offer diagnostic tips, repair procedures, and software updates. Using online resources enhances problem-solving skills and keeps technicians up-to-date.

10.4. Participating in Technical Forums

Why is participating in technical forums beneficial for technicians? Participating in technical forums allows technicians to share knowledge and learn from others. Forums provide a platform for discussing diagnostic challenges, repair strategies, and new technologies. Engaging in technical forums enhances problem-solving skills and fosters collaboration.

10.5. Investing in Advanced Tools

Why is investing in advanced diagnostic tools important for modern technicians? Investing in advanced diagnostic tools ensures that technicians have the equipment needed to diagnose and repair modern steering systems. Advanced tools provide accurate data, perform actuator tests, and support module programming. Equipping technicians with the right tools enhances efficiency and quality of service.

By thoroughly understanding these parameters and utilizing the advanced diagnostic tools available at CARDIAGTECH.NET, technicians can efficiently diagnose and repair steering systems, ensuring vehicle safety and optimal performance.

Is your steering system giving you trouble? Contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States or Whatsapp at +1 (641) 206-8880 for expert diagnostics and top-quality tools. Let us help you steer clear of problems and drive with confidence! Visit CARDIAGTECH.NET today!

FAQ: Diagnosing Steering System Parameters

1. What is the most important parameter to check when diagnosing a steering problem?

The steering angle sensor (SAS) is critical for diagnosing modern steering systems, as it provides data on steering wheel position and rate of turn. Inaccurate SAS readings can lead to steering assist issues and stability control errors.

2. How does a torque sensor affect steering system performance?

The torque sensor measures the force applied to the steering wheel, which is used by the EPS module to determine the level of power assist needed. Proper torque sensor readings are essential for maintaining good steering feel and responsiveness.

3. Why is vehicle speed input important for electric power steering (EPS) systems?

Vehicle speed input allows the EPS module to adjust steering assist based on the vehicle’s speed, providing higher assist at low speeds and lower assist at high speeds for stability.

4. What does low hydraulic pressure indicate in a hydraulic power steering (HPS) system?

Low hydraulic pressure in an HPS system can indicate a failing pump, leaks, or a blocked filter. Monitoring hydraulic pressure helps diagnose issues with the power steering pump and hydraulic lines.

5. What are the common symptoms of a failing power steering pump?

Common symptoms of a failing power steering pump include noisy operation, reduced steering assist, and leaks. Evaluating the hydraulic pressure and flow rate can help diagnose pump issues.

6. How can diagnostic trouble codes (DTCs) help diagnose EPS problems?

Diagnostic trouble codes provide valuable information about the nature and location of the problem in EPS systems. A “C-series” code typically indicates issues within the EPS system, while a “U-series” code suggests communication problems between modules.

7. What is the role of actuator tests in EPS diagnostics?

Actuator tests allow technicians to command the EPS motor to operate at different levels, verifying its functionality and helping identify issues with the motor, wiring, or EPS module.

8. Why is it important to check wiring and connections in steering systems?

Inspecting wiring and connections for corrosion, damage, or loose connections is crucial for steering system reliability, as wiring problems can cause intermittent issues or complete system failure.

9. How does wheel alignment affect steering system performance?

Wheel alignment plays a crucial role in steering feedback, handling, and tire wear. Incorrect alignment can cause vague steering, pulling, and uneven tire wear.

10. What are some advanced tools used for diagnosing steering systems?

Advanced diagnostic tools for steering systems include scan tools, hydraulic pressure gauges, alignment machines, multimeters, and oscilloscopes, providing valuable data for accurate troubleshooting and repairs.