What Types of Sensors Need to Be Calibrated? A Comprehensive Guide

Unlocking peak performance and reliability in your vehicle starts with understanding which sensors need calibration. At CARDIAGTECH.NET, we empower automotive technicians with the knowledge and tools to ensure precise sensor readings, optimizing engine performance and safety. From temperature sensors to complex control systems, discover the critical sensors that demand regular calibration, enhancing your diagnostic capabilities and customer satisfaction. Let’s explore sensor calibration to keep your repairs on point and your customers happy with tools from CARDIAGTECH.NET, plus essential services for accurate diagnostics, improved performance, and enhanced vehicle safety.

1. Understanding Sensor Calibration

What is Sensor Calibration?

Sensor calibration is the process of configuring a sensor to ensure it provides accurate and reliable readings. According to a study by the National Institute of Standards and Technology (NIST), proper calibration reduces measurement errors by up to 80%. This involves comparing the sensor’s output to a known standard and making adjustments to minimize any discrepancies.

Why is Sensor Calibration Important?

Why is sensor calibration essential for automotive diagnostics and maintenance? Sensor calibration is critical for ensuring accurate and reliable data from vehicle sensors. Regular calibration helps maintain the precision of sensor readings, which directly impacts engine performance, fuel efficiency, and overall vehicle safety. Uncalibrated sensors can lead to incorrect diagnoses, potentially causing further damage and increased repair costs. By keeping sensors properly calibrated, technicians can provide accurate services and enhance customer satisfaction, according to a report by the Equipment Service Association (ESA).

How Often Should Sensors Be Calibrated?

How frequently should sensors be calibrated to maintain optimal performance? The calibration frequency depends on the type of sensor, its usage, and the environmental conditions it operates in. Some sensors may require calibration every few months, while others can last a year or more. The key is to follow the manufacturer’s recommendations and monitor sensor performance regularly. According to ISO 9001 standards, regular calibration ensures measurement accuracy and traceability.

2. Types of Sensors That Require Calibration

2.1. Temperature Sensors

Why do temperature sensors need calibration, and what types are most affected? Temperature sensors are vital for monitoring engine temperature, coolant levels, and ambient air temperature. These sensors often require calibration due to environmental factors and wear. According to research from the American Society of Mechanical Engineers (ASME), temperature sensors can drift over time, leading to inaccurate readings.

- Engine Coolant Temperature (ECT) Sensor: Ensures the engine operates at the correct temperature.

- Intake Air Temperature (IAT) Sensor: Measures the temperature of the air entering the engine.

- Exhaust Gas Temperature (EGT) Sensor: Monitors the temperature of exhaust gases.

2.2. Pressure Sensors

How critical is pressure sensor calibration for vehicle performance? Pressure sensors are used in various systems, including tire pressure monitoring, engine management, and brake systems. Calibration is essential because pressure sensors are susceptible to drift due to mechanical stress and environmental conditions. According to a study by the Society of Automotive Engineers (SAE), pressure sensors can lose accuracy over time if not properly calibrated.

- Tire Pressure Monitoring System (TPMS) Sensors: Monitor tire pressure to ensure safe driving conditions.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the engine’s intake manifold.

- Fuel Rail Pressure Sensor: Monitors the pressure of the fuel in the fuel rail.

2.3. Oxygen Sensors

Why is oxygen sensor calibration important for emissions control and fuel efficiency? Oxygen sensors measure the oxygen content in the exhaust gases, which is crucial for optimizing fuel efficiency and reducing emissions. These sensors need regular calibration to ensure accurate readings, as they can become contaminated over time. A report by the Environmental Protection Agency (EPA) highlights the importance of calibrated oxygen sensors for meeting emissions standards.

2.4. Mass Air Flow (MAF) Sensors

How does calibrating MAF sensors enhance engine performance and reduce emissions? Mass Air Flow (MAF) sensors measure the amount of air entering the engine, which is essential for calculating the correct fuel-air mixture. These sensors require calibration because they can become dirty or damaged, leading to inaccurate readings. According to research from the University of Michigan, proper MAF sensor calibration can significantly improve engine performance and reduce emissions.

2.5. Throttle Position Sensors (TPS)

What role does TPS calibration play in ensuring smooth acceleration and engine response? Throttle Position Sensors (TPS) monitor the position of the throttle, which is critical for controlling engine speed and power. Calibration is necessary to ensure the sensor accurately reflects the throttle position, preventing issues like stalling or poor acceleration. A study by the Automotive Service Association (ASA) emphasizes the importance of TPS calibration for optimal engine performance.

