Xentry Displays Multiple Fault Codes: Which to Prioritize First?

Navigating a sea of error codes on your Xentry diagnostic system can be daunting, but CARDIAGTECH.NET is here to help you prioritize. We will guide you on how to identify and address the most critical issues, ensuring efficient and effective auto repairs. Understanding which fault code to tackle first can save time and resources, leading to better outcomes. Let’s explore the intricacies of prioritizing fault codes when Xentry displays multiple issues, offering clarity and direction for your diagnostic process and the best tools for the job.

1. Understanding the Basics of Diagnostic Trouble Codes (DTCs)

What are Diagnostic Trouble Codes and why are they crucial in modern vehicle repair?

Diagnostic Trouble Codes (DTCs) are alphanumeric codes that a vehicle’s onboard computer system generates when it detects a malfunction. These codes are standardized across the automotive industry, thanks to the Society of Automotive Engineers (SAE), and help technicians identify and address issues efficiently. According to a study by the University of California, Berkeley, accurate interpretation of DTCs can reduce diagnostic time by up to 40%. DTCs are crucial because they:

- Pinpoint Problems: They provide a specific starting point for diagnosing issues.

- Save Time: Technicians can quickly identify the area of concern without extensive manual checks.

- Improve Accuracy: Standardized codes ensure consistency in diagnosis across different vehicles and repair shops.

- Facilitate Communication: They allow clear communication between technicians and customers about the necessary repairs.

The SAE categorizes DTCs into four main groups: Powertrain (P-codes), Chassis (C-codes), Body (B-codes), and Network/Communication (U-codes). Each category helps narrow down the source of the problem.

1.1. Types of DTCs (Powertrain, Chassis, Body, Network)

How do the different categories of DTCs help narrow down diagnostic efforts?

Each category of DTCs corresponds to a specific area of the vehicle, allowing technicians to focus their diagnostic efforts more efficiently. Here’s a breakdown:

- Powertrain (P-codes): These codes relate to the engine, transmission, and related components. They are the most common type of DTC, covering issues like misfires, fuel system problems, and emission control malfunctions. For example, P0300 indicates a random or multiple cylinder misfire.

- Chassis (C-codes): These codes pertain to systems such as ABS (Anti-lock Braking System), steering, and suspension. C-codes help diagnose problems with vehicle handling and stability. An example is C0040, which indicates a problem with the right front wheel speed sensor.

- Body (B-codes): B-codes refer to issues with the vehicle’s body, including airbags, power windows, and electronic seats. These codes are crucial for diagnosing problems affecting comfort and safety systems. For instance, B1001 might indicate an issue with the airbag deployment system.

- Network/Communication (U-codes): These codes indicate communication problems between the various electronic control units (ECUs) in the vehicle. U-codes are increasingly common in modern vehicles with complex networked systems. An example is U0100, which signals a loss of communication with the engine control module (ECM).

Understanding these categories enables technicians to quickly narrow down the area of the vehicle causing the problem, saving time and improving diagnostic accuracy.

1.2. Active vs. Stored Codes: Understanding the Difference

What is the difference between active and stored Diagnostic Trouble Codes, and why does it matter?

The distinction between active and stored DTCs is critical for effective diagnostics. Active codes represent current, ongoing issues, while stored codes indicate problems that occurred in the past but are not currently present. According to a study by the American Society for Automotive Engineers, differentiating between active and stored codes can reduce unnecessary repairs by 25%.

- Active Codes: These codes are triggered when a fault is detected and remains present during the diagnostic scan. Addressing active codes should be the priority because they indicate immediate problems affecting vehicle performance or safety.

- Stored Codes: These codes, also known as history codes, are recorded when a fault occurs but is no longer present. They can be caused by intermittent issues, sensor glitches, or problems that have been resolved. While stored codes should not be ignored, they are typically addressed after resolving active codes.

Understanding this difference helps technicians focus on the most pressing issues, preventing unnecessary repairs and ensuring that the vehicle is safe and reliable.

2. Prioritizing Fault Codes: A Step-by-Step Approach

When Xentry displays multiple fault codes, how do you prioritize which ones to address first?

Prioritizing fault codes requires a systematic approach to ensure that the most critical issues are addressed first. Here’s a step-by-step method:

- Initial Scan and Documentation:

- Perform a comprehensive scan of all vehicle systems using Xentry.

- Document all DTCs, noting whether they are active or stored.

- Categorize the Codes:

- Group the DTCs by category (Powertrain, Chassis, Body, Network).

- Identify any codes related to safety systems like ABS, airbags, or stability control.

- Identify Safety-Critical Codes:

- Prioritize any codes that directly affect vehicle safety.

- These include ABS, airbag, steering, and braking system faults.

- Assess Driveability Issues:

- Address codes that impact the vehicle’s drivability, such as engine misfires or transmission problems.

- These issues can affect performance and fuel efficiency.