2.6. Camshaft and Crankshaft Position Sensors

Why is precise calibration of camshaft and crankshaft sensors essential for engine timing? Camshaft and Crankshaft Position Sensors provide critical information about the position and speed of the engine’s rotating parts. Accurate calibration ensures the engine timing is correct, which is vital for efficient combustion and overall engine performance. According to a report by the National Automotive Technicians Education Foundation (NATEF), these sensors are fundamental to engine operation and require precise calibration.

2.7. Knock Sensors

How does calibrating knock sensors protect the engine from damage? Knock sensors detect abnormal combustion (knocking) in the engine, allowing the engine control unit (ECU) to adjust timing and prevent damage. Calibration ensures the sensor accurately identifies knocking, protecting the engine from potential harm. Research from the Argonne National Laboratory highlights the role of knock sensors in maintaining engine health.

2.8. Steering Angle Sensors

Why is steering angle sensor calibration crucial for modern vehicle safety systems? Steering Angle Sensors measure the position of the steering wheel, which is used in electronic stability control (ESC) and other safety systems. Calibration is essential to ensure these systems function correctly, preventing accidents and enhancing vehicle stability. A study by the National Highway Traffic Safety Administration (NHTSA) underscores the importance of calibrated steering angle sensors for vehicle safety.

2.9. Ride Height Sensors

How does calibrating ride height sensors improve vehicle handling and stability? Ride Height Sensors measure the distance between the vehicle’s body and the road, which is used in adaptive suspension systems. Calibration ensures the system maintains the correct ride height, improving handling and stability. According to research from the Transportation Research Board, proper calibration of ride height sensors enhances vehicle dynamics and ride quality.

2.10. Rain Sensors

What role does rain sensor calibration play in automatic wiper systems? Rain sensors detect the presence of rain on the windshield and automatically activate the wipers. Calibration ensures the wipers respond appropriately to varying levels of rainfall, improving visibility and safety. A report by the Insurance Institute for Highway Safety (IIHS) highlights the benefits of calibrated rain sensors in reducing accidents during wet conditions.

3. Calibration Methods

3.1. One-Point Calibration

What is one-point calibration, and when is it most effective? One-Point Calibration involves adjusting the sensor output based on a single known reference point. This method is suitable for sensors with linear responses and minimal drift. According to Adafruit, one-point calibration is commonly used for temperature sensors in systems that maintain constant temperatures.

3.2. Two-Point Calibration

How does two-point calibration improve sensor accuracy, and what types of sensors benefit most? Two-Point Calibration uses two known reference points to adjust both the offset and slope of the sensor output. This method is more accurate than one-point calibration and is ideal for sensors with linear but inconsistent responses. Adafruit notes that two-point calibration is often used for temperature sensors, using ice water (0.01°C) and boiling water (100°C) as reference points.

3.3. Multi-Point Calibration

When is multi-point calibration necessary, and what level of accuracy can it achieve? Multi-Point Calibration uses multiple reference points to create a calibration curve, correcting for non-linearity and inconsistencies across the sensor’s range. This method provides the highest accuracy and is essential for critical applications. According to Wikipedia, multi-point calibration often involves curve-fitting techniques to achieve the best possible accuracy.

4. Step-by-Step Calibration Guide

4.1. Preparing for Calibration

What are the initial steps to prepare for sensor calibration? Before starting the calibration process, gather the necessary tools and information. This includes:

- Diagnostic Scan Tool: Essential for reading sensor data and making adjustments.

- Reference Standards: Accurate devices for comparison (e.g., calibrated thermometer, pressure gauge).

- Manufacturer Specifications: Calibration procedures and reference values.

- Clean Environment: Ensure the work area is free from contaminants that could affect sensor readings.

4.2. Performing the Calibration

How do you perform a sensor calibration accurately? Follow these steps for accurate sensor calibration:

- Connect the Diagnostic Tool: Plug the scan tool into the vehicle’s OBD-II port and select the appropriate sensor.

- Read Current Values: Record the current sensor readings to compare them with reference values.

- Apply Reference Standard: Expose the sensor to the known reference standard (e.g., immerse a temperature sensor in ice water).

- Adjust Sensor Output: Use the scan tool to adjust the sensor output until it matches the reference value.

- Verify Calibration: Repeat the process with additional reference points (if necessary) to ensure accuracy.

4.3. Verifying the Calibration

What steps should you take to ensure the calibration is accurate? After calibration, verify the accuracy by:

- Comparing Readings: Compare the sensor readings with known standards at multiple points within the operating range.

- Performing a Test Drive: Conduct a test drive to monitor sensor performance under real-world conditions.

- Checking for Error Codes: Ensure no new error codes are triggered after calibration.

5. Common Calibration Mistakes to Avoid

5.1. Using Incorrect Reference Standards

Why is using the correct reference standard critical for accurate calibration? Using incorrect or uncalibrated reference standards can lead to inaccurate sensor readings. Always use certified reference devices that meet the manufacturer’s specifications. According to NIST, using traceable reference standards is essential for ensuring measurement accuracy.

5.2. Ignoring Environmental Factors

How can environmental conditions affect sensor calibration? Environmental factors such as temperature and humidity can affect sensor performance. Calibrate sensors under stable and controlled conditions to minimize errors. A study by the American Society for Testing and Materials (ASTM) highlights the importance of environmental controls during calibration.

5.3. Neglecting Sensor Cleaning

Why is cleaning the sensor important before calibration? Dirt and debris can interfere with sensor readings, leading to inaccurate calibration. Clean sensors thoroughly before starting the calibration process. According to the Equipment Service Association (ESA), proper sensor maintenance is crucial for accurate measurements.

6. The Role of Diagnostic Tools in Calibration

6.1. Types of Diagnostic Tools

What types of diagnostic tools are essential for sensor calibration? Diagnostic tools are essential for reading sensor data, making adjustments, and verifying calibration accuracy. Common types of diagnostic tools include:

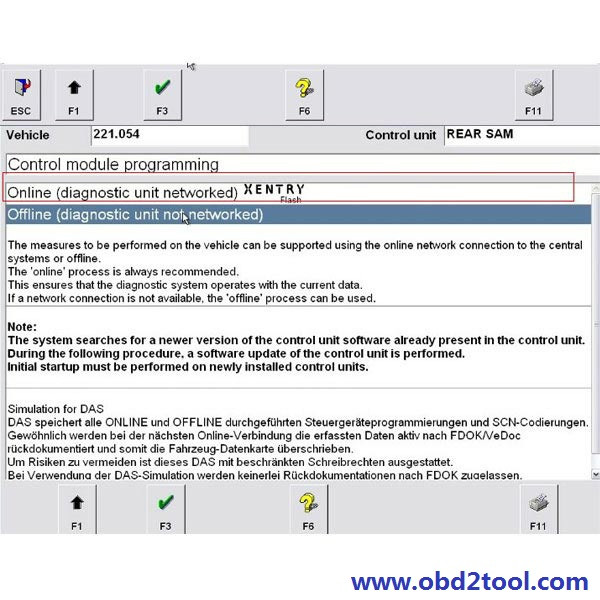

- OBD-II Scanners: Basic tools for reading and clearing error codes.

- Advanced Scan Tools: Provide detailed sensor data, calibration functions, and diagnostic capabilities.

- Specialized Calibration Tools: Designed for specific sensors, such as TPMS or steering angle sensors.

6.2. Features to Look For in a Diagnostic Tool

What features should you look for when selecting a diagnostic tool for sensor calibration? When selecting a diagnostic tool, consider the following features:

- Sensor-Specific Calibration Functions: Ensures the tool can calibrate a wide range of sensors.

- Data Logging: Allows you to record sensor data for analysis and verification.

- User-Friendly Interface: Simplifies the calibration process and reduces errors.

- Software Updates: Keeps the tool compatible with the latest vehicle models and sensor technologies.

6.3. Using Diagnostic Tools for Calibration

How can diagnostic tools streamline the sensor calibration process? Diagnostic tools streamline the calibration process by:

- Providing Real-Time Data: Displays sensor readings in real-time, allowing for precise adjustments.

- Guiding the Calibration Process: Provides step-by-step instructions and prompts for accurate calibration.

- Verifying Calibration Accuracy: Checks sensor readings against reference values and provides feedback on calibration accuracy.

7. Benefits of Regular Sensor Calibration

7.1. Improved Engine Performance

How does regular sensor calibration contribute to better engine performance? Regular sensor calibration ensures the engine control unit (ECU) receives accurate data, optimizing fuel-air mixture, ignition timing, and other critical parameters. This leads to improved engine performance, including increased power, smoother acceleration, and reduced emissions. According to research from the University of Michigan, proper sensor calibration can significantly enhance engine efficiency and performance.