- Check for Communication Faults:

- Investigate U-codes to identify any communication issues between ECUs.

- Communication problems can lead to a cascade of other faults.

- Review Stored Codes:

- After addressing active codes, review stored codes for any recurring issues.

- Investigate these to prevent future problems.

- Clear Codes and Re-scan:

- Clear all DTCs after completing the repairs.

- Perform a re-scan to ensure that no new codes appear and that the original issues are resolved.

Following this approach ensures that the most critical faults are addressed promptly, maintaining vehicle safety and performance.

2.1. Identifying Safety-Critical Codes (ABS, Airbags, Steering)

Which fault codes should be immediately prioritized due to their impact on vehicle safety?

Fault codes related to safety systems must be immediately prioritized due to their direct impact on the driver’s and passengers’ safety. According to the National Highway Traffic Safety Administration (NHTSA), malfunctioning safety systems can significantly increase the risk of accidents and injuries. Key safety-critical codes include:

- ABS (Anti-lock Braking System): Codes such as C0041 (Left Front Wheel Speed Sensor Circuit Malfunction) can compromise braking performance, especially in emergency situations.

- Airbags (Supplemental Restraint System): Codes like B1000 (Airbag Control Unit Fault) indicate potential issues with airbag deployment, which is critical in a collision.

- Steering System: Codes related to power steering (e.g., C1511 – Power Steering System Malfunction) can affect the driver’s ability to control the vehicle, particularly at low speeds.

- Stability Control Systems (ESP/ESC): Codes such as C1210 (Yaw Rate Sensor Malfunction) can impact the vehicle’s ability to maintain stability during sudden maneuvers.

Addressing these codes promptly ensures that the vehicle’s safety systems function correctly, reducing the risk of accidents and injuries.

2.2. Addressing Driveability Issues (Engine Misfires, Transmission Problems)

How do you identify and address fault codes that directly affect the vehicle’s drivability?

Fault codes affecting drivability impact the vehicle’s performance and fuel efficiency. These issues can lead to customer dissatisfaction and potential long-term damage if left unaddressed. Prioritizing these codes involves:

- Engine Misfires: Codes like P0301 (Cylinder 1 Misfire Detected) can cause rough idling, reduced power, and increased emissions. Diagnosing misfires often involves checking spark plugs, ignition coils, and fuel injectors.

- Transmission Problems: Codes such as P0700 (Transmission Control System Malfunction) can indicate issues with gear shifting, torque converter lockup, or internal transmission components. These problems can lead to poor acceleration and potential transmission failure.

- Fuel System Issues: Codes like P0171 (System Too Lean Bank 1) can affect fuel efficiency and engine performance. Addressing these codes may involve checking fuel injectors, fuel pump, and air intake system for leaks.

- Sensor Malfunctions: Codes related to critical sensors such as the mass airflow (MAF) sensor (e.g., P0101) or oxygen sensors (e.g., P0131) can disrupt engine management and lead to poor performance.

Addressing drivability issues promptly ensures a smooth driving experience, optimal fuel efficiency, and prevents further damage to critical vehicle components.

2.3. Communication Faults and Their Implications

Why are communication fault codes significant, and how should they be addressed?

Communication fault codes, or U-codes, are significant because they indicate problems with the communication network between the vehicle’s electronic control units (ECUs). Modern vehicles rely heavily on these networks to share data and coordinate functions. According to a study by Bosch, communication faults are increasingly common due to the growing complexity of vehicle electronics.

Implications of communication faults include:

- System-Wide Malfunctions: Communication issues can cause a cascade of other faults, as ECUs rely on each other for data.

- Inaccurate Data: Faulty communication can lead to incorrect data being used by various systems, affecting their performance.

- Diagnostic Challenges: Communication problems can make diagnosing other issues more difficult, as the scan tool may not be able to communicate with certain modules.

Addressing U-codes involves:

- Identifying the Affected Modules: Determine which ECUs are experiencing communication issues.

- Checking Wiring and Connections: Inspect the wiring harness and connectors for damage or corrosion.

- Verifying Power and Ground: Ensure that all ECUs have proper power and ground connections.

- Using Advanced Diagnostics: Use Xentry to perform network tests and identify the source of the communication fault.

Promptly addressing communication faults is crucial for maintaining the overall functionality and reliability of the vehicle’s electronic systems.

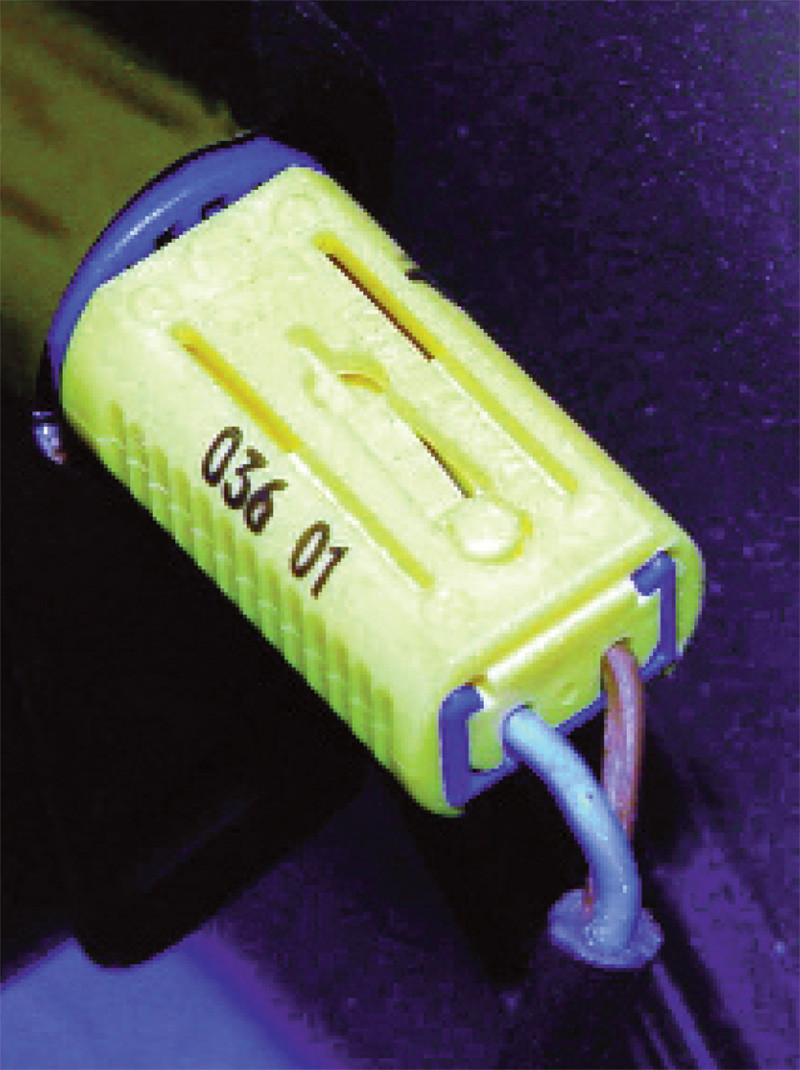

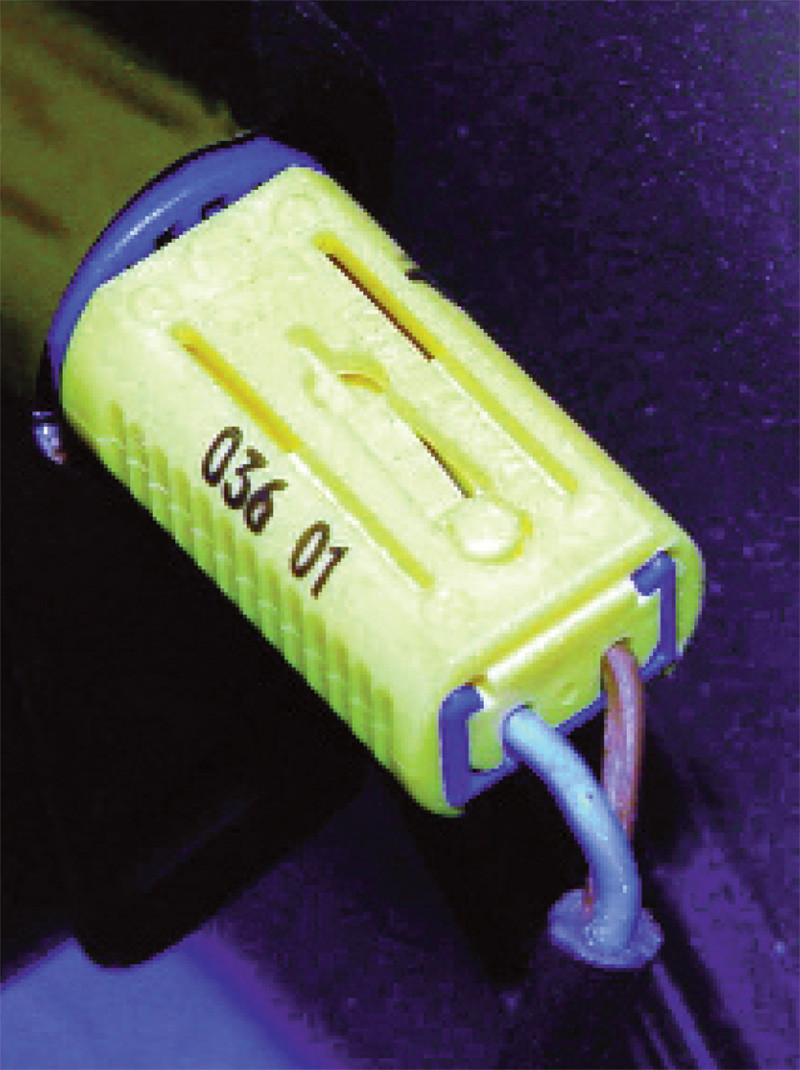

Yellow connectors and harness tape indicate that this is airbag system wiring

Yellow connectors and harness tape indicate that this is airbag system wiring

2.4. Utilizing Xentry for Efficient Diagnosis

How can Xentry diagnostic tools be used effectively to diagnose and prioritize fault codes?