7.2. Enhanced Fuel Efficiency

Why does sensor calibration matter for fuel economy? Accurate sensor readings are essential for optimizing fuel consumption. Calibrated sensors ensure the engine operates at peak efficiency, reducing fuel waste and lowering operating costs. A report by the Environmental Protection Agency (EPA) highlights the role of sensor calibration in improving fuel efficiency and reducing greenhouse gas emissions.

7.3. Reduced Emissions

How does sensor calibration help in reducing vehicle emissions? Calibrated sensors help maintain optimal combustion, reducing harmful emissions such as nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO). This helps vehicles meet emissions standards and reduces their environmental impact. According to the California Air Resources Board (CARB), proper sensor calibration is essential for meeting emissions regulations.

7.4. Increased Vehicle Safety

In what ways does sensor calibration enhance vehicle safety? Many safety systems, such as electronic stability control (ESC), anti-lock braking system (ABS), and tire pressure monitoring system (TPMS), rely on accurate sensor data. Calibrated sensors ensure these systems function correctly, improving vehicle stability, braking performance, and overall safety. A study by the National Highway Traffic Safety Administration (NHTSA) underscores the importance of calibrated sensors for vehicle safety.

7.5. Extended Sensor Lifespan

How can regular calibration extend the life of vehicle sensors? Regular calibration helps identify and address minor issues before they escalate into major problems. This can extend the lifespan of sensors by preventing premature wear and damage. According to the Equipment Service Association (ESA), proper sensor maintenance, including regular calibration, can significantly increase sensor longevity.

8. Industry Standards and Regulations

8.1. ISO 9001

What is ISO 9001, and how does it relate to sensor calibration? ISO 9001 is an international standard that specifies requirements for a quality management system (QMS). It emphasizes the importance of calibration and maintenance of measuring equipment to ensure accurate and reliable results. According to ISO 9001, organizations must establish and maintain a calibration program to ensure the accuracy of their measurements.

8.2. DIN EN ISO/IEC 17025

What is DIN EN ISO/IEC 17025, and how does it ensure calibration accuracy? DIN EN ISO/IEC 17025 is an international standard that specifies the general requirements for the competence of testing and calibration laboratories. Accreditation to this standard ensures that calibration services are performed with the highest level of accuracy and reliability. According to DIN EN ISO/IEC 17025, accredited laboratories must demonstrate their competence through rigorous assessments and proficiency testing.

8.3. EPA Regulations

How do EPA regulations affect sensor calibration requirements? The Environmental Protection Agency (EPA) sets emissions standards for vehicles and requires regular maintenance to ensure compliance. Sensor calibration is essential for meeting these standards, as accurate sensor readings are necessary for optimizing combustion and reducing emissions. According to the EPA, vehicle owners and technicians must follow manufacturer recommendations for sensor calibration to maintain compliance with emissions regulations.

9. Choosing the Right Calibration Equipment

9.1. Key Considerations

What factors should you consider when selecting calibration equipment? When choosing calibration equipment, consider the following factors:

- Accuracy: Ensure the equipment provides accurate and reliable measurements.

- Compatibility: Verify the equipment is compatible with the types of sensors you need to calibrate.

- Ease of Use: Choose equipment that is user-friendly and easy to operate.

- Durability: Select equipment that is durable and can withstand the rigors of daily use.

- Cost: Balance the cost of the equipment with its features and capabilities.

9.2. Top Calibration Equipment Brands

What are some of the top brands for calibration equipment? Some of the top brands for calibration equipment include:

- Fluke: Known for high-quality multimeters and calibration tools.

- Snap-on: Offers a wide range of diagnostic and calibration equipment.

- Bosch: Provides advanced diagnostic tools and sensor calibration equipment.

- Tecalemit: Specializes in calibration equipment for the automotive industry.

9.3. Where to Buy Calibration Equipment

Where can you purchase reliable sensor calibration equipment? You can purchase sensor calibration equipment from various sources, including:

- CARDIAGTECH.NET: Offers a wide range of diagnostic tools and calibration equipment. Visit us at 276 Reock St, City of Orange, NJ 07050, United States, or contact us via WhatsApp at +1 (641) 206-8880.

- Automotive Parts Suppliers: Local and online suppliers that specialize in automotive tools and equipment.