Xentry diagnostic tools are essential for efficiently diagnosing and prioritizing fault codes in Mercedes-Benz vehicles. These tools provide in-depth access to the vehicle’s electronic systems, enabling technicians to accurately identify and address issues. According to Mercedes-Benz training materials, Xentry can reduce diagnostic time by up to 50% compared to generic scan tools.

Key features of Xentry for efficient diagnosis:

- Comprehensive System Scanning: Xentry can scan all vehicle systems and retrieve DTCs, providing a complete overview of the vehicle’s health.

- Detailed Fault Information: Xentry provides detailed information about each DTC, including possible causes, related components, and diagnostic steps.

- Guided Diagnostics: Xentry offers guided diagnostic procedures that walk technicians through step-by-step testing, helping to pinpoint the root cause of the problem.

- Wiring Diagrams and Component Locations: Xentry provides access to wiring diagrams and component locations, making it easier to inspect and test circuits.

- Software Updates and Programming: Xentry allows technicians to update software and program ECUs, ensuring that the vehicle is running the latest software versions.

To use Xentry effectively:

- Perform a Quick Test: Start by performing a quick test to identify all stored and active DTCs.

- Review Fault Details: Carefully review the details of each fault code, paying attention to the fault description, possible causes, and related components.

- Follow Guided Diagnostics: Use the guided diagnostic procedures to perform targeted testing and pinpoint the root cause of the problem.

- Consult Technical Documentation: Refer to Mercedes-Benz technical documentation for additional information and troubleshooting tips.

By leveraging the capabilities of Xentry, technicians can diagnose and prioritize fault codes efficiently, ensuring accurate and effective repairs. For expert tools, CARDIAGTECH.NET offers top-tier diagnostic equipment to enhance your repair process. Contact us at +1 (641) 206-8880 for assistance.

3. Case Studies: Real-World Prioritization Scenarios

How can real-world examples help illustrate the process of prioritizing fault codes?

Real-world case studies can provide valuable insights into how to prioritize fault codes in different scenarios. Here are a few examples:

3.1. Scenario 1: Multiple Codes After a Collision

Situation: A Mercedes-Benz arrives at the shop after a minor collision. The Xentry scan reveals the following codes:

- B1001: Airbag Control Unit Fault (Active)

- C1000: ABS Control Unit Fault (Stored)

- P0401: EGR Flow Insufficient Detected (Stored)

Prioritization:

- B1001 (Airbag Control Unit Fault): This is the highest priority due to its direct impact on safety. The airbag system must be inspected and repaired immediately.

- C1000 (ABS Control Unit Fault): This is a stored code, but still important. Investigate the ABS system after addressing the airbag issue.

- P0401 (EGR Flow Insufficient Detected): This is a stored powertrain code and the lowest priority. Address this after the safety and chassis issues are resolved.

3.2. Scenario 2: Drivability Issues with Communication Faults

Situation: A customer complains of poor engine performance and frequent stalling. The Xentry scan reveals:

- P0300: Random/Multiple Cylinder Misfire Detected (Active)

- U0100: Lost Communication With ECM/PCM (Active)

- B2201: Right Front Power Window Motor Fault (Stored)

Prioritization:

- U0100 (Lost Communication With ECM/PCM): This is the highest priority as it affects the entire engine management system. Diagnose and repair the communication issue first.

- P0300 (Random/Multiple Cylinder Misfire Detected): Address the misfire after resolving the communication issue, as the misfire may be a result of the communication problem.

- B2201 (Right Front Power Window Motor Fault): This is a stored body code and the lowest priority. Address this after resolving the engine and communication issues.

3.3. Scenario 3: ABS and Steering System Faults

Situation: A vehicle exhibits poor handling and the ABS light is on. The Xentry scan reveals:

- C0040: Right Front Wheel Speed Sensor Circuit Malfunction (Active)

- C1511: Power Steering System Malfunction (Active)

- P0171: System Too Lean Bank 1 (Stored)

Prioritization:

- C0040 (Right Front Wheel Speed Sensor Circuit Malfunction): This is a high priority as it directly affects the ABS system and braking performance. Repair immediately.

- C1511 (Power Steering System Malfunction): This is also a high priority as it affects the vehicle’s handling. Address after the ABS issue is resolved.

- P0171 (System Too Lean Bank 1): This is a stored powertrain code and the lowest priority. Address this after resolving the safety and handling issues.

These case studies illustrate the importance of assessing the impact of each fault code and prioritizing them based on safety, drivability, and system-wide effects.

4. Common Mistakes to Avoid When Prioritizing Codes

What are some common mistakes technicians make when prioritizing fault codes, and how can they be avoided?

Several common mistakes can hinder the effectiveness of fault code prioritization. Recognizing and avoiding these mistakes can improve diagnostic accuracy and efficiency.

4.1. Ignoring Safety-Critical Codes

Mistake: Overlooking or postponing the repair of safety-critical codes in favor of seemingly more pressing drivability issues.

Consequences: Increased risk of accidents and injuries due to malfunctioning safety systems like ABS, airbags, and stability control.

Solution: Always prioritize safety-critical codes first. Ensure that all safety systems are functioning correctly before addressing other issues.

4.2. Neglecting Communication Faults

Mistake: Dismissing communication faults (U-codes) as minor issues without investigating their root cause.

Consequences: Communication problems can lead to a cascade of other faults and inaccurate data, affecting multiple systems and making diagnosis more difficult.

Solution: Treat communication faults as high priority and thoroughly investigate the underlying cause. Ensure that all ECUs can communicate properly before addressing other issues.

4.3. Failing to Differentiate Between Active and Stored Codes

Mistake: Treating all codes equally without distinguishing between active and stored codes.

Consequences: Wasting time and resources on diagnosing issues that are no longer present, while neglecting current, active problems.

Solution: Prioritize active codes, which represent current issues, and address stored codes after resolving active faults. Use stored codes as a guide for identifying potential recurring problems.

4.4. Not Clearing Codes and Re-scanning

Mistake: Failing to clear DTCs after completing repairs and not performing a re-scan to verify that the issues are resolved.

Consequences: Inability to confirm that the repairs were successful and potential for overlooking new or recurring faults.

Solution: Always clear DTCs after completing repairs and perform a re-scan to ensure that no new codes appear and that the original issues are resolved.

4.5. Over-Reliance on Code Definitions Without Further Investigation

Mistake: Relying solely on the code definition provided by the scan tool without conducting further diagnostic testing.

Consequences: Misdiagnosis and unnecessary repairs based on incomplete information, leading to customer dissatisfaction and wasted resources.

Solution: Use the code definition as a starting point, but always conduct further diagnostic testing to pinpoint the root cause of the problem. Consult wiring diagrams, component locations, and technical documentation for additional information.

Avoiding these common mistakes can significantly improve the accuracy and efficiency of fault code prioritization, leading to better repair outcomes and increased customer satisfaction. Contact CARDIAGTECH.NET at +1 (641) 206-8880 for the latest diagnostic tools and support.

5. Advanced Diagnostic Techniques for Complex Scenarios

What advanced diagnostic techniques can be employed when dealing with complex fault code scenarios?

In complex scenarios, advanced diagnostic techniques can help pinpoint the root cause of elusive problems. These techniques require a deeper understanding of vehicle systems and the use of specialized tools.

5.1. Using Oscilloscopes for Signal Analysis

Technique: Employing an oscilloscope to analyze electrical signals from sensors and actuators.

Application: Oscilloscopes can help identify intermittent faults, signal noise, and other electrical anomalies that may not be apparent with a standard scan tool.

Example: Analyzing the signal from a crankshaft position sensor to detect dropouts or irregularities that could cause intermittent misfires.

5.2. Performing Network Communication Tests

Technique: Conducting network communication tests to verify the integrity of the vehicle’s communication network.

Application: These tests can help identify communication bottlenecks, data corruption, and other network-related issues.

Example: Using Xentry to perform a CAN bus test to identify faulty modules or wiring issues that are disrupting communication.

5.3. Conducting Component-Level Testing

Technique: Testing individual components to verify their functionality.

Application: Component-level testing can help isolate faulty parts and rule out other potential causes.

Example: Testing a fuel injector’s resistance and spray pattern to determine if it is functioning correctly.

5.4. Using Factory Scan Tools for Advanced Diagnostics

Technique: Utilizing factory scan tools like Xentry for advanced diagnostic functions.

Application: Factory scan tools provide access to detailed diagnostic data, guided testing procedures, and component programming capabilities that are not available with generic scan tools.

Example: Using Xentry to perform adaptive learning resets on a transmission control module after replacing a valve body.

5.5. Performing Data Logging and Analysis

Technique: Logging real-time data from various sensors and actuators and analyzing the data to identify patterns and anomalies.

Application: Data logging can help identify intermittent faults and performance issues that occur under specific driving conditions.

Example: Logging data from the mass airflow sensor, oxygen sensors, and fuel trims during a road test to diagnose a lean running condition.