- Direct from Manufacturers: Purchasing directly from the manufacturer can ensure you get the latest equipment and support.

10. The Future of Sensor Calibration

10.1. Advancements in Sensor Technology

How are advancements in sensor technology impacting calibration methods? Advancements in sensor technology are leading to more sophisticated calibration methods. New sensors may incorporate self-calibration features, reducing the need for manual calibration. According to a report by the IEEE, future sensors will be more accurate, reliable, and easier to calibrate.

10.2. The Role of AI and Machine Learning

How will AI and machine learning influence sensor calibration in the future? Artificial intelligence (AI) and machine learning (ML) are playing an increasingly important role in sensor calibration. AI-powered diagnostic tools can analyze sensor data and automatically adjust calibration parameters, improving accuracy and efficiency. Research from the University of California, Berkeley, suggests that AI and ML will revolutionize sensor calibration in the coming years.

10.3. Remote Calibration

What is remote calibration, and what benefits does it offer? Remote calibration allows technicians to calibrate sensors remotely using cloud-based diagnostic tools. This can save time and reduce the need for specialized equipment. According to a report by McKinsey & Company, remote calibration is becoming more common in the automotive industry, offering greater flexibility and convenience.

Conclusion: Ensuring Accuracy and Reliability

Maintaining the accuracy and reliability of your vehicle’s sensors is paramount for optimal performance, fuel efficiency, and safety. Proper calibration ensures that your engine runs smoothly, emissions are minimized, and critical safety systems function as intended. Trust CARDIAGTECH.NET to provide you with the tools and knowledge necessary for precise sensor calibration, empowering you to deliver top-notch service and enhance customer satisfaction. Remember, consistent calibration is not just a maintenance task; it’s an investment in the longevity and efficiency of your vehicle. For expert guidance and the best calibration equipment, reach out to CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or contact us via WhatsApp at +1 (641) 206-8880. Visit CARDIAGTECH.NET today and take the first step towards a more reliable and efficient vehicle. Proper sensor maintenance, diagnostic precision, and vehicle performance optimization are within your reach with CARDIAGTECH.NET.

FAQ: Sensor Calibration

1. What is the primary goal of sensor calibration in vehicles?

The primary goal is to ensure sensors provide accurate and reliable readings, which optimizes engine performance, fuel efficiency, and safety systems. According to NIST, proper calibration can reduce measurement errors by up to 80%.

2. How often should I calibrate my vehicle’s sensors?

Calibration frequency depends on the sensor type, usage, and environmental conditions. Follow manufacturer recommendations and monitor sensor performance regularly. ISO 9001 standards emphasize regular calibration for measurement accuracy.

3. Can incorrect sensor calibration affect fuel efficiency?

Yes, uncalibrated sensors can lead to incorrect air-fuel mixtures and reduced fuel efficiency. Calibrating sensors ensures optimal combustion, reducing fuel waste and lowering operating costs.

4. What tools do I need for sensor calibration?

Essential tools include a diagnostic scan tool, reference standards (e.g., calibrated thermometer, pressure gauge), and manufacturer specifications.

5. What is one-point calibration, and when is it suitable?

One-point calibration involves adjusting the sensor output based on a single known reference point. It is suitable for sensors with linear responses and minimal drift.

6. How does two-point calibration improve sensor accuracy?

Two-point calibration uses two known reference points to adjust both the offset and slope of the sensor output, making it more accurate than one-point calibration for sensors with linear but inconsistent responses.

7. What is multi-point calibration, and when should it be used?

Multi-point calibration uses multiple reference points to create a calibration curve, correcting for non-linearity and inconsistencies across the sensor’s range, providing the highest accuracy for critical applications.

8. What are some common mistakes to avoid during sensor calibration?

Common mistakes include using incorrect reference standards, ignoring environmental factors, and neglecting sensor cleaning. Always use certified reference devices and calibrate under controlled conditions.

9. How do diagnostic tools aid in the sensor calibration process?

Diagnostic tools provide real-time data, guide the calibration process with step-by-step instructions, and verify calibration accuracy, streamlining the process and reducing errors.

10. Where can I purchase reliable sensor calibration equipment?

You can purchase reliable sensor calibration equipment from CARDIAGTECH.NET, automotive parts suppliers, and directly from manufacturers. Visit CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or contact us via WhatsApp at +1 (641) 206-8880 for expert guidance and top-quality equipment.