By employing these advanced diagnostic techniques, technicians can effectively troubleshoot complex fault code scenarios and ensure accurate and reliable repairs. To enhance your diagnostic capabilities, consider the advanced tools available at CARDIAGTECH.NET. Call us at +1 (641) 206-8880 for more details.

SRS deploys airbag by time occupant contacts

SRS deploys airbag by time occupant contacts

6. The Role of Software Updates in Resolving Fault Codes

How do software updates play a role in resolving fault codes and improving vehicle performance?

Software updates are crucial for resolving fault codes and improving vehicle performance in modern vehicles. According to a study by McKinsey & Company, software-related issues account for up to 40% of vehicle recalls. Software updates can address known bugs, improve system performance, and enhance vehicle functionality.

6.1. Addressing Known Software Bugs

Role: Software updates often include fixes for known bugs that can trigger fault codes.

Example: A software update may correct an issue in the transmission control module (TCM) that causes erratic shifting and triggers a P0700 code (Transmission Control System Malfunction).

6.2. Improving System Performance

Role: Software updates can optimize system performance by improving algorithms and calibrations.

Example: An update to the engine control module (ECM) may improve fuel efficiency by fine-tuning the air-fuel mixture and ignition timing.

6.3. Enhancing Vehicle Functionality

Role: Software updates can add new features and enhance existing functionalities.

Example: An update to the infotainment system may add support for new smartphone integration features or improve the navigation system’s accuracy.

6.4. Ensuring Compatibility with New Hardware

Role: Software updates ensure compatibility with new hardware components.

Example: If a new sensor is installed, a software update may be required to properly integrate the sensor into the vehicle’s control system.

6.5. Addressing Security Vulnerabilities

Role: Software updates can address security vulnerabilities and protect the vehicle from cyber threats.

Example: An update may patch a security flaw in the vehicle’s communication network that could be exploited by hackers.

To ensure that vehicles are running the latest software versions:

- Check for Updates Regularly: Use Xentry to check for available software updates.

- Follow Manufacturer Recommendations: Follow the manufacturer’s recommendations for installing software updates.

- Verify Compatibility: Ensure that the software update is compatible with the vehicle’s hardware and software configuration.

- Test After Installation: After installing a software update, perform a thorough test to verify that the update was successful and that no new issues have been introduced.

Software updates are an essential tool for resolving fault codes and improving vehicle performance. By keeping vehicle software up-to-date, technicians can ensure that vehicles are running at their best and are protected from potential problems.

7. Preventative Measures to Minimize Fault Codes

What preventative measures can vehicle owners and technicians take to minimize the occurrence of fault codes?

Preventative measures are essential for minimizing the occurrence of fault codes and maintaining vehicle reliability. Regular maintenance, proper driving habits, and proactive diagnostics can help prevent many common issues.

7.1. Regular Maintenance

Measure: Following the manufacturer’s recommended maintenance schedule.

Benefits: Regular oil changes, filter replacements, and fluid checks can prevent engine and transmission problems that can trigger fault codes.

Example: Changing the engine oil every 5,000 miles can prevent sludge buildup and reduce the risk of engine misfires.

7.2. Proper Driving Habits

Measure: Avoiding aggressive driving habits, such as excessive acceleration and hard braking.

Benefits: Smooth driving habits can reduce wear and tear on the engine, transmission, and brakes, minimizing the risk of component failures and fault codes.

Example: Avoiding frequent hard acceleration can reduce stress on the engine and prevent issues like misfires and fuel system problems.

7.3. Proactive Diagnostics

Measure: Performing regular diagnostic scans to identify potential issues before they escalate.

Benefits: Proactive diagnostics can help detect early signs of problems, allowing technicians to address them before they trigger fault codes and cause more significant damage.

Example: Performing a diagnostic scan every 6 months can identify sensor malfunctions or communication issues before they cause drivability problems.

7.4. Using High-Quality Parts and Fluids

Measure: Using high-quality parts and fluids that meet the manufacturer’s specifications.

Benefits: High-quality parts and fluids can improve vehicle performance and reliability, reducing the risk of component failures and fault codes.

Example: Using OEM (Original Equipment Manufacturer) spark plugs can ensure proper ignition and prevent misfires.

7.5. Keeping the Vehicle Clean

Measure: Regularly cleaning the vehicle, including the engine compartment and undercarriage.

Benefits: Cleaning the vehicle can prevent corrosion and damage to electrical connectors and wiring, reducing the risk of communication faults and sensor malfunctions.

Example: Cleaning the engine compartment can prevent dirt and debris from interfering with sensor connections and causing false readings.

By implementing these preventative measures, vehicle owners and technicians can minimize the occurrence of fault codes and maintain vehicle reliability. For top-quality diagnostic tools and maintenance equipment, visit CARDIAGTECH.NET or call us at +1 (641) 206-8880.

8. Leveraging Online Resources and Communities for Support

How can online resources and communities assist in diagnosing and prioritizing fault codes?

Online resources and communities provide valuable support for diagnosing and prioritizing fault codes. These platforms offer access to a wealth of information, expert advice, and shared experiences that can help technicians troubleshoot complex issues.

8.1. Online Forums and Discussion Boards

Resource: Online forums and discussion boards dedicated to automotive diagnostics and repair.

Benefits: These platforms provide a space for technicians to share their knowledge, ask questions, and discuss common issues.

Example: Websites like iATN (International Automotive Technicians Network) and automotive-specific subreddits on Reddit offer forums where technicians can discuss fault code diagnosis and repair strategies.

8.2. Technical Databases and Knowledge Bases

Resource: Technical databases and knowledge bases that provide access to wiring diagrams, component locations, and diagnostic procedures.

Benefits: These resources can help technicians quickly access the information they need to diagnose and repair fault codes.

Example: ALLDATA and Mitchell 1 offer comprehensive technical databases with detailed information on vehicle systems and diagnostic procedures.

8.3. Manufacturer Websites and Resources

Resource: Manufacturer websites and resources that provide access to technical service bulletins (TSBs), recall information, and diagnostic tips.

Benefits: These resources can help technicians stay up-to-date on the latest information from the manufacturer and address common issues.

Example: Mercedes-Benz’s website offers access to TSBs and other technical information for their vehicles.

8.4. Video Tutorials and Online Training Courses

Resource: Video tutorials and online training courses that provide step-by-step instructions on diagnosing and repairing fault codes.

Benefits: These resources can help technicians learn new diagnostic techniques and improve their skills.

Example: YouTube channels like ScannerDanner and online training platforms like Autotech eTraining offer video tutorials and courses on automotive diagnostics.

8.5. Social Media Groups and Communities

Resource: Social media groups and communities dedicated to automotive diagnostics and repair.

Benefits: These platforms provide a space for technicians to connect with each other, share information, and ask questions in real-time.

Example: Facebook groups dedicated to automotive diagnostics offer a forum for technicians to share their experiences and get help with challenging issues.

By leveraging these online resources and communities, technicians can enhance their diagnostic skills, stay up-to-date on the latest information, and get the support they need to tackle complex fault code scenarios.

9. Investing in the Right Tools and Equipment

Why is investing in the right tools and equipment essential for diagnosing and prioritizing fault codes effectively?

Investing in the right tools and equipment is essential for diagnosing and prioritizing fault codes effectively. Modern vehicles are equipped with complex electronic systems that require specialized tools for accurate diagnosis and repair.

9.1. Diagnostic Scan Tools

Tool: Advanced diagnostic scan tools like Xentry.

Benefits: These tools provide access to detailed diagnostic data, guided testing procedures, and component programming capabilities that are not available with generic scan tools.

Example: Xentry allows technicians to perform comprehensive system scans, access detailed fault information, and perform guided diagnostics on Mercedes-Benz vehicles.

9.2. Multimeters and Electrical Testers

Tool: High-quality multimeters and electrical testers.

Benefits: These tools are essential for testing circuits, sensors, and actuators to identify electrical faults.

Example: A multimeter can be used to test the resistance of a sensor, the voltage of a circuit, and the continuity of a wire.

9.3. Oscilloscopes

Tool: Oscilloscopes for signal analysis.

Benefits: Oscilloscopes can help identify intermittent faults, signal noise, and other electrical anomalies that may not be apparent with a standard scan tool.

Example: An oscilloscope can be used to analyze the signal from a crankshaft position sensor to detect dropouts or irregularities that could cause intermittent misfires.

9.4. Component Testers

Tool: Component testers for testing individual components.

Benefits: Component testers can help isolate faulty parts and rule out other potential causes.

Example: A fuel injector tester can be used to test the resistance and spray pattern of a fuel injector to determine if it is functioning correctly.

9.5. Software and Information Systems

Tool: Access to comprehensive software and information systems like ALLDATA and Mitchell 1.

Benefits: These resources provide access to wiring diagrams, component locations, and diagnostic procedures that can help technicians quickly diagnose and repair fault codes.

Example: ALLDATA provides detailed wiring diagrams and component locations for a wide range of vehicles.

Investing in these tools and equipment can significantly improve the accuracy and efficiency of fault code diagnosis and repair, leading to better repair outcomes and increased customer satisfaction. CARDIAGTECH.NET offers a wide range of diagnostic tools and equipment to meet your needs. Contact us at +1 (641) 206-8880 for expert advice and support.

10. The Future of Automotive Diagnostics

What trends and technologies are shaping the future of automotive diagnostics and fault code prioritization?

The future of automotive diagnostics is being shaped by several key trends and technologies, including advanced data analytics, artificial intelligence (AI), and remote diagnostics.

10.1. Advanced Data Analytics

Trend: The use of advanced data analytics to analyze vehicle data and identify potential issues.

Impact: Data analytics can help predict component failures, optimize maintenance schedules, and improve vehicle performance.

Example: Analyzing data from a vehicle’s sensors to identify patterns that indicate a failing component before it triggers a fault code.

10.2. Artificial Intelligence (AI)

Trend: The use of AI to automate diagnostic processes and provide expert guidance.

Impact: AI can help technicians quickly diagnose complex issues, access relevant information, and make informed decisions.

Example: AI-powered diagnostic tools that analyze fault codes and provide step-by-step troubleshooting instructions.

10.3. Remote Diagnostics

Trend: The use of remote diagnostics to diagnose and repair vehicles remotely.

Impact: Remote diagnostics can help technicians troubleshoot issues from a distance, reducing the need for on-site visits and improving efficiency.

Example: Remote diagnostic tools that allow technicians to access vehicle data, perform tests, and even program components remotely.

10.4. Over-the-Air (OTA) Updates

Trend: The use of over-the-air (OTA) updates to update vehicle software and address known issues.

Impact: OTA updates can help resolve fault codes, improve vehicle performance, and enhance vehicle functionality without requiring a visit to the repair shop.

Example: Tesla’s use of OTA updates to improve vehicle performance and address security vulnerabilities.

10.5. Enhanced Cybersecurity Measures

Trend: The implementation of enhanced cybersecurity measures to protect vehicle systems from cyber threats.

Impact: Cybersecurity measures can help prevent hackers from accessing vehicle systems, triggering false fault codes, and compromising vehicle safety.

Example: The use of encryption and authentication protocols to protect vehicle communication networks from cyber attacks.

These trends and technologies are transforming the automotive diagnostics landscape, making it more efficient, accurate, and connected. By staying up-to-date on these advancements, technicians can ensure that they are well-prepared to diagnose and repair the vehicles of the future.

FAQ: Prioritizing Fault Codes with Xentry

Here are some frequently asked questions about prioritizing fault codes with Xentry:

-

Q: What is Xentry, and why is it important for diagnosing Mercedes-Benz vehicles?

A: Xentry is the official diagnostic software used for Mercedes-Benz vehicles. It provides comprehensive access to vehicle systems, detailed fault information, and guided diagnostic procedures, making it essential for accurate and efficient diagnosis.

-

Q: How do I access fault codes using Xentry?

A: Connect the Xentry diagnostic tool to the vehicle’s OBD-II port, launch the software, and perform a quick test to scan all vehicle systems for stored and active fault codes.

-

Q: What should I do if Xentry displays multiple fault codes?

A: Prioritize the fault codes based on their impact on safety, drivability, and system-wide effects. Address safety-critical codes first, followed by drivability issues and communication faults.

-

Q: What is the difference between active and stored fault codes?

A: Active fault codes represent current, ongoing issues, while stored fault codes indicate problems that occurred in the past but are not currently present. Prioritize active codes, and address stored codes after resolving active faults.

-

Q: How can I identify safety-critical fault codes?

A: Safety-critical fault codes relate to systems such as ABS, airbags, steering, and stability control. These codes should be immediately prioritized due to their direct impact on vehicle safety.

-

Q: What are communication fault codes (U-codes), and why are they significant?

A: Communication fault codes indicate problems with the communication network between the vehicle’s electronic control units (ECUs). They are significant because they can cause a cascade of other faults and affect multiple systems.

-

Q: How can I use Xentry to diagnose communication faults?

A: Use Xentry to perform network tests and identify the source of the communication fault. Check wiring and connections, and verify power and ground connections to the affected modules.

-

Q: Are software updates important for resolving fault codes?

A: Yes, software updates often include fixes for known bugs that can trigger fault codes. They can also improve system performance and enhance vehicle functionality.

-

Q: Where can I find technical service bulletins (TSBs) for Mercedes-Benz vehicles?

A: TSBs can be found on Mercedes-Benz’s website and in technical databases like ALLDATA and Mitchell 1.

-

Q: What tools and equipment are essential for diagnosing fault codes effectively?

A: Essential tools include advanced diagnostic scan tools like Xentry, multimeters, oscilloscopes, component testers, and access to comprehensive software and information systems.

By understanding these FAQs and utilizing Xentry effectively, technicians can diagnose and prioritize fault codes efficiently, ensuring accurate and reliable repairs.

Prioritizing fault codes when Xentry displays multiple issues is crucial for efficient and effective auto repairs. By understanding the basics of DTCs, following a step-by-step approach, avoiding common mistakes, and leveraging advanced diagnostic techniques, technicians can ensure that the most critical issues are addressed first. Remember to invest in the right tools and equipment, utilize online resources and communities, and stay up-to-date on the latest trends in automotive diagnostics.

Is your diagnostic equipment up to the task? Contact CARDIAGTECH.NET today at +1 (641) 206-8880 or visit our location at 276 Reock St, City of Orange, NJ 